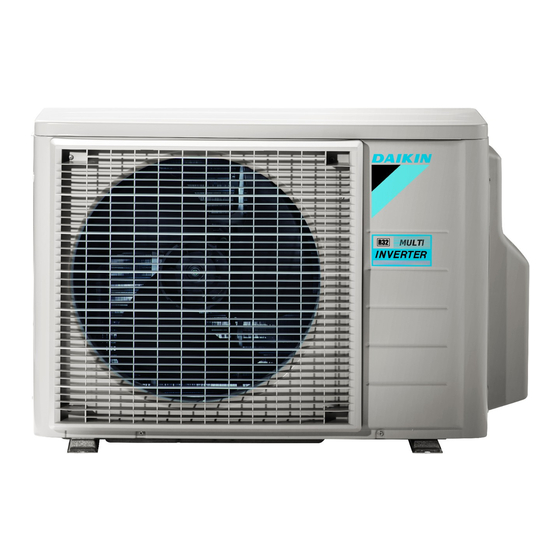

Daikin 2MXM68N2V1B Installation Manual

R32 split series

Hide thumbs

Also See for 2MXM68N2V1B:

- Installation manual (28 pages) ,

- Installer's reference manual (84 pages) ,

- Installer's reference manual (84 pages)

Table of Contents

Summary of Contents for Daikin 2MXM68N2V1B

- Page 1 Installation manual R32 Split series 2MXM68N2V1B 3MXM40N2V1B9 3MXM40N2V1B8 3MXM40N2V1B7 3MXM52N2V1B9 3MXM52N2V1B8 3MXM52N2V1B7 3MXM68N2V1B9 3AMXM52N2V1B9 3AMXF52A2V1B9 3MXF52A2V1B9 3MXF68A2V1B9 4MXM68N2V1B9 Installation manual 4MXM80N2V1B9 English R32 Split series 5MXM90N2V1B9...

- Page 2 2P427092-20V...

- Page 3 2P427092-20V...

- Page 4 2P630134-1...

- Page 5 2P630134-1...

- Page 6 2P630134-4...

- Page 7 2P630134-4...

- Page 8 2P630134-6C...

- Page 9 2P630134-6C...

-

Page 10: Table Of Contents

▪ A subset of the latest technical data is available on the regional 9.5.1 To turn on cool mode lock........... 21 Daikin website (publicly accessible). 10 Commissioning ▪ The full set of latest technical data is available on the Daikin 10.1 Checklist before commissioning..........21 Business Portal (authentication required). 10.2 Checklist during commissioning .......... - Page 11 2 Specific installer safety instructions Unit installation (see "4 Unit installation" [ 4 12]) CAUTION ▪ Incomplete flaring may cause refrigerant gas leakage. WARNING ▪ Do NOT re-use flares. Use new flares to prevent Installation shall be done by an installer, the choice of refrigerant gas leakage.

-

Page 12: About The Box

3 About the box Multilingual fluorinated greenhouse gases label WARNING Drain socket If the supply cord is damaged, it MUST be replaced by the Screw bag. The screws will be used for fixing the electrical wire anchor bands. manufacturer, its service agent or similarly qualified Drain cap (small) persons in order to avoid a hazard. -

Page 13: Additional Installation Site Requirements Of The Outdoor Unit In Cold Climates

4 Unit installation INFORMATION The sound pressure level is less than 70 dBA. The outdoor unit is designed for outdoor installation only, and for ambient temperatures within the following ranges (unless otherwise specified in the operation manual of the connected indoor unit): Cooling mode Heating mode –10~46°C DB... -

Page 14: Piping Installation

5 Piping installation 2 Install the drain socket. Depending on the applicable legislation and the maximum working pressure of the unit (see "PS High" on the unit name plate), larger piping thickness might be required. Usage of reducers might be required based on the indoor unit. See "5.2.1 ... -

Page 15: Connecting The Refrigerant Piping

5 Piping installation Outdoor unit Refrigerant piping Refrigerant piping Outdoor unit Total indoor unit capacity length to each indoor total length class unit 3MXM52, 3AMXM52, 3MXF52, ≤9.0 kW 2MXM68, ≤25 m ≤50 m 3AMXF52 3MXM40, 3MXM68, 4MXM68, 3MXF68 ≤11.0 kW 3MXM52, 4MXM80 ≤14.5 kW 3AMXM52, 5MXM90 ≤15.6 kW 3MXM68,... -

Page 16: To Connect The Refrigerant Piping To The Outdoor Unit

5 Piping installation Reducer type Connection WARNING Ø12.7 mm → Ø9.5 mm Connect the refrigerant piping securely before running the compressor. If the refrigerant piping is NOT connected and Ø15.9 mm → Ø9.5 mm the stop valve is open when the compressor is run, air will Ø15.9 mm →... -

Page 17: Charging Refrigerant

6 Charging refrigerant If the pressure… Then… WARNING Does not change There is no moisture in the The refrigerant inside the unit is mildly flammable, but system. This procedure is normally does NOT leak. If the refrigerant leaks in the finished. -

