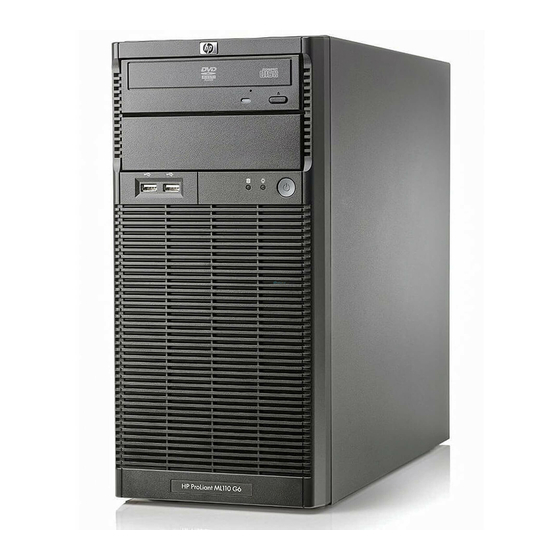

HP ProLiant ML110 G6 Maintenance And Service Manual

Hide thumbs

Also See for ProLiant ML110 G6:

- User manual (112 pages) ,

- Datasheet (4 pages) ,

- Installation sheet (2 pages)

Table of Contents

Quick Links

See also:

User Manual

Table of Contents

Troubleshooting

Summary of Contents for HP ProLiant ML110 G6

- Page 1 HP ProLiant ML1 10 G6 Server Maintenance and Service Guide Part number 580133-003 Third edition March 2010...

- Page 2 © Copyright 2009, 2010 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty.

-

Page 3: Table Of Contents

Troubleshooting resources ........................68 HP Insight Diagnostics ..........................68 Survey Utility ............................69 Array Diagnostic Utility........................... 69 HP Instant Support Enterprise Edition ......................69 Web-Based Enterprise Service ......................... 69 Open Services Event Manager ........................ 70 Phoenix SecureCore BIOS software ......................70 Configuring the system BIOS ...................... - Page 4 BIOS splash screen ........................... 93 Recording custom Setup values ......................94 Loading system defaults ........................94 Clearing CMOS ..........................95 Recovering BIOS..........................95 Flashing the system BIOS ........................96 Power-On-Self-Test ..........................97 Connectors, switches, and LEDs ......................100 Connectors and components ......................... 100 Front panel.............................

-

Page 5: Customer Self Repair

If during the diagnosis period HP (or HP service providers or service partners) identifies that the repair can be accomplished by the use of a CSR part, HP will ship that part directly to you for replacement. There are two categories of CSR parts: •... - Page 6 Centre d'assistance technique HP. Dans les documents envoyés avec la pièce de rechange CSR, HP précise s'il est nécessaire de lui retourner la pièce défectueuse. Si c'est le cas, vous devez le faire dans le délai indiqué, généralement cinq (5) jours ouvrés. La pièce et sa documentation doivent être retournées dans l'emballage fourni.

- Page 7 In caso di necessità si può richiedere l'assistenza telefonica di un addetto del centro di supporto tecnico HP. Nel materiale fornito con una parte di ricambio CSR, HP specifica se il cliente deve restituire dei componenti. Qualora sia richiesta la resa ad HP del componente difettoso, lo si deve spedire ad HP entro un determinato periodo di tempo, generalmente cinque (5) giorni lavorativi.

- Page 8 Flexibilität beim Austausch defekter Bauteile zu ermöglichen. Wenn HP (oder ein HP Servicepartner) bei der Diagnose feststellt, dass das Produkt mithilfe eines CSR-Teils repariert werden kann, sendet Ihnen HP dieses Bauteil zum Austausch direkt zu. CSR-Teile werden in zwei Kategorien unterteilt: •...

- Page 9 HP podrá cobrarle por el de sustitución. En el caso de todas sustituciones que lleve a cabo el cliente, HP se hará cargo de todos los gastos de envío y devolución de componentes y escogerá la empresa de transporte que se utilice para dicho servicio.

