Summary of Contents for Allen-Bradley 2094-AC05-MP5

- Page 1 User Manual Original Instructions Kinetix 6000 Multi-axis Servo Drives Catalog Numbers 2094-AC -M -S, 2094-BC -M -S, 2094-AM -S, 2094-BM -S 2094-AC -M , 2094-BC -M , 2094-AM , 2094-BM , 2094-BSP2, 2094-PRF, 2094-SEPM-B24-S...

- Page 2 Important User Information Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

-

Page 3: Table Of Contents

Table of Contents ..........9 Summary of Changes Preface Conventions Used in This Manual . - Page 4 Table of Contents Chapter 4 2094 IAM/AM Module Connector Data ..... . . 58 Connector Data and Feature Safe Torque-off Connector Pinout......60 Descriptions I/O Connector Pinout .

- Page 5 Table of Contents Wire the Motor/Resistive Brake (BC) Connector ... 113 Apply the Motor Cable Shield Clamp......116 Feedback and I/O Cable Connections .

- Page 6 Table of Contents Chapter 8 Before You Begin..........181 Remove and Replace the Remove Kinetix 6000 Drive Modules .

- Page 7 Table of Contents Auto-tune Gain Settings ........244 Tuning Mode Summary.

- Page 8 Table of Contents Notes: Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 9: Summary Of Changes

Summary of Changes This manual contains new and updated information as indicated in the following table. Topic Page Updated the internal solid-state motor short-circuit protection rating to include 200,000 A (fuses) and 65,000 A (circuit breakers). Added Mersen HSJ fuses for 2094-BCxx-Mxx-S integrated axis module DC-bus power. Updated absolute position examples table. - Page 10 Summary of Changes Notes: Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 11: Preface

Preface This manual provides detailed installation instructions for mounting, wiring, and troubleshooting Kinetix® 6000 drives; and system integration for your drive and motor/actuator combination with a Logix5000™ controller. For information on wiring and troubleshooting your Kinetix 6000 servo drive with the safe torque-off feature, refer to the Kinetix Safe Torque-off Feature Safety Reference Manual, publication GMC-RM002. -

Page 12: Additional Resources

A glossary of industrial automation terms and abbreviations. You can view or download publications at http://www.rockwellautomation.com/literature. To order paper copies of technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative. Rockwell Automation Publication 2094-UM001J-EN-P - March 2017... -

Page 13: Iam/Am Module Series Changes

Chapter Start Use this chapter to become familiar with the design and installation requirements for Kinetix® 6000 drive systems. Topic Page IAM/AM Module Series Changes About the Kinetix 6000 Drive Systems Typical Hardware Configurations Typical Communication Configurations Catalog Number Explanation Kinetix Drive Component Compatibility Kinetix 6000M Integrated Drive-Motor System Compatibility Agency Compliance... -

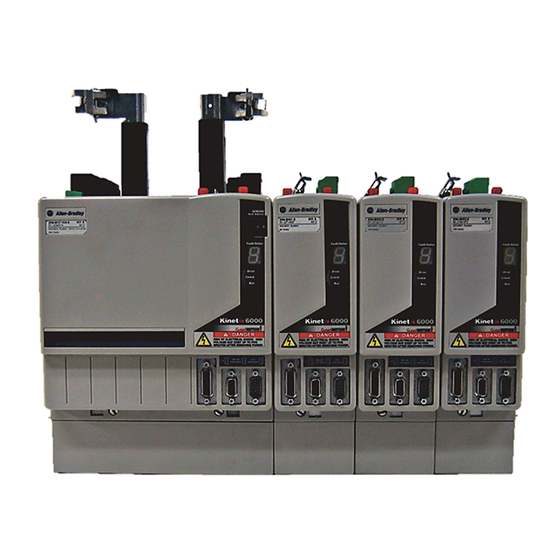

Page 14: About The Kinetix 6000 Drive Systems

Chapter 1 Start The Kinetix 6000 multi-axis servo drives are designed to provide a Kinetix About the Kinetix 6000 Drive Integrated Motion solution for your drive/motor/actuator applications. Systems Table 2 - Kinetix 6000 Drive System Overview System Cat. No. Description Component Integrated Axis Modules (IAM) with the safe torque-off feature with 200V or 400V-class AC input power. -

Page 15: Typical Hardware Configurations

Start Chapter 1 Typical Kinetix 6000 system installations include three-phase AC Typical Hardware configurations, with and without the line interface module (LIM), and DC Configurations common-bus configurations. SHOCK HAZARD: To avoid personal injury due to electrical shock, place a 2094-PRF slot-filler module in all empty slots on the power rail. Any power rail connector without a module installed disables the Bulletin 2094 system;... - Page 16 Chapter 1 Start Figure 2 - Typical Kinetix 6000 System Installation (without LIM) Three-phase Input Power Line Disconnect Device 2090-XXLF-xxxx AC Line Filter Input (required for CE) Fusing Single-phase Control Power Magnetic 2090-XXLF-xxxx Contactor Kinetix 6000 Multi-axis Servo Drive System AC Line Filter (required for CE) 2094-BSP2...

- Page 17 Start Chapter 1 This configuration illustrates the Kinetix 6000M integrated drive-motor (IDM) system with IDM power interface module (IPIM) installed on the Bulletin 2094 power rail. The IPIM module is included in the drive-to-drive fiber-optic cable installation along with the axis modules. Figure 3 - Typical Kinetix 6000M Integrated Drive-Motor System Installation 2094-SEPM-B24-S IPIM Module...

- Page 18 Chapter 1 Start Figure 4 - Typical (400V-class) DC Common Bus System Installation 2090-XXLF-xxxx Three-phase AC Line Filter Input Power (required for CE) 115/230V Control Power 2094-BSP2 Kinetix 6000 Multi-axis Servo Drive System Shunt Module (optional component) 2094-BCxx-Mxx-S 2094-PRF IAM Module Slot-filler Module Common Bus Leader (required to fill...

-

Page 19: Typical Communication Configurations

Start Chapter 1 In this example, drive-to-drive Sercos cables and catalog numbers are shown Typical Communication when Kinetix 6000, Kinetix 6000M, and Kinetix 6200 drive modules exist on Configurations the same power rail. The Kinetix 6200 control modules use Sercos interface for configuring the Logix5000 module and the EtherNet/IP network for diagnostics and configuring safety functions. -

Page 20: Catalog Number Explanation

Cat. No. Integrated Axis Modules (230V) (with safe torque-off feature) (without safe torque-off feature) Kinetix 6000, IAM, 200V-class, 3 kW converter, 5 A inverter 2094-AC05-MP5-S 2094-AC05-MP5 Kinetix 6000, IAM, 200V-class, 3 kW converter, 9 A inverter 2094-AC05-M01-S 2094-AC05-M01 Kinetix 6000, IAM, 200V-class, 6 kW converter, 15 A inverter... -

Page 21: Kinetix Drive Component Compatibility

Start Chapter 1 The 2094-BCxx-Mxx-M and 2094-BMxx-M power modules contain the same Kinetix Drive Component power structure as the 2094-BCxx-Mxx-S and 2094-BMxx-S drive modules. Compatibility Because of this, the 2094-BSP2 shunt module, 2094-PRF slot-filler module, and 2094-PRSx power rails are supported by both drive families. In addition, 2094-BMxx-M AM power modules with Sercos interface are supported on power rails with a 2094-BCxx-Mxx-S IAM drive module. -

Page 22: Agency Compliance

Chapter 1 Start If this product is installed within the European Union and has the CE mark, Agency Compliance the following regulations apply. ATTENTION: Meeting CE requires a grounded system, and the method of grounding the AC line filter and drive must match. Failure to do this renders the filter ineffective and can cause damage to the filter. -

Page 23: Ce Requirements (System With Lim Module)

Start Chapter 1 CE Requirements (system with LIM module) To meet CE requirements when your Kinetix 6000 system includes the LIM module, follow all the requirements as stated in CE Requirements (system without LIM module) and these additional requirements as they apply to the AC line filter. - Page 24 Chapter 1 Start Notes: Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

- Page 25 Chapter Plan the Kinetix 6000 Drive System Installation This chapter describes system installation guidelines used in preparation for mounting your Kinetix® 6000 drive components. Topic Page System Design Guidelines Electrical Noise Reduction ATTENTION: Plan the installation of your system so that you can perform all cutting, drilling, tapping, and welding with the system removed from the enclosure.

-

Page 26: System Design Guidelines

Chapter 2 Plan the Kinetix 6000 Drive System Installation Use the information in this section when designing your enclosure and System Design Guidelines planning to mount your system components on the panel. For on-line product selection and system configuration tools, including AutoCAD (DXF) drawings of the product, refer to http://www.rockwellautomation.com/en/e-tools. -

Page 27: Transformer Selection

Table 7 - Kinetix 6000 (three-phase) AC Line Filter Selection Current Weight, approx Drive AC Line Filter Voltage Cat. No. Cat. No. A @ 50 °C (122 °F) kg (lb) 2094-AC05-MP5-S 2094-AC05-M01-S 2.7 (5.9) 2090-XXLF-X330B 500V AC 2094-AC09-M02-S 50/60 Hz 2094-AC16-M03-S 5.2 (11.4) 2090-XXLF-375 2094-AC32-M05-S 9.5 (20.9) -

Page 28: Circuit Breaker/Fuse Options

200,000 A (fuses) and 65,000 A (circuit breakers). Table 8 - Control and DC-bus Circuit Protection Specifications Control Input Power DC-bus Power IAM Module Allen-Bradley® Circuit Breaker Cat. No. Bussmann Fuse Bussmann Fuse Mersen Fuse (non-UL) - Page 29 Plan the Kinetix 6000 Drive System Installation Chapter 2 Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 30: Enclosure Selection

Chapter 2 Plan the Kinetix 6000 Drive System Installation Enclosure Selection This example is provided to assist you in sizing an enclosure for your Bulletin 2094 drive system. The example system consists of these components: • 6-axis Bulletin 2094 servo drive system •... - Page 31 Plan the Kinetix 6000 Drive System Installation Chapter 2 Table 11 - ControlLogix System Heat Dissipation Example Enclosure Backplane Power Load Heat Dissipation Description Component watts watts 1756-M08SE 8-axis Sercos interface module 1756-L5563 L63 ControlLogix processor 1756-IB16D 16 -point input module 0.84 1756-OB16D 16 -point output module...

