Summary of Contents for Bosch Rexroth A10VG

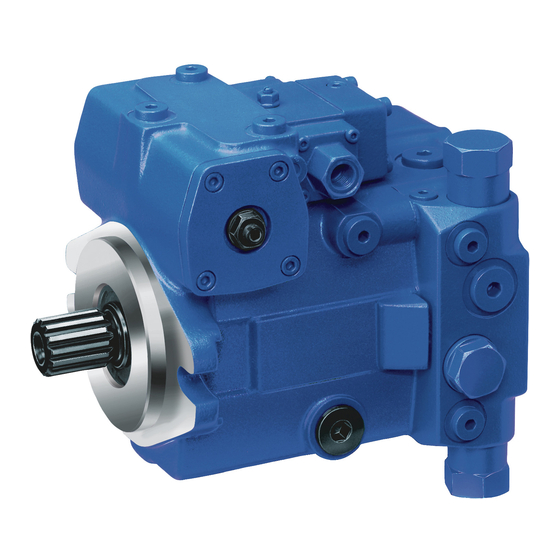

- Page 1 Axial piston variable pump A10VG Series 10 Instruction manual Replaces: 02.10 RE 92750-01-B/06.2018 English...

- Page 2 © Bosch Rexroth AG 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. The data specified within only serves to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from our information.

-

Page 3: Table Of Contents

Above-reservoir installation Installing the axial piston unit 7.4.1 Preparation 7.4.2 Dimensions 7.4.3 General instructions 7.4.4 Installation with a coupling 7.4.5 Installation on a gearbox 7.4.6 Installation with cardan shaft 7.4.7 Completing installation RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... - Page 4 11.2 Preparing for removal 11.3 Removal 11.4 Preparing components for storage or further use Disposal Extension and conversion Troubleshooting 14.1 How to proceed for troubleshooting 14.2 Malfunction table Technical data Alphabetical index Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 5: About This Documentation

BODAS-drive eDA application software 95315 Data sheet BODAS-drive eDA is a software solution integrated in the Rexroth SRC-eDA1/31 control unit for controlling the hydrostatic drive train in wheeled vehicles. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 6: Representation Of Information

Identifies a dangerous situation that may result in minor to CAUTIOn moderate injury if it is not avoided. NOTICE Property damage: The product or surrounding area may be damaged. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 7: Symbols

Metal screw, pressure-resistant Protective plug Made out of plastic, not pressure-resistant, only for transportation As umbrella term for “axial piston variable pump A10VG” the designation “axial piston unit” will be used in the following. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 8: Abbreviations

International Organization for Standardization Rexroth document in the English language VDI 2230 Standard for the systematic calculation of heavy-duty threaded connections and cylindrical screw joints from the VDI (Verein Deutscher Ingenieure - Association of German Engineers) Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 9: Safety Instructions

2.3 Improper use Any use other than that described as intended use is considered improper. Bosch Rexroth AG is not liable for damages resulting from improper use. The user is solely responsible for any risks arising from improper use. The following foreseeable misuses are also considered improper (this list is not exhaustive): •... -

Page 10: Personnel Qualifications

• In particular, fully understanding the relationships with regard to safety devices • Understanding how hydraulic components work and are put together. Bosch Rexroth offers training support for specialized fields. An overview of the training contents can be found online at: www.boschrexroth.com/training. -

Page 11: General Safety Instructions

(e.g. PWM signal). The machine manufacturer should conduct appropriate tests and take appropriate measures to ensure that other components or operators (e.g. with a pacemaker) are not affected by this potentiality. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 12: Product-Specific Safety Instructions

Operating the unit above the max. permissible pressure can cause components to burst and hydraulic fluid to escape under high pressure. ▶ Changes to the factory settings should only be made by Bosch Rexroth specialists. ▶ In addition, a pressure relief valve is required in the hydraulic system as a back- up. - Page 13 Check whether your application requires remedial measures on your machine in order to bring the driven consumer to a safe position (e.g., safe stop). ▶ If necessary, make sure these are properly implemented. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 14 Risk of slipping! Risk of slipping on wet surfaces when climbing on the axial piston unit. ▶ Never grab or climb onto the axial piston unit. ▶ Check how to safely get on top of the machine/system. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 15: Personal Protective Equipment

