Siemens SINAMICS S120 Equipment Manual

Booksize power sections

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Quick Links

Table of Contents

Summary of Contents for Siemens SINAMICS S120

- Page 1 Equipment Manual 04/2004 Edition SINAMICS S120 Booksize Power Sections...

- Page 3 Preface System Overview Line Connection Booksize SINAMICS Line Modules Booksize SINAMICS S120 Booksize Power Sections Motor Modules Booksize DC Link Components Booksize Equipment Manual Cabinet Configuration and EMC Booksize Service and Support Booksize Appendix A Appendix B (GH2), 04.2004 Edition...

- Page 5 ® ® ® ® Siemens. Other product names used in this documentation may be trademarks which, if used by third parties, could infringe the rights of their owners. Further information is available on the Internet under: http://www.siemens.com/motioncontrol This publication was produced with SIPS...

- Page 7 All obligations entered into by Siemens result from the respective contract of sale that contains the complete and sole valid warranty arrangements. These contractual warranty provisions are neither extended nor curbed as a result of the statements made in this documentation.

- Page 8 Preface Danger and warning notices – symbol explanations The following danger and warning notices are used in this document: Danger Indicates an imminently hazardous situation which, if not avoided, will result in death, serious injury, or substantial damage to property. Warning Indicates an potentially hazardous situation which, if not avoided, could result in death, or serious injury, or substantial property damage.

- Page 9 Preface Definition: Qualified personnel With reference to this manual and the warning labels on the product, a "qualified person" is someone who is familiar with the installation, mounting, startup, and operation of the equipment and who has certified qualifications for the type of responsibility involved, such •...

- Page 10 A&D Technical Support Tel.: +49 (0) 180 5050 - 222 Fax: +49 (0) 180 5050 - 223 E-mail: [email protected] Please send any questions about the documentation (suggestions for improvement, corrections, and so on) to the following fax number or e-mail address:...

- Page 11 Preface ESD notices Caution Electrostatic sensitive devices (ESDs) are individual components, integrated circuits, or boards that may be damaged by either electrostatic fields or electrostatic discharge. Regulations for handling ESD components: When handling components, make sure that personnel, workplaces, and packaging are well earthed! Personnel in ESD areas with conductive flooring may only handle electronic components if They are grounded with an ESD wrist band...

- Page 12 Preface Safety guidelines Danger Commissioning shall not start until you have ensured that the machine in which the components described here are to be installed complies with Directive 98/37/EC. SINAMICS S equipment must only be commissioned by suitably qualified personnel. The personnel must take into account the information provided in the technical customer documentation for the product, and be familiar with and observe the specified danger and warning notices.

- Page 13 Preface Caution As part of routine tests, SINAMICS equipment with three-phase motors will undergo a voltage test in accordance with EN 50178. Before the voltage test is performed on the electrical equipment of industrial machines to EN 60204-1, Section 19.4, all connectors of SINAMICS equipment must be disconnected/unplugged to prevent the equipment from being damaged.

- Page 14 Preface Notes Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 15: Table Of Contents

System Overview............................ 1-1 Applications..........................1-1 Versions ............................. 1-2 Platform concept and Totally Integrated Automation..............1-3 Introduction ..........................1-4 SINAMICS S120 components....................1-7 Power sections........................... 1-9 System data ..........................1-10 Line Connection Booksize ........................2-1 Introduction ..........................2-1 Line connection variations ......................2-2 2.2.1... - Page 16 Table of Contents Smart line module booksize internal air cooling............... 3-17 3.3.1 Description ..........................3-17 3.3.2 Safety information ........................3-18 3.3.3 Interface description......................... 3-19 3.3.4 Dimension drawing........................3-23 3.3.5 Electrical connection ........................ 3-24 3.3.6 Technical specification ......................3-25 Motor Modules Booksize......................... 4-1 Introduction ..........................

- Page 17 Table of Contents 24 V DC supply voltage ......................6-7 6.3.1 General ............................6-7 6.3.2 Selection of power supply units ....................6-8 6.3.3 Typical 24-V component power consumption................6-9 6.3.4 Overcurrent protection ......................6-10 Arrangement of components and devices ................6-13 6.4.1 General ............................

-

Page 19: System Overview

System Overview Applications SINAMICS is the new range of drives from Siemens designed for mechanical and plant engineering applications. SINAMICS offers solutions for all drive tasks: • Simple pump and fan applications in the process industry • Complex individual drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems •... -

Page 20: Versions

System Overview 1.2 Versions Versions SINAMICS offers different versions designed to meet a range of requirements: • SINAMICS G is designed for standard applications with asynchronous motors. These applications have less stringent requirements regarding the dynamics and accuracy of the motor speed. •... -

Page 21: Platform Concept And Totally Integrated Automation

The different SINAMICS versions can be easily combined with each other. SINAMICS is a part of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering configuration, data storage, and communication at automation level, ensure low-maintenance solutions with SIMATIC, SIMOTION, and SINUMERIK. -

Page 22: Introduction

SINAMICS S120 System Overview Modular system for complex drive tasks SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Users can choose from many different harmonized components and functions to create a solution that best meets their requirements. - Page 23 DC link, which allows cost-saving energy balancing between braking and driving axes. SINAMICS S120 features infeeds and inverters that cover a large power range, are designed for seamless integration, and enable space-saving, multi-axis drive configurations.

