Summary of Contents for Honeywell HON 670

- Page 1 HON 670 / HON 671 Controllers Component documentation, Maintenance manual and spare parts...

-

Page 2: Table Of Contents

K19: Spare parts drawing for metal bellows measuring unit 6.10 K16, K17, K18, K19: Spare parts drawing for pressure unit 6.11 Maintenance and servicing parts for the controllers 6.12 Lubricants, threadlockers, and special tools HON 670 / HON 671 Controllers Component Documentation... -

Page 3: General Considerations

▪ Spare parts drawings and spare parts lists Illustration Honeywell offers products with identical functions in a number of different sizes. For this reason, we are unable to guarantee that the illustrations in this documentation will match the dimensions of your product. In these cases, the illustrations should be viewed as a concept sketch. - Page 4 Constructive changes The written approval from Honeywell Gas Technologies GmbH, Kassel, is required for any modifications and additions to the product. Any violation will void the legal liability for con- sequences arising thereof.

- Page 5 CAUTION an accident may or will happen. minor or moderate bodily injury. Warnings about material Warnings about possible material damages are identified with the word Attention in this damages document. HON 670 / HON 671 Controllers Component Documentation...

-

Page 6: Description

Technical specifications Intended use Intended use The controllers HON 670 / HON 671 are used to trigger safety equipment within a controlled gas system. The controllers can be used for neutral, non-aggressive gases and the gases specified in DVWG Code of Practice G260. -

Page 7: Device Models

Description Device models Variants of the controllers The configuration levels of the controllers HON 670 / HON 671 can be varied in some respects using individual components. HON 670 / HON 671 The following individual components are always part of the device: ▪... - Page 8 Interpreting the type The details on the type plate have the following meaning: plate on the monitoring Figure Description device Manufacturer ID Manufacturer’s address Type designation Serial number PS = Maximum allowable pressure HON 670 / HON 671 Controllers Component Documentation...

-

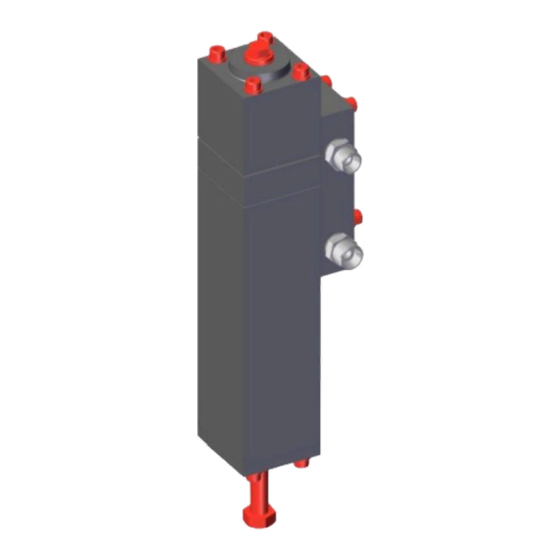

Page 9: Physical Design And Operation

Physical design of the The controller is made up of the following individual components: controllers K16 / K17 Figure Description Spring adjuster Pilot spring Comparator stage with diaphragm meas- uring unit Amplifying valve Base plate HON 670 / HON 671 Controllers Component Documentation... - Page 10 The controller is made up of the following individual components: controllers K18 / K19 Figure Description Spring adjuster Pilot spring Ball guide sleeve Amplifying valve Comparator stage with metal bellows measuring unit Base plate HON 670 / HON 671 Controllers Component Documentation...

- Page 11 Piston Controller connection Controller connection The controller features the following connections: lines Figure Connection Pipe connection thread type Metric Imperial Measuring line E12L 1/2" Vent line E12L 1/2" Pressure unit E10L 3/8" HON 670 / HON 671 Controllers Component Documentation...

- Page 12 ▪ When the pressure between the upper and the lower actuator chamber has equalized, the safety relief valve closes again on its own. HON 670 / HON 671 Controllers Component Documentation...

-

Page 13: Technical Specifications

The figure below shows the dimensions for the controller K16 / K17 for the control range = 0.8 – 40 bar: Comparator stage: Diaphragm measuring unit and diaphragm measuring unit with ball guide sleeve *) Stage with ball guide sleeve HON 670 / HON 671 Controllers Component Documentation... - Page 14 *) Stage with ball guide sleeve Gas properties The properties of the gas conveyed through the controllers HON 670 / HON 671 must meet the requirements specified by the DVGW German Technical and Scientific Association for Gas and Water in the latest version of DVGW Code of Practice G 260 (A).

