Summary of Contents for GE Masoneilan 4700P

- Page 1 GE Oil & Gas Masoneilan 4700P/4700E & 4800P/4800E Pneumatic and Electropneumatic Positioners Maintenance Manual (Rev. C) GE Data Classification: Public...

- Page 2 ARE STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

- Page 3 Copyright The complete design and manufacture is the intellectual property of GE Oil & Gas. All information contained herein is believed to be accurate at the time of publication and is subject to change without notice. All other trademarks and copyrights are properties of their respective corporations.

- Page 4 This page intentionally left blank.

-

Page 5: Table Of Contents

Span Adjustment............................48 Cam Lobe Change ............................49 Air to Open / Direct Acting Positioner ....................49 Air to Open / Reverse Acting Positioner ..................49 © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 5... - Page 6 Cam Lobe Selection and Lever Arm Orientation ................65 Parts Reference 4700P/4800P 3-15 and 6-30 Range..............68 Parts Reference 4700E/4800E ......................71 Parts Reference............................73 Specification Data............................75 Specifications .................... 75 Drawings ....................77 © 2015 General Electric Company. All rights reserved 6 | =GE Oil & Gas...

- Page 7 Split Range ........................43 Lobe Identification.....................44 Pilot Subassembly......................62 4700P/4800P 3-15 and 6-30 Ranges ...............68 4700E/4800E........................71 Bypass Option (4700 Only)..................74 Positioner and Cast Body Assembly ..............77 © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 7...

- Page 8 This page intentionally left blank.

- Page 9 Mounting Parts Reference ................28 Split Range Operation..................64 Parts Reference 4700P/4800P 3-15 and 6-30 Range ......69 Parts Reference 4700E/4800E................ 72 Specification Data ....................75 © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 9...

- Page 10 This page intentionally left blank.

-

Page 11: Safety Information

CAUTION notices is required for safe operation. Indicates a potentially hazardous situation, which if not avoided WARNING could result in serious injury or death. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 11... -

Page 12: 4700P/4700E And 4800P/4800E Product Safety

All surrounding pipe lines must be thoroughly flushed to ensure all entrained debris has been removed from the system. © 2015 General Electric Company. All rights reserved 12 | =GE Oil & Gas... - Page 13 Changes to specifications, structure, and components used may not lead to the revision of this manual unless such changes affect the function and performance of the product. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 13...

- Page 14 This page intentionally left blank.

-

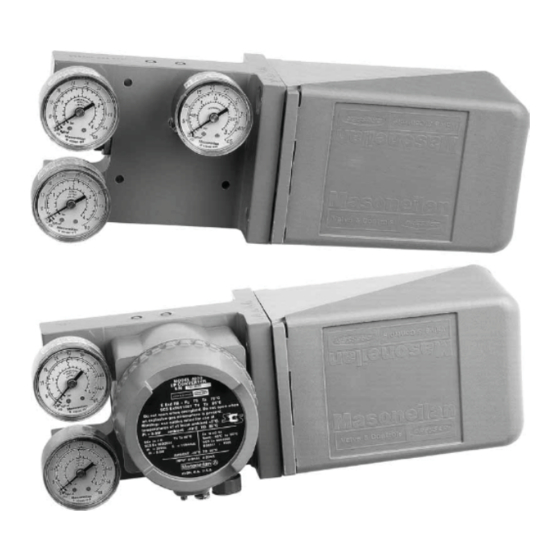

Page 15: Introduction

In the new balanced state, the valve plug is positioned in a programmed relationship to the instrument signal. Figure 1 Model 4700P/4700E and 4800P/4800E Positioner Numbering System © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 15... -

Page 16: Pilot

The by- pass valve does not block supply pressure to the pilot. Therefore, the supply line should be shut off before disassembling the positioner. © 2015 General Electric Company. All rights reserved 16 | =GE Oil & Gas... - Page 17 2, 4 bar), or if the controller is capable of operating the valve directly. When bypassing a positioner, ensure that the controller output is equal to supply required to operate valve. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 17...

- Page 18 This page intentionally left blank.

