Summary of Contents for ABB ACS 601

- Page 1 DATASHEET ACS60100053A00D1500001 OTHER SYMBOLS: RGB ELEKTRONIKA AGACIAK CIACIEK SPÓŁKA JAWNA Jana Dlugosza 2-6 Street 51-162 Wrocław www.rgbelektronika.pl Poland [email protected] +48 71 325 15 05 www.rgbautomatyka.pl www.rgbautomatyka.pl www.rgbelektronika.pl...

- Page 2 YOUR PARTNER IN MAINTENANCE Repair this product with RGB ELEKTRONIKA ORDER A DIAGNOSIS LINEAR ENCODERS SYSTEMS INDUSTRIAL COMPUTERS ENCODERS CONTROLS SERVO AMPLIFIERS MOTORS MACHINES OUR SERVICES POWER SUPPLIERS OPERATOR SERVO PANELS DRIVERS At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair works and test each later sold unit.

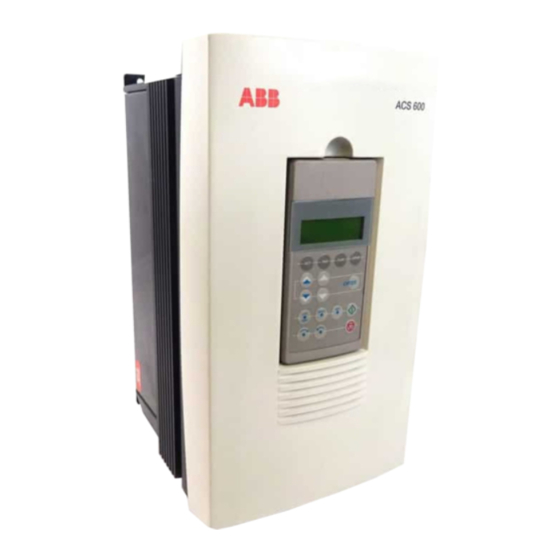

- Page 3 Hardware Manual ACS 600 ACS/ACC/ACP 601 AC Drives This manual includes • Safety 3 to 150 Hp • Installation (2.2 to 110 kW) • Maintenance • Product Information ACS 600 FUNC DRIVE ENTER RESET...

- Page 5 ACS/ACC/ACP 601 AC Drives 3 to 150 Hp (2.2 to 110 kW) Hardware Manual This manual concerns the ACS 601, ACC 601 and ACP 601 AC Drives. In the text, they are collectively referred to as ACx 601. ACS601-5.0-US-04 3AUA 489002B4973 R0101 REV A...

-

Page 7: Safety Instructions

Safety Instructions Overview This chapter states the safety instructions which must be followed when installing, operating and servicing the ACx 600. If neglected, physical injury and death may follow, or damage may occur to the AC drive, the motor and driven equipment. The material in this chapter must be studied before attempting any work on, or with, the unit. - Page 8 Safety Instructions Installation and These safety instructions are intended for all work on the ACx 600. In addition to the instructions given below, there are more safety Maintenance Safety instructions on the first pages of the appropriate hardware manual. WARNING! All electrical installation and maintenance work on the ACS 600 should be carried out by qualified electricians.

- Page 9 EMC filter capacitors before connecting the ACx 601 to an ungrounded power system. For detailed instructions on how to do this, please contact your local ABB distributor. Ground Fault The ACx 600 (with Standard and Motion Control Application Programs)

-

Page 10: Emergency Stop Devices

Safety Instructions Emergency Stop The person responsible for the overall design and operation of the driven process must make sure that the installation includes Devices emergency stop devices and any other safety equipment that may be needed. Pressing the STOP key on the Control Panel of ACx 600 does not generate an emergency stop of the motor or separate the drive from dangerous potential. - Page 11 The following table lists the insulation requirements for motors used with ACx 600 AC drives. Nominal Motor Type Motor Insulation Requirement AC Line Voltage < 500 V ABB Motors Standard insulation system (manufactured 525 V < V ≤ 690 V Standard insulation and dv/dt filter from beginning of...