- Page 10 Optioneel—Onderdelen waarvoor reparatie door de klant optioneel is. Ook deze onderdelen zijn ontworpen voor reparatie door de klant. Als u echter HP verzoekt deze onderdelen voor u te vervangen, kunnen daarvoor extra kosten in rekening worden gebracht, afhankelijk van het type garantieservice voor het product.

- Page 11 CSR de reposição se a peça com defeito deve ser devolvida à HP. Nos casos em que isso for necessário, é preciso enviar a peça com defeito à HP dentro do período determinado, normalmente cinco (5) dias úteis. A peça com defeito deve ser enviada com a documentação correspondente no material de transporte fornecido.

- Page 12 Customer Self Repair 12...

- Page 13 Customer Self Repair 13...

- Page 14 Customer Self Repair 14...

- Page 15 Customer Self Repair 15...

-

Page 16: Illustrated Parts Catalog

Illustrated parts catalog Mechanical components Illustrated parts catalog 16... - Page 17 Optional—Parts for which customer self repair is optional. These parts are also designed for customer self repair. If, however, you require that HP replace them for you, there may or may not be additional charges, depending on the type of warranty service designated for your product.

- Page 18 No: No—Algunos componentes no están diseñados para que puedan ser reparados por el usuario. Para que el usuario haga valer su garantía, HP pone como condición que un proveedor de servicios autorizado realice la sustitución de estos componentes. Dichos componentes se identifican con la palabra “No”...

- Page 19 Illustrated parts catalog 19...

-

Page 20: System Components

System components Illustrated parts catalog 20... - Page 21 Item Description Spare part number Customer self repair System drive cables Mandatory Power button / front panel LED cable 576929-001 Front USB port cable 576928-001 External ambient thermal sensor cable 592430-001 SATA HDD / ODD cable 452334-001 SAS HDD cable 576925-001 SAS LED cable 576926-001...

- Page 22 Item Description Spare part number Customer self repair FBWC capacitor pack 587324-001 Mandatory FBWC cache module, 512-MB 578882-001 Mandatory FBWC cache module, 1-GB 505908-001 Mandatory Illustrated parts catalog 22...

- Page 23 Optional—Parts for which customer self repair is optional. These parts are also designed for customer self repair. If, however, you require that HP replace them for you, there may or may not be additional charges, depending on the type of warranty service designated for your product.

- Page 24 No: No—Algunos componentes no están diseñados para que puedan ser reparados por el usuario. Para que el usuario haga valer su garantía, HP pone como condición que un proveedor de servicios autorizado realice la sustitución de estos componentes. Dichos componentes se identifican con la palabra “No”...

- Page 25 Illustrated parts catalog 25...

-

Page 26: Hp Contact Information

• In North America: ○ Call 1-800-HP-INVENT (1-800-474-6836). This service is available 24 hours a day, 7 days a week. For continuous quality improvement, calls may be recorded or monitored. ○ If you have purchased a Care Pack (service upgrade), call 1-800-633-3600. For more information about Care Packs, refer to the HP website at www.hp.com. -

Page 27: Removal And Replacement Procedures

T-15 Torx screwdriver (for processor replacement) • Flat-blade screwdriver (for system battery replacement) The following references and software tools may also be used: • HP ProLiant ML110 G6 Server Easy Set-up CD • IPMI Event Log • Diagnostics software Server warnings and cautions Before installing a server, be sure that you understand the following warnings and cautions. -

Page 28: Symbols On Equipment

Symbols on equipment The following symbols may be placed on equipment to indicate the presence of potentially hazardous conditions. This symbol indicates the presence of hazardous energy circuits or electric shock hazards. Refer all servicing to qualified personnel. WARNING: To reduce the risk of injury from electric shock hazards, do not open this enclosure. -

Page 29: Electrostatic Discharge Information

Electrostatic discharge information An electrostatic discharge (ESD) can damage static-sensitive devices or microcircuitry. Proper packaging and grounding techniques are necessary precautions to prevent damage. To prevent electrostatic damage, observe the following precautions: • Transport products in static-safe containers such as conductive tubes, bags, or boxes. •... -

Page 30: Post-Installation Procedure

Post-installation procedure Perform the steps below after installing or removing a server component. Be sure all components are installed according to the described step-by-step instructions. Check to make sure you have not left loose tools or parts inside the server. Reinstall any expansion board, peripheral, and system cables that have previously been removed. -

