Table of Contents

Quick Links

Manual, Tool Changer, QC-313

Document #9620-20-B-313 Series Base Tool Changer-06

B. Robotic Tool Changer .............................................................................................................B-3

QC-313 Series-Robotic Tool Changer ......................................................................................B-3

1.

Product Overview ..................................................................................................................B-3

1.1

Master Plate Assembly ............................................................................................................. B-4

1.2

Tool Plate Assembly .................................................................................................................. B-5

1.3

Optional Modules ...................................................................................................................... B-5

2.

Installation .............................................................................................................................B-6

2.1

Master Interface ......................................................................................................................... B-7

2.2

Master Plate Installation ........................................................................................................... B-8

2.3

Master Plate Removal ............................................................................................................... B-8

2.4

Tool Interface ............................................................................................................................. B-9

2.5

Tool Plate Installation ............................................................................................................. B-10

2.6

Tool Plate Removal ................................................................................................................. B-10

2.7

Pneumatic Connections ..........................................................................................................B-11

2.7.1

Valve Requirements for Air Adapter Modules ................................................................B-11

2.8

Electrical Connections ............................................................................................................ B-12

2.8.1

PNP Type Lock, Unlock and RTL Sensors (-SM sensor designations) .........................B-12

3.

Operation .............................................................................................................................B-13

3.1

Conditions for Coupling ......................................................................................................... B-14

3.2

Fail-Safe Operation ................................................................................................................. B-15

3.3

Conditions for Uncoupling ..................................................................................................... B-16

3.4

3.5

Tool Storage Considerations ................................................................................................. B-17

4.

Maintenance .........................................................................................................................B-18

4.1

Preventive Maintenance ......................................................................................................... B-18

4.2

Cleaning and Lubrication of the Locking Mechanism and Alignment Pins ....................... B-19

4.3

Pin Block Inspection and Cleaning ....................................................................................... B-21

5.

Troubleshooting and Service Procedures ........................................................................B-22

5.1

Troubleshooting Procedures ................................................................................................. B-22

5.2

Service Procedures ................................................................................................................. B-23

5.2.1

Lock and Unlock Sensor Replacement Procedures ......................................................B-23

5.2.2

RTL Sensor Replacement Procedure ............................................................................B-25

5.2.3

R1 Sensor Cable Replacement .....................................................................................B-26

5.2.4

R2 Sensor Cable Replacement .....................................................................................B-28

5.2.5

V-ring Seal Inspection and Replacement ......................................................................B-30

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 •

Table of Contents

B-1

• Email:

www.ati-ia.com

Table of Contents

Summary of Contents for ATI Technologies QC‑313

-

Page 1: Table Of Contents

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 Table of Contents B. Robotic Tool Changer ......................B-3 QC-313 Series—Robotic Tool Changer ..................B-3 Product Overview ........................B-3 Master Plate Assembly ......................B-4 Tool Plate Assembly ........................B-5 Optional Modules ........................B-5 Installation ..........................B-6 Master Interface ......................... - Page 2 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.6 Alignment Pin Replacement ..................B-31 Serviceable Parts ........................B-33 Master Serviceable Parts ......................B-33 Tool Serviceable Parts ......................B-34 7. Specifications ........................B-35 Drawings ..........................B-36 QC-313 Tool Changer ......................B-36 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • •...

-

Page 3: Robotic Tool Changer

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 B. Robotic Tool Changer QC-313 Series—Robotic Tool Changer 1. Product Overview ATI Tool Changers enhance the versatility of a robot by enabling the use of multiple customer tools, such as: grippers, vacuum cup tooling, pneumatic and electric motors, weld guns, and more. -

