Summary of Contents for METROTEC GSM Series

- Page 1 METROTEC S y st ems fo r o xy g en mea su re men t GSM-touch Oxygen Measuring and Control Device Typ GSM Series *** Version 2.2 ***...

- Page 2 Quality management system DIN EN ISO 9001:2015, No. 12 100 27736 TMS This declaration becomes invalid if changes are made without our consent. Kirchheim/Teck, 07/10/2019 Place, Date Signature © 2019 METROTEC GmbH Heinkelstraße 12 • D-73230 Kirchheim Telefon 07021/95336-0 • Fax 07021/95336-13 www.metrotec.eu • [email protected]...

-

Page 3: Table Of Contents

METROTEC Contents Level “2” ........ 23 SAFETY INSTRUCTIONS ... 4 Level “3” ........ 23 PREFACE ........5 Menu Structure ....... 24 INTRODUCTION ......7 CONFIGURATION ..... 31 Measurement principle ..... 7 Enabling Configuration ... 32 Measuring Electronics ....8 Correcting the Measured Value Sensor ........ -

Page 4: Safety Instructions

METROTEC Safety instructions Please read through this operating manual very carefully before & installing and commissioning the unit. Incorrect utilisation will invalidate the guarantee! Correct functioning and the operating safety of the unit can only be guaranteed if the ambient conditions specified in the Specifications chapter are maintained. -

Page 5: Preface

METROTEC Preface With the aid of an oxygen sensor , the measurement unit serves to measure the oxygen partial pressure in gaseous atmospheres. Such sensors work at high temperatures and so it is necessary for measures to be taken to ensure that no flammable gas mixtures contact the sensor or the unit. - Page 6 METROTEC...

-

Page 7: Introduction

METROTEC Introduction Measurement principle Oxygen measurement units are designed to process signals transmitted from an oxygen sensor constructed of stabilized zirconium oxide. Zirconium oxide, a ceramic material that is also spoken of as a solid-state electrolyte, acts as an excellent oxygen-ion conductor when at a high temperature. -

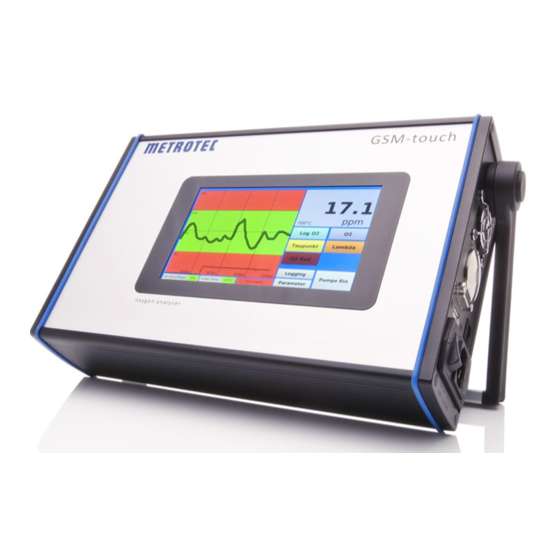

Page 8: Measuring Electronics

METROTEC Measuring Electronics The electronic system of the GSM measuring device features the following functions: Measurement of the partial pressure of oxygen Generation of alarms Calculation of the dew point Calculation of the Lambda air factor The measuring device is operated through the touch screen. -

Page 9: Description Of The Sensor

METROTEC Graphic display Reading Unit Alarm band Selection of measuring values Pump ON-OFF Footer Begin recording Open menu Status information measuring values Description of the Sensor After switching on the power supply, the sensor will be heated up to its measuring temperature within 10 –... -

Page 10: Drawing Of Cable Routing

METROTEC Drawing of Cable Routing... -

Page 11: Device Start-Up

METROTEC Device Start-up Switching the Measuring Device on After connecting the power cable, the device can be switched on by pressing the power switch. The display lights up briefly. After ca. 15 seconds system start information will show up, depending on the setup, and after the boot routine the standard screen of the measuring device will appear. -