Page 31: Cable Management

Disconnect the AC power cord from the AC outlet and then from the server. Check that the power LED indicator is turned off and that the fan noise has stopped. Disconnect all external peripheral devices from the server. Cable management Always follow good cable management practices when working inside the computer. -

Page 32: System Covers

System covers The access panel and the front bezel are both detachable. You must remove these system covers before you can remove or replace a server component. Access panel The access panel must be removed to access the internal components and the non-hot-plug mass storage devices. -

Page 33: Front Bezel

Front bezel The front bezel must be removed to access the hard drives and the removable media devices. To remove the front bezel: Remove the access panel. Remove the front bezel. Press the three release tabs (marked by white arrows) located on the inner left edge of the bezel (1). -

Page 34: Drive Bay Configuration

Drive bay configuration The server supports a maximum of six internal drives. The two upper drive bays are primarily for removable media drives, while the four lower drive bays are only for hard drives. Item Description removable media drive removable media drive SAS/SATA hard drive SAS/SATA hard drive SAS/SATA hard drive... -

Page 35: System Drive Cable Management

System drive cable management The figures in this section illustrate the system drives' data and power cable connections. Observe the proper cable management guidelines described on page 31 when routing the cables. Data cable management SATA hard drive cables SAS hard drive cables Item Description SATA cables... - Page 36 Power cable management PSU cable label Connects to removable media drive removable media drive hard drive hard drive hard drive hard drive 24-pin power connector (ATXPWRCN1) 4-pin power connector (ATXPWRCN2) Removal and replacement procedures 36...

-

Page 37: Removable Media Drives

Removable media drives The two upper bays are half height bays that can accommodate a variety of removable media drives including: • CD, DVD, CD-RW/DVD combo, DVD-RW drives • DAT 24i, 40i, 72i, Disk to Disk Backup Autoloaders (Internal/External) DAT 40x6, 72x6 drives To install a removable media drive: Perform the pre-installation procedure. - Page 38 Remove four screws from the sides of the drive. Reuse these screws when you install the new removable media drive. Place the old media drive on a static-dissipating work surface or inside an anti-static bag. Proceed to step 5. CAUTION: Do not discard the EMI shield.

- Page 39 Remove the new media drive from its protective packaging. Do one of the following: ○ If you intend to replace an old media drive, insert the four screws you removed in step 3-d into the top screw holes on the sides of the new media drive. ○...

-

Page 40: Hard Drives

Hard drives The four lower drive bays can accommodate 3.5-inch non-hot-plug SAS or SATA hard drives. The following drive capacities are supported. • Non-hot-plug SAS HDD – 146-, 300-, 400-, and 450-GB • Non-hot-plug SATA HDD – 160-, 250-, 500-, and 750-GB; 1-TB IMPORTANT: SAS hard drives require that you also install a SAS controller board. - Page 41 Remove the hard drive you intend to replace. For a SATA drive, disconnect the power and data cables from the back of the installed drive (1). For a SAS drive, disconnect the SAS HDD cable from the back of the installed drive. Pull and hold the corresponding drive release tab (2).

- Page 42 Remove four screws from the sides of the drive. Reuse these screws when you install the new hard drive. Place the old hard drive on a static-dissipating work surface or inside an anti-static bag. Remove the new hard drive from its protective packaging. Do one of the following: ○...

- Page 43 Install the new SAS hard drive. Slide the new hard drive into the selected bay until it clicks into place (1). Connect the SAS HDD data cable to the back of the hard drive (2). Connect the drive power cable to the back of the SAS HDD cable (3). Perform the post-installation procedure.

-

Page 44: System Board Configuration

System board configuration Refer to the following sections for instructions about how to remove or replace the processor, the memory modules, the expansion cards, and the system battery. The procedure for installing the Lights-Out 100c remote management card option is also provided. Processor The Intel LGA 1156 processor socket supports the following Intel Xeon 3400 series processors: •... -

Page 45: Processor Installation

Processor installation WARNING: To reduce the risk of personal injury from hot surfaces, allow the heat sink and the processor to cool before touching them. CAUTION: To prevent the heat sink from tilting to one side during installation/removal procedures, observe a diagonally opposite pattern (an “X” pattern) when loosening and tightening the four spring loaded screws. - Page 46 To remove the default processor: Release the load lever. Open the retention plate to expose the socket body. Gently lift the processor out of its socket. Place the old processor on a static-dissipating work surface or inside an anti-static bag. To apply thermal compound: Perform the procedure below only if you will be using the same heat sink as before.