- Page 32 2094-AC16-M03-S 2094-AC32-M05-S 2094-BC01-MP5-S 2094-BC01-M01-S 2094-BC02-M02-S 2094-BC04-M03-S 2094-BC07-M05-SS IAM (inverter) module or AM module 2094-AC05-MP5-S or 2094-AMP5-S 2094-AC05-M01-S or 2094-AM01-S 2094-AC09-M02-S or 2094-AM02-S 2094-AC16-M03-S or 2094-AM03-S 2094-AC32-M05-S or 2094-AM05-S 2094-BC01-MP5-S or 2094-BMP5-S 2094-BC01-M01-S or 2094-BM01-S 2094-BC02-M02-S or 2094-BM02-S 2094-BC04-M03-S or 2094-BM03-S...

-

Page 33: Minimum Clearance Requirements

Plan the Kinetix 6000 Drive System Installation Chapter 2 Minimum Clearance Requirements This section provides information to assist you in sizing your cabinet and positioning your Bulletin 2094 system components. IMPORTANT Mount the module in an upright position. Do not mount the module on its side. -

Page 34: Electrical Noise Reduction

Chapter 2 Plan the Kinetix 6000 Drive System Installation This section outlines best practices that minimize the possibility of noise- Electrical Noise Reduction related failures as they apply specifically to Kinetix 6000 system installations. For more information on the concept of high-frequency (HF) bonding, the ground plane principle, and electrical noise reduction, refer to the System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001. - Page 35 Plan the Kinetix 6000 Drive System Installation Chapter 2 These illustrations show details of recommended bonding practices for painted panels, enclosures, and mounting brackets. Figure 8 - Recommended Bonding Practices for Painted Panels Stud-mounting the Subpanel Stud-mounting a Ground Bus to the Enclosure Back Wall or Chassis to the Subpanel Subpanel...

-

Page 36: Bonding Multiple Subpanels

Chapter 2 Plan the Kinetix 6000 Drive System Installation Bonding Multiple Subpanels Bonding multiple subpanels creates a common low impedance exit path for the high frequency energy inside the cabinet. If subpanels are not bonded together, and do not share a common low impedance path, the difference in impedance can affect networks and other devices that span multiple panels: •... -

Page 37: Establishing Noise Zones

Plan the Kinetix 6000 Drive System Installation Chapter 2 Establishing Noise Zones Observe these guidelines when the 2094-ALxxS, 2094-BLxxS, or 2094-XL75S-Cx LIM module is used in the Bulletin 2094 system and mounted left of the IAM module with the AC (EMC) line filter mounted above the LIM module: •... - Page 38 Chapter 2 Plan the Kinetix 6000 Drive System Installation Observe these guidelines when the 2094-ALxxS, 2094-BLxxS, or 2094-XL75S-Cx LIM module is used in the Bulletin 2094 system and mounted right of the IAM module with the AC (EMC) line filter mounted behind the IAM module: •...

- Page 39 Plan the Kinetix 6000 Drive System Installation Chapter 2 Observe these guidelines when the 2094-ALxxS, 2094-BLxxS, or 2094-XL75S-Cx LIM module is used in the Bulletin 2094 system and mounted right of the drive with the AC (EMC) line filter mounted behind the LIM module: •...

- Page 40 Chapter 2 Plan the Kinetix 6000 Drive System Installation Keep the DC common-bus cable (very dirty) segregated from all other cables (not in a wireway) when the 2094-ALxxS, 2094-BLxxS, or 2094-XL75S-Cx LIM module is used in a DC common-bus configuration and the follower IAM module is mounted below the leader IAM module.

- Page 41 Plan the Kinetix 6000 Drive System Installation Chapter 2 Observe these guidelines when the 2094-AL09 or 2094-BL02 LIM module is used in the Bulletin 2094 system and mounted left of the IAM module: • The clean zone (C) is to the right and beneath the Bulletin 2094 system (gray wireway).

- Page 42 Chapter 2 Plan the Kinetix 6000 Drive System Installation Observe these guidelines when the 2094-AL09 or 2094-BL02 LIM module is used in the Bulletin 2094 system and mounted above the IAM module: • The clean zone (C) is to the right and beneath the Bulletin 2094 system (gray wireway).

- Page 43 Plan the Kinetix 6000 Drive System Installation Chapter 2 Observe these guidelines when your system includes the 2094-SEPM-B24-S IPIM module. In this example, a 2094-BL02 LIM module is used in the Bulletin 2094 system and mounted left of the IAM module: •...

- Page 44 Chapter 2 Plan the Kinetix 6000 Drive System Installation Observe these guidelines when individual input power components are used in the Bulletin 2094 system and the Bulletin 2094 LIM module is not used: • The clean zone (C) is beneath the Bulletin 2094 system and includes the I/O wiring, feedback cable, and DC filter (gray wireway).

-

Page 45: Cable Categories For Kinetix 6000 Systems

Plan the Kinetix 6000 Drive System Installation Chapter 2 Observe these guidelines when installing your Logix5000™ Sercos interface module: • The clean zone (C) is beneath the less noisy modules (I/O, analog, encoder, registration, an so forth (gray wireway). • The dirty zone (D) is above and below the power supply and noisy modules (black wireway). - Page 46 Chapter 2 Plan the Kinetix 6000 Drive System Installation Table 15 - AM Module or Axis Module (inverter side) Zone Method Wire/Cable Connector Very Ferrite Shielded Dirty Clean Dirty Sleeve Cable U, V, W (motor power) COM, PWR (24V DC), filtered COM, PWR (24V DC), unfiltered DBRK-, DBRK+ (resistive brake) MBRK-, MBRK+ (motor brake)

-

Page 47: Noise Reduction Guidelines For Drive Accessories

Plan the Kinetix 6000 Drive System Installation Chapter 2 Table 18 - IDM Power Interface Module (IPIM) Zone Method Wire/Cable Very Dirty Dirty Clean Ferrite Sleeve Shielded Cable Hybrid DC bus power, control power, inter-module communication, and Safe Torque Off Enable input Fiber-optic No restrictions... - Page 48 Metal Enclosure 150 mm (6.0 in.) clearance (min) on all four Metal Conduit 1394 Digital Servo Controller 300W Shunt Module sides of the shunt module. ALLEN-BRADLEY BULLETIN 1394 300W SHUNT MODULE (where required CAT. PART SER. INPUT DC INPUT AC FOR FUSE REPLACEMENT USE: BUSSMAN CAT.

- Page 49 Dirty Wireway Enclosure 150 mm (6.0 in.) clearance (min) on all four sides of the shunt module. 1394 Digital Servo Controller 300W Shunt Module ALLEN-BRADLEY BULLETIN 1394 300W SHUNT MODULE CAT. PART SER. INPUT DC INPUT AC FOR FUSE REPLACEMENT USE: BUSSMAN CAT.

- Page 50 Chapter 2 Plan the Kinetix 6000 Drive System Installation Resistive Brake Modules Observe these guidelines when mounting your RBM module: • Mount circuit components and wiring in the dirty zone or in an external shielded enclosure. If mounting the RBM module in a separate ventilated shielded enclosure, run wiring inside metal conduit to minimize the effects of EMI and RFI.

-

Page 51: Chapter 3 Before You Begin

Chapter Mount the Kinetix 6000 Drive System This chapter provides the system installation procedures for mounting your Kinetix® 6000 drive components on the Bulletin 2094 power rail. Topic Page Before You Begin Determine Mounting Order Mount Modules on the Power Rail This procedure assumes you have prepared your panel, mounted your Bulletin 2094 power rail, and understand how to bond your system. -

Page 52: Installing The 2094 Power Rail

Chapter 3 Mount the Kinetix 6000 Drive System Installing the 2094 Power Rail The Bulletin 2094 power rail comes in lengths to support one IAM module and up to seven additional AM/IPIM modules, or up to six additional AM/ IPIM modules and one shunt module. The connector pins for each slot are covered by a protective cover. - Page 53 Mount the Kinetix 6000 Drive System Chapter 3 Figure 22 - Module Mounting Order Example Highest Power Utilization Lowest Power Utilization Integrated Axis Module Axis Module Axis Module Shunt Module IPIM Module Axis Module Axis Module Slot-filler Module 2094-BC02-M02-x 2094-SEPM-B24-S 2094-BM02-x 2094-BM01-x 2094-BSP2...

-

Page 54: Mount Modules On The Power Rail

Chapter 3 Mount the Kinetix 6000 Drive System Follow these steps to mount the IAM, AM, IPIM, shunt, and slot-filler Mount Modules on the modules. Power Rail TIP All modules mount to the power rail by using the same technique; however, only the IAM module is used in the examples. - Page 55 Mount the Kinetix 6000 Drive System Chapter 3 4. Pivot module downward and align the guide pins on the power rail with the guide pin holes in the back of the module. Pivot module downward and align with guide pins. Guide Pin Guide Pins Holes...

- Page 56 Chapter 3 Mount the Kinetix 6000 Drive System 6. Use 2.26 N•m (20 lb•in) torque to tighten the mounting screws. Bottom front view of Bottom front view of single-wide AM, IPIM, shunt, double-wide IAM or AM module or slot-filler module (AM module is shown).

- Page 57 Chapter Connector Data and Feature Descriptions This chapter illustrates drive connectors and indicators, including connector pinouts, and provides descriptions for Kinetix® 6000 drive features. Topic Page 2094 IAM/AM Module Connector Data Control Signal Specifications Power and Relay Specifications Feedback Specifications For the Kinetix 6000M integrated drive-motor (IDM) unit and IDM power interface module (IPIM) connector locations and signal descriptions, refer to the Kinetix 6000M Integrated Drive-Motor System User Manual, publication...