-

Page 15: Safety

▪ All personnel must be provided with the personal protective equipment required for their work. This personal protective equipment must be in good condition at all times. ▪ All personnel must wear the personal protective equipment required for their work. HON 670 / HON 671 Controllers Component Documentation... -

Page 16: Requirements Concerning The Workforce, Personal Protective Gear, Workplaces

The workplaces for performing the various tasks are at the following locations: Task Workplaces ▪ Maintenance, repairs All around the device, depending on the task ▪ Storage ▪ Disposal HON 670 / HON 671 Controllers Component Documentation... -

Page 17: Maintenance

Please refer to the Special tools section in Lubricants, thread- lockers, and special tools (see page 65). You will also need a magnetic bowl for the maintenance of your controller to enable removal of the balls of the guide sleeve. HON 670 / HON 671 Controllers Component Documentation... -

Page 18: Removing The Pressure Unit From The Controller

If necessary, secure removed components so that they will not fall or topple over. Wear the required personal protective equipment. Exercise caution when performing the relevant tasks. HON 670 / HON 671 Controllers Component Documentation... -

Page 19: Maintenance On The Controller With Diaphragm Measuring Unit

▪ Before assembly, all parts must be cleaned in order to remove any foreign particles (swarf) and soiling. ▪ If screws, bolts, or washers are replaced with identical new parts, any oil on these new parts must first be removed. HON 670 / HON 671 Controllers Component Documentation... - Page 20 Remove the baseplate (1). Replace the 4 O-rings (1) with 4 new, lubricated O-rings. Bear in mind that the O-rings differ. Note: See the appendix for the lubricants to be used. HON 670 / HON 671 Controllers Component Documentation...

- Page 21 Screw the hex flange nut (2) back in a bit and screw in the spring adjuster (1) by a few turns. The correct setpoint adjustment cannot be carried out until before commissioning with the controller installed. HON 670 / HON 671 Controllers Component Documentation...

- Page 22 (1). Remove the following parts: ▪ Diaphragm plate (1) ▪ Diaphragm (2) Turn the double diaphragm system over. Counter the diaphragm plate (2) and unscrew the cap nut (1). HON 670 / HON 671 Controllers Component Documentation...

- Page 23 ▪ Diaphragm plate (1) ▪ Diaphragm (2) Screw the assembly aid (1) into the internal thread of the nozzle (2). Hold the connecting piece in place (1) and pull the nozzle (2) out. HON 670 / HON 671 Controllers Component Documentation...

- Page 24 Put the new diaphragm (2) and the dia- phragm plate (1) in place. Make sure that the diaphragm is aligned correctly: The side of the diaphragm that has a depression at the center should be facing upward. HON 670 / HON 671 Controllers Component Documentation...

- Page 25 Proceed as follows: Mounting the controller Figure Step Description To align the diaphragm plate correctly: Turn the diaphragm plate all the way to the right. Mark this position. HON 670 / HON 671 Controllers Component Documentation...

- Page 26 Put the double diaphragm system into place. Put the bottom cover (2) in place. Tighten the 4 screws (1) only finger tight. Mount the baseplate (1). Tighten the 4 screws (2) only finger tight. HON 670 / HON 671 Controllers Component Documentation...

-

Page 27: Maintenance On The Controller With Metal Bellows Measuring Unit

If necessary, secure removed components so that they will not fall or topple over. Wear the required personal protective equipment. Exercise caution when performing the relevant tasks. HON 670 / HON 671 Controllers Component Documentation... - Page 28 Unscrew the 4 screws (1) on the baseplate. Remove the baseplate (1). Replace the 4 O-rings (1) with 4 new, lubricated O-rings. Bear in mind that the O-rings differ. Note: See the appendix for the lubricants to be used. HON 670 / HON 671 Controllers Component Documentation...

- Page 29 Screw the hex flange nut (2) back in a bit and screw in the spring adjuster (1) by a few turns. The correct setpoint adjustment cannot be carried out until before commissioning with the controller installed. HON 670 / HON 671 Controllers Component Documentation...

- Page 30 (2). Unscrew the metal bellows (1) from the base plate (2). Replace the 2 O-rings (1) with 2 new, lubricated O-rings. Note: See the appendix for the lubricants to be used. HON 670 / HON 671 Controllers Component Documentation...

- Page 31 ▪ Diaphragm plate (1) ▪ Diaphragm (2) Screw the assembly aid (1) into the internal thread of the nozzle (2). Hold the connecting piece in place (1) and pull the nozzle (2) out. HON 670 / HON 671 Controllers Component Documentation...

- Page 32 Note: See the appendix for the lubricants to be used. Assembling the dia- Proceed as follows: phragm system Figure Step Description Turn the nozzle (1) such that the pin (3) is positioned coaxially to the bore. HON 670 / HON 671 Controllers Component Documentation...