-

Page 12: Power Factor Correction Capacitors

Safety Instructions Without Filter Below is a diagram of V and dv/dt as a function of cable length when no dv/dt filter is used. dv/dt / (kV/µs) 1000 (feet) Cable length With dv/dt Filter Below is a diagram of V and dv/dt as a function of cable length with dv/dt filter at the output of the ACx 600. -

Page 13: Output Contactors

Safety Instructions 600 make sure that the capacitors and the ACx 600 are not charged simultaneously to avoid voltage surges which might damage the unit. Output Contactors If a contactor is used between the output of the ACx 600 and the motor with DTC control mode selected, the output voltage of the ACx 600 must be controlled to zero before the contactor is opened: ACS 600 units via parameter 21.3 (ACP: 10.4), choose COAST. - Page 14 Safety Instructions ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 15: Table Of Contents

Table of Contents Safety Instructions Warnings and Notes ............. iii Warnings . - Page 16 Conduit ..............3-4 Armored Cable .

- Page 17 Materials ..............A-20 Disposal .

- Page 18 ACx=ACS/ACC/ACP ACS/ACC/ACP Drives...

-

Page 19: Chapter 1 - Introduction

Chapter 1 – Introduction General The ACS 600 product family of three phase AC drives includes • the ACS 600 (for most applications) • the ACP 600 (for positioning, synchronizing and other high-precision control applications) • the ACC 600 (for crane drive applications) •... -

Page 20: Acx 601 Type Code

Chapter 1 – Introduction ABB Industry Oy U1 3-380...500V U1 3-380...480V U2 3-0...U1 U2 3-0...U1 *1983509999* I1n/I1nsq 168/198A I1hd/I1n 143/184A Serno I2n/I2nsq 164/193A I2hd/I2n 141/180A f1 48...63Hz f1 57...63Hz f2 0...300Hz f2 0...300Hz 000C150001 ACS60101405... ACS60101404... IEC Ratings NEMA Ratings... -

Page 21: Inquiries

Inquiries Any inquiries about the product should be addressed to the local distributor or ABB representative, quoting the type code and the serial number of the unit. If the local ABB representative cannot be contacted, inquiries should be directed to the address and phone numbers on the back cover of this manual. - Page 22 Chapter 1 – Introduction ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 23: Chapter 2 - Mechanical Installation

Chapter 2 – Mechanical Installation The ACx 601 should be installed in an upright position with the cooling section mounted against a flat surface. The mounting surface should be as close to vertical as possible and of non-flammable material. Sufficient room around the ACx 601 is required to enable cooling air flow, service and maintenance. -

Page 24: Installation Procedure

Chapter 2 – Mechanical Installation Installation Procedure Appendix B contains detailed dimensional drawings showing the overall dimensions of the ACx 601 drives and the sizes and locations of the mounting bolt holes or slots. The drives have four mounting holes or slots as shown in Figure 2-1. - Page 25 Chapter 2 – Mechanical Installation A-12 for ambient air. If the air in the cooling duct is not clean the enclosure class of the ACx 601 must be IP 54. Note the power ratings of the IP 54 units given on page A-4. To install the ACx 601 in a cooling air duct, carry out the following steps: 1.

- Page 26 Chapter 2 – Mechanical Installation ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 27: Chapter 3 - Electrical Installation

Chapter 3 – Electrical Installation WARNING! The electrical installation described in this chapter should only be carried out by a qualified electrician. The Safety Instructions on the first pages of this manual must be followed. Negligence of these instructions can cause injury or death. Note: The information presented in this chapter is primarily directed towards the North American market. -

Page 28: Disconnecting Means

Chapter 3 – Electrical Installation be greater than 1 MΩ. 5. Measure the insulation resistance of the motor cable between the phases and between each phase and Ground (PE). The insulation resistance must be greater than 1 MΩ. Disconnecting Means The ACx 601 does not include a disconnecting means. -