-

Page 58: Connector Data And Feature Descriptions

Chapter 4 Connector Data and Feature Descriptions Use these illustrations to identify the connectors and indicators for the 2094 IAM/AM Module IAM/AM modules. Sercos interface and Ethernet network connectors for the Connector Data Kinetix 6000M IPIM module are also shown. For the remainder of the IPIM module features and indicators, refer to the Kinetix 6000M Integrated Drive- Motor System User Manual, publication 2094-UM003. - Page 59 Connector Data and Feature Descriptions Chapter 4 Figure 24 - Axis Module Features and Indicators Kinetix 6000 AM Module, Top View (2094-AM01-S module is shown) Kinetix 6000 AM Module, Front View (2094-AM01-S module is shown) MBRK - MBRK + DBRK - DBRK + 2094-SEPM-B24-S IPIM Module, Top View...

-

Page 60: Safe Torque-Off Connector Pinout

Chapter 4 Connector Data and Feature Descriptions Safe Torque-off Connector Pinout Each 2094-xCxx-Mxx-S IAM module and 2094-xMxx-S AM module ships with the (9-pin) wiring-plug header and motion-allowed jumper installed in the safe torque-off (STO) connector. With the motion-allowed jumper installed, the safe torque-off feature is not used. Figure 25 - Motion-allowed Jumper Kinetix 6000 IAM/AM Module (AM module is shown) -

Page 61: I/O Connector Pinout

Connector Data and Feature Descriptions Chapter 4 I/O Connector Pinout Table 25 - IAM/AM I/O 26-pin (IOD) Connector IOD Pin Description Signal IOD Pin Description Signal Hardware enable 24V DC power supply +24V_PWR High speed registration 1 input REG1 Hardware enable input ENABLE Common for registration REG_COM... -

Page 62: Motor Feedback Connector Pinout

Chapter 4 Connector Data and Feature Descriptions Motor Feedback Connector Pinout Table 26 - Stegmann Hiperface (SRS/SRM) MF Pin Description Signal MF Pin Description Signal Sine differential input+ SIN+ Reserved – Sine differential input- SIN- Hiperface data channel DATA- Cosine differential input+ COS+ Motor thermal switch (normally closed) Cosine differential input-... - Page 63 CLK+ (1) Not applicable unless the motor has integrated thermal protection. (2) When used with Allen-Bradley® motors and Bulletin 2090 cables, pin 12 is reserved. IMPORTANT Combined motor-power cable length for all axes on the same DC bus must not exceed 240 m (787 ft) with 460V systems or 160 m (525 ft) with 230V systems.

-

Page 64: Auxiliary Feedback Connector Pinout

Chapter 4 Connector Data and Feature Descriptions Auxiliary Feedback Connector Pinout For TTL devices, the position count increases when A leads B. For sinusoidal devices, the position count increases when cosine leads sine. Table 30 - Stegmann Hiperface (SRS and SRM only) AF Pin Description Signal... -

Page 65: Iam Input Connector Pinout

Connector Data and Feature Descriptions Chapter 4 IAM Input Connector Pinout Table 32 - Control Power Connector CPD Pin Description Signal CTRL 2 Control power VAC input CTRL 1 Table 33 - DC Bus and Input Power Connector IPD Pin Description Signal An integral, unregulated power supply, consisting of AC line input,... -

Page 66: Iam And Am Motor Power And Brake Connector Pinout

Chapter 4 Connector Data and Feature Descriptions IAM and AM Motor Power and Brake Connector Pinout Table 35 - Motor Power Connector MP Pin Description Signal Chassis ground Three-phase motor power IMPORTANT Combined motor-power cable length for all axes on the same DC bus must not exceed 240 m (787 ft) with 460V systems or 160 m (525 ft) with 230V systems. -

Page 67: Control Signal Specifications

Connector Data and Feature Descriptions Chapter 4 This section provides a description of the Kinetix 6000 drive Control Signal Specifications I/O (IOD), communication, contactor enable (CED), brake (BC), and control power (CPD) connectors. Digital Inputs Two fast registration inputs and four other inputs are available for the machine interface on the IAM module and AM module. -

Page 68: Sercos Communication Specifications

Chapter 4 Connector Data and Feature Descriptions Figure 29 - Enable, Home, and Overtravel Digital Input Circuits 24V DC IOD-1, -4, -7, -10 I/O SUPPLY IOD-2, -5, -8, -11 INPUT 3k Ω CTRL_INPUT 0.1 μF 511 Ω IOD-3, -6, -9, -12 IO_COM 1k Ω... -

Page 69: Analog Outputs

Connector Data and Feature Descriptions Chapter 4 Analog Outputs The IAM and AM modules include two analog outputs (IOD-23 and IOD-25) that you can configure through software to represent drive variables. Figure 31 - Analog Output Circuit Kinetix 6000 IAM/AM Oscilloscope Module (second channel not shown) -

Page 70: Contactor Enable Relay

Chapter 4 Connector Data and Feature Descriptions Contactor Enable Relay Contactor enable is a relay-driven contact used in the three-phase power- enable control string to protect the drive electronics during certain fault conditions. It is capable of handling 120V AC or 24V DC at 1 A or less. Contactor enable is a function of the converter and is not available in the axis modules. -

Page 71: Power And Relay Specifications

Connector Data and Feature Descriptions Chapter 4 This section provides a description of the Kinetix 6000 brake relay (BC), input Power and Relay power (IPD), motor power (MP), and control power (CPD) connectors. Specifications Motor/Resistive Brake Relay The brake option is a spring-set holding brake that releases when voltage is applied to the brake coil in the motor. - Page 72 213 for brake coil currents. IMPORTANT Holding brakes that are available on Allen-Bradley rotary motors are designed to hold a motor shaft at 0 rpm for up to the rated brake- holding torque, not to stop the rotation of the motor shaft, or be used as a safety device.

-

Page 73: Input Power Cycle Capability

Refer to Appendix C on page 227 to calculate total system capacitance. Table 43 - Maximum Input Power Cycling Specifications (230V) Attribute 2094-AC05-MP5-S 2094-AC05-M01-S 2094-AC09-M02-S 2094-AC16-M03-S 2094-AC32-M05-S Main AC input power cycling (cycles per minute for 10,000 μf) 0.69... -

Page 74: Peak Enhancement Specifications

Chapter 4 Connector Data and Feature Descriptions Peak Enhancement Specifications Drives that support the Peak-enhanced mode have the capability of increasing the maximum inverter peak current to achieve greater overload performance. IMPORTANT The peak enhancement feature requires the use of RSLogix 5000® software or the Logix Designer application, and drive firmware as specified in Table Table 45 - Peak Enhancement Software and Firmware Requirements... - Page 75 Connector Data and Feature Descriptions Chapter 4 Figure 34 - Load Duty-cycle Profile Example Cont D = T x 100% Base Table 48 - Peak Duty Cycle Definition of Terms Term Definition Continuous Current Rating (I The maximum value of current that can be output continuously. Cont The maximum value of peak current that the drive can output.

- Page 76 Chapter 4 Connector Data and Feature Descriptions Figure 35 - Peak Inverter Overload (T < 2.0 s) Legend = 150% = 200% = 250% Applies to these Kinetix 6000 drives: 2094-BC01-MP5-S, 2094-BMP5-S, 2094-BC01-M01-S, 2094-BM01-S, 2094-BC02-M02-S, 2094-BM02-S, 2094-BC04-M03-S, 2094-BM03-S 100% % Base Current (I Base Cont (1) Base current (I...

-

Page 77: Control Power

Connector Data and Feature Descriptions Chapter 4 Control Power The IAM module requires AC input power for logic circuitry. IMPORTANT The control power input requires an AC (EMC) line filter for CE certification. For filter examples, refer to Agency Compliance on page IMPORTANT 2094-BCxx-Mxx-x (460V) IAM modules require a step down transformer for single-phase control power input. -

Page 78: Feedback Specifications

2090-K6CK-KENDAT low-profile feedback module for EnDat to Hiperface conversion. TIP Auto-configuration in the Logix Designer application of intelligent absolute, high- resolution, incremental, and EnDat encoders is possible only with Allen-Bradley motors. Absolute Position Feature The drive’s absolute position feature tracks the position of the motor, within the multi-turn retention limits, while the drive is powered off. -

Page 79: Motor Feedback Specifications

Connector Data and Feature Descriptions Chapter 4 Motor Feedback Specifications AM, BM, and IM input encoder signals are filtered by using analog and digital filtering. The inputs also include illegal state change detection. Figure 38 - AM, BM, and IM Motor Encoder Input Circuits +5 V 1k Ω... -

Page 80: Feedback Power Supply Specifications

Chapter 4 Connector Data and Feature Descriptions Table 53 - AM, BM, and IM Input Specifications for TTL Encoders Parameter Description AM, BM, and IM Input voltage difference between the plus (+) input and the +1.0V +7.0V On-state input voltage minus (-) input that is detected as an on-state. -

Page 81: Auxiliary Position Feedback Encoders

Connector Data and Feature Descriptions Chapter 4 Auxiliary Position Feedback Encoders Allen-Bradley Bulletin 842HR, 844D, 847H, and 847T encoders are the preferred encoders for auxiliary feedback connections. Table 56 - Allen-Bradley Auxiliary Feedback Encoders Cat. No. Description 842HR-MJDZ115FWYD (multi-turn) Size 25, sine/cosine (serial), square flange, 3/8 in. solid shaft with 842HR-SJDZ115FWYD (single-turn) flat, 5…12V DC, digital RS-485 interface, M23, 17-pin connector... - Page 82 Chapter 4 Connector Data and Feature Descriptions Notes: Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 83: Connect The Kinetix 6000 Drive System

Chapter Connect the Kinetix 6000 Drive System This chapter provides procedures for wiring your Kinetix® 6000 drive system components and making cable connections. Topic Page Basic Wiring Requirements Determine the Input Power Configuration Set the Ground Jumper in Select Power Configurations Grounding the Kinetix 6000 Drive System Power Wiring Requirements Power Wiring Guidelines... -

Page 84: Building Your Own Cables

Chapter 5 Connect the Kinetix 6000 Drive System IMPORTANT This section contains common PWM servo system wiring configurations, size, and practices that can be used in a majority of applications. National Electrical Code, local electrical codes, special operating temperatures, duty cycles, or system configurations take precedence over the values and methods provided. -

Page 85: Determine The Input Power Configuration

Connect the Kinetix 6000 Drive System Chapter 5 Before wiring input power to your Kinetix 6000 system, you must determine Determine the Input Power the type of input power you are connecting to. The IAM module is designed to Configuration operate in both grounded and ungrounded environments. - Page 86 Chapter 5 Connect the Kinetix 6000 Drive System Figure 40 - Corner-grounded Power Configuration (Delta Secondary) Kinetix 6000 IAM Module, Top View CTRL 2 CTRL 1 Transformer (Delta) Secondary Transformer Three-phase MBRK - AC Line Filter MBRK + Circuit CONT EN- DBRK - Protection CONT EN+...