-

Page 19: Installation

The 4700E/4800E is not available with reverse action, hence NOTE if the application demands reverse action, a 4700P/4800P with an external I/P Transducer is required. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 19... -

Page 20: Cover Removal

To remove the cover (Figure 2), press the latch bar inward as shown in the figure below, pull cover away from body until latch tab is clear, then pull along body axis to free the two top locking tabs. Figure 2 Cover Removal © 2015 General Electric Company. All rights reserved 20 | =GE Oil & Gas... -

Page 21: Rotary

(numbers 1 and 2 above), and the supply and exhaust ports (number 3 above). * Option 4700P only © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 21... -

Page 22: 87/88 Actuator

Post Hub Locknut Input Shaft Locknut Washer Instruction Plate Elbow Pan Head Screw Ref. Nos 109, 110, and 112 are not included in the mounting kit. © 2015 General Electric Company. All rights reserved 22 | =GE Oil & Gas... -

Page 23: Actuator

Figure 5 87/88 Actuator © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 23... -

Page 24: Mounting 4700P And 4700E On Series 87/88 Actuators

4700 25.4 4700/4800 38.1 4700/4800 50.8 4700/4800 63.5 NOTE Strokes shorter than 20.3 mm (0.8"), require a special mounting kit. Consult with the factory for information. © 2015 General Electric Company. All rights reserved 24 | =GE Oil & Gas... -

Page 25: Actuator: Bracket Mounting Travel Settings

Figure 6 87/88 Actuator: Bracket Mounting Travel Settings © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 25... -

Page 26: 87U/88U Actuator

Description Lever Lockwasher Bracket Washer,.531 ID Input Shaft Cap Screw Turnbuckle Screw Clevis Washer Back Lever Pan Head Screw Clevis Pin Screw Retaining Clip Lockwasher Locknut © 2015 General Electric Company. All rights reserved 26 | =GE Oil & Gas... -

Page 27: U/88U Actuator

Table 2: Mounting Parts Reference 87U/88U (Continued) Ref. Description Ref. Description Ring, Retaining Washer Cap Screw Inst. Plate Figure 7 87U/88U Actuator © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 27... -

Page 28: Positioner Mounting And Orientation

The remainder of the mounting kit parts are used to before tightening mounting screws. assemble the cam to the actuator. See “Mounting Cam Coupling” on page 44. © 2015 General Electric Company. All rights reserved 28 | =GE Oil & Gas... -

Page 29: Camflex Ii And Varimax

Figure 8 Camflex II and Varimax Figure 9 Ball II and MiniTork II For detail of Positioner Mounting Parts, see Figure 8. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 29... -

Page 30: High Performance Butterfly Valve

Figure 10 High Performance Butterfly Valve For detail of Positioner Mounting Parts, see Figure 8. © 2015 General Electric Company. All rights reserved 30 | =GE Oil & Gas... -

Page 31: Pneumatic Installation

The use of soft setting anaerobic hydraulic seal, such as Loctite Hydraulic Seal 542, is recommended. Follow manufacturer’s instructions. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 31... - Page 32 WARNING Never exceed actuator or positioner maximum supply pressure. Damage to equipment or injury to personnel may result. © 2015 General Electric Company. All rights reserved 32 | =GE Oil & Gas...

-

Page 33: Pneumatic Installation

Figure 11 Pneumatic Installation © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 33... -

Page 34: Electrical Installation Of 4700E/4800E

The positioner is normally supplied with a 1/2" NPT conduit entry. (M20 is optional) Internal and external ground terminals are provided for use if grounding is required. © 2015 General Electric Company. All rights reserved 34 | =GE Oil & Gas... -

Page 35: Hazardous Area Installations

If a certified instrument should fail it must be returned to the manufacturer for repair. Maximum pressure 150 PSI. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 35... -

Page 36: Factory Mutual Approved Version

National Electrical Code ANSI / NFPA-70, ANSI / ISA RP 12.6 “Installa- tion of Intrinsically Safe Instrument Systems in Class I Hazardous (Classified) Locations, Figure 13 on page 40, and manufacturer’s instructions. © 2015 General Electric Company. All rights reserved 36 | =GE Oil & Gas... -

Page 37: Csa (Canadian Standards Association) Approved Version

Installation must be in accordance with the current edition of the Canadian National Electrical Code Part I, Figure 14 on page 41, and manufacturer’s instructions. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 37... -

Page 38: Sira Approved Version

Ex ia IIC T4 Ga = -40 °C to +80 °C, P = 1.1 W Ex ia IIC T6 Ga = -40 °C to +55 °C, P = 0.33 W © 2015 General Electric Company. All rights reserved 38 | =GE Oil & Gas... - Page 39 The installer shall ensure that the Model 4000 I/P Converter is installed in a location where there is a low risk of mechanical impact to the plastic baffle. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 39...