Page 18: To Fix The Fluorinated Greenhouse Gases Label

7 Electrical installation Prerequisite: Before charging refrigerant, make sure the refrigerant WARNING piping is connected and checked (leak test and vacuum drying). ▪ Do NOT use locally purchased electrical parts inside 1 Connect the refrigerant cylinder to the service port. the product. -

Page 19: To Connect The Electrical Wiring To The Outdoor Unit

8 Finishing the outdoor unit installation Model 3MXM40 3- core cable 2.5 mm 16 A 2MXM68, 20 A H05RN-F (60245 IEC 57) 3AMXM52, H07RN-F (60245 IEC 66) 3AMXF52, 3MXF52, 3- core cable 4.0 mm 3MXM52, H07RN-F (60245 IEC 66) 1 2 3 3MXF68, 3MXM68, 4MXM68 4MXM80 3- core cable 4.0 mm... -

Page 20: To Turn On Standby Electricity Saving Function

9 Configuration ▪ turns ON the standby electricity saving mode on the indoor unit. The standby electricity saving function works with following units: 1× 3MXM40, 3MXM52, 3AMXM52 FTXM, FTXP, FTXJ, FVXM If another indoor unit is used, the connector for standby electric saving must be plugged in. -

Page 21: About Cool Mode Lock

General commissioning checklist. Next commissioning instructions in this chapter, a general commissioning checklist is also available on the Daikin 10.3 Trial operation and testing Business Portal (authentication required). The general commissioning checklist is complementary to For the Hybrid for Multi, certain precautions are required before the instructions in this chapter and can be used as a using this function. -

Page 22: To Perform A Test Run

▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). Status of LEDs: ▪ The full set of latest technical data is available on the Daikin ▪ All LEDs flash: automatic correction is NOT possible. Business Portal (authentication required). -

Page 23: Piping Diagram: Outdoor Unit

12 Technical data Symbol Meaning Symbol Meaning Symbol Meaning Earth Relay connector PCB* Printed circuit board Power module Field wiring Short-circuit connector Switching power supply Fuse Terminal PTC* PTC thermistor Indoor unit Terminal strip Insulated gate bipolar transistor INDOOR (IGBT) Outdoor unit Wire clamp Circuit breaker... - Page 24 12 Technical data 2MXM68 7.9CuT 7.9CuT 6.4CuT 7.9CuT (6.4CuT) 7.9CuT 12.7CuT 7.9CuT 7.9CuT 6.4CuT 9.5CuT (6.4CuT) 7.9CuT 9.5CuT 6.4CuT Solenoid valve 9.5CuT 9.5CuT 9.5CuT 12.7CuT 12.7CuT 15.9CuT 12.7CuT 15.9CuT 9.5CuT 12.7CuT (9.5CuT) 9.5CuT 12.7CuT (12.7CuT) 15.9CuT 12.7CuT Heat exchanger 4-way valve Thermistor (gas) Outdoor air temperature Muffler...

- Page 25 12 Technical data 3MXM40, 3MXM52, 3AMXM52, 3AMXF52, 3MXF52 7.9CuT 7.9CuT 6.4CuT 7.9CuT (6.4CuT) 7.9CuT 12.7CuT 7.9CuT 7.9CuT 6.4CuT 9.5CuT (6.4CuT) 7.9CuT 9.5CuT 7.9CuT 6.4CuT 9.5CuT (6.4CuT) 12.7CuT 9.5CuT 12.7CuT 15.9CuT 12.7CuT (9.5CuT) 9.5CuT 12.7CuT (12.7CuT) 12.7CuT (12.7CuT) 15.9CuT 12.7CuT 3MXM68, 3MXF68 7.9CuT 7.9CuT 6.4CuT...

- Page 26 12 Technical data 4MXM68 7.9CuT 7.9CuT 6.4CuT (6.4CuT) 7.9CuT 7.9CuT 12.7CuT 7.9CuT 7.9CuT 6.4CuT 9.5CuT (6.4CuT) 7.9CuT 9.5CuT 7.9CuT 6.4CuT (6.4CuT) 7.9CuT 6.4CuT 6.4CuT 9.5CuT (6.4CuT) 9.5CuT 9.5CuT 12.7CuT 12.7CuT 15.9CuT 12.7CuT 15.9CuT 9.5CuT 12.7CuT (9.5CuT) 9.5CuT 12.7CuT (9.5CuT) 12.7CuT (12.7CuT) 15.9CuT 12.7CuT...

- Page 27 12 Technical data 5MXM90 7.9CuT 7.9CuT 7.9CuT 6.4CuT 9.5CuT (6.4CuT) 7.9CuT 9.5CuT 7.9CuT 6.4CuT 7.9CuT (6.4CuT) 7.9CuT 12.7CuT 7.9CuT 7.9CuT 7.9CuT 6.4CuT 9.5CuT 7.9CuT (6.4CuT) 9.5CuT 7.9CuT 7.9CuT 7.9CuT 6.4CuT 6.4CuT 9.5CuT (6.4CuT) 9.5CuT 7.9CuT 6.4CuT (6.4CuT) 9.5CuT 12.7CuT 12.7CuT 15.9CuT 12.7CuT 15.9CuT...

- Page 28 3P600450-1G 2021.03 Verantwortung für Energie und Umwelt...