-

Page 87: Ungrounded Power Configurations

Connect the Kinetix 6000 Drive System Chapter 5 Ungrounded Power Configurations The ungrounded power configuration (Figure 42) does not provide a neutral ground point. Ungrounded, impedance-grounded, and corner-grounded power configurations are allowed, but you must move a jumper (internal to the IAM module) across a 120 kΩ... -

Page 88: Dc Common Bus Configurations

Chapter 5 Connect the Kinetix 6000 Drive System When the IAM module is used in a DC common-bus configuration, the IAM DC Common Bus module is known as a leader IAM or follower IAM module. The IAM (non- Configurations common bus) and leader IAM module have identical three-phase input power connections. -

Page 89: Common Bus Fusing Requirements

Connect the Kinetix 6000 Drive System Chapter 5 Common Bus Fusing Requirements When using a Kinetix 6000 leader IAM module, DC-bus fuses are required only when wiring to more than one Kinetix 6000 follower IAM module. When wiring multiple follower IAM modules, terminal blocks are required to extend the DC common-bus power to additional drives. -

Page 90: Set The Ground Jumper

Chapter 5 Connect the Kinetix 6000 Drive System When using ungrounded input power in common-bus configurations, use this table to determine where to set the ground jumper. Table 58 - Ground Jumper to Set Leader Drive Follower Drive Set the Jumper in This Drive Kinetix 6000 IAM module Kinetix 6000 IAM module Leader drive... - Page 91 Connect the Kinetix 6000 Drive System Chapter 5 3. Swing the front panel open to the right, as shown, and locate the ground jumper. IMPORTANT Do not attempt to remove the front panel from the IAM module. The front panel status indicators and switches are also connected to the IAM module with a ribbon cable.

- Page 92 Chapter 5 Connect the Kinetix 6000 Drive System Figure 44 - Setting the Ground Jumper (230V Series A and C IAM modules) Top Screw 2094-ACxx-Mxx-x IAM Module (230V) Ground jumper set for ungrounded configuration. Ground jumper set for grounded configuration (default setting).

- Page 93 Connect the Kinetix 6000 Drive System Chapter 5 Figure 45 - Setting the Ground Jumper (460V Series A IAM modules) Top Screw 2094-BC01-MP5-x, 2094-BC01-M01-x, or 2094-BC02-M02-x IAM Module (460V) Ground jumper set for ungrounded configuration. Ground jumper set for grounded configuration (default setting).

- Page 94 Chapter 5 Connect the Kinetix 6000 Drive System Figure 46 - Setting the Ground Jumper (460V Series B and C IAM modules) (behind P18) Top Screw 2094-BC01-MP5-S, 2094-BC01-M01-S, 2094-BC02-M02-S, 2094-BC04-M03-S, or 2094-BC07-M05-S Ground jumper set IAM Module (460V) for grounded configuration (default setting).

-

Page 95: Grounding The Kinetix 6000 Drive System

Connect the Kinetix 6000 Drive System Chapter 5 All equipment and components of a machine or process system must have a Grounding the Kinetix 6000 common earth ground point connected to chassis. A grounded system provides Drive System a ground path for short circuit protection. Grounding your modules and panels minimize shock hazard to personnel and damage to equipment caused by short circuits, transient overvoltages, and accidental connection of energized conductors to the equipment chassis. -

Page 96: Ground Multiple Subpanels

Chapter 5 Connect the Kinetix 6000 Drive System For mounting bracket dimensions, refer to the 2094 Mounting Brackets Installation Instructions, publication 2094-IN008. IMPORTANT When 2094 mounting brackets are used to mount the power rail or LIM module over the AC line filter, the braided ground strap must be removed from the power rail and attached to a mounting bracket ground stud. -

Page 97: Power Wiring Requirements

Connect the Kinetix 6000 Drive System Chapter 5 Wire must be copper with 75 °C (167 °F) minimum rating. Phasing of main Power Wiring Requirements AC power is arbitrary and earth ground connection is required for safe and proper operation. For IPIM module power wiring requirements, refer to the Kinetix 6000M Integrated Drive-Motor System User Manual, publication 2094-UM003. - Page 98 Chapter 5 Connect the Kinetix 6000 Drive System Table 61 - IAM/AM Power Wiring Requirements Connects to Terminals Recommended Strip Length Torque Value Kinetix 6000 Drive Wire Size Description Cat. No. mm (in.) N•m (lb•in) Signal (AWG) 2094-AC05-Mxx-x, Motor power cable 2094-AC09-M02-x, depends on motor/ 2094-BC01-Mxx-x,...

-

Page 99: Power Wiring Guidelines

Connect the Kinetix 6000 Drive System Chapter 5 Use these guidelines as a reference when wiring the power connectors on your Power Wiring Guidelines IAM and AM drive modules. For IPIM module power wiring guidelines, refer to the Kinetix 6000M Integrated Drive-Motor System User Manual, publication 2094-UM003. -

Page 100: Wiring The Iam/Am Module Connectors

Chapter 5 Connect the Kinetix 6000 Drive System This section provides examples and wiring tables to assist you in making Wiring the IAM/AM Module connections to the IAM and AM modules. Connectors Wire the Control Power (CPD) Connector This example applies to any IAM, leader IAM, or follower IAM module. Figure 49 - IAM Module (CPD connector) Kinetix 6000 IAM Module, Top View... -

Page 101: Wire The Input Power (Ipd) Connector

Connect the Kinetix 6000 Drive System Chapter 5 Wire the Input Power (IPD) Connector This example applies to any IAM module or common-bus leader IAM module. ATTENTION: Make sure the input power connections are correct when wiring the IPD connector plug and that the plug is fully engaged in the module connector. - Page 102 Chapter 5 Connect the Kinetix 6000 Drive System This example applies to a common-bus follower IAM module. ATTENTION: Make sure the common-bus power connections are correct when wiring the IPD connector plug and that the plug is fully engaged in the module connector.

-

Page 103: Wire The Contactor Enable (Ced) Connector

Connect the Kinetix 6000 Drive System Chapter 5 Wire the Contactor Enable (CED) Connector This example applies to any IAM, common-bus leader IAM, or common-bus follower IAM module. Figure 52 - IAM Module (CED connector) Kinetix 6000 IAM Module, Top View ATTENTION: Wiring the contactor enable relay is required. -

Page 104: Wiring The Safe Torque-Off (Sto) Connector

Chapter 5 Connect the Kinetix 6000 Drive System Wiring the Safe Torque-off (STO) Connector This example applies to any IAM or AM module equipped with the torque-off (STO) connector. Figure 53 - IAM/AM Module (STO connector) Kinetix 6000 IAM/AM Module (AM module is shown) Motion-allowed Jumper Safe Torque-off... -

Page 105: Wire The Motor Power (Mp) Connector

Connect the Kinetix 6000 Drive System Chapter 5 Wire the Motor Power (MP) Connector Connections to the motor power (MP) connector include rotary motors, linear motors, and motor driven actuators. ATTENTION: Make sure the motor power connections are correct when wiring the MP connector plug and that the plug is fully engaged in the module connector. -

Page 106: Rockwell Automation Publication 2094-Um001J-En-P - March

Chapter 5 Connect the Kinetix 6000 Drive System Pigtail Terminations TL-Series motors have a short pigtail cable that connects to the motor, but is not shielded. The preferred method for grounding the TL-Series power cable on the motor side is to expose a section of the cable shield and clamp it directly to the machine frame. - Page 107 Connect the Kinetix 6000 Drive System Chapter 5 MP-Series Motor and Actuator Connectors Bulletin MPL motors equipped with circular DIN connectors (specified by 4 or 7 in the catalog number) are not compatible with cables designed for motors equipped with bayonet connectors (specified by 2 in the catalog number). The motors with bayonet connectors are being discontinued.

- Page 108 Chapter 5 Connect the Kinetix 6000 Drive System Motor Power Wiring Examples The procedure for wiring motor power varies slightly, depending on the motor family. The cables compatible with your motor or actuator depend on the connectors installed on the motor or actuator. Refer to MP-Series Motor and Actuator Connectors on page 107 for more information on circular DIN and...

- Page 109 Connect the Kinetix 6000 Drive System Chapter 5 Table 73 - Motor Power Cable Compatibility - SpeedTec DIN Connectors Connector Motor Power Cables Motor Power Cables Motor/Actuator Motor/Actuator Cat. No. Type (with brake wires) (without brake wires) MPL-A/B15xxx-xx7xAA, MPL-A/B2xxx-xx7xAA, MPL-A/B3xxx-xx7xAA, MPL-A/B4xxx-xx7xAA, MP-Series (Bulletin MPL) MPL-A/B45xxx-xx7xAA, MPL-A/B5xxx-xx7xAA, MPL-B6xxx-xx7xAA, MPL-B8xxx-xx7xAA...

- Page 110 Chapter 5 Connect the Kinetix 6000 Drive System These cables contain three-phase power wires and brake wires. The brake wires have a shield braid (shown below as gray) that folds back under the cable clamp before the conductors are attached to the motor brake (BC) connector. Thermal switch wires are included in the feedback cable.

- Page 111 Connect the Kinetix 6000 Drive System Chapter 5 The 1326AB (resolver) power cables (catalog number 1326-CPx1T-L-xxx) contain the three-phase wires, brake wires, and thermal switch wires. To improve the EMC performance of your system, route the wires as shown. Refer to Axis Module/Rotary Motor Wiring Examples beginning on page 198 for interconnect diagrams.