Page 4: Master Plate Assembly

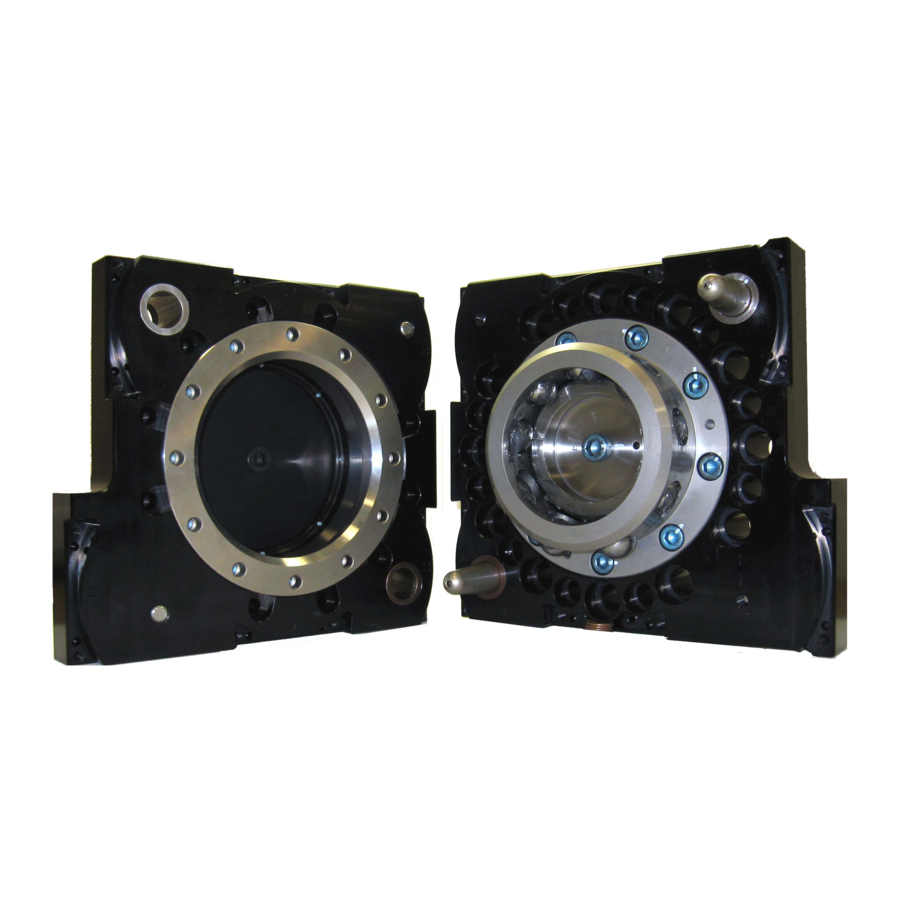

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 1.1 Master Plate Assembly The Master plate assembly includes an anodized aluminum body, a hardened stainless steel locking mechanism, and hardened steel alignment pins (see Figure 1.1). The body or Master plate has (6) flat sides for mounting of optional modules. In general, flat ‘A’ is reserved for an air/valve adapter module and a control/signal module. -

Page 5: Tool Plate Assembly

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 1.2 Tool Plate Assembly The Tool plate assembly includes an anodized aluminum body, alignment bushings, and a hardened stainless steel bearing race. The Tool plate has (6) flat sides for mounting of optional modules. Proximity sensor targets are mounted to the body of the Tool plate to verify Tool plate presence when coupled. -

Page 6: Installation

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2. Installation Mounting the Tool Changer requires the following, refer to Table 2.1. WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical, air, water, etc.) are turned off, pressurized connections are purged and power is discharged from circuits in accordance with the customer specific safety practices and policies. -

Page 7: Master Interface

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.1 Master Interface The Master plate is typically attached to the robot arm. An interface plate can adapt the Master plate to a specific robot arm. Alignment features (dowel holes and bosses) accurately position and bolt holes secure the Master plate to the robot arm or an interface plate. -

Page 8: Master Plate Installation

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.2 Master Plate Installation Tools required: 10 mm or 14 mm hex key Supplies required: Clean rag, Loctite ® 1. Make sure mounting surface of the Master plate and robot arm or interface plate are clean and free of debris. -

Page 9: Tool Interface

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.4 Tool Interface The Tool plate is attached to the customer’s tooling. An interface plate can adapt the Tool plate to customer tooling. Alignment features (dowel holes and a recess) accurately position and bolt holes to secure the Tool plate to customer tooling. -