Page 12: Measurement

METROTEC After heating up, the measuring unit shows the measured oxygen content. The status field reads: “Ready”, with the box lit up in green. A stable measuring value will only be achieved ca. 15 minutes after heating up has finished. -

Page 13: Flow

METROTEC 5.2.2 Flow In order to examine sample gases, these will need to be directed into the measuring instrument. In case the sample gas source is pressurized, for example a gas bottle, the gas flow must be reduced to an appropriate level by means of a pressure reducer. - Page 14 METROTEC The pump performance setting can be adjusted in the “Parameter” menu. Touch field After actuating the button “Parameter”, the Level 1 menu selection for which no CODE has to be entered will open. After pressing the line “008 Pump speed” the “ENTER” is activated.

-

Page 15: Bottled Gases

METROTEC The value can be entered numerically or can be incremented or decremented by means of the arrow keys. The button “Save” will store the value and at the same time initiate a jump to the previous menu page. To go back to the main menu, press the “Exit” button. -

Page 16: Specific Information

METROTEC 5.4.4 Specific Information In case a condensate separator is used, it must be ensured that the collecting tank is placed at the lowest point of the entire line system, particularly in the case of water. The dead volume of condensate tanks and filters will likely cause a delay in the measuring process. - Page 17 METROTEC Selection of the value to be displayed can be accomplished by pressing the respective button. The measured oxygen value will be displayed in percent and changes its unit automatically into ppm (parts per million), when the measured value is below 0.1 %.

-

Page 18: Log O2

METROTEC Log O2 The display can take on values between 0.0 und –30.0. The value shown is the logarithm of the oxygen partial pressure. Displaying the logarithmic value permits values up to many powers of ten to be shown as a number consisting of only a few characters. -

Page 19: Dew Point

METROTEC Dew Point Some measuring tasks require a result given as the dew point temperature. This is often the case with nitrogen/hydrogen mixtures. Here the measured O value will be converted into a dew point if the exact hydrogen proportion is known. Therefore it is mandatory to input the H proportion into menu line 26. -

Page 20: O 2 Red (O 2 In H 2 )

METROTEC Example of a display with trend in the range between 0 – 10 Red (O in H In order to obtain the oxygen value in a mixture which may for example consist of nitrogen and hydrogen, the oxygen partial pressure can be used to calculate this value based on the hydrogen proportion. -

Page 21: Parameterisation

METROTEC Parameterisation The parameter level can be reached from the main screen. Touch area LEVEL “0” will open, for which no CODE is required. Line 002,003, 004, 005 006 or 008 is selectable. -

Page 22: Level "0

METROTEC In order to enable access level 1, the CODE for LEVEL “1” must be entered. The code is “1234” as defined by the manufacturer (can be changed by the operator). After pressing the Save button, one of the following pages will appear, depending on the desired LEVEL “1”... -

Page 23: Level "1

METROTEC Level “1” Access for this level is: · General settings · Pump · Graphs · Gas constants · Alarms · Analog Outputs · Logging · Date and Time Level “2” Access for this level is: · General settings · Pump ·... -

Page 24: Menu Structure

METROTEC Menu Structure 001 General Settings Menu line, Menu title, [actual value] Access code Access without CODE Menu Line Comment Language Change to other language Screen brightness Multiple level brightness setting 004- Enable Level 1 access Entry of required CODE... - Page 25 METROTEC 007 Graphs Menu line, Menu title, [actual value] Access code Access with CODE = 1234 Menu Line Comment 10-12 O trend graphic Settings are only active if this measured value was selected Definition: 1,000 ppm = 0.1 % 10,000 ppm = 1 %...

- Page 26 METROTEC 025 Gas constants Menu line, Menu title, [actual value] Access code Only required for mathematical functions Access with CODE = 1234 Menu Line Comment Input value Measured e.g. by hydrogen analyser Input value Calculated from hydro carbons 028 Alarms...

- Page 27 METROTEC Menu Line Comment Acoustic alarm This setting is valid for all alarms (yes/no) 030- alarm Alarm will only be triggered if it has been activated. In this case the conditions and limits entered for this block are valid. 034-...