- Page 33 When doing so, the castellated nut of the new piston will close. Turn the diaphragm system and screw the metal bellows (1) onto the base plate (2). Tighten the screws firmly. Tightening torque: 15 Nm (11 ft lbs) HON 670 / HON 671 Controllers Component Documentation...

- Page 34 Put the metal bellows (1) with the base plate (2) in place. Put the lower cover (2) in place. Tighten the 4 screws (1) of the lower cover only finger tight. HON 670 / HON 671 Controllers Component Documentation...

-

Page 35: Maintenance On The Pressure Unit

▪ Before assembly, all parts must be cleaned in order to remove any foreign particles (swarf) and soiling. ▪ If screws, bolts, or washers are replaced with identical new parts, any oil on these new parts must first be removed. Tightening torques HON 670 / HON 671 Controllers Component Documentation... - Page 36 Unscrew and remove the 6 screws (1) of the cover. Remove the cover. Replace the O-ring with a new, lubricated O-ring. Note: See the appendix for the lubricants to be used. Take out the piston. HON 670 / HON 671 Controllers Component Documentation...

- Page 37 Put the cover in place. Tighten the 6 screws (1) using a crosswise pattern. Tightening torque: 8 Nm (6 ft lbs) Next task Proceed as follows: Mounting the pressure unit on the controller HON 670 / HON 671 Controllers Component Documentation...

-

Page 38: Mounting The Pressure Unit On The Controller

Next task Depending on what you want to do next, proceed as indicated in the relevant section: ▪ Storing the device (see page 39) ▪ Disposing of the device (see page 40) HON 670 / HON 671 Controllers Component Documentation... -

Page 39: Storage And Disposal

▪ Storage periods: Check the device for damage and soiling at least annually. When it comes to maintenance cycles, take the preceding operating time into account in addi- tion to the storage time. HON 670 / HON 671 Controllers Component Documentation... - Page 40 ▪ Recycle elements made of synthetic materials. ▪ Dispose of any other components according to the quality of the materials. HON 670 / HON 671 Controllers Component Documentation...

-

Page 41: Appendix

1 here as of 1 bar to 5 bar. **) on SAV HON 711/S2 control range W with spring as of 2 bar to 10 bar ***) The better accuracy group applies for the 2nd half of the control range. HON 670 / HON 671 Controllers Component Documentation... -

Page 42: Additional Information Regarding Spare Parts

“Part No.” column. If no quantity is specified, this means that only one unit is re- quired. Control ranges The spare part drawings for the controllers HON 670 / HON 671 are divided into the following six control ranges: ▪ W = 0.8 –... - Page 43 ▪ K19: Spare parts drawing for metal bellows measuring unit ▪ Spare parts kits for SAV response (NBR, FKM and NBR low-temperature vari- ants) ▪ K16, K17, K18, K19: Spare parts drawing for pressure unit HON 670 / HON 671 Controllers Component Documentation...

-

Page 44: K16, K17, K18, K19: Spare Parts Drawing For Baseplate And Connections

Appendix K16, K17, K18, K19: Spare parts drawing for baseplate and connections K16, K17 K18, K19 HON 670 / HON 671 Controllers Component Documentation... -

Page 45: K16: Spare Parts Drawing For Diaphragm Measuring Unit

▪ 1 each of no. 108 ▪ 1 each of no. 113 ▪ 2 each of no. 119 ▪ 1 each of no. 122 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 HON 670 / HON 671 Controllers Component Documentation... - Page 46 ▪ 1 each of no. 108 ▪ 1 each of no. 113 ▪ 2 each of no. 119 ▪ 1 each of no. 122 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 HON 670 / HON 671 Controllers Component Documentation...

- Page 47 ▪ 1 each of no. 122 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally nos. 107; 207; 407; 507 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded 33/28/0,52+PTFE HON 670 / HON 671 Controllers Component Documentation...

-

Page 48: K16: Spare Parts Drawing For Diaphragm Measuring Unit With Ball Guide Sleeve

K16: Spare parts drawing for diaphragm measuring unit with ball guide sleeve Controller 16 diaphragm measuring unit with ball guide sleeve W 10 bar to 40 bar Stage - rising performance curve HON 670 / HON 671 Controllers Component Documentation... - Page 49 ▪ 1 each of no. 208 ▪ 1 each of no. 213 ▪ 2 each of no. 219 ▪ 1 each of no. 222 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 HON 670 / HON 671 Controllers Component Documentation...

- Page 50 ▪ 1 each of no. 222 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally nos. 107; 207; 407; 507 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded 33/28/0,52+PTFE HON 670 / HON 671 Controllers Component Documentation...