Page 10: Tool Plate Installation

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.5 Tool Plate Installation Tools required: 8 mm or 10 mm hex key Supplies required: Clean rag, Loctite 242 1. Make sure the mounting surface of the Tool plate and tool interface plate is clean and free of debris. Refer to Figure 2.2. -

Page 11: Pneumatic Connections

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.7 Pneumatic Connections Proper operation of the locking mechanism requires a constant supply of clean, dry, non‑lubricated air, with the following conditions: • Pressure range of 60 to 100 psi (4.1 ‑ 6.9 bar) Suggested 80 psi. •... -

Page 12: Electrical Connections

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 2.8 Electrical Connections Tool Changer is available with integrated lock/unlock sensors. If sensors are not used, plugs will be provided to seal the locking mechanism. If a control/signal module is to be utilized on Flat A when ordered, the sensors will be connected to the module prior to shipping. -

Page 13: Operation

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 3. Operation The Master plate locking mechanism is pneumatically driven to couple and uncouple with the Tool plate bearing race. CAUTION: Operation of the Tool Changer is dependent on maintaining an air pressure of 60 to 100 psi (4.1 - 6.9 bar). -

Page 14: Conditions For Coupling

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 3.1 Conditions for Coupling The following conditions should be considered when operating the Tool Changer. For more details about programming the robot, refer to the Operation section of the Control/Signal Module Manual. CAUTION: Do not attempt to couple the Tool Changer when in locked position. -

Page 15: Fail-Safe Operation

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 6. A sufficient delay must be programmed between locking valve actuation and robot motion so that the locking process is complete before moving the robot. If equipped with Lock and Unlock sensors, the Lock signal should read “ON”... -

Page 16: Conditions For Uncoupling

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 3.3 Conditions for Uncoupling Refer to your Air/Valve Adapter and/or Control/Signal Module Manual’s Operation section for operation during coupling/uncoupling. 1. Move the robot to position the Tool plate in the tool stand. The position for coupling and uncoupling are the same. -

Page 17: Tool Storage Considerations

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 3.5 Tool Storage Considerations NOTICE: Tool stand design is critical to the operation of the Tool Changer. Improperly designed tool stands can cause jamming and excessive wear of the Tool Changer components. Tool plates with customer tooling attached may be stored in a tool stand. -

Page 18: Maintenance

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 4. Maintenance WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical, air, water, etc.) are turned off, pressurized connections are purged and power is discharged from circuits in accordance with the customer specific safety practices and policies. -

Page 19: Cleaning And Lubrication Of The Locking Mechanism And Alignment Pins

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 4.2 Cleaning and Lubrication of the Locking Mechanism and Alignment Pins Supplies required: Clean rag, MobilGrease XHP222 Special Grease 1. Place the Tool in a secure location. 2. Uncouple the Master and Tool plates. 3. - Page 20 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 6. Check each ball bearing to make sure it moves freely in the male coupling. Additional cleaning may be necessary to free up any ball bearings that are sticking in place. Figure 4.3—Check Ball Bearing Movement 7.

-

Page 21: Pin Block Inspection And Cleaning

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 4.3 Pin Block Inspection and Cleaning Tools required: Nylon Brush (ATI Part Number 3690‑0000064‑60) 1. Place the Tool in a secure location. 2. Uncouple the Master and Tool plates. 3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.). 4. -

Page 22: Troubleshooting And Service Procedures

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5. Troubleshooting and Service Procedures The following section provides troubleshooting and service information to help diagnose conditions and repair the Tool Changer or control/signal module. WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. -

Page 23: Service Procedures

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2 Service Procedures Component replacement procedures are provided in the following section. 5.2.1 Lock and Unlock Sensor Replacement Procedures Parts required: Refer to Section 6.1—Master Serviceable Parts Tools required: 2 mm and 5 mm hex key, torque wrench Supplies required: Clean rag, Loctite 242 1. - Page 24 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 10. Install the new Lock and/or Unlock sensor assembly, routing the cable into the cable channel of the Tool Changer body. 11. Attach the Lock and/or Unlock sensor cable connectors to the proper connector on the control/ signal module.