- Page 24 1.4 Introduction Electronic type plates in all components All SINAMICS S120 components have an electronic type plate that contains all the relevant data about that particular component. In the motors, for example, this data includes the parameters of the electric equivalent circuit diagram and characteristic values for the in-built motor encoder.

-

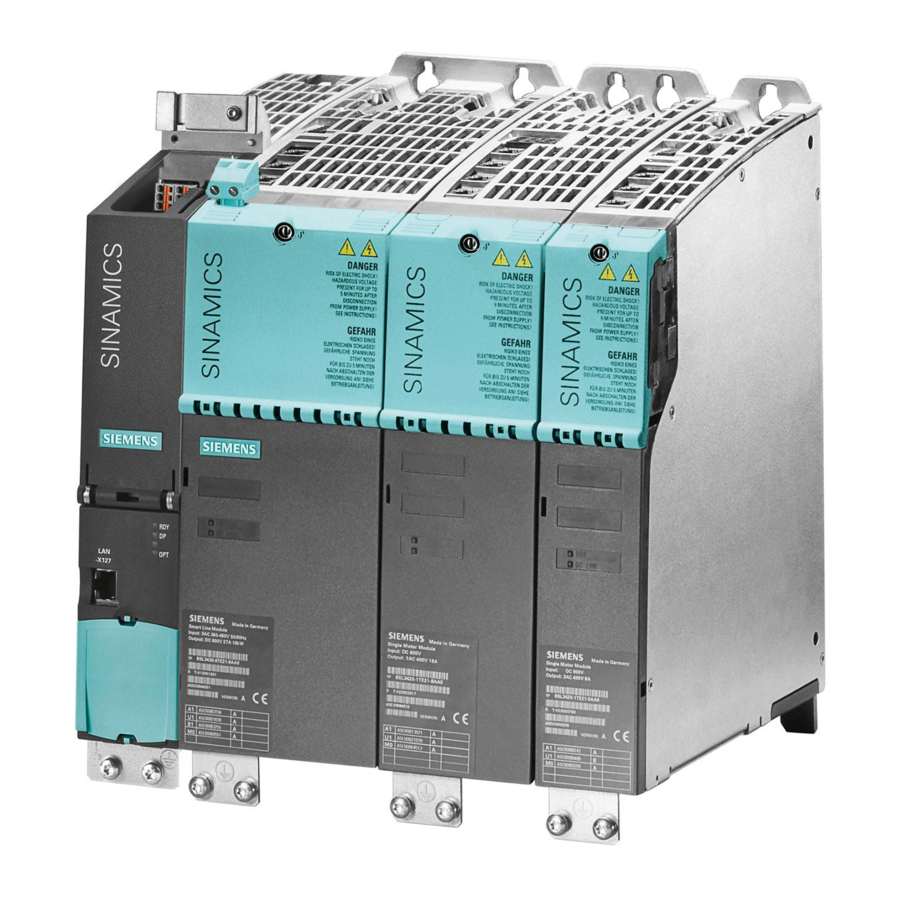

Page 25: Sinamics S120 Components

System Overview 1.5 SINAMICS S120 components SINAMICS S120 components This overview features the SINAMICS S120 components that are primarily used for multi- axis drive tasks. Figure 1-5 SINAMICS S120 component overview Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... - Page 26 • Additional system components that enhance functionality and offer different interfaces for encoders and process signals. The SINAMICS S120 components were developed for installation in cabinets. They have the following features and characteristics: • Easy to handle, simple installation and wiring •...

-

Page 27: Power Sections

System Overview 1.6 Power sections Power sections Line modules Convert the three-phase supply into a DC voltage for the DC link. • Smart line modules The smart line modules generate a non-stabilized DC link voltage and are capable of regenerative feedback. •... -

Page 28: System Data

1.7 System data System data Technical specifications Unless explicitly specified otherwise, the following technical specifications are valid for all components of the SINAMICS S120 booksize drive system. Electrical data Line connection voltage 3 AC 380 V to 480 V ±10 % (-15 % <... - Page 29 System Overview 1.7 System data Climatic ambient conditions Storage • Class 1K3 to EN 60 721-3-1 Temperature -25 °C to +55 °C Class 2K4 to EN 60 721-3-3 Transportation • Temperature -40 °C to +70 °C Max. humidity 95 % at 40 °C Class 3K3 to EN 60 721-3-3 Operation •...