-

Page 51: K17: Spare Parts Drawing For Diaphragm Measuring Unit

▪ 1 each of no. 408 ▪ 1 each of no. 413 ▪ 2 each of no. 419 ▪ 1 each of no. 422 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 HON 670 / HON 671 Controllers Component Documentation... - Page 52 ▪ 1 each of no. 422 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally nos. 107; 207; 407; 507 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded 33/28/0,52+PTFE HON 670 / HON 671 Controllers Component Documentation...

-

Page 53: K17: Spare Parts Drawing For Diaphragm Measuring Unit With Ball Guide Sleeve

Appendix K17: Spare parts drawing for diaphragm measuring unit with ball guide sleeve Controller 17 diaphragm measuring unit W 10 bar to 40 bar Stage - falling performance curve HON 670 / HON 671 Controllers Component Documentation... - Page 54 ▪ 1 each of no. 522 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally nos. 107; 207; 407; 507 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded 33/28/0,52+PTFE HON 670 / HON 671 Controllers Component Documentation...

-

Page 55: K18: Spare Parts Drawing For Metal Bellows Measuring Unit

Appendix K18: Spare parts drawing for metal bellows measuring unit Controller 18 metal bellows measuring unit W 20 bar to 90 bar Stage - rising performance curve HON 670 / HON 671 Controllers Component Documentation... - Page 56 ▪ 1 each of no. 319 ▪ 1 each of no. 322 ▪ 1 each of no. 327 ▪ 1 each of no. 328 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 HON 670 / HON 671 Controllers Component Documentation...

- Page 57 ▪ 1 each of no. 327 ▪ 1 each of no. 328 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally no. 307 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded HON 670 / HON 671 Controllers Component Documentation...

-

Page 58: K19: Spare Parts Drawing For Metal Bellows Measuring Unit

Appendix K19: Spare parts drawing for metal bellows measuring unit Controller 19 metal bellows measuring unit W 20 bar to 90 bar Stage - falling performance curve HON 670 / HON 671 Controllers Component Documentation... - Page 59 ▪ 1 each of no. 627 ▪ 1 each of no. 628 ▪ 1 each of no. 1004 ▪ 1 each of no. 1005 *) Optionally no. 607 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded HON 670 / HON 671 Controllers Component Documentation...

-

Page 60: 6.10 K16, K17, K18, K19: Spare Parts Drawing For Pressure Unit

Maintenance parts for baseplate low-temperature variant No. / No. / No. / No. / Name Part no. Part no. Part no. Letter Letter Letter Letter O-ring 20225-RMK 20633-RMK 100444-RMK (3 units) (3 units) (3 units) HON 670 / HON 671 Controllers Component Documentation... - Page 61 *) Optionally no. 107 sprayed with Teflon Mat.No.: 10002796 diaphragm, beaded Maintenance parts for diaphragm measuring unit with ball guide sleeve SAV response No. / No. / Name Letter Letter low-temperature Part no. Part no. variant Part no. O-ring 20225-RMK 20633-RMK 100444-RMK HON 670 / HON 671 Controllers Component Documentation...

- Page 62 Part no. O-ring 20225-RMK 20633-RMK 100444-RMK Diaphragm, beaded 10000191* 10000191* 10000191* O-ring 20332-RMK 20704 100992-RMK O-ring 20293-RMK 20705 100992-RMK Snap-on gasket 10000066 18357450 10000066 Piston, pre-assembled 10000186 10000186 10000186 O-ring 20293-RMK 20705 100331-RMK HON 670 / HON 671 Controllers Component Documentation...

- Page 63 Letter Letter Letter Letter 1004 1004 1004 1004 O-ring 20398 21114-RMK 100968-RMK 1005 1005 1005 1005 O-ring 20336 20599 100967-RMK 1015 1015 1015 1015 O-ring 20310-RMK* 20748-RMK* 101464-RMK* *) HON 721 only HON 670 / HON 671 Controllers Component Documentation...

- Page 64 10009672 SBV valve insert 10000061 SAV valve insert 10009672 SAV valve insert 10009672 SAV valve insert 10011776 SBV valve insert 10011775 SAV valve insert 10011776 *) Diaphragm system with ball guide sleeve HON 670 / HON 671 Controllers Component Documentation...

-

Page 65: 6.12 Lubricants, Threadlockers, And Special Tools

Topic: ▪ Maintenance on the controller with dia- phragm measuring unit (see page 27) Assembly aid 19 083 319 ▪ Maintenance on the controller with metal bellows measuring unit (see page 27) HON 670 / HON 671 Controllers Component Documentation... - Page 66 Honeywell's integrated gas solutions can help you to better manage your gas assets and optimize your value chain. Additional information To learn more about Honeywell’s product contact your Honeywell Process Solutions representative, or visit www.honeywellprocess.com or www.hongastec.de. Honeywell Process Solutions...