- Page 28 METROTEC 060 Analog Output Menu line, Menu title, [actual value] Access code Access with CODE = 1234 Menu Line Comment Switch 0-20/4-20mA This setting is valid for all analog outputs Output 1: Selection This setting connects the selected measured value (O...

- Page 29 METROTEC Dew point max. in degree This setting will be connected with menu no. Celsius 62/63, if “Dew point” was selected there. Lambda minimum This setting will be connected with menu no. 62/63, if “Lambda” was selected there. Lambda maximum This setting will be connected with menu no.

- Page 30 METROTEC 076 Measured value correction Menu line, Menu title, [actual value] Access code Detailed explanation found in “Corrections of Measured Value” Access with CODE = 5678 Menu Line Comment >21% oxygen: correction If measured values between 21 and 100 % O...

-

Page 31: Configuration

METROTEC programmed. Warning!! If this password is lost it can only be read by the manufacturer. Password Password for enabling Level 2. Important entries are protected from unauthorized changes by hiding secured menus. They can only be called up after entering the password (see “Enabling Configuration”). -

Page 32: Enabling Configuration

METROTEC Enabling Configuration 1. Select level 2. touch ENTER 1. Input CODE 2. Store... -

Page 33: Correcting The Measured Value

METROTEC Correcting the Measured Value The current measured value can be corrected, as required. In this case it is advisable to make the adjustment after a stable measurement has been achieved and possible errors in measurement can be ruled out. -

Page 34: Setting The Alarms

METROTEC Notes on the correction: The additive value will be used to adjust the display to 20.9 % when correcting § the oxygen. For this purpose the sample gas input will be kept open when the sample gas § pump is switched on so that ambient air will be sucked in. The result of the correction is shown on the right half of the display. -

Page 35: Calculating The Dew Point

METROTEC Calculating the Dew Point The dew point will be calculated based on the measured oxygen partial Ø pressure and knowing the hydrogen proportion in the gas mixture. The hydrogen proportion must be entered in percent. (See menu line No. 26.) - Page 36 METROTEC Note: All values will stored locally on GSM-touch. File name is: “GSM_Touch_log.txt” For Data Logging a storage medium must first be connected to the designated USB socket. Then the “Logging” button must be pressed.

-

Page 37: Closing The Data Logging

METROTEC Note: Data will be stored on USB-stick “NAME” ( in this example the NAME is STORENGO). The filename is created by date and time at the moment of plug in. When touched “START” information of current status is displayed, such as interval (time period), record number and timer. -

Page 38: Data File

METROTEC Data File The data set can be read out from the USB stick and further processed, for example with Microsoft EXCEL. Example of a data recording The individual parts of information are separated by semicolons as delimiters. -

Page 39: Network

METROTEC 10 Network 10.1 Setting up an Ethernet Network Warning: Operating on the WINDOWS platform requires special knowledge and may only be performed by trained personnel. A cable connection between GSM-touch an the network router is needed. Now the Windows data explorer must be opened and “NETWORK” clicked blck. Then input in the search field \\gsmtouch. -

Page 40: Interfaces

METROTEC Data of file “GSM_Touch_log” are now accessable 11 Interfaces 11.1 Analog Interfaces There are 2 analog 0/4-20 mA interfaces. These can be used at the same time. 11.2 Digital Interfaces Relay for minimum limit Relay for maximum limit Relay for collective alarm... -

Page 41: Connection Diagram

METROTEC 11.3 Connection Diagram Digital Analog Collective alarm Collective alarm Alarm min-max Alarm max Alarm min mA Output 1 “plus” mA Output 1 “minus” mA Output 2 “plus” mA Output 2 “minus” Note: Digital outputs are floating relay contacts (1A, 24V) -

Page 42: Specifications

METROTEC 12 Specifications Measuring range 100 % to 10 bar O Ambient temperature 0 to 45 degrees Celsius Measuring accuracy +/- 0.3 mV of the sensor e.m.f. +/- 2 degrees Celsius +/- 2% of the mA output +/- 2% of the log oxygen partial pressure...