Page 29: Wiring Practices

Chapter 3 – Electrical Installation connecting cable insulation must accommodate the voltage peaks described under Motor Insulation Requirements on page vi of the Safety Instructions. For drives that are rated up to 500 V, cables that have a 600 VAC insulation rating are suitable for both input power and motor wiring. -

Page 30: Conduit

Chapter 3 – Electrical Installation symmetrical grounds is the best type of wiring to provide a good low impedance high frequency ground return path between the motor and the drive. This helps to prevent high frequency ground current from flowing in a potentially damaging path through the motor bearings and connected load bearings. -

Page 31: Wiring Connections

In remote use the cable connecting the Control Panel to the ACx 600 must not exceed 3 meters (10 ft). The cable type tested and approved by ABB is provided in Control Panel option kits. Wiring Connections WARNING! This work should only be carried out by a qualified electrician. -

Page 32: Cover Removal

Refer to Figure 3-4 on page 3-8 for the recommended wiring configuration. See Appendix B - ACS 601 Dimensional Drawings to locate the terminals on each ACS 601 type. See Appendix A page A-7 and A-8 for control connection details. Refer to the ACx 600 Firmware Manual for control I/O programming information. - Page 33 Chapter 3 – Electrical Installation Remove the Control Panel. 2. Remove the telephone connector. 3. Remove the two screws at the lower front edge of the unit and remove the front cover by lifting it carefully from the bottom. 4. After connecting the input power, motor and control wiring, replace the cover as shown in Figure 3-6 on page 3-9.

- Page 34 Chapter 3 – Electrical Installation Signals Metallic Conduit Figure 3-4 A view of the recommended wiring configuration. In the R7 Frame, bolt connections are provided for connecting wires with ring lugs. Crimp ring lugs onto the phase conductors. Insulate the ends of the lugs using self-fusing (self-amalgam- ating) tape or shrink tubing.

- Page 35 Chapter 3 – Electrical Installation Frame R7 Frames R2 to R3 Connect the Control Panel cable to the connector X2, and replace the front cover. Frames R4 to R6 1. Replace the front cover. 2. Replace the telephone connector. 3. Attach the Control Panel by pushing it softly down onto the connector in the front cover hollow.

-

Page 36: Pulse Encoder Insulation (Acp 600)

Chapter 3 – Electrical Installation Pulse Encoder The pulse encoder shall be insulated electrically from stator or rotor to prevent forming of current path through the pulse encoder. The usual Insulation (ACP 600) coupling-type encoder must have an electrically insulating coupling. When a hollow-shaft type pulse encoder is used, the insulation can be implemented by insulating the ball joints of the engaging arm, or insulating the bar of the engaging arm. - Page 37 Chapter 3 – Electrical Installation Connection Examples Fieldbus Adapter Module ACx 600 NAMC NIOC/ NIOCP NDCO NIOC Terminal X23 NIOCP Terminal X4 The terminals for the power supply connection vary. Consult adapter module manual. I/O Extension Module ACx 600 Pulse Encoder Module with NAMC NIOC ACS 600 Crane, System, Master/Follower...

- Page 38 Chapter 3 – Electrical Installation Connection Examples Pulse Encoder Module (NTAC) with ACS 600 Standard Application Program ACS 600* NAMC NIOC NDCO NIOC Terminal X23 The terminals for * The ACP 600 supports the the power supply NTACP Double Pulse Encod- connection vary.