- Page 112 Chapter 5 Connect the Kinetix 6000 Drive System Cable shield and lead preparation is provided with most Allen-Bradley® cable assemblies. Follow these guidelines if your motor power cable shield and wires require preparation. Figure 60 - Cable Shield and Lead Preparation...

-

Page 113: Wire The Motor/Resistive Brake (Bc) Connector

Connect the Kinetix 6000 Drive System Chapter 5 Wire the Motor/Resistive Brake (BC) Connector This example applies to AM modules and the inverter section of IAM modules. Figure 61 - IAM/AM Module (BC connector) Kinetix 6000 IAM/AM Module (IAM module is shown) Motor/Resistive Brake (BC) Connector 24V DC Brake Input Power Connections... - Page 114 Chapter 5 Connect the Kinetix 6000 Drive System Motor Brake Connections The procedure for wiring your motor brake varies slightly, depending on the motor family. The cables compatible with your motor or actuator depend on the connectors installed on the motor or actuator. Refer to MP-Series Motor and Actuator Connectors on page 107 for more information on circular DIN...

- Page 115 Connect the Kinetix 6000 Drive System Chapter 5 Figure 62 - Brake Cable Preparation Outer Insulation Strip Length 10 mm (0.375 in.) Brake Cable 105 mm (4.1 in.) Table 81 - Motor/Resistive Brake (BC) Connector BC Connector Motor Brake Wires (IAM/AM module) 2090-XXNPMF-xxSxx 2090-UXxBMP-18Sxx...

-

Page 116: Apply The Motor Cable Shield Clamp

Chapter 5 Connect the Kinetix 6000 Drive System This procedure assumes you have completed wiring your motor power (MP) Apply the Motor Cable Shield connector and are ready to apply the cable shield clamp. Clamp TIP Your drive can be equipped with either the pivot-open or slide-open cable clamp. -

Page 117: Feedback And I/O Cable Connections

Connect the Kinetix 6000 Drive System Chapter 5 Factory made cables with premolded connectors are designed to minimize Feedback and I/O Cable EMI and are recommended over hand-built cables to improve system Connections performance. However, other options are available for building your own feedback and I/O cables. - Page 118 Chapter 5 Connect the Kinetix 6000 Drive System Table 85 - Motor Feedback Cable Compatibility - Threaded DIN/Plastic Connectors Feedback Cable Connector Motor/Actuator Feedback Type Type Premolded Flying-lead MPL-A/B15xxx-V/Ex4xAA High-resolution encoder MPL-A/B2xxx-V/Ex4xAA MPL-A/B15xxx-Hx4xAA 2090-XXNFMF-Sxx Incremental encoder MPL-A/B2xxx-Hx4xAA Circular (standard) or (threaded) DIN 2090-CFBM4DF-CDAFxx MPS-A/Bxxxx-S/M...

-

Page 119: Flying-Lead Feedback Cable Pinouts

Connect the Kinetix 6000 Drive System Chapter 5 Flying-lead Feedback Cable Pinouts Refer to the following tables for the motor-to-drive feedback cable pinout used in your application. Table 87 - 2090-XXxFMP-Sxx Feedback Cable Bayonet High-resolution Feedback Incremental Feedback Connector Pin Drive MF MPL-B3xxx…MPL-B9xxx-M/Sx2xAA MPL-A3xxx-M/Sx2xAA... - Page 120 Chapter 5 Connect the Kinetix 6000 Drive System Table 90 - 2090-XXNFMF-Sxx or 2090-CFBMxDF-xxAxxx Feedback Cables Circular DIN High-resolution Feedback Incremental Feedback Connector Pin MPL-B15xxx…MPL-B2xxx-V/Ex4/7xAA MPL-A15xxx…MPL-A2xxx-V/Ex4/7xAA MPF/MPS-Bxxx-M/S MPF/MPS-A3xx-M/S MPL-A15xxx-Hx4/7xAA MPF-A5xxx-M/S MPF/MPS-A4xx-M/S MPL-A2xxx-Hx4/7xAA MPF/MPS-A45xx-M/S MPL-B15xxx-Hx4/7xAA MPS-A5xxx-M/S Rotary Motors MPL-B2xxx-Hx4/7xAA MPL-B3xxx…MPL-B9xxx-M/Sx7xAA Drive MF RDB-Bxxxxx-3/7 MPL-A3xxx-Hx7xAA MPL-A5xxx-M/Sx7xAA...

- Page 121 Connect the Kinetix 6000 Drive System Chapter 5 Table 92 - 2090-XXNFHF-Sxx Feedback Cable Incremental Feedback Rotary Motor Drive MF Connector Pin Connector Pin F-Series Motors Reserved – Reserved – EPWR_5VM EPWR_5VM ECOMM ECOMM Table 93 - 1326-CCUT-L-xxx Feedback Cable Table 94 - 1326-CPx1T-L-xxx Power Cable Thermal Switch Rotary Motor...

-

Page 122: Wiring The Feedback And I/O Connectors

Chapter 5 Connect the Kinetix 6000 Drive System These procedures assume you have mounted your Kinetix 6000 system, Wiring the Feedback and I/O completed all power wiring, and are ready to connect your feedback and I/O Connectors cables. For This Connection Go to Premolded cable Connect Premolded Motor Feedback Cables on... -

Page 123: Connect Panel-Mounted Breakout Board Kits

Connect the Kinetix 6000 Drive System Chapter 5 Connect Panel-mounted Breakout Board Kits The 2090-UXBK-D15xx panel-mounted breakout board kit includes a DIN- rail breakout board and cable. The cable connects between the breakout board and the motor feedback (MF) connector. Wires from your flying-lead motor feedback cable connect to the terminals. -

Page 124: Wire Low-Profile Connector Kits

Chapter 5 Connect the Kinetix 6000 Drive System Wire Low-profile Connector Kits The 2090-K6CK-xxxx low-profile connector kits are suitable for terminating flying-lead motor feedback, auxiliary feedback, and I/O connections. They also apply to I/O connections on the 2094-AL09 and 2094-BL02 LIM modules. - Page 125 Connect the Kinetix 6000 Drive System Chapter 5 Figure 66 - Wiring (15-pin) Flying-lead Feedback Cable Connections 2090-K6CK-D15M and 2090-K6CK-D15F Connector Kit 15-pin (male) Motor Feedback 15-pin (female) Auxiliary Feedback Low-profile Connector Low-profile Connector Bare Wires Wire Insulation Pin 10 Pin 6 Pin 5 Pin 15...

- Page 126 Chapter 5 Connect the Kinetix 6000 Drive System Figure 68 - Wiring (15-pin) Flying-lead Feedback Cable Connections 2090-K6CK-D15MF Connector Kit Bare Wires 15-pin (male) Motor Feedback Low-profile Connector Drain Wire Wire Insulation Pin 10 Foil Shield Pin 15 Pin 5 Mounting Braided Shield Screws...

-

Page 127: External Shunt Module Connections

Connect the Kinetix 6000 Drive System Chapter 5 Follow these guidelines when wiring your external active or passive shunt External Shunt Module module. Connections IMPORTANT When tightening screws to secure the wires, refer to the tables beginning on page 97 for torque values. -

Page 128: Ipim Module Connections

Chapter 5 Connect the Kinetix 6000 Drive System An overview of the Kinetix 6000M integrated drive-motor (IDM) system IPIM Module Connections connections are shown here. • Refer to Chapter 2 page 25, for noise zone considerations. • Refer to Appendix A, on page 212, for an interconnect diagram featuring the Kinetix 6000M integrated drive-motor (IDM) system. -

Page 129: Rbm Module Connections

Connect the Kinetix 6000 Drive System Chapter 5 Follow these guidelines when wiring your Bulletin 2090 Resistive Brake RBM Module Connections Module (RBM). IMPORTANT To be sure of system performance, run wires and cables in the wireways as established in Chapter If your application requires an RBM module and you are wiring to a Kinetix 6000 IAM/AM module, then refer to the following:... -

Page 130: Sercos Fiber-Optic Cable Connections

Chapter 5 Connect the Kinetix 6000 Drive System This procedure assumes you have your Logix5000™ Sercos interface module/ Sercos Fiber-optic Cable PCI card and Kinetix 6000 IAM/AM modules mounted and are ready to Connections connect the fiber-optic cables. The Sercos fiber-optic ring is connected by using the Sercos receive (Rx) and transmit (Tx) connectors. - Page 131 Connect the Kinetix 6000 Drive System Chapter 5 Figure 74 - Fiber-optic Cable Example - SoftLogix Controller SoftLogix Controller 1784-PM16SE Sercos interface PCI Card Transmit Receive Sercos fiber-optic ring Receive Transmit Receive Transmit Kinetix 6000 Kinetix 6000 System System In this example, two Logix5000 modules are installed in separate chassis. Figure 75 - Fiber-optic Cable Example - Two Logix5000 Controllers 1756-MxxSE Sercos interface Modules SERCOS interface...

- Page 132 Chapter 5 Connect the Kinetix 6000 Drive System When connecting 2094-BM03-x and 2094-BM05-x (double-wide) axis modules, use 2090-SCEP0-2, 0.2 m (7.0 in.) cables. When connecting 2094- AMxx-x, 2094-BMP5-x, 2094-BM01-x, and 2094-BM02-x (single-wide) axis modules, use 2090-SCEP0-1, 0.1 m (5.1 in.) cables. Figure 76 - Fiber-optic Cable Example - Logix5000 Controller with Double-wide Drive Modules 1756-M16SE Sercos Interface Module...