- Page 47 Apply 0.5 gram (0.25 ml) of the thermal compound evenly onto the top of the processor. The figure below shows the correct pattern of applying the thermal compound. To install the new processor: With the load lever and the retention plate still disengaged, align the processor with the socket and install the processor.

- Page 48 To install the heat sink: CAUTION: To prevent overheating or a possible system crash, use only a heat sink specified for your ProLiant server. If you are using a new heat sink, remove the cover protecting the preapplied thermal compound. Be careful not to touch or scratch the thermal compound.

-

Page 49: Memory

DDR3 DIMM slot Memory installation guidelines Observe the following important guidelines when installing memory modules: • Use only HP supported PC3-10600E UDIMM in 1 GB, 2 GB, or 4 GB capacities. • Supported DIMM configurations include: ○ Single DIMM (non-interleaving) – It must be installed in the DIMM2A slot. - Page 50 CAUTION: DIMMs can be damaged by improper handling. Always use an anti-static wrist strap and grounding mat, and discharge static electricity before touching DIMMs. To install a memory module: Perform the pre-installation procedure. Lay the server on its side (components showing). Locate an empty DIMM slot on the system board.

-

Page 51: Expansion Board

Expansion board Your ProLiant server has four expansion slots with four separate bus channels. Item Connector code Slot type Full-height full-length Slot 4 PCIe x16 (16) 45W Full-height/full-length PCIe Gen2 x16 slot (x16) Full-height full-length Slot 3 PCIe x8 (4) 25W Full-height/full-length PCIe Gen1 x8 slot (x4) Full-height full-length Slot 2 PCI 32-bit 33 MHz 25W Full-height/full-length 32-bit/33 MHz PCI slot... - Page 52 Identify the slot that is compatible with the expansion board you intend to install, and then pull out its slot cover (3). Store it for reassembly later. CAUTION: Do not discard the slot cover. If the expansion board is removed in the future, the slot cover must be reinstalled to maintain proper cooling Remove the expansion board from its protective packaging, handling it by the edges.

- Page 53 NOTE: For a full-length expansion board installation: Remove the full-length card retainer first (see the zoomed in section in the step 4 figure) opposite the expansion slot you are using and secure the board in it, and then install the board in the slot. Connect the necessary cables to the board.

- Page 54 To install the SAS controller board: Perform steps 1 and 2 of the “To install an expansion board” section. Remove the SAS controller board from its protective packaging, handling it by the edges. Install the SAS controller board. It is recommended that the SAS controller board be installed in the full-height/full-length PCIe Gen1 x8 expansion slot.

- Page 55 Connect the SAS LED cable to the HDDLEDCN1 connector on the system board (6). Secure the SAS HDD and LED cables in the cable clamp located on the chassis base. If you will be using a SAS cache battery, proceed to the next section for instructions on how to install the SAS cache battery.

-

Page 56: Flash-Backed Write Cache Procedures

Install the SAS cache battery. Mount the SAS cache battery on the chassis indentation located below the HDD cage (1). Connect the BBWC cable to the SAS controller board (2). Proceed to page 40 for instructions on how to install a SAS hard drive. Flash-backed write cache procedures Two types of procedures are provided for the FBWC option: •... - Page 57 CAUTION: In systems that use external data storage, be sure that the server is the first unit to be powered down and the last to be powered back up. Taking this precaution ensures that the system does not erroneously mark the drives as failed when the server is powered up. Extend the server from the rack.

- Page 58 CAUTION: Do not use this controller with cache modules designed for other controller models, because the controller can malfunction and you can lose data. Also, do not transfer this cache module to a different controller module, because you can lose data. Back up all data.