-

Page 39: Braking Chopper

Chapter 3 – Electrical Installation Braking Chopper Refer to the Braking Choppers Installation and Start-Up Guide for braking chopper installation and application information. WARNING! The brake control terminals (UDC+, UDC-, R+ and R- terminals) carry a dangerous DC voltage (over 500V). An external braking resistor must be connected to a terminal block that is supplied with the braking chopper. - Page 40 Chapter 3 – Electrical Installation 3-14 ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 41: Chapter 4 - Installation Checklist

Chapter 4 – Installation Checklist Installation Checklist The ACx 600 mechanical and electrical installation should be checked before start-up. It is advisable to go through the checklist below together with another person. Study carefully the Safety Instructions on the first pages of this manual before attempting any work on, or with, the unit. - Page 42 Chapter 4 – Installation Checklist ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 43: Chapter 5 - Maintenance

Capacitor failure is usually followed by an input line fuse failure or a Fault trip. Contact ABB if capacitor failure is suspected. Replacements are available from ABB. Do not attempt operation with other than ABB specified spare parts. Reforming For more information on reforming (re-aging) spare part capacitors, contact Technical Support. - Page 44 Chapter 5 – Maintenance ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 45: Appendix A - Acs/Acc/Acp 601 Technical Data

Appendix A – ACS/ACC/ACP 601 Technical Data IEC Ratings for IP2/22 Below are the IEC ratings for ACS/ACC/ACP 601 with 50 Hz and 60 Hz supplies. ACx = ACS/ACC/ACP. The 690 V series is not available for Enclosures ACP 600. Symbols are described following the table. Normal Use Heavy-duty Use Duty Cycle... - Page 46 Appendix A – ACS/ACC/ACP 601 Technical Data Rating table continued Current ratings are for drives in IP 20/21 enclosures. For drives in IP 54 enclosures, Pump and Fan Use see page A-4. For output current (Squared Load) temperature derating, see page A-3. ACx 601 2Nsq Frame...

-

Page 47: Output Current Temperature Derating

Appendix A – ACS/ACC/ACP 601 Technical Data Rating table continued Normal Use Heavy-duty Use Duty Cycle Duty Cycle Duty Cycle 1/10 min 1/10 min 2/15 s ACx 601 Frame 2Nmax 2hdmax 2hdmax Type Type 9/10min 1/10min 9/10min 1/10min 13/15s 2/15s [HP] [HP] Three-phase supply voltage 380 V, 400 V, 415 V, 440 V, 460 V, 480 V or 500 V... -

Page 48: Output Current Ratings For Ip54 Enclosures

Appendix A – ACS/ACC/ACP 601 Technical Data • Example 2. If the ambient temperature is 122 °F, the output current for ACx 601-0006-3 is first calculated at 104 °F (derating factor 92 % or 0.92 from Curve 2) and the result is multiplied by factor 0.65 (See Example 1 (IP 21/22)). - Page 49 Appendix A – ACS/ACC/ACP 601 Technical Data Fuses ACx 601 Type Type Type Manufacturer Size Size DIN 43620 DIN 43653 ACx 601-0005-3 Bussmann 170M1559 170M1359 000/80 ACx 601-0006-4 ACx 601-0006-5 ACx 601-0006-3 Bussmann 170M1559 170M1359 000/80 ACx 601-0009-4 ACx 601-0009-5 ACx 601-0009-3 Bussmann 170M1561...

-

Page 50: Example

The fuses recommended in the table are UL recognized. Example For ACS 601-0120-3, the recommended fuses for the input bridge protection are 400 A ultrarapid fuses. The values I and I for ACS 601-0120-3 are 175 A and 145 A respectively. -

Page 51: External Control Connections (Nioc

Appendix A – ACS/ACC/ACP 601 Technical Data External Control External control connections of ACS 600 with standard application software (Factory Macro) are below. External control connections are Connections (NIOC) different with other application macros and softwares (see Firmware Manual ). Programmable I/O Factory Settings Terminal Block Size... -

Page 52: External Control Connections (Niocp)

Appendix A – ACS/ACC/ACP 601 Technical Data External Control External control connections of ACP 600 with NIOCP board are below. Connections (NIOCP) Terminal Block X1 Function Specifications +10 V Reference Voltage +10 VDC 2 kΩ ≤ R ≤ 10 kΩ LOAD AGND Analog Ground... -