-

Page 133: Kinetix 6000M Integrated Drive-Motor Sercos Connections

Connect the Kinetix 6000 Drive System Chapter 5 The Kinetix 6000 Sercos ring includes the Kinetix 6000M integrated drive- Kinetix 6000M Integrated motor (IDM) units and IDM power interface modules (IPIM). Fiber-optic Drive-Motor Sercos connections are made from drive-to-drive and drive-to-IPIM module. IDM Connections network connections continue from the IPIM module to the IDM units. -

Page 134: Ethernet Cable Connections

Chapter 5 Connect the Kinetix 6000 Drive System This procedure assumes you have your ControlLogix or CompactLogix Ethernet Cable Connections EtherNet/IP module and Bulletin 2094 control modules mounted and are ready to connect the Ethernet network cables. The EtherNet/IP network is connected by using the PORT 1 and/or PORT 2 connectors. -

Page 135: Configure And Start The Kinetix 6000 Drive System

Chapter Configure and Start the Kinetix 6000 Drive System This chapter provides procedures for configuring the Kinetix® 6000 drive components with your Logix5000™ Sercos communication module. Topic Page Configure the Kinetix 6000M Integrated Drive-Motor System Configure the Drive Modules Configure the Logix5000 Sercos interface Module Apply Power to the Kinetix 6000 Drive Test and Tune the Axes Configure Drive Parameters and System Variables... -

Page 136: Configure The Drive Modules

Chapter 6 Configure and Start the Kinetix 6000 Drive System Follow these steps to configure the integrated axis module (IAM) and axis Configure the Drive Modules modules (AM). IMPORTANT If you have one or more IDM power interface modules (IPIM) on your power rail, refer to the Kinetix 6000M Integrated Drive-Motor System User Manual, publication 2094-UM003, for system configuration information specific to the Kinetix 6000M IDM system. - Page 137 Configure and Start the Kinetix 6000 Drive System Chapter 6 IMPORTANT When two or more IAM modules are connected to the same Sercos interface module, each node address must be unique. Refer to the node addressing examples beginning on page 138.

- Page 138 Chapter 6 Configure and Start the Kinetix 6000 Drive System Figure 80 - Node Addressing Example 1 1756-MxxSE Sercos interface Module SERCOS interface Logix5000 Controller (ControlLogix® controller is shown) Tx (rear) Rx (front) Transmit Receive Sercos Fiber-optic Ring Receive Transmit Kinetix 6000 Drive System 2 Receive...

- Page 139 Configure and Start the Kinetix 6000 Drive System Chapter 6 Figure 81 - Node Addressing Example 2 1756-MxxSE Sercos 1756-MxxSE Sercos interface Module 1 interface Module 2 SERCOS interface SERCOS interface Logix5000 Controller Logix5000 Controller (ControlLogix controller is shown) (ControlLogix controller is shown) Tx (rear) Tx (rear) Rx (front)

- Page 140 Chapter 6 Configure and Start the Kinetix 6000 Drive System Figure 82 - Node Addressing Example 3 1756-MxxSE Sercos interface Module SERCOS interface Logix5000 Controller (ControlLogix controller is shown) Tx (rear) Rx (front) Transmit Receive Sercos Fiber-optic Ring Transmit Receive Kinetix 6000 Drive System (8-axis power rail) 08 = Slot-filler module slot location...

- Page 141 Configure and Start the Kinetix 6000 Drive System Chapter 6 Figure 83 - Node Addressing Example 4 1756-MxxSE Sercos Interface Module Sercos Fiber-optic Ring 0.1 m SERCOS interface Logix5000 Controller (5.1 in.) (ControlLogix controller is shown) Receive Transmit Tx (rear) Rx (front) Transmit Receive...

-

Page 142: Configure The Logix5000 Sercos Interface Module

Chapter 6 Configure and Start the Kinetix 6000 Drive System This procedure assumes that you have wired your Kinetix 6000 system and Configure the Logix5000 have configured the communication rate and optical power switches. Sercos interface Module For help with using the Logix Designer application as it applies to configuring the ControlLogix, CompactLogix™, or SoftLogix™... - Page 143 Configure and Start the Kinetix 6000 Drive System Chapter 6 The Controller Properties dialog box opens. 6. Click the Date/Time tab. 7. Check Enable Time Synchronization. This assigns the controller as the Grandmaster clock. The motion modules set their clocks to the module you assign as the Grandmaster. IMPORTANT You can assign only one module in the Logix5000 chassis as the Grandmaster clock.

-

Page 144: Configure The Logix5000 Module

Chapter 6 Configure and Start the Kinetix 6000 Drive System Configure the Logix5000 Module Follow these steps to configure the Logix5000 module. 1. Right-click I/O Configuration in the Controller Organizer and choose New Module. The Select Module dialog box opens. 2. - Page 145 Configure and Start the Kinetix 6000 Drive System Chapter 6 6. Click the Sercos Interface tab and reference the table below. Logix5000 Sercos Module Number of Axes Data Rate 1756-M03SE or Up to 3 1756-L60M03SE 1756-M08SE Up to 8 4 or 8 Mbps 1756-M16SE or Up to 16 1784-PM16SE...

-

Page 146: Configure The Kinetix 6000 Drive Modules

Chapter 6 Configure and Start the Kinetix 6000 Drive System Configure the Kinetix 6000 Drive Modules Follow these steps to configure the Kinetix 6000 drive modules. 1. Right-click the Logix5000 module you just created and choose New Module. The Select Module dialog box opens. 2. - Page 147 Configure and Start the Kinetix 6000 Drive System Chapter 6 c. Check Open Module Properties. 5. Click OK. 6. Click the Associated Axes tab. 7. Click New Axis. The New Tag dialog box opens. 8. Type the axis Name. AXIS_SERVO_DRIVE is the default Data Type. 9.

- Page 148 Chapter 6 Configure and Start the Kinetix 6000 Drive System 11. Click Apply. TIP With drive firmware revision 1.80 or later, and the Logix Designer application or RSLogix 5000 software, version 13 or later, it is possible to configure the Auxiliary Axis feedback port as a Feedback Only axis. With this feature, you can configure each IAM inverter or AM module to appear as two axes/nodes on the Sercos ring.

- Page 149 Configure and Start the Kinetix 6000 Drive System Chapter 6 To avoid damage to your Bulletin 1394 external shunt module when wired to the 2094-BSP2 shunt module, verify that the proper 230V or 460V fuse is installed prior to applying power. Refer to Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004, for more information.

-

Page 150: Configure The Motion Group

Chapter 6 Configure and Start the Kinetix 6000 Drive System Configure the Motion Group Follow these steps to configure the motion group. 1. Right-click Motion Groups in the Controller Organizer and choose New Motion Group. The New Tag dialog box opens. 2. -

Page 151: Configure Axis Properties

Configure and Start the Kinetix 6000 Drive System Chapter 6 Configure Axis Properties The peak current ratings of the Kinetix 6000 AM modules (series A, B, and C) are configured at the factory as 150% of continuous current. You can program 460V (series B and C) AM modules and the equivalent IAM (inverter) modules, for up to 250% of continuous inverter current. - Page 152 Chapter 6 Configure and Start the Kinetix 6000 Drive System 6. On the Drive/Motor tab, check Drive Enable Input Checking. When checked (default), means a hard drive-enable input signal is required. Uncheck to remove that requirement. 7. Click Apply. 8. Click the Motor Feedback tab and verify the Feedback Type shown is appropriate for your actual hardware configuration.

- Page 153 Configure and Start the Kinetix 6000 Drive System Chapter 6 14. Configure the delay times. a. Type the Brake Engage Delay Time. b. Type the Brake Release Delay Time. c. Set the Resistive Brake Contact Delay time (0 - 1000 ms range). TIP For recommended motor brake response times, refer to the Kinetix Rotary Motion Specifications Technical Data, publication KNX-TD001.

-

Page 154: Download The Program

Chapter 6 Configure and Start the Kinetix 6000 Drive System The Drive/Motor tab displays the amplifier being used and the Loop Configuration is Aux Feedback Only. This is the only choice if the amplifier is using the primary node for Servo (motor) configuration. 3. -

Page 155: Apply Power To The Kinetix 6000 Drive

Configure and Start the Kinetix 6000 Drive System Chapter 6 This procedure assumes that you have wired and configured your Kinetix 6000 Apply Power to the system (with or without the LIM module) and your Sercos interface module. Kinetix 6000 Drive ATTENTION: Capacitors on the DC bus can retain hazardous voltages after input power has been removed. - Page 156 Chapter 6 Configure and Start the Kinetix 6000 Drive System 4. Determine your source of three-phase input power. If Your Three-phase Then Power 1. Set CB1 to the ON position. 2. Verify the Hardware Enable Input signal (IOD-2) for each axis is at 0 Is sourced from a volts.

-

Page 157: Test And Tune The Axes

Configure and Start the Kinetix 6000 Drive System Chapter 6 These procedures assume that you have configured your Kinetix 6000 drive, Test and Tune the Axes your Logix5000 Sercos interface module, and applied power to the system. For help with using the Logix Designer application, as it applies to testing and tuning your axes with ControlLogix, CompactLogix, or SoftLogix Sercos modules, refer to Additional Resources on page... - Page 158 Chapter 6 Configure and Start the Kinetix 6000 Drive System IMPORTANT Hardware Enable input for IDM units is on the IPIM module. 6. Click the desired test (Marker/Feedback/Command & Feedback) to verify connections. The Online Command dialog box opens. Follow the on-screen test instructions.

-

Page 159: Tune The Axes

Configure and Start the Kinetix 6000 Drive System Chapter 6 Tune the Axes The load observer feature (available with drive firmware revision 1.124 or later) can provide good performance without having to tune your axis. Using load observer with auto-tuned gains can maximize system performance. Refer to Appendix D beginning on page 237 for more load observer information. - Page 160 Chapter 6 Configure and Start the Kinetix 6000 Drive System 7. Click Start Tuning to auto-tune your axis. The Online Command - Tune Servo dialog box opens. When the test completes, the Command Status changes from Executing to Command Complete. 8.

- Page 161 Configure and Start the Kinetix 6000 Drive System Chapter 6 12. Determine if your test completed successfully. Then Your test completes successfully, this dialog box opens. 1. Click OK. 2. Remove the Hardware Enable Input signal (IOD-2) applied earlier. 3. Go to step Your test failed, this dialog box opens.

-

Page 162: Configure Drive Parameters And System Variables

Chapter 6 Configure and Start the Kinetix 6000 Drive System This section provides information for accessing and changing parameters not Configure Drive Parameters accessible through the Logix Designer application. and System Variables IMPORTANT Drive parameters for the Kinetix 6000M IDM system are not accessible through the HIM module or DriveExplorer software. -

Page 163: Monitor System Variables With Analog Test Points

Configure and Start the Kinetix 6000 Drive System Chapter 6 Change Parameters with the HIM Module When using the HIM module to monitor or change parameters, use the up and down arrows (∧ and ∨) to arrive at selections. Refer to the instructions that came with your HIM module for more information. - Page 164 Chapter 6 Configure and Start the Kinetix 6000 Drive System Parameters begin with a variable to identify a specific axis by slot number, as follows: • IAM module = 0 for parameters 0…999 • 1st AM module = 1 for parameters 1000…1999 •...