-

Page 59: Flash-Backed Write Cache Capacitor Pack

Install the capacitor pack. Route the cable. Install the access panel. For ML110 G6 servers, slide the server back into the rack. For ML150 G6 servers, do one of the following: • Close or install the tower bezel, as needed. Slide the server back into the rack. - Page 60 If the capacitor pack is connected to the cache module, disconnect the capacitor pack cable from the connector on the top of the cache module. Disconnect the capacitor pack from the air baffle. To replace the component, reverse the removal procedure. Removal and replacement procedures 60...

-

Page 61: System Battery

System battery replacement warnings Observe the following reminders when replacing the system battery: • Replace the battery with the same type as the battery recommended by HP. Use of another battery may present a risk of fire or explosion. •... - Page 62 To replace the system battery: Perform the pre-installation procedure. Lay the server on its side (components showing). If necessary, remove any accessory boards or cables that prevent access to the battery socket. Locate the system battery. Replace the system battery. IMPORTANT: Do not bend the spring latch when replacing the RTC battery.

- Page 63 Push the other edge down until the clamp snaps over the battery (2). Perform the post-installation procedure. Removal and replacement procedures 63...

-

Page 64: System Fan

System fan A new system fan can be installed to allow the server to operate properly in case the default system fan becomes defective. To replace the system fan: CAUTION: Be sure to support the system fan with your hand when removing screws from the chassis. - Page 65 Install the new system fan. Align the rubber bolts to their chassis holes (1). While holding the new fan against the chassis, pull the rubber bolts through their chassis holes (2). Connect the system fan cable to its system board connector (3). Perform the post-installation procedure.

-

Page 66: Power Supply Unit

Power supply unit Located on the rear panel of the server is a single standard autoranging 300W power supply unit (PSU). PSU replacement warnings Observe the following reminders to reduce the risk of personal injury from electric shock hazards and/or damage to the equipment •... - Page 67 Install the new power supply unit. Align the new power supply unit inside the chassis (1). Secure the power supply unit to the chassis using the four screws you removed in step 2-b (2). Reconnect the system power cables you removed in step 2-a (3). Perform the post-installation procedure.

-

Page 68: Diagnostics Tools

To obtain the guide, refer to any of the following sources and then select the HP ProLiant Servers Troubleshooting Guide: •... -

Page 69: Survey Utility

Survey text files to reflect the latest changes in the configuration. Array Diagnostic Utility The HP Array Diagnostics Utility is a web-based application that creates a report of all HP storage controllers and disk drives. This report provides vital information to assist in identifying faults or conditions that may require attention. -

Page 70: Open Services Event Manager

OSEM is a standalone tool that performs real-time reactive and proactive service event filtering, analysis, and notification. The tool gathers event data from SNMP traps or information provided over an HTTP interface and notifies an administrator or HP through SMTP and ISEE. For more information, refer to the HP website (http://h18000.www1.hp.com/support/svctools/). - Page 71 ○ Installing PCI expansion boards ○ Upgrading the system BIOS ○ Configuring the power management modes ○ Setting up system passwords or making other changes to the security setup • When a configuration error is detected by the system and you are prompted (Run Setup message) to make changes to the BIOS settings.

-

Page 72: Setup Utility Navigation Keys

Setup Utility navigation keys Use the following keyboard keys to work your way through the various menu and submenu screens of the Setup Utility. Functions ← and → To move between selections on the menu bar. ↑ and ↓ To move the cursor to the field you want. The currently selected field will be highlighted. -

Page 73: Setup Utility Menus

Setup Utility menus The Setup Utility provides a menu bar with the menu selections. The menu bar choices are described in the following sections. Main menu Field Description Product Name Server model name ProLiant BIOS System BIOS revision number BIOS Version System BIOS version BIOS Date BIOS build date... -

Page 74: Boot Features Submenu

Boot Features submenu Field Description Options Embedded VGA Control Select the status of the embedded graphics controller when an Auto Detect external VGA card is installed. Always Enabled • Auto Detect – Disable the embedded graphics controller when an external VGA card is installed. •... -

Page 75: Advanced Menu

Field Description Options POST Speed Up Enable this option to skip certain POST routines and shortening Enabled others. This will decrease the time needed to boot up the system. Disabled Extended Memory Testing Select the type of memory test to employ during bootup. None •... -