Page 53: Enclosures, Space Requirements

Appendix A – ACS/ACC/ACP 601 Technical Data Enclosures, Space The cabinets, degrees of protection and free space requirements of ACx 600 types are given below. Requirements Degree of Space Space Space on Space in front/ ACx 600 Type Enclosure Protection above below left/right... -

Page 54: Cooling Air Flow Requirements

Appendix A – ACS/ACC/ACP 601 Technical Data Cooling Air Flow Cooling air flow requirements are given below. Requirements Flow Flow ACx 601 ACx 601-0005-3/0006-5 ACx 601-0006-3/0009-5 ACx 601-0009-3/0011-5 ACx 601-0011-3/0016-5/0009-6/0011-6 ACx 601-0016-3/0020-5/0016-6/0020-6 ACx 601-0020-3/0025-5/0025-6 ACx 601-0025-3/0030-5/0030-6 ACx 601-0030-3/0040-5/0040-6 ACx 601-0040-3/0050-5/0050-6 ACx 601-0050-3/0060-5 ACx 601-0060-3/0070-5/0060-6 ACx 601-0070-3/0100-5/0070-6... -

Page 55: Dimensions And Weights

Appendix A – ACS/ACC/ACP 601 Technical Data Dimensions and Weights Dimensions and weights of the wall-mounted ACS/ACC/ACP 601 units are given below. Height Width Depth Weight ACS 601 Type mm/in mm/in mm/in kg/lb 0005-3 0006-5 420/16.5 220/8.7 292/11.5 14/31 0006-3 0009-5 420/16.5... -

Page 56: Efficiency And Cooling

601-0005-3 to ACx 601-0016-3, ACx 601-0006-5 to ACx 601-0020-5, ACx 601-0009-6 to ACx 601-0020-6, if the motor cable length exceeds 70 meters (230 ft.), an ABB representative should be consulted. Bearings of motors larger than 90 kW (125 Hp): Insulated bearing at non-driven end is recommended. -

Page 57: Ambient Conditions

At sites over 1000 m (3300 ft) above sea level, the maximum output current is derated 1 % for every additional 100 m (330 ft). If the installation site is higher than 2000 m (6600 ft) above sea level, please contact your local ABB distributor or office for further information. -

Page 58: External Control Connections

Appendix A – ACS/ACC/ACP 601 Technical Data External Control Data of the external control connection boards of the ACS 600 product family are given below. Connections ACS/ACC/ACP 600 ACP 600 NIOC-01 Board NIOCP-01 Board Analog Inputs ACS 600: Two Programmable Differential Two Bipolar Differential Voltage Inputs: = 100 Ω... - Page 59 Isolation Test Voltage: 4 kVAC, 1 minute Output Updating Time: 100 ms (ACS 600), Output Updating Time: 2 ms 44 ms (ACC 600), 8 ms (ACP 600) DDCS Fiber Optic Protocol: DDCS (ABB Distributed Drives Communication System) Link ACS/ACC/ACP 601 Drives ACx=ACS/ACC/ACP A-15...

-

Page 60: Encoder Signals

COMBICON connector, 15 pins. Meets the EIA standard RS 422. Required Encoder Type: Contact ABB Application Engineer or your local ABB Representative fo assistance. Encoder Signals: Signal level/Load capacity: 5 V rectangular-pulse signals; Time between edges: a > 0,8 µs at f ≤... -

Page 61: Application Program

Appendix A – ACS/ACC/ACP 601 Technical Data Application Program Various application programs are available for the ACS 600 AC drives. In the tables of this section, the ACS 600 product family program selections are referred to with the following abbreviations. Not all selections are available for all types. -

Page 62: Languages

Appendix A – ACS/ACC/ACP 601 Technical Data Languages Languages and application macros included in the ACx 600 software are shown below. Not all selections are available for all types. Code Application Macros Languages Factory, Hand/Auto, PID Control, English (UK & Am), French, Spanish, Torque Control, Sequential Control Portuguese Factory, Hand/Auto, PID Control,... -