-

Page 165: Troubleshooting The Kinetix 6000 Drive System

Chapter Troubleshooting the Kinetix 6000 Drive System This chapter provides troubleshooting tables for your Kinetix® 6000 drive system components. Topic Page Safety Precautions Interpret Status Indicators General System Anomalies Logix5000/Drive Fault Behavior Observe these safety precautions when troubleshooting your Kinetix 6000 Safety Precautions drive. -

Page 166: Interpret Status Indicators

Chapter 7 Troubleshooting the Kinetix 6000 Drive System Refer to these troubleshooting tables to identify faults, potential causes, and Interpret Status Indicators the appropriate actions to resolve the fault. If the fault persists after attempting to troubleshoot the system, please contact your Rockwell Automation sales representative for further assistance. -

Page 167: Kinetix 6000 Drive System Error Codes

Troubleshooting the Kinetix 6000 Drive System Chapter 7 Kinetix 6000 Drive System Error Codes The following list of problematic symptoms (no error code shown) and faults with assigned error codes is designed to help you resolve anomalies. When a fault is detected, the seven-segment status indicator displays an E followed by the flashing of the two-digit error code, one digit at a time. - Page 168 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 102 - Seven-segment Status Indicator Error Codes (continued) Error Fault Message - Logix Anomaly or Symptom Potential Cause Possible Resolution Code Designer (HIM) • Verify voltage level of the incoming AC power. With three-phase power •...

- Page 169 Troubleshooting the Kinetix 6000 Drive System Chapter 7 Table 102 - Seven-segment Status Indicator Error Codes (continued) Error Fault Message - Logix Anomaly or Symptom Potential Cause Possible Resolution Code Designer (HIM) Low AC input voltage. Check input AC voltage on all phases. DriveUndervoltage Fault Converter precharge cycle failed.

- Page 170 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 102 - Seven-segment Status Indicator Error Codes (continued) Error Fault Message - Logix Anomaly or Symptom Potential Cause Possible Resolution Code Designer (HIM) No Fault Message (condition indicated by • Check motor power/feedback wiring. Hookup procedure failed Motor or feedback device malfunction.

- Page 171 Troubleshooting the Kinetix 6000 Drive System Chapter 7 Table 102 - Seven-segment Status Indicator Error Codes (continued) Error Fault Message - Logix Anomaly or Symptom Potential Cause Possible Resolution Code Designer (HIM) Refer to Temperature Fault Status Indicator on Over-temperature fault indicator on Bulletin 2094 shunt module is steady red. page 174.

-

Page 172: Iam/Am Module Status Indicators

Chapter 7 Troubleshooting the Kinetix 6000 Drive System IAM/AM Module Status Indicators Table 103 - Drive Status Indicator Drive Status Indicator Drive Status Possible Resolution Normal, no faults Refer to seven-segment error code and Kinetix 6000 Drive Steady red Drive faulted System Error Codes troubleshooting on page 167. -

Page 173: Shunt Module Status Indicators

Troubleshooting the Kinetix 6000 Drive System Chapter 7 Shunt Module Status Indicators Each of the shunt module status indicators provide specific troubleshooting information. Table 106 - General Shunt Module Troubleshooting Module Status Under These Conditions Fault is latched. Until fault condition is corrected and cleared. •... - Page 174 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 107 - Bus Status Indicator Bus Status Indicator Status Potential Cause Possible Resolution Flashing Normal condition when control power is applied and bus voltage is less than 60V DC. Steady Green Normal condition when control power is applied and bus voltage is greater than 60V DC.

-

Page 175: General System Anomalies

Troubleshooting the Kinetix 6000 Drive System Chapter 7 These anomalies do not always result in a fault code, but can require General System Anomalies troubleshooting to improve performance. Table 111 - General System Anomalies Condition Potential Cause Possible Resolution The position feedback device is incorrect or open. Check wiring. - Page 176 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 111 - General System Anomalies (continued) Condition Potential Cause Possible Resolution The motor connections are loose or open. Check motor wiring and connections. Foreign matter is lodged in the motor. Remove foreign matter. The motor load is excessive.

-

Page 177: Logix5000/Drive Fault Behavior

Troubleshooting the Kinetix 6000 Drive System Chapter 7 These fault actions are configurable from the Axis Properties dialog box, Fault Logix5000/Drive Fault Actions tab in the Logix Designer application. Behavior Table 112 - Drive Fault Action Definitions Drive Fault Action Definition The drive disables the axis as defined in Logix5000/Drive Fault... - Page 178 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 113 - Logix5000/Drive Fault Behavior Logix Designer Logix5000 Fault Message Error Drive Fault Action/ Description Programmable (HIM Message) Code Attribute Fault Action? BusUndervoltageFault Coast/Disable (open A blown fuse was detected in the inverter pcb. contactor enable relay) (Blown fuse) The motor thermal switch was tripped.

- Page 179 Troubleshooting the Kinetix 6000 Drive System Chapter 7 Table 113 - Logix5000/Drive Fault Behavior (continued) Logix Designer Logix5000 Fault Message Error Drive Fault Action/ Description Programmable (HIM Message) Code Attribute Fault Action? Coast/Disable (open One or two phases of the input AC power are missing. contactor enable relay) PowerPhaseLossFault •...

- Page 180 Chapter 7 Troubleshooting the Kinetix 6000 Drive System Table 113 - Logix5000/Drive Fault Behavior (continued) Logix Designer Logix5000 Fault Message Error Drive Fault Action/ Description Programmable (HIM Message) Code Attribute Fault Action? DriveHardFault Coast/Disable (open Nonvolatile memory corrupted. contactor enable relay) (NV Mem Init) DriveHardFault Coast/Disable (open...

-

Page 181: Chapter 8 Before You Begin

Chapter Remove and Replace the Kinetix 6000 Drive Modules This chapter provides remove and replace procedures for your Kinetix® 6000 drive system components. Topic Page Before You Begin Remove Kinetix 6000 Drive Modules Replace Kinetix 6000 Drive Modules Remove the Power Rail Replace the Power Rail ATTENTION: This drive contains electrostatic discharge (ESD) sensitive parts and assemblies. -

Page 182: Remove Kinetix 6000 Drive Modules

Chapter 8 Remove and Replace the Kinetix 6000 Drive Modules Follow these steps to remove the IAM, AM, and IPIM modules from the Remove Kinetix 6000 Drive Bulletin 2094 power rail. Modules 1. Verify that all control and input power has been removed from the system. -

Page 183: Replace Kinetix 6000 Drive Modules

Remove and Replace the Kinetix 6000 Drive Modules Chapter 8 7. Lift the bracket out of the power rail slot and remove the module from the power rail. Guide Pins Power Rail Kinetix 6000 Drive Module (side view) (side view) (IAM module is shown) TIP This procedure also applies to Bulletin 2094-BSP2 shunt module, 2094-PRF slot-filler module, and 2094-SEPM-B24-S IPIM module. -

Page 184: Remove The Power Rail

Chapter 8 Remove and Replace the Kinetix 6000 Drive Modules 8. Verify that the system is operating properly. TIP Because parameter settings reside in the Logix Designer application, you do not need to perform any tuning or set-up procedures. This procedure assumes you have removed all modules from the power rail. Remove the Power Rail Follow these steps to remove the power rail. -

Page 185: Replace The Power Rail

Remove and Replace the Kinetix 6000 Drive Modules Chapter 8 This procedure assumes you do not need to change the location of the power Replace the Power Rail rail on the panel and you intend to reuse the mounting bolts of the power rail you just removed. - Page 186 Chapter 8 Remove and Replace the Kinetix 6000 Drive Modules Notes: Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

- Page 187 Appendix Interconnect Diagrams This appendix provides wiring examples and system block diagrams for your Kinetix® 6000 drive system components. Topic Page Interconnect Diagram Notes Power Wiring Examples Axis Module/Rotary Motor Wiring Examples Axis Module/Linear Motor/Actuator Wiring Examples Kinetix 6000M Integrated Drive-Motor Wiring Example Controlling a Brake Example System Block Diagrams Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 188: Interconnect Diagram Notes

Appendix A Interconnect Diagrams This appendix provides wiring examples to assist you in wiring the Interconnect Diagram Notes Kinetix 6000 drive system. These notes apply to the wiring examples on the following pages. Note Information For power wiring specifications, refer to Power Wiring Requirements on page For input fuse and circuit breaker sizes, refer to Circuit Breaker/Fuse Options on page... -

Page 189: Power Wiring Examples

Interconnect Diagrams Appendix A These examples apply to power wiring configurations with and without the Power Wiring Examples Bulletin 2094 line interface module (LIM), DC common bus wiring, and shunt module wiring. Figure 87 - Single IAM Module with 2094-AL09 or 2094-BL02 LIM Module 2094-ACxx-Mxx-x or 2094-BCxx-Mxx-x Refer to table on... - Page 190 Appendix A Interconnect Diagrams Figure 88 - Multiple IAM Module with LIM Module 2094-ACxx-Mxx-x or 2094-BCxx-Mxx-x Refer to table on page 188 for note information. IAM Module (IAM_1) Note 10 Bonded Cabinet Power Rail Ground Bus* Ground Stud Cable Shield Clamp 2094-ALxxS, 2094-BLxxS, or Three-phase...

- Page 191 Interconnect Diagrams Appendix A Figure 95 - Multiple IAM Module with LIM Module (continued) 2094-ACxx-Mxx-x or Refer to table on page 188 for note information. 2094-BCxx-Mxx-x IAM Module (IAM_2) Power Rail Note 10 Ground Stud Bonded Cabinet Cable Shield Ground Bus* Clamp Three-phase Motor Power...