2.7 Personal protective equipment Personal protective equipment is the responsibility of the user of the axial piston unit. Observe the safety regulations in your country. All pieces of personal protective equipment should be intact. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 16: General Notices Regarding Property And Product Damage

Before installation, remove all fluids from the axial piston unit to prevent mixing with the hydraulic fluid used in the machine/system. ▶ Never mix hydraulic fluids from different manufacturers or different types from the same manufacturer. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... - Page 17 Hydraulic fluid can escape if leaks occur. ▶ Take appropriate steps to protect the axial piston unit from chemical or corrosive environmental conditions. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 18 The warranty only applies to the machine as delivered. The warranty will be voided if the product is incorrectly installed, commissioned or operated, or if it is used or handled improperly. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 19: Scope Of Delivery

The following parts come assembled on the unit: • Protective covers (1) • Protective plug/threaded plugs (2) • Connector protective covers (3) • For version with through drive, protective cover and mounting bolts (4) RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 20: About This Product

3 Stroking piston 6 Low-pressure side 12 Piston 4 Control unit 7 Boost pump 13 Slipper pad (using the EP as an 8 Control plate 14 Cradle example here) (distributor plate) 9 Suction port Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 21: Functional Description

Use an appropriate emergency-off device to ensure that the drive can be brought to a safe position at any time. The machine or system manufacturer is responsible for the installation of a proper emergency-off device. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 22: Bypass Function

Turning the corresponding screw allows the hydraulic fluid to flow freely. If necessary, Bosch Rexroth recommends always activating the bypass function on both pressure relief valves (avoiding a function in only one travel direction). The bypass function must be deactivated again before restarting the machine. - Page 23 Retighten the lock nut (2), turning clockwise to a torque of 10 Nm for size 18 and 22 Nm for size 28 to 63. Place a tamper-proof cap on the screw (1) to protect the pressure relief valve against unauthorized adjustment. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

-

Page 24: Product Identification

4 Direction of rotation (viewed on drive 11 Serial number shaft) – here: clockwise 12 Material number of the axial piston 5 Designated area for inspection stamp unit 6 Weight (optional) 13 Type code 7 Power (optional) Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 25: Transport And Storage

To do this, screw an eye bolt completely into the female thread on the drive shaft. The thread size is indicated in the installation drawing. ▶ Make sure that the eye bolt can bear the total weight of the axial piston unit plus 20%. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... - Page 26 Place the lifting strap around the axial piston unit in such a way that it does not pass over assembled parts (e.g., valves, piping) and that the axial piston unit is not suspended from assembled parts (see Fig. 6). Fig. 6: Transporting with lifting strap Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 27: Storing The Axial Piston Unit

Once the max. storage time has elapsed, we recommend that you have the axial piston unit inspected by your Bosch Rexroth service partner. For questions regarding repair and spare parts, contact your proper Bosch Rexroth service partner or the service department of the plant that manufactured the axial piston unit, see chapter 10.5 “Spare parts”... - Page 28 Package the axial piston unit with desiccant in corrosion protection film so it is airtight. Store the axial piston unit in a shock-proof manner; see “Requirements” on page 27 in this chapter. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 29: Installation

▶ Direct the leakage in the housing the reservoir through the highest drain port. Use a line size appropriate for the port. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... - Page 30 Fig. 7. See data sheet for pressure values. Fig. 7: Suction pressure 1 Absolute pressure gauge 2 Standard pressure gauge (relative) Suction conditions are better in a below-reservoir installation. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 31: Installation Position

Make sure that the machine or the system is in a safe state during the air bleed process. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 32: Below-Reservoir Installation (Standard)

S + T Horizontal Below – – S + T Below Horizontal – S + T S + T Above Horizontal – S + T Horizontal Vertical – S + T Horizontal Vertical – Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 33: Above-Reservoir Installation

