Table of Contents

Quick Links

Operator's

Manual

DANGER is used in this manual to warn of high

voltages capable of causing shock, burns, or death.

WARNING is used in this manual to warn

of possible personal injury.

CAUTION is used in this manual to warn

of possible equipment damage.

An experienced licensed electrician must install the ATS.

Refer to the outline and wiring drawings provided

with ASCO Series 300 ATS for installation details.

ASCO POWER TECHNOLOGIES CANADA PO Box 1238, 17 Airport Road, Brantford, Ontario, Canada N3T 5T3

telephone 519 758–8450, fax 519 758–0876, for service call 1 888 234–2726 (ASCO)

Automatic Transfer Switches

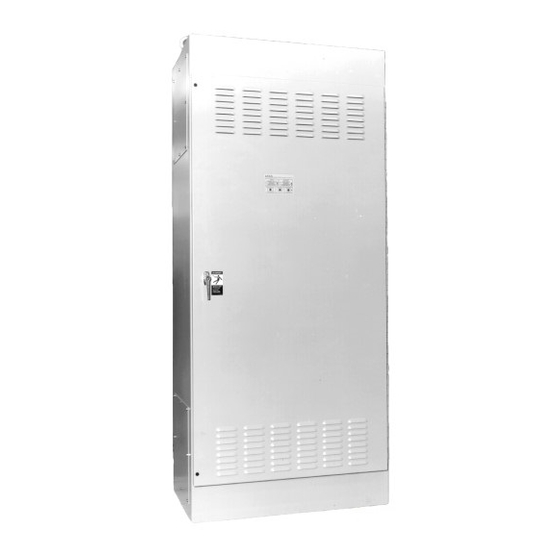

H–design 600 through 1200 amps

600, 800, 1000 amp. sizes

50 Hanover Road, Florham Park, New Jersey 07932–1591 USA

For sales or service call 1 800 800–2726 (ASCO) www.ascopower.com

Series 300

TABLE OF CONTENTS

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . .

SEQUENCE OF OPERATION

TESTING & SERVICE

. . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS

. . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL FEATURES

. . . . . . . . . . . . . . . . . . .

INDEX

. . . . . . . . . . . . . . . . . . . . . . . . .

www.asco.ca

section

1

. . . . . . . . . . . . .

2

3

4

5

back cover

1200 amp. size

381333–201 E

Table of Contents

Summary of Contents for Emerson Series 300

- Page 1 ......back cover Refer to the outline and wiring drawings provided with ASCO Series 300 ATS for installation details. 600, 800, 1000 amp. sizes 1200 amp. size 50 Hanover Road, Florham Park, New Jersey 07932–1591 USA...

- Page 2 The Transfer Switch nameplate includes data for each A typical Catalog Number is shown below with its specific ASCO Series 300 ATS. Use the ATS only elements explained. The example is for a Series 300 within the limits shown on this nameplate.

-

Page 3: Rating Label

ASCO Series 300 Automatic Transfer Switches (ATSs) are Standby Systems, NFPA 99 Health Care Facilities, and Listed under Underwriters Laboratories UL 1008 Standard NFPA 110 Emergency and Standby Power Systems. for Safety for Automatic Transfer Switches. All control Rating Label... - Page 4 membrane Controller controls neutral connections power connections Transfer Switch terminal block TB for engine start and switch position contacts power connections neutral connections 1200 amp. size in typical enclosure with location of customer connections...

-

Page 5: Installation

Standard terminal lugs are template to maintain proper conduit alignment. solderless screw type and will accept the wire sizes listed on the drawings provided with the Series 300. Be careful when stripping insulation from the cables; avoid nicking Mounting or ringing the conductor. -

Page 6: Engine Starting Contacts

TB which is mounted on the front lower left of the left side of transfer switch. Refer to wiring diagram provided with transfer switch the Series 300 ATS and connect the engine start wires to the appropriate terminals. See Figure 1–1 and Table A. Table A. Engine start connections. -

Page 7: Functional Test

INSTALLATION (continued) Functional Test The Functional Test consists of three checks: manual operation, voltage checks, and electrical operation. Do these checks in the order presented to avoid damaging the automatic transfer switch. Read all instructions on the Wiring Diagram and labels affixed to the automatic transfer switch. -

Page 8: Voltage Checks

INSTALLATION (continued) observe these lights Figure 1–5. St andard controls and indicators. 2 – Voltage Checks Close the normal source circuit First check nameplate on transfer switch; rated voltage Source Accepted breaker. The Normal Transfer must be the same as normal and emergency line voltages. Switch Position and the Normal Normal Source Accepted lights should... -

