Summary of Contents for Global-Tek GT-CR1/BU

- Page 1 Global-Tek (Singapore) Pte Ltd Single-Tank Conveyor Type Dish Washing Machine Model - GT-CR1/BU Instruction & Installation Manual Page 1...

-

Page 2: Table Of Contents

Global-Tek (Singapore) Pte Ltd CONTENTS GENERAL……………………………..…………….. Technical Data..…………………….………….…….. Standard Equipment……..………………..………… INSTALLATION……………………..………………. Unpacking…………………………………………….. Assembly………..……………………………….…… Plumbing Connections……………..…………….…. Drain Connections………………………..…….…… Fill Connection……………………………..…..…….. 9-10 ELECTRICAL CONNECTIONS…..…….………… OPERATION………….……………………………… Preparation………………………………..…………. Operating The Machine………..…………………… 11-12 CLEANING………….………………………………. MAINTIANANCE……..….………………………….. 15-17 TROUBLESHOOTING……………………………... CIRCUIT DIAGRAMS………………………………. 18-20 Page 2... -

Page 3: General

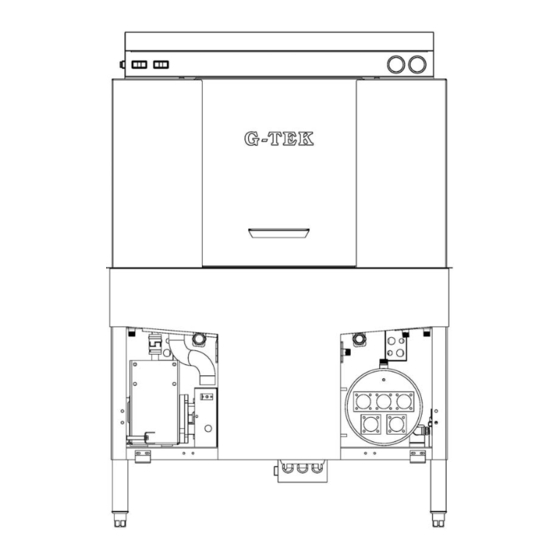

Global-Tek (Singapore) Pte Ltd Model : GT-CR-1/BU GENERAL GT-CR1/BU dishwasher is a fully automatic, rack-type single-tank conveyor machine. It has a stainless tank and chamber with welded stainless steel angle frame, stainless steel legs, and stainless steel adjustable feet. Front inspection door provide ready access to the interior of the wash chambers. -

Page 4: Standard Equipment

Global-Tek (Singapore) Pte Ltd STANDARD EQUIPMENT The control panel and booster are mounted on the top of the chamber. There are three operational control switches housed in the control panel : POWER -OFF ); MOTOR (START -STOP );and TIMER (MANUAL -AUTO Mechanical thermostat for wash is located outside the tank, rinse thermostats are located inside the control panel. - Page 5 Global-Tek (Singapore) Pte Ltd Booster Protection The booster water temperature is regulated by the thermostats to keep the rinse water temperature between 82-95 ℃ . Thermostats are preset at the factory and no adjustment is needed. If necessary, contact your local authorized service office.

-

Page 6: Installation

Global-Tek (Singapore) Pte Ltd Auto Fill Close door and push the POWER switch to ON. The machine fills automatically from two different areas, final rinse & fill valve. Water is heated in booster, and then flows into wash tank. After the tank is filled with required level, fill will stop automatically. -

Page 7: Assembly

Global-Tek (Singapore) Pte Ltd After unpacking the dishwasher, remove the items shipped uninstalled (overflow tube, pump intake strainer, curtains, and chamber hole plug kit) and instruction manual inside the machine. Set the dishwasher in its proper location. Adjust the height and level by turning the adjustable feet. NOTE: The dishwasher must be positioned and leveled before making plumbing connections. -

Page 8: Electrical Connections

Global-Tek (Singapore) Pte Ltd WARNING: Do not operate the machine when flowing pressure is under 1.0 kg/cm Low pressure may result in inadequate rinsing. The water fill connection must be 65 ℃ maximum and flow pressure should not exceed 16kg/cm , otherwise, the pressure regulator valve will be damaged. -

Page 9: Operation

Global-Tek (Singapore) Pte Ltd If the impeller does not rotate in the direction of the arrow, DISCONNECT POWER SUPPLY to the machine and interchange any two power supply leads at the control box terminal block. Or machine with a circuit breaker, reverse any two leads at the incoming power supply block in the circuit breaker (three-phase only). -

Page 10: Operating The Machine

Global-Tek (Singapore) Pte Ltd Scatter the initial charge of detergent on the dishwasher strainer pans. Replenish as needed. When an automatic detergent dispenser has been added (by private supplier), follow supplier’s instructions. Operating The Machine After machine has filled, start pumps by pushing MOTOR switch to ON. - Page 11 Global-Tek (Singapore) Pte Ltd 5. Remove wash arms. Thoroughly flush the wash arm in a sink and replace the wash arm end caps(a twisting action helps ensure proper seating). 6. Clean off any scraps from machine walls. 7. Remove all strainer pans and strainer basket(s). Empty contents into garbage can or disposer and thoroughly clean pans and basket(s).

-

Page 12: Troubleshooting

Global-Tek (Singapore) Pte Ltd TROUBLESHOOTING NOTE: if symptom persists after possible causes have been checked, contact your authorized service office. SYMPTOM POSSIBLE CAUSES No Machine Operation 1. Blow fuse or tripped circuit breaker at power supply. 2. Conveyor may be jammed. - Page 13 Global-Tek (Singapore) Pte Ltd Inadequate Rinse 1. Dirty line strainer causing reduced water flow. Turn off water supply, remove strainer cap, withdraw and clean screen. Reassemble. 2. Low supply pipeline line pressure. 3. Clogged rinse nozzle(s). Spotting of Silverware, 1. Improperly loaded racks.

- Page 14 Global-Tek (Singapore) Pte Ltd No or Slow Fill 1.Dirty line strainer (not included in the machine) causing reduced water flow. Turn off water supply, remove strainer cap, withdraw and clean screen. Reassemble. 1. Make sure doors are closed. 2. Check interlock switch.

- Page 15 Global-Tek (Singapore) Pte Ltd Page 15...

- Page 16 Global-Tek (Singapore) Pte Ltd Page 16...

- Page 17 Global-Tek (Singapore) Pte Ltd Page 17...