- Page 192 Appendix A Interconnect Diagrams This configuration does not include a LIM module. You must supply input power components. The single-phase and three-phase line filters are wired downstream of fusing and the M1 contactor. ATTENTION: Wiring the contactor enable (CED) relay is required. To avoid injury or damage to the drive, wire the contactor enable relay into your control string.

-

Page 193: Dc Common Bus Wiring Examples

Interconnect Diagrams Appendix A DC Common Bus Wiring Examples Figure 90 - Leader IAM Module with Single Follower IAM Module Rockwell Automation Publication 2094-UM001J-EN-P - March 2017... - Page 194 Appendix A Interconnect Diagrams Figure 91 - Leader IAM Module with Multiple Follower IAM Modules To Follower DC Bus Connections Refer to table on page 188 for note information. To Follower Control Power Connections 2094-ACxx-Mxx-x or 2094-BCxx-Mxx-x Common-bus Leader Bonded Cabinet IAM Module Ground Bus * Power Rail...

- Page 195 Interconnect Diagrams Appendix A Figure 98 - Leader IAM Module with Multiple Follower IAM Modules (continued) 2094-ACxx-Mxx-x or Refer to table on page 188 for note information. 2094-BCxx-Mxx-x Common-bus Follower Bonded Cabinet Ground Bus * IAM Module Power Rail Ground Stud Cable Shield Clamp Note 4...

- Page 196 Appendix A Interconnect Diagrams Figure 92 - 8720MC-RPS Leader Drive with Single Follower IAM Module Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 197: Shunt Module Wiring Examples

Interconnect Diagrams Appendix A Shunt Module Wiring Examples Refer to Kinetix Motion Accessories Technical Data, publication KNX-TD004 for the Bulletin 1394 external shunt module catalog numbers available for the Kinetix 6000 drive systems. Figure 93 - Shunt Module Wired for Internal Operation (default configuration) 2094-BSP2 Kinetix 6000 Shunt Module... -

Page 198: Axis Module/Rotary Motor Wiring Examples

Appendix A Interconnect Diagrams These examples apply to Kinetix 6000 drives with Allen-Bradley® rotary Axis Module/Rotary Motor motors. Wiring Examples IMPORTANT The Bulletin MPL motor wiring examples on this page apply to motors equipped with bayonet connectors. Figure 95 - AM Module with MP-Series™ (Bulletin MPL-B) Rotary Motors IAM (inverter) or MPL-B3xx…MPL-B9xx... - Page 199 Interconnect Diagrams Appendix A IMPORTANT The Bulletin MPL motor wiring examples on this page apply to motors equipped with bayonet connectors. Figure 96 - AM Module Wiring Example with MP-Series (Bulletin MPL-A/B) Rotary Motors MPL-A3xx…MPL-A5xx IAM (inverter) or Refer to table on page 188 for note information.

- Page 200 Appendix A Interconnect Diagrams IMPORTANT The Bulletin MPL motor wiring examples on this page apply to motors equipped with circular DIN (threaded) connectors. Figure 97 - AM Module with MP-Series (Bulletin MPL-A/B and MPS-A/B) Motors MPL-A/B15xx…MPL-A/B2xx IAM (inverter) or Refer to table on page 188 for note information.

- Page 201 Interconnect Diagrams Appendix A IMPORTANT The Bulletin MPL motor wiring examples on this page apply to motors equipped with circular DIN (SpeedTec) connectors. Figure 98 - AM Module with MP-Series Motors (MPL-A/B, MPM-A/B, MPF-A/B, and MPS-A/B) MPL-A15xx…MPL-A5xx, IAM (inverter) or Refer to table on page 188 for note information.

- Page 202 Appendix A Interconnect Diagrams IMPORTANT The Bulletin MPL motor wiring examples on this page apply to motors equipped with circular DIN (SpeedTec) connectors. Figure 99 - AM Module Wiring Example with MP-Series Resolver Motors (Bulletin MPL-B and MPM-A/B) IAM (inverter) or MPL-B3xxx-R…MPL-B45xxx-R Refer to table on page 188...

- Page 203 Interconnect Diagrams Appendix A Figure 100 - AM Module with RDD-Series™ Direct Drive Motors RDB-Bxxxx Direct Drive IAM (inverter) or AM Refer to table on page 188 for note information. Servo Motors with Module High Resolution Feedback Note 15 2090-K6CK-KENDAT Cable Shield Feedback Module Clamp...

- Page 204 Appendix A Interconnect Diagrams Figure 101 - AM Module (230V) Wiring Example with TL-Series™ Motors (Bulletin TLY-A) IAM (inverter) or AM TLY-Axxxx-H (230V) Refer to table on page 188 for note information. Module Servo Motors with Note 15 Incremental Feedback Cable Shield 2090-K6CK-D15M Clamp...

- Page 205 Interconnect Diagrams Appendix A Figure 102 - AM Module (460V) Wiring Examples with 1326AB Motors 1326AB (M2L/S2L) IAM (inverter) or AM Refer to table on page 188 for note information. Servo Motors with Module High Resolution Feedback Note 15 Cable Shield 2090-K6CK-D15M Clamp Connector Kit...

- Page 206 Appendix A Interconnect Diagrams Figure 103 - AM Module (230V) Wiring Example with F-Series Motors F-Series (230V) IAM (inverter) or AM Refer to table on page 188 for note information. Servo Motors with Module Incremental Feedback Note 15 Cable Shield Clamp Note 10 Green/Yellow...

-

Page 207: Axis Module/Linear Motor/Actuator Wiring Examples

Interconnect Diagrams Appendix A These examples apply to Kinetix 6000 drives with Allen-Bradley linear motors Axis Module/Linear Motor/ and actuators. Actuator Wiring Examples Figure 104 - AM Module with MP-Series Integrated Linear Stages MPAS-A/Bxxxxx-VxxSxA Refer to table on page 188 for note information. - Page 208 Appendix A Interconnect Diagrams Figure 105 - AM Module with MP-Series Electric Cylinders MPAR-A/Bxxxxx (series B) and Refer to table on page 188 for note information. IAM (inverter) or AM MPAI-A/Bxxxxx Module Electric Cylinders with Note 15 High Resolution Feedback 2090-K6CK-D15M Cable Shield Connector Kit...

- Page 209 Interconnect Diagrams Appendix A Table 114 - MP-Series Electric Cylinder Power and Feedback Cables MP-Series Electric Cylinder Power Cable Feedback Cable Cat. No. Cat. No. Cat. No. MPAR-A/B1xxx (series A) 2090-XXNPMF-16Sxx (standard) or 2090-XXNFMF-Sxx (standard) or 2090-CPxM4DF-16AFxx (continuous-flex) 2090-CFBM4DF-CDAFxx (continuous-flex) MPAR-A/B2xxx (series A) MPAR-A/B1xxx (series B) MPAR-A/B2xxx (series B)

- Page 210 Appendix A Interconnect Diagrams Figure 107 - AM Module with LDC-Series™ or LDL-Series™ Linear Motors (cable connectors) IAM (inverter) or AM LDC-Cxxxxxx-xHTx1 or Refer to table on page 188 for note information. Module LDL-xxxxxxx-xHTx1 Linear Motor Coil with Note 15 Sin/Cos or TTL External Encoder and Cable Connectors Cable Shield...

- Page 211 Interconnect Diagrams Appendix A Figure 108 - AM Module with LDC-Series or LDL-Series Linear Motors (flying-lead cables) IAM (inverter) or AM Refer to table on page 188 for note information. Module Note 15 LDC-Cxxxxxx-xHTx0 or LDL-xxxxxxx-xHTx0 Cable Shield Linear Motor Coil with Clamp Sin/Cos or TTL External Encoder Note 10...

-

Page 212: Kinetix 6000M Integrated Drive-Motor Wiring Example

Appendix A Interconnect Diagrams This example applies to Kinetix 6000 drives with Kinetix 6000M integrated Kinetix 6000M Integrated drive-motor (IDM) systems. Drive-Motor Wiring Example ATTENTION: When using the Kinetix 6000M IDM system, with Kinetix 6000 drives, the IPIM module only forwards the safety- feedback monitoring signals to the adjacent (downstream) drive on the power rail. -

Page 213: Controlling A Brake Example

Interconnect Diagrams Appendix A The relay output of the Kinetix 6000 (MBRK± BC-5 and BC-6) is suitable for Controlling a Brake Example directly controlling a motor brake, subject to the relay voltage limit of 30V DC, and the relay current limit as shown below. Table 115 - Brake Relay Current Limit Brake Current Value, max Kinetix 6000 IAM/AM Module... -

Page 214: System Block Diagrams

Appendix A Interconnect Diagrams This section provides block diagrams of the Kinetix 6000 drive modules. For System Block Diagrams block diagrams of the LIM module and RBM module, refer to Additional Resources on page 12 for the documentation available for those products. Figure 110 - IAM/AM Module (inverter) Block Diagram Rockwell Automation Publication 2094-UM001J-EN-P - March 2017... - Page 215 Interconnect Diagrams Appendix A Figure 111 - IAM Module (converter) Block Diagram Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

- Page 216 Appendix A Interconnect Diagrams Figure 112 - Shunt Module Block Diagram Internal or External Shunt Resistor SYSOK Shunt Circuit SMPS GSHUNT (2) +5V (Control) +/-15V (IGBT) 24V (Control) Chassis Rockwell Automation Publication 2094-UM001J-EN-P - March 2017...

-

Page 217: Upgrade Kinetix 6000M System Firmware

Appendix Upgrade the Drive Firmware This appendix provides procedures for upgrading Kinetix® 6000 drive firmware by using ControlFLASH™ software. Topic Page Upgrade Kinetix 6000M System Firmware Upgrade Drive Firmware with ControlFLASH Software Upgrading firmware for the Kinetix 6000M integrated drive-motor (IDM) Upgrade Kinetix 6000M system is done by using ControlFLASH software. -

Page 218: Upgrade Drive Firmware With Controlflash Software

Appendix B Upgrade the Drive Firmware Upgrading axis module firmware by using ControlFLASH software involves Upgrade Drive Firmware configuring your controller communication, selecting the drive to upgrade, and with ControlFLASH Software upgrading the firmware. Before You Begin You need the following software and information before you begin. Firmware Revision or Description Cat. -

Page 219: Configure Logix5000 Communication