Page 9: Electrical Operation

The Normal Transfer Position Switch Position light should Normal This completes the Functional Test of the ASCO Series 300 come on and the Emergency Emergency light should go off. Automatic Transfer Switch. Leave the engine–generator starting control in the automatic position. -

Page 10: Section 2 Sequence Of Operation

SECTION 2 SEQUENCE OF OPERATION Lights show position of transfer switch. Lights show the sources accepted. Transfer To Emergency Light for built–in engine exercise timer: The sequence for load transfer to blinks rapidly when emergency source begins automati- button is held 5 sec. cally when normal source voltage while being set falls below the preset dropout point... -

Page 11: Preventive Maintenance

SECTION 3 TESTING & SERVICE PREVENTIVE MAINTENANCE DISCONNECTING THE CONTROLLER The harness disconnect plugs are furnished for repair Reasonable care in preventive maintenance will insure purposes only and should not have to be unplugged. If the high reliability and long life for the automatic transfer controller must be isolated, follow these steps carefully. -

Page 12: Manual Load Transfer

TESTING & SERVICE (continued) MANUAL LOAD TRANSFER 1. Open normal and emergency source circuit breakers. This procedure will manually transfer the load if the 2. Use the maintenance handle to manually operate controller is disconnected. transfer switch to the opposite source. See page 1–3, Manual Operation Test. -

Page 13: Section 4 Adjustments

SECTION 4 ADJUSTMENTS Time Delay Adjustment To change a setting, follow procedure on page 4-2. Use Table 4-1 as a guide to time delay values and their corre- Standard time delays are set to customer specifications sponding adjustment DIP switch or potentiometer. (if none specified, standard factory settings are used). -

Page 14: How To Change A Setting

ADJUSTMENTS (continued) cover thumb Do not make any setting changes latch while the controller is energized. How to Change a Setting 1. Prevent the transfer switch from operating by discon- hook on left side necting one source first, then the other, as follows: If the transfer switch is in the Normal position, open the emergency source circuit breaker. -

Page 15: Dip Switch Settings

20 minutes, or follow the recommendations of the engine-generator set manufacturer. Refer to page 4–2 for location of DIP switches, battery (provided), and jumper block in the controller. BUILT–IN ENGINE EXERCISER DIP Switch Settings The engine exerciser included in ASCO Series 300 S1 DIP S2 DIP FUNCTION... - Page 16 CONTROL FEATURES (continued) Optional Accessory 11BG – SOURCE AVAILABILITY SIGNAL & PROGRAMMABLE ENGINE EXERCISER MODULE 2–line display connections for source availability signal contacts 3 buttons Figure 5–2. Accessory 11BG module (mounted behind operator interface and connected to the controller) includes source availability signal contacts and a programmable engine exerciser. Source Availability Signal Contacts The module provides one Form C contact each for the normal and emergency sources signal the acceptability of...

-

Page 17: Navigating The Menu

CONTROL FEATURES (continued) How to Set Optional Programmable Engine Exerciser (part of Acc. 11BG module) For example, if the user wants the exerciser to run every other Saturday at 3 PM, the proper configuration would Hazardous voltage capable of causing shock, burns, or death is used in this transfer switch. -

Page 18: Remote Control Features

CONTROL FEATURES (continued) INPHASE MONITOR LOAD DISCONNECT FEATURE FOR MOTOR LOAD TRANSFER Connect external circuits to the terminals indicated on the Wiring Diagram provided with the ATS. Inphase monitoring logic controls transfer and retransfer of motor loads, so that inrush currents do not exceed The double throw (Form C) contact is rated for 28 VDC or normal starting currents. - Page 19 CONTROL FEATURES (continued) OPTIONAL STRIP HEATER (Accessory 44) Accessory 44 Strip Heater is designed to keep ambient thermostat temperatures within the Automatic Transfer Switch enclosure at acceptable levels. This accessory consists of a mounting bracket with strip heater, thermostat, and dial terminal block.

- Page 20 INDEX strip heater, 5–5 accessories, 5–2, 5–5 ground, controller, 1–1 auxiliary circuits, 1–2 parts, 3–1 problem, 3–2 handle, maintenance, 1–3 warning, 1–3 programmable engine exerciser, 5–2, battery, 4–2, 5–1 5–3 harness, 1–2 buttons, push, 3–1 disconnect plugs, 3–1 bypass time delay, 1–5, 2–1, 3–1 HELP 800–800–2726 (ASCO) rating label, cover...