Page 76: Advanced Chipset Control Submenu

Field Description Options I/O Device Configuration Displays the settings related to the serial port. Press Enter to access the related submenu. Hard Disk Configuration Displays the settings related to the system hard drives. Press Enter to access the related submenu. USB Configuration Displays the settings related to the USB function. - Page 77 Field Description Options Enable Multimedia Timer Select whether to enable or disable the High Precision Event Enabled Timer (HPET). When enabled, multimedia streams are better Disabled synchronized providing smoother playback. Note: This option must be enabled to allow Windows Vista installation.

- Page 78 Advanced Processor Options submenu Field Description Options Active Processor Select the number of CPU cores to activate. Max. Cores Two cores One core Processor Hyper-Threading Select whether to enable Intel Hyper-Threading (HT) Technology Enabled in your server. HT enables the host operating system to view a Disabled single physical processor to appear as two logical processors.

- Page 79 CPU Power Management submenu Field Description Options EIST (GU3) Select whether to enable Enhanced Intel SpeedStep Technology. Enabled EIST allows a compliant OS to dynamically adjust the processor Disabled voltage and core frequency based on system usage. This can result in decreased average power consumption and decreased average heat production.

- Page 80 I/O Device Configuration submenu Field Description Options Embedded Serial Port Select the serial port operation mode. Mode • Shared BMC – Only the BMC command line interface (CLI) is available at the BMC UART. System • Shared – The switching operation between the BMC CLI and USI is available at the BMC UART.

- Page 81 Hard Disk Configuration submenu Field Description Options SATA Mode Selection Select whether to enable the Advanced Host Controller Interface Compatible (AHCI) function of the SATA controller. Enhanced • Enhanced – The SATA controller enables AHCI. The RAID function (if available) will also be enabled. The RAID setup utility will be accessible during boo-up.

- Page 82 SATA Port 0–5 submenus Field Description Options Type Select the type of drive connected to the related port. User • Auto Auto – BIOS detects what the drive is capable of, not the translation mechanism that was used to format the drive. CD-ROM Note: In this mode, if a drive is run in a mode other than the mode in ATAPI Removable...

-

Page 83: Usb Configuration Submenu

Field Description Options LBA Mode Control Select whether to use the logical block addressing (LBA) scheme Enabled instead of the CHS scheme in specifying the location of data blocks. Disabled Note: When the Type field is set to Auto this field is automatically detected and is not user-configurable. -

Page 84: Ipmi Submenu

Field Description Options USB BIOS Support Select whether to allow USB keyboard usage when accessing the Enabled BIOS Setup. Disabled USB Device Boot Priority Set this field to High to enable the server to look for bootable High USB devices first before any other device in booting the system. A USB key drive will be the first priority device. - Page 85 Field Description Options IPMI Watchdog Time-out Select a countdown value for the IPMI watchdog timer. When the 5, 10, 15, 20, countdown reaches zero, the system event selected in the IPMI or 30 minutes Watchdog Timer field is initiated. Blowout Feature Select whether to enable the blowout feature.

- Page 86 System Event Log submenu Field Description Options Clear System Event Select whether to delete all system event log (SEL) entries during the Enabled next system start-up. Disabled Existing Event Log Number of recorded SEL entries Number Remaining Event Number of remaining SEL entries Log Number System Event Log Press Enter to view the SEL in list mode.

-

Page 87: Console Redirection Submenu

Each SEL entry indicates the: • Event ID (number assigne d to identify the event type) • Device sensor that was activated • Device that caused the event • Date and time of event occurr ence • Event description Real Time Sensor Data screen The Real Time Sensor Data screen displays the current thermal and voltage values for various hardware monitors. -

Page 88: Security Menu

Field Description Options Baud Rate Select the baud rate for console redirection. 9600 19.2K 38.4K 57.6K 115.2K Security menu Field Description Admin Password Is Current admin password status (Clear or Set) Admin Password Select the field, and then press Enter to set, change, or remove the admin password. - Page 89 To set an admin password: In the Security menu screen, select the Admin Password field then press Enter. Type a new password in the password box. The password may consist of up to eight alphanumeric characters (A-Z, a-z, 0-9). Retype the password to verify the first entry, and then press Enter. Press F10 to save the password and close the Setup Utility.