Page 63: Protection Features

Appendix A – ACS/ACC/ACP 601 Technical Data Protection Features Application program dependent features of the ACx 600 are listed below. available as standard, optional Preprogrammed Programmable Programm. ACS ACC ACP Multi ACS ACC ACP Multi ACS ACC ACP Multi Faults Fault Functions Supervision Drive... -

Page 64: Applicable Standards

C11 to C13.) They must be removed and handled according to local regulations. For further information on environmental aspects, please contact your local ABB distributor. CE Marking A CE mark is attached to ACx 601/607 drives to verify that the unit follows the provisions of the European Low Voltage and EMC Directives (Directive 73/23/EEC, as amended by 93/68/EEC and Directive 89/336/EEC, as amended by 93/68/EEC). - Page 65 Appendix A – ACS/ACC/ACP 601 Technical Data The EMC Directive defines the requirements for immunity and emissions of electrical equipment used in European Economic Area. The EMC product standard EN 61800-3 covers the requirements stated for drives. The ACx 601 drives comply with the EMC Directive in industrial low-voltage network, public low-voltage network (restricted distribution) and IT networks (ungrounded power) with the following provisions: Industrial Low-Voltage...

-

Page 66: Machinery Directive

EEC) requirements for an equipment intended to be incorporated into machinery. UL/CSA Markings The UL/UL /CSA markings of the ACS 600 drives are listed below (x). ACx 600 Type ACS 601 (IP 22) 400 V, 500 V and 600 V ranges ACS 601 (IP 54) pending... -

Page 67: Equipment Warranty And Liability

Equipment or part thereof or services which give rise to the Claim. All clauses of action against ABB arising out of or relating to the contract or the ACS/ACC/ACP 601 Drives ACx=ACS/ACC/ACP... - Page 68 In no event, regardless of cause, shall ABB assume responsibility for or be liable for penalties or penalty clauses of any description or for indemnification of customer or others for costs, damages, or expenses each arising out of or related to the goods or services of the order.

-

Page 69: Gland Plate Holes (Iec Units

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings The following drawing package is effective from 5/10/98. Gland Plate Holes (IEC Units) Frame ACx = ACx = ACx = ACx = ACx = ACx = ACS/ACC/ACP ACS/ACC/ACP ACS/ACC/ACP ACS/ACC/ACP ACS/ACC/ACP ACS/ACC/ACP Hole ACx 601-0005-3 ACx 601-0009-6 ACx 601-0020-3... -

Page 70: Frame R2

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R2 TYPE (ACx = ACS/ACC/ACP) WEIGHT ACx 601-0005-3 14 kg ACx 601-0006-3 14 kg ACx 601-0009-3 14 kg ACx 601-0006-5 14 kg ACx 601-0009-5 14 kg ACx 601-0011-5 14 kg Air out Air out Main air out Air in... -

Page 71: Frame R2 Flange Mounting

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R2 Flange Mounting Frame R3 Flange Mounting ACS/ACC/ACP 601 Drives ACx=ACS/ACC/ACP... -

Page 72: Frame R3

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R3 TYPE (ACx = ACS/ACC/ACP) WEIGHT ACx 601-0011-3 17.5 kg ACx 601-0016-3 17.5 kg ACx 601-0016-5 17.5 kg ACx 601-0020-5 17.5 kg ACx 601-0009-6/0011-6 17.5 kg ACx 601-0009-6/0020-6 17.5 kg Bottom view Air out Air out Air out... -

Page 73: Frame R4

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R4 TYPE (ACx = ACS/ACC/ACP) WEIGHT ACx 601-0020-3 25 kg ACx 601-0025-3 25 kg ACx 601-0025-5 25 kg ACx 601-0030-5 25 kg ACx 601-0025-6 25 kg ACx 601-0030-6 25 kg ACS/ACC/ACP 601 Drives ACx=ACS/ACC/ACP... -

Page 74: Frame R4 Flange Mounting

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R4 Flange Mounting Frame R5/R6 Flange Mounting ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives... - Page 75 Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R5/R6 TYPE (ACx = ACS/ACC/ACP) WEIGHT ACx 601-0030...0050-3 35 kg 190.5 ACx 601-0040...0060-5 35 kg 190.5 ACx 601-0040-6/-0060-6 35 kg 190.5 ACx 601-0060...0070-3 50 kg 262.5 ACx 601-0070...0100-5 50 kg 262.5 ACx 601-0060-6/-0070-6 50 kg 262.5 ACS/ACC/ACP 601 Drives...