-

Page 40: Fm Installation

Figure 13 FM Installation © 2015 General Electric Company. All rights reserved 40 | =GE Oil & Gas... -

Page 41: Csa Installation

Figure 14 CSA Installation © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 41... -

Page 42: Atex Installation

Figure 15 ATEX Installation © 2015 General Electric Company. All rights reserved 42 | =GE Oil & Gas... -

Page 43: Split Range Operation

Lobe Selection and Lever Arm Orientation” on page 65. NOTE With this configuration, the voltage burden of the 4-20 mA controller is 10 V instead of 5 V. Figure 16 Split Range © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 43... -

Page 44: Mounting Cam Coupling

The relative position of the lever S/A (3) for a selected cam lobe must be correct. The lever S/A can be mounted with its pivot post to the left or right of the cam center. © 2015 General Electric Company. All rights reserved 44 | =GE Oil & Gas... -

Page 45: Changing Lever S/A Orientation

S/A (3) on spring end 180° to desired position. (Do not rotate spring end; socket head screw on spring must face outward.) Replace flat washer (16) and retaining ring (17) on pivot post. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 45... - Page 46 This page intentionally left blank.

-

Page 47: Calibration

(low end of range). Refer to calibration instruction for proper valve action and positioner action before removing or replacing cam and tightening set screws (35) to proper torque. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 47... -

Page 48: Zero Adjustment

When installing positioner with cam in place, check the position of the spring (5) on diaphragm S/A (9) to ensure that it is centered on the diaphragm. © 2015 General Electric Company. All rights reserved 48 | =GE Oil & Gas... -

Page 49: Cam Lobe Change

3. With cam at low signal line remove screw (28) and washer (27). Note the relative position of the cam lobe being changed and then remove the cam (26). © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 49... -

Page 50: Air To Close / Direct Acting Positioner

Connect supply pressure and signal to positioner. Check zero and span adjustment. Refer to “Zero Adjustment” on page 48 and “Span Adjustment” on page 48. © 2015 General Electric Company. All rights reserved 50 | =GE Oil & Gas... -

Page 51: Field Mounting And Complete Calibration, Rotary Actuators

(Handwheel may be used to open the valve in place of regulated air line.) Align the travel indicator with the open end of travel scale. Do not over travel. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 51... -

Page 52: Air To Close / Direct Acting Positioner

(i.e., 3 psig for a 3-15 psig range 4700P/4800P; 4 mA for 4-20 mA 4700E/4800E). Adjust zero and span. Refer to “Zero Adjustment” on page 48 and “Span Adjustment” on page 48. © 2015 General Electric Company. All rights reserved 52 | =GE Oil & Gas... -

Page 53: Air To Close / Reverse Acting Positioner

10. Adjust signal to low end of signal (i.e., 3 psig for a 3-15 psig range 4700P/4800P). Adjust zero and span. Refer to “Zero Adjustment” on page 48 and “Span Adjustment” on page 48. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 53... -

Page 54: Field Mounting And Complete Calibration Reciprocating Valves Using 87/88

Cam will now be at high signal line. 4. Disconnect the independent regulated air line and connect the positioner output line to the actuator. Connect supply pressure and signal to the positioner. © 2015 General Electric Company. All rights reserved 54 | =GE Oil & Gas... -

Page 55: Air To Close / Direct Acting Positioner

Adjustment” on page 48 until travel range is correct. After adjustments are satisfactory, re-tighten the spring locking screw (8), zero locknut (4C), and turnbuckle locknut (107). © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 55... -

Page 56: Air To Close/Reverse Acting Positioner (4700P/4800P Only)

Turn clockwise until desired stability is obtained. CAUTION Screw must never be backed out further than top flush with housing. © 2015 General Electric Company. All rights reserved 56 | =GE Oil & Gas... -

Page 57: Positioner Action Change (4700P/4800P Only)

3. Proceed to Field Mounting and Calibration section for Air to Close/Direct Acting Positioner and proceed as stated. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 57... -

Page 58: Maintenance

3. Install the spring in the pilot spool. The end having the smallest diameter must be in contact with the plug. Screw the pilot end plug into the pilot spool. 4. Install the pilot subassembly (11) into the body (1). © 2015 General Electric Company. All rights reserved 58 | =GE Oil & Gas... -

Page 59: Body

Carefully reassemble O-rings into grooves. Make sure they are seated in bottom of groove. CAUTION Do not use any lubrication on O-rings or base. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 59... -

Page 60: Reassembly

Remove positioner from valve if module mounting screws are not accessible. Remove and replace module as outlined under “Disassembly” on page 59. NOTE There are no adjustments in the I/P module. © 2015 General Electric Company. All rights reserved 60 | =GE Oil & Gas... -

Page 61: Bypass Valve Option (4700P Only)

(45), making sure they are seated in the bottom of the recess. 4. Assemble to positioner using four 8-32 x 1.25" long screws (21). 5. Reinstall vent plug, instrument gauge, and air connections. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 61... -

