Quick Links

*

4

L

3

1 A 1

7

1 E 0

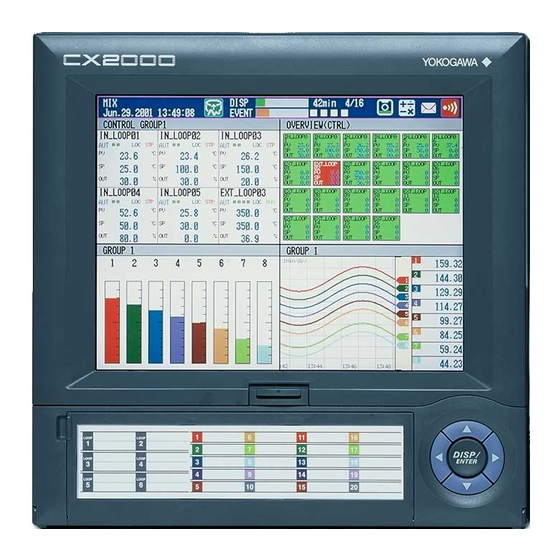

CX2000 Installation and

Connection Guide

IM 04L31A01-71E 4th Edition

4thEdition: May 2007 (YK)

All Right Reserved, Copyright © 2001

Yokogawa Electric Corporation

Y okogawa Electric Corporation

Thank you for purchasing the CX2000.

This manual contains simple explanations about how to install and connect

the CX2000. For more information about the procedures described herein,

safety precautions, and the CX2000 functions and operation, please refer to

the PDF manual found on the provided CD-ROM.

Installation Procedure

1. Cut the instrument panel according to the diagram below.

Panel Cut Diagram

Units : mm

360 min.

+2

281

0

2. Insert the CX2000 into the front of the panel.

3. Using the mounting brackets, attach the CX2000 to the panel as shown

in the following figure.

First, attach the two mounting brackets and temporarily fasten the

attachment screws. Next, fix the CX2000 in place by tightening the

attachment screws with the appropriate torque (0.7 to 0.9 N-m.). As you

fasten the screws, press the mounting bracket against the case so that

they are in contact with each other.

Screw temporarily

Panel

Mounting

bracket

Attachment

screw

Fix in place

Case

Panel

Mounting bracket

In contact

Front

with each other

Torque driver

(The figure shows the case when

(flat blade)

the mounting brackets are used

Attachment screw

on the top and bottom of the case.)

For details about the CX2000 external dimensions, installation environment,

and more, please refer to the CX2000 User's Manual (IM 04L31A01-01E)

found on the provided CD-ROM.

4

*

Connection Types and Procedures

There are various terminals and connectors on the rear panel of the CX2000. Connecting them to peripheral devices allows you to perform control and measurement operations. Below are the names of each connector and terminal, as

well as connection procedures.

Connecting the Ethernet Interface

•

When only Connecting to a Hub

Connect the CX2000 and the PC through a HUB as shown in the

following figure.

10 Base-T straight cable

Ethernet

interface connector

(Multiple devices can be

CX

connected by using a hub.)

HUB

PC

Ethernet

interface connector

CX

Ethernet cable

10 Base-T straight cable

•

When Connecting to a Preexisting Network

The following figure illustrates an example in which the CX2000 and

a PC are connected to the network. When connecting the CX2000 or

the PC to a preexisting network such things as the transfer rate and

connector type must match. For details, consult your system or

network administrator.

Network

10 Base-T straight cable

(Adapters that support

Ethernet

the 10 Base-T (hubs and

interface connector

routers, for example)

CX

Ethernet cable

Connecting a Monitor to the VGA Output Terminal

(Option /D5)

Supported monitors: VGA monitors and multisync monitors with VGA

display capability.

1. Turn off the CX2000 and the monitor.

2. Connect the CX2000 and the monitor using an analog RGB cable (D-

Sub connector).

3. Turn on the CX2000 and the monitor. The screen of the CX2000 is

displayed on the monitor.