Suction port Baffle (baffle plate) Control pressure port Ports F and F are part of the external piping and must be provided on the customer side to make filling and air bleeding easier. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 34: Installing The Axial Piston Unit

5.4 “Product identification” on page 24. For information on the direction of rotation of the drive motor, please refer to the drive motor manufacturer's instruction manual. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 35: Dimensions

The type of installation used for the axial piston unit depends on the connecting elements to the drive side. The following descriptions explain the installation of the axial piston unit: • With a coupling • On a gearbox • On a cardan shaft RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 36: Installation With A Coupling

(observe tolerances) and that no excessive axial or radial forces are acting on the drive shaft of the axial piston unit (installation length). ▶ Protect the drive shaft against frictional corrosion by providing permanent lubrication. ▶ Fasten the axial piston unit at the installation location. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 37: Installation With Cardan Shaft

Use a suitable tool for this to prevent damage to the sealing and functional surfaces. If sealing or functional surfaces are damaged, contact your Bosch Rexroth service partner or the service department of the factory that manufactured the axial piston unit. - Page 38 For versions with through drive, install the auxiliary pump according to the pump manufacturer's instructions. The protective cover (4) is not pressure-resistant and should not be used during operation. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 39: Changing The Lever Position Of The Hw Control

Loosen the clamping screw (1) of the DA lever (2). Turn the DA lever to the desired position. Tighten the clamping screw (1) again. Tightening torque M = 5.2 Nm. Fig. 13: Changing the lever position of the DA control valve RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 40: Hydraulically Connecting The Axial Piston Unit

– The hose must be pressure-resistant, including to external air pressure. • Pressure line – For the pressure lines, use only pipes, hoses and connecting elements rated for the working pressure range specified in data sheet 92750 (see Table 10). Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... - Page 41 Make sure the right fittings, mounting bolts and threaded plugs are installed. ▶ For all female threads, use a stud end from the same system of units and of the correct size. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 42 42/64 Installation Port overview Fig. 14: Port overview, size 18 Fig. 15: Port overview, sizes 28 and 45 Fig. 16: Port overview, size 63 Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

- Page 43 For values, see Table 11. • Mounting bolts: For mounting bolts with DIN 13 metric ISO threads or ASME B1.1 threads, we recommend checking the tightening torque in individual cases in accordance with VDI 2230. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 44 Check all pipes and hose lines and every combination of connecting pieces, couplings or connecting points with hoses or pipes to ensure they are in safe working condition. For relationship between direction of rotation and flow direction, please refer to data sheet 92750. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 45: Electrically Connecting The Axial Piston Unit

Loosen the mounting nut (1) of the solenoid. To do this, turn the mounting nut (1) one turn counter-clockwise. Turn the solenoid body (2) to the desired position. Re-tighten the mounting nut. Tightening torque of the mounting nut: 5+1 Nm. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 46: Performing Flushing Cycle

Installation 7.5 Performing flushing cycle In order to remove foreign particles from the system, Bosch Rexroth recommends a flushing cycle for the entire system before initial commissioning. To avoid internal contamination, do not include the axial piston unit in the flushing cycle. -

Page 47: Commissioning

▶ During commissioning, monitor the temperature of the hydraulic fluid in the reservoir to ensure that it lies within permissible viscosity limits. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 48: Filling The Axial Piston Unit

Use only a hydraulic fluid that conforms to the following requirements: You can find details on the minimum requirements for hydraulic fluids in Bosch Rexroth data sheets 90220, 90221, 90222 and 90225. The titles of the data sheets can be found in Table 1 “Required and supplementary documentation” on page 5. -

Page 49: Testing The Hydraulic Fluid Supply

▶ Perform a leak test without and with load prior to normal operation. ▶ If necessary, disconnect the pressure gauge and plug the ports with the specified threaded plugs. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 50: Running-In Phase