Page 62: Disassembly

Krytox or other silicone-compatible lubricant. Replace valve in block and secure with retaining ring (49). 3. . Reassemble bypass module to positioner. Figure 18 Pilot Subassembly © 2015 General Electric Company. All rights reserved 62 | =GE Oil & Gas... -

Page 63: Troubleshooting

Foreign matter such as dirt, metal particles, etc. b. Partial blockage of air passages caused by too much oil in the air lines. c. Blocking of vent holes. © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 63... -

Page 64: Split Range Operation - 4700P/4800P

Valve Plug Position Valve Plug Position (3-9 psig) (9-15 psig) Full Open Full Open Half Open Full Open Closed Full Open Closed Half Open 1034 Closed Closed © 2015 General Electric Company. All rights reserved 64 | =GE Oil & Gas... -

Page 65: Cam Lobe Selection And Lever Arm Orientation

Cam Lobe Selection and Lever Arm Orientation © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 65... - Page 66 © 2015 General Electric Company. All rights reserved 66 | =GE Oil & Gas...

- Page 67 © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 67...

-

Page 68: Parts Reference 4700P/4800P 3-15 And 6-30 Range

Parts Reference 4700P/4800P 3-15 and 6-30 Range Figure 19 4700P/4800P 3-15 and 6-30 Ranges © 2015 General Electric Company. All rights reserved 68 | =GE Oil & Gas... -

Page 69: Parts Reference 4700P/4800P 3-15 And 6-30 Range

Cap Screw Pilot S/A Lockwasher Supply Gauge Washer Output Gauge Post Hub Instrument Gauge Input Shaft Screw, Washer Head Washer Retaining Clip Cover, Case © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 69... - Page 70 Table 5: Parts Reference 4700P/4800P 3-15 and 6-30 Range (Continued) (Continued) Ref. No. Description Ref. No. Description Vent Plug Screw, Sealing, Set 5/16-24 x .5 © 2015 General Electric Company. All rights reserved 70 | =GE Oil & Gas...

-

Page 71: Parts Reference 4700E/4800E

Parts Reference 4700E/4800E Figure 20 4700E/4800E © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 71... -

Page 72: Parts Reference 4700E/4800E

Pilot S/A Lockwasher Supply Gauge Washer Output Gauge Post Hub Input Shaft Plug, Pipe 1/4" NPT Washer I/P Module Assembly Retaining Clip Cover, Case Vent Plug © 2015 General Electric Company. All rights reserved 72 | =GE Oil & Gas... -

Page 73: Parts Reference

O-ring 2.38" ID Breather Parts Reference Ref.No. Description Vent Plug Screw 8-32 x 1.25 SEMS Bypass S/A O-ring O-ring Valve, Bypass Ring, Retaining O-ring © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 73... -

Page 74: Bypass Option (4700 Only)

Figure 21 Bypass Option (4700 Only) © 2015 General Electric Company. All rights reserved 74 | =GE Oil & Gas... -

Page 75: Specification Data

Electrical: 1/2" NPT or M20 4700P: 3.5 lbs (1.6 kg); 4800P: 4.2 lbs (1.9 kg) Weight 4700E: 4.7 lbs (2.1 kg); 4800E: 5.3 lbs (2.4 kg) © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 75... - Page 76 Sensitivity Better than 0.2% of span Better than 0.3% of span Conformity +1% of span +1% of span Input Resistance 170 Ohms nominal 4-20 mA signal © 2015 General Electric Company. All rights reserved 76 | =GE Oil & Gas...

-

Page 77: Drawings

Drawings Figure 22 Positioner and Cast Body Assembly © 2015 General Electric Company. All rights reserved Masoneilan 4700P/E & 4800P/E Positioners Manual =| 77... - Page 78 This page intentionally left blank.

- Page 80 DIRECT SALES OFFICE LOCATIONS AUSTRALIA ITALY SOUTH AFRICA Brisbane Phone:++39-081-7892-111 Phone:++27-11-452-1550 Phone:++61-7-3001-4319 Fax:++++39-081-7892-208 Fax:++++27-11-452-6542 Fax:++++61-7-3001-4399 Perth JAPAN SOUTH & CENTRAL Phone:++61-8-6595-7018 Chiba AMERICA AND THE CARIBBEAN Fax:++++61-8-6595-7299 Phone:++81-43-297-9222 Phone:++55-12-2134-1201 Fax:++++81-43-299-1115 Fax:++++55-12-2134-1238 Melbourne KOREA SPAIN Phone:++61-3-8807-6002 Phone:++82-2-2274-0748 Phone:++34-93-652-6430 Fax:++++61-3-8807-6577 Fax:++++82-2-2274-0794 Fax:++++34-93-652-6444 BELGIUM MALAYSIA UNITED ARAB EMIRATES...