Loop 1 and 2 control output terminal block

Magnet

switch

Loop 3 and 4 control output terminal block

Loop 5 and 6 control output terminal block

Option terminal block (Options /A6, /A4F, /A4FR,

/A6R, /CST1,and /TPS4)

Connecting the Serial Interface

•

RS-232 (When Connecting to a Computer or Other Such Devices)

Verify that the CX2000 has an RS-232 connector, and then connect a serial cable to it. Connect the other end of the serial cable to the other device.

1

2

3 4

5

Pin No. Signal Name

2

3

5

7

6

7

8

9

8

* Pins 1, 4, 6, and 9 are not used.

•

RS-422/485 (When Connecting to a PLC, Temperature Controller or

Other Such Devices)

Verify that the CX2000 has an RS-422/485 connector, and then connect the crimp

connectors (for 4-mm screws) to the terminal strip as illustrated on the right. Do not

expose more than 5 cm of the cable surface from the shield.

With an RS-422/485

PC

CX2000 Rear Panel

VIDEO OUT(VGA)

R1

SSR

Contact

Contact

input (6)

output (6)

R2

Connecting Input/Output Connectors

Magnet

Contact

Contact

switch

input (6)

output (6)

When connecting various input/output connectors for control or

measurement, proceed as described below.

Connect the crimp connectors (for 4-mm screws) to the terminal

strip.

R3

Contact

Contact

1. Turn off the CX2000 and remove the terminal cover.

input (6)

output (6)

2. Wire the signal wires to the terminals.

Attach the terminal cover and secure it with the screws.

Signal Meaning

RD (Received Data)

Received data from the connected device. Input signal.

SD (Send Data)

Send data to the connected device. Output signal.

SG (Signal Ground)

Signal ground.

RS (Request to Send) Handshaking signal used when receiving data from the connected device. Output signal.

CS (Clear to Send)

Handshaking signal used when sending data to the connected device. Input signal.

Four-wire

Shield potential

Connecting the Power Supply

When using electrical wiring, be certain to follow the safety

recommendations prescribed in the CX2000 User's Manual.

Use a power supply that meets the following conditions:

Rated supply voltage:

Supply voltage range used:

With an RS-232

Rated supply voltage frequency:

Permitted supply voltage frequency range:

L N

Maximum power consumption:

1. Turn OFF the CX2000 and open the cover (transparent) for the

power supply wires.

2. Connect the power cord and the protective ground cord to the power

supply terminals.

Power cord

3. Close the cover (transparent) for the power supply wires and secure

it in place with screws.

For the power supply specifications and connection method of the 24VDC/AC

power supply option, please refer to the CX2000 User's Manual.

Two-wire

FG

SG SDB SDA RDB RDA

FG

SG SDB SDA RDB RDA

Shield

Shield potential

Shield

100 to 240 VAC

90 to 132, 180 to 264 VAC

50/60 Hz

50/60 Hz ± 2%

75 VA (100 V), 106 VA (240 V)

100-240V

AC~

50/60Hz

106VA MAX

L

N

Protective grounding cord

Control input terminal block (loops 1, 2, 3, 4, 5,

and 6)

Measurement input terminal block (CH1 to 10)

Measurement input terminal block (CH11 to 20)

Summary of Contents for YOKOGAWA CX2000

- Page 1 CX2000 Installation and There are various terminals and connectors on the rear panel of the CX2000. Connecting them to peripheral devices allows you to perform control and measurement operations. Below are the names of each connector and terminal, as Connection Guide well as connection procedures.

- Page 2 The terminal numbers are written on the label on the front of the terminal cover. Terminal numbers are LOOP4 LOOP6 LOOP3 LOOP2 LOOP5 LOOP1 CX2000 Output unique three-digit numbers. They are used to locate terminals on the wiring diagram, etc. The highest Current Number of loops: 4 PULSE PULSE digit indicates the arrangement position of the terminal block;...