10 operating hours is concluded. To ensure that contamination in the hydraulic system does not damage the axial piston unit, Bosch Rexroth recommends the following after the running-in phase: ▶ After the running-in phase, have a hydraulic fluid sample analyzed for the required cleanliness level. -

Page 51: Operation

Use only water and, if necessary, a mild cleaning agent to clean the axial piston unit. Never use solvents or corrosive cleaning agents. ▶ Remove major external contamination and keep clean sensitive and important components, such as solenoids, valves, displays and sensors. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 52: Inspection

Maintenance and repair 10.2 Inspection In order for the axial piston unit to be reliable and long-lasting, Bosch Rexroth recommends inspecting the hydraulic system and axial piston unit on a regular basis, and documenting and archiving the following operating conditions:... -

Page 53: Repair

Maintenance and repair 53/64 10.4 Repair Bosch Rexroth offers a comprehensive range of services for the repair of Rexroth axial piston units. Repairs on the axial piston unit and its assembled parts should only be performed by service centers certified by Bosch Rexroth. -

Page 54: Removal And Replacement

Remove the axial piston unit. Use a suitable lifting device. Completely drain the axial piston unit. Plug all openings. 11.4 Preparing components for storage or further use ▶ Proceed as described in chapter 6.2 “Storing the axial piston unit” on page 27. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 55: Disposal

Changes to settings on the customer side should only be made using the product- specific setting instructions. The warranty from Bosch Rexroth only applies to the product as delivered. The warranty will be voided if the unit is modified or extended. -

Page 56: Troubleshooting

Try to get a clear idea of the cause of the fault. Directly ask the (machine) operator. ▶ Document the work carried out. ▶ If you cannot rectify the fault, get in touch with one of the contact addresses found at: www.boschrexroth.com/addresses. Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... -

Page 57: Malfunction Table

Optimize the setting of the pressure limitation and pressure control valve Mechanical damage to the axial piston unit Replace axial piston unit (e.g., bearing damage) Contact Bosch Rexroth Service Increased, unusual vibration Bearings worn Contact Bosch Rexroth Service RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... - Page 58 Control of the control device defective Check control (contact machine/system manufacturer or Bosch Rexroth Service) Wear or mechanical damage to the axial piston Replace axial piston unit unit Contact Bosch Rexroth Service Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

- Page 59 Bosch Rexroth Service) Wear or mechanical damage to the axial piston Replace axial piston unit unit Contact Bosch Rexroth Service Output unit defective (e.g. hydraulic motor or Contact machine/system manufacturer cylinder) RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 60 Contact Bosch Rexroth Service Contact machine/system manufacturer Flushing flow of the flushing valve too low Contact Bosch Rexroth Service Axial piston unit worn Replace axial piston unit; contact Bosch Rexroth Service Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018...

-

Page 61: Technical Data

The data sheet can be found online at www.boschrexroth.com/mediadirectory You can find further information in the Mobile Hydraulics online product catalog: www.boschrexroth.com/axial-piston-pumps Order-related technical data for your axial piston unit can be found in the order confirmation. RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG... -

Page 62: Alphabetical Index

Dimensions 25, 35 Layout Direction of rotation Lifting device Disassembly Lifting strap – Performing Low-pressure side – Preparing Disposal ▶ M Drive shaft Maintenance 51, 52 Malfunction table ▶ E Eye bolt Bosch Rexroth AG, Series 10 A10VG, RE 92750-01-B/06.2018... - Page 63 Running-in phase ▶ S Safety instructions – General – Product-specific – Signal word Scope of delivery Slipper pad Solenoid position – Changing Spare parts Storage Storage time Storing Stroking piston Suction port Symbols RE 92750-01-B/06.2018, A10VG, Series 10, Bosch Rexroth AG...

- Page 64 Bosch Rexroth AG Glockeraustraße 4 89275 Elchingen Germany Phone: +49 7308 82-0 [email protected] www.boschrexroth.com Your local contact person can be found at: www.boschrexroth.com/addresses Subject to change Printed in Germany RE 92750-01-B/06.2018...