-

Page 76: Frame R7

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Frame R7 TYPE (ACx = ACS/ACC/ACP) WEIGHT ACx 601-0100-3/-6 88 kg ACx 601-0120-3 88 kg ACx 601-0120-5/-6 88 kg ACx 601-0140-5 88 kg ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives... -

Page 77: Conduit Plates

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings Conduit Plates The following figures show the conduit plate (bottom view) of the different size ACS 600 units: (USA Version) At least three separate rigid metallic conduits must be used; one each for input power, output power, and control wires. Additionally, a separate conduit must be used for dynamic braking device, if used. - Page 78 Appendix B – ACS/ACC/ACP 601 Dimensional Drawings 1-1/4” 3/4” 1-1/4” 1-1/4” 1-1/4” 3/4” 1-1/2” 1-1/2” 2-1/2” 2-1/2” 2-1/2” Figure 2-1 Conduit Entry Plates, R5- R7 USA Version B-10 ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 79: Acp 601 Control Cable Connections

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings ACP 601 Control The deliveries include a bag with four clamps, screws and copper tape (frame size R4 also an assembly plate). Clamp the control and encoder Cable Connections cables as explained below. If more than four cables are needed, connect the twisted screen (grounding wires) of the additional cables as short as possible to the grounding rail next to the NIOC(P) -

Page 80: Acp 601 Frame R4

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings ACP 601 Frame R4 Grounding rail Assembly plate Screw for encoder Clamp cable grounding Stripped part of cable Encoder cable B-12 ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives... -

Page 81: Acp 601 Frame R5/R6

Appendix B – ACS/ACC/ACP 601 Dimensional Drawings ACP 601 Frame R5/R6 Grounding rail Screw for encoder Clamp cable grounding Stripped part of cable Encoder cable ACS/ACC/ACP 601 Drives ACx=ACS/ACC/ACP B-13... - Page 82 Appendix B – ACS/ACC/ACP 601 Dimensional Drawings B-14 ACx=ACS/ACC/ACP ACS/ACC/ACP 601 Drives...

-

Page 83: Appendix C - Iec Installation

Appendix C – IEC Installation IEC Installations This appendix is a supplement to Chapter 3 – Electrical Installation . It contains additional information to be used in IEC installations. For installations requiring CE compliance, refer also to the section entitled CE Marking in Appendix A. -

Page 84: Motor Cable Shield

Appendix C – IEC Installation Motor Cable Shield To effectively supress radiated and conducted radio-frequency emissions, the shield conductivity must be at least 1/10 of the phase conductor conductivity. One way of evaluating the effectiveness of the shield is the shield inductance, which must be low and only slightly dependent on the frequency. - Page 85 Appendix C – IEC Installation Cable Connections Recommended earthing, mains and motor cable connections are presented below. See Appendix B – Dimensional Drawings to locate the terminals 1) Alternative to earthing of the ACx 601 and the motor through the cable screen. Note: Connecting the fourth conductor of the motor cable at the motor end increases bearing currents, thus causing extra wear.

-

Page 86: Components Connected To Digital/Analog Inputs

Appendix C – IEC Installation the grounding rail next to the NIOC/NIOCP board. Components Connected to Digital/ Analog Inputs WARNING! IEC 664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non-conductive or conductive but not connected to the ground (PE). - Page 88 ABB Industrial Systems, Inc. 16250 W. Glendale Drive New Berlin, WI 53151 Telephone (414) 785-3416 (414) 785-8525 Service (800) 243-4384...