-

Page 25: Rtl Sensor Replacement Procedure

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.2 RTL Sensor Replacement Procedure Parts required: Refer to Section 6.1—Master Serviceable Parts Tools required: 1/2” wrench, torque wrench 1. Place the Tool in a secure location. 2. Uncouple the Master and Tool plates. 3. -

Page 26: R1 Sensor Cable Replacement

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.3 R1 Sensor Cable Replacement Parts required: Refer to Section 6.1—Master Serviceable Parts Tools required: 2 mm and 5 mm hex key, torque wrench Supplies required: Clean rag, Loctite 242 1. - Page 27 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 14. Confirm the operation of the RTL sensor by bringing a metallic object into close proximity to the face of the sensor and watching for the LED in the sensor cable to light up. NOTICE: Some control/signal modules supply power to the RTL sensors in series.

-

Page 28: R2 Sensor Cable Replacement

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.4 R2 Sensor Cable Replacement Parts required: Refer to Section 6.1—Master Serviceable Parts Tools required: 2 mm and 5 mm hex key, torque wrench Supplies required: Clean rag, Loctite 242 1. - Page 29 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 15. Confirm the operation of the RTL sensor by bringing a metallic object into close proximity to the face of the sensor and watching for the LED in the sensor cable to light up. NOTICE: Some control/signal modules supply power to the RTL sensors in series.

-

Page 30: V-Ring Seal Inspection And Replacement

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.5 V-ring Seal Inspection and Replacement Parts required: Refer to Section 6—Serviceable Parts The seal protects the electrical connection between the Master and Tool module. If the seal becomes worn or damaged, replace the seal. 1. -

Page 31: Alignment Pin Replacement

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5.2.6 Alignment Pin Replacement Parts required: Refer to Section 6—Serviceable Parts Tools required: 3 mm or 4 mm hex key, torque wrench Supplies required: Clean rag, MobilGrease XHP222, Loctite 242 1. - Page 32 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 5. Another approach would be to use the access hole in the back side of the Master plate. If not already removed, remove the Master plate refer to Section 2.3—Master Plate Removal.

-

Page 33: Serviceable Parts

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 6. Serviceable Parts 6.1 Master Serviceable Parts Table 5.2—QC-313 Master Plates Item No. Part Number Description 9121-313AM-0-00-0-00 QC-313 Base Master, No Options QC-313 Master with no Boss and PNP lock/unlock and RTL 9121-313AM-0-00-0-00-SM sensing, LED cables QC-313 Master with 125 mm Boss and PNP lock/unlock and... -

Page 34: Tool Serviceable Parts

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 6.2 Tool Serviceable Parts Table 5.3—Standard Tool Plate Item No. Part Number Description 9121-313DT-0-0-0-0 QC-313 Tool with 125 mm Recess and no other options 9005-20-1334 Race Cover QC 310 Tool Assembly Diaphragm Grommet - One Sided Cutout, Black, .630 in Hole Dia, 4010-0000099-01 .060 in Panel Thk... -

Page 35: Specifications

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 7. Specifications Table 5.4—Master and Tool Plates Recommended Max Payload 1,120 lbs (500kg) The mass attached to the Tool Changer. -20–150°F Operating Temperature Range Optimal operating temperature range. (-30–66°C) Locking mechanism supply pressure operating 60–100 psi range. -

Page 36: Drawings

Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 8. Drawings 8.1 QC-313 Tool Changer Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • • Email: www.ati‑ia.com info@ati‑ia.com B-36... - Page 37 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • • Email: www.ati‑ia.com info@ati‑ia.com B-37...

- Page 38 Manual, Tool Changer, QC‑313 Document #9620‑20‑B‑313 Series Base Tool Changer‑06 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • • Email: www.ati‑ia.com info@ati‑ia.com B-38...