- Page 90 Diagnostics tools 90...

- Page 91 To change the admin password: In the Security menu screen, select the Admin Password field, and then press Enter. Type the original password in the password box. Type a new password, and then press Enter. Retype the new password to verify the first entry, and then press Enter again. Press F10 to save the password and close the Setup Utility.

-

Page 92: Boot Menu

Boot menu Use this menu to set the preferred drive sequence in which the Setup Utility attempts to boot the operating system. By default, the server searches for boot devices in the following order: • Removable devices • CD-ROM/DVD-ROM drive •... -

Page 93: Bios Splash Screen

Field Description Exit Discarding Changes Discards changes made and closes the Setup Utility. Restore Default Settings Loads the factory-default settings for all Setup parameters. Keyboard shortcut: F9 Discard Changes Discards all changes made to the Setup Utility and loads the previous configuration settings. -

Page 94: Recording Custom Setup Values

Be sure to use a CMOS backup utility that is designed for the particular CMOS type and OS version installed in your ProLiant server. For information on a compatible CMOS backup utility, contact your local HP representative. Loading system defaults If your system fails after you make changes in the Setup menus, reboot the server, enter Setup and load the system default settings to correct the error. -

Page 95: Clearing Cmos

To execute the BIOS boot block code: Go to www.hp.com and download the following files to the root directory of a bootable device. You can use a diskette, an external USB drive, or a CD/DVD. -

Page 96: Flashing The System Bios

Refer to the previous section for instructions on how to execute the boot block code. To flash the system BIOS: Go to www.hp.com and download the following files to the root directory of a bootable device. You can use a diskette, an external USB drive, or a CD/DVD. -

Page 97: Power-On-Self-Test

Verify that the keyboard cable is securely connected to the keyboard port (not the mouse port) on the rear panel of the server. If the problem persists, replace the keyboard or contact your HP Customer Support provider. 0212 Keyboard Controller Failed Keyboard controller failed test. - Page 98 CMOS. Access Setup, and then either load the system default values or enter your own custom values. If the error persists, check the system battery or contact your HP Customer Support provider. 0260 System timer error The timer test failed. Requires repair of the system board.

-

Page 99: Post Related Troubleshooting

POST related troubleshooting Perform the following procedures when POST fails to run, displays error messages, or emits beep codes. If the POST failure is during a routine boot up, check the following: • All external cables and power cables should be firmly plugged in. •... -

Page 100: Connectors, Switches, And Leds

Connectors, switches, and LEDs Connectors and components Front panel Item Icon Component Optical disc drive (ODD) ODD manual eject hole ODD eject button Power button Front USB 2.0 ports External ambient thermal sensor HDD EMI shield thumbscrew HDD EMI shield Second removable media drive bay EMI shield NOTE: The location of items 2 and 3 may vary depending on the model of the installed removable media drive. -

Page 101: Rear Panel

Rear panel Item Icon Component Kensington lock notch Cable lock provision notch Access panel thumbscrew Expansion slot cover retainer thumbscrew Expansion slot cover retainer Expansion slot 1 cover Expansion slot 2 cover Expansion slot 3 cover Expansion slot 4 cover Management NIC port (RJ-45) Video port Serial port... -

Page 102: System Board

System board Item Code Component ATXPWRCN2 4-pin ATX processor power connector DIMM4B Channel B 1 DDR3 DIMM slot DIMM3D Channel B 2 DDR3 DIMM slot DIMM2A Channel A 1 DDR3 DIMM slot DIMM1C Channel A 2 DDR3 DIMM slot ATXPWRCN1 24-pin ATX system board power connector CPU1 Processor... - Page 103 Item Code Component TPMCN1 TPM (Trusted Platform Module) connector Full-height full-length Slot 4 Full-height/full-length PCIe Gen2 x16 slot (x16) PCIe x16 (16) 45W Full-height full-length Slot 3 Full-height/full-length PCIe Gen1 x8 slot (x4) PCIe x8 (4) 25W Full-height full-length Slot 2 Full-height/full-length 32-bit/33 MHz PCI slot PCI 32-bit 33 MHz 25W THERSNRCN1...

-

Page 104: System Configuration Switch

System configuration switch PCHSW1 is an eight-position switch on the system board used to implement the various protections and override functions. All eight switches will have the off position as the default setting. Position Function Default Description Configuration reset Off: Normal On: System configuration settings and registry are reset to default values. -

Page 105: Status Led Indicators

Status LED indicators The status LED indicators aid in problem diagnosis by indicating the status of system components and operations of the server. External LED indicators Item Indicator Status Description ODD activity Green Ongoing ODD activity HDD activity Green Ongoing HDD activity System power Green Power on mode... -

Page 106: System Board Led Indicators

System board LED indicators Item Indicator Status Description Heat sink failure Amber Heat sink error detected DC power on Green System is turned on. Management controller Blinking green Baseboard Management Controller (BMC) activity heartbeat System/processor over Amber A system or processor temperature sensor has been temperature (OTP) breached. -

Page 107: System Specifications

System specifications Hardware specifications System unit Item Description Processor socket Intel LGA 1156 Processor support Intel Celeron G1101, Intel Pentium G6950, Intel Core i3-530, Intel Core i3-540, and Intel Xeon 3400 series processors Core logic Intel Platform Controller Hub (PCH) Bridge interface Intel DMI (Direct Media Interface), 2.5 GT/s Hardware monitoring... -

Page 108: Memory

Item Description Server management • Onboard hardware failure indicators • Management NIC ○ IPMI 2.0 compliant ○ Dedicated 10/100 Mbps LAN port for online system health monitoring Thermal solution • One system fan • One heat sink • One PSU fan Memory Item Description... -

Page 109: Power Supply Unit

Power supply unit Item Description Model DPS-300AB-50 A Output power 300 W Input requirements Input voltage range VAC, single phase –264 Nominal input voltage –240 Line frequency 63 Hz – Maximum input current 5 A at 100 VAC; 2.5 A at 200 VAC Dimensions Height 86 mm (3.39 in) -

Page 110: Software Specifications

SUSE Linux Enterprise Server System diagnostics • HP Insight Dia gnostics • Survey Utility • Array Diagnostic Utility • HP Instant Support Enterprise Ed ition • Web-Based Enterprise Service • Open Services Event Manager • Phoenix SecureCore Setup Utility System specifications 110... -

Page 111: Physical Specifications

Physical specifications Item Description System board platform uATX (Micro Advanced Technology Extended) System board dimensions Length 244 mm (9.6 in) Width 244 mm (9.6 in) Server dimensions (not including the front bezel and foot stand) 365.22 mm (14.38 in) Height 175 mm (6.9 in) Width With bezel –... -

Page 112: Index

LED indicator, 105 Array Diagnostic Utility, 69 access panel HP Insight Diagnostics, 68 part number, 17 HP Instant Support Enterprise Edition, 69 removing, 32 Open Services Event Manager, 70 admin password Phoenix SecureCore, 70 changing, 90 Survey Utility, 69... - Page 113 contact information, 26 technical support, 26 front bezel part number, 17 removing, 33 I/O ports front panel, 99 listing, 106 I/O subsystem, 106 illustrated parts catalog General Help window, 72 mechanical components, 16 system components, 20 hard disk drive Item Specific Help panel, 72 configuring, 76 installing, 40 MAC address, 73...

- Page 114 admin password, 88 configuring, 75 Advanced menu, 75 installation guidelines, 44 BIOS recovery, 94 installing, 47 Boot menu, 91 part numbers, 21 clearing the CMOS RAM, 94 removing, 46 closing, 91 socket location, 44 CMOS RAM, 71 technical specifications, 107 General Help window, 72 thermal compound, 46 Item Specific Help panel, 72...

- Page 115 connections, 35 system date server management POST error message, 97 configuring, 76 setting, 73 specification, 107 system fan status LED indicators, 104 error LED indicator, 105 software specifications part number, 21 NOS, 109 replacement warning, 64 system diagnostics, 109 replacing, 64 spare parts system time mechanical components, 16...