-

Page 31: Line Connection Booksize

Line Connection Booksize Introduction The line connection for a SINAMICS booksize drive line-up comprises the following components: • A line filter (optional) • A line reactor To line module Line filter Line reactor (optional) Figure 2-1 Overview diagram: Line connection Note The limit values for the radio interference voltage are only observed when the filter is used. -

Page 32: Line Connection Variations

Line Connection Booksize 2.2 Line connection variations Line connection variations 2.2.1 Methods of line connection A distinction is made between: • Direct operation of the line connection components on the supply • Operation of the Line Connection Components via an Autotransformer •... - Page 33 Line Connection Booksize 2.2 Line connection variations Direct connection 3AC 380 V to 3AC 480 V +/-10% RCCB AC/DC sensitive (optional) Autotrans. Line voltage < 3AC 480 V + 10% Line voltage Isol. trans. > 3AC 480 V + 10% L1 L2 L3 TN system Line...

-

Page 34: Operation Of The Line Connection Components On The Supply Network

Line Connection Booksize 2.2 Line connection variations 2.2.2 Operation of the line connection components on the supply network The SINAMICS S booksize drive system is rated for direct operation on TN, TT, and IT supply systems with a nominal voltage of 3AC 380 V to 3AC 480 V. Operation with a line filter is only permitted for a TN supply system. -

Page 35: Operation Of The Line Connection Components Via An Autotransformer

Line Connection Booksize 2.2 Line connection variations 2.2.3 Operation of the line connection components via an autotransformer An autotransformer can be used for voltage adaptation in the range up to 480 V 3AC +10%. Applications: • The motor insulation must be protected from excessive voltages. •... -

Page 36: Operation Of The Line Connection Components Via An Isolating Transformer

Line Connection Booksize 2.2 Line connection variations 2.2.4 Operation of the line connection components via an isolating transformer The isolating transformer converts the network configuration of the system (e.g. IT/TT system) to a TN system. Additional voltage adaptation to the permissible voltage tolerance range is possible. -

Page 37: Line Connection Via A Ground-Fault Circuit Interrupter

Line Connection Booksize 2.2 Line connection variations 2.2.5 Line connection via a ground-fault circuit interrupter In addition to protection measures against hazardous shock current (e.g. overcurrent trip), selectively tripping AC/DC-sensitive residual-current circuit-breakers can be used. Note A direct connection to a power system with selectively tripping AC/DC-sensitive residual- current circuit-breakers is only possible with the 5 kW, 10 kW, 16 kW and 36 kW line modules. - Page 38 35 ms delay time between closing and opening individual main contacts. Recommendation SIEMENS selectively switching AC/DC-sensitive residual-current circuit-breakers to EN 50178, type 5SZ (e.g. 5SZ6 468–0KG00 or 5SZ6468–0KG30 with auxiliary disconnector (1NC/1NO) for rated current 63 A, rated fault current 0.3 A) (see also catalog CA01).

-

Page 39: Line Filters

Line Connection Booksize 2.3 Line filters Line filters 2.3.1 Description Line filters limit the conducted interference emitted by the converter units to permissible values for industry. 2.3.2 Safety information Caution Line filters are only suitable for direct connection to TN systems. Danger The 100 mm clearances above and below the components must be observed. - Page 40 Line Connection Booksize 2.3 Line filters Caution The line filters listed conduct a high leakage current via the PE conductor. Because of the high leakage current of the line filters, a permanent PE connection of the line filter or switching cabinet is required. Measures according to EN 50178/94 Part 5.3.2.1 must be taken, e.g.

-

Page 41: Interface Description

Line Connection Booksize 2.3 Line filters 2.3.3 Interface description Load connection U V W Warning and connection Rating plate PE conductor Mounting position Line connection Figure 2-7 Line filter (example: 16 kW) Booksize Power Sections 2-11 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... - Page 42 Line Connection Booksize 2.3 Line filters Line/load connection The line filter is rated for a voltage range from 380 V 3AC -10% to 480 V 3AC +10% (-15% <1 min) at 47 Hz to 63 Hz Table 2-1 Type of connection Terminals Designations Line connection (line)

-

Page 43: Dimension Drawing

Line Connection Booksize 2.3 Line filters 2.3.4 Dimension drawing Figure 2-8 Dimension drawings: Line filter Booksize Power Sections 2-13 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 44: Technical Specification

Line Connection Booksize 2.3 Line filters Table 2-2 Dimensions of line filter For active line Order number: a [mm] w [mm] c [mm] [mm] [mm] module 6SL3000- 16 kW 0BE-21-6AAx 36 kW 0BE-23-6AAx 55 kW 0BE-25-5AAx 80 kW 0BE-28-0AAx 120 kW 0BE-31-2AAx Table 2-3 Dimensions of line filter... -

Page 45: Line Reactors

Caution Only the line filters listed in Catalog NC Z must be used. Using line reactors not approved by SIEMENS for SINAMICS 6SL31: - Can damage/destroy line modules. - Cause line reactions that can damage or destroy other loads powered from the same network. -

Page 46: Interface Description

Line Connection Booksize 2.4 Line reactors 2.4.3 Interface description The line reactor is rated for a voltage range from 380 V 3AC -10% to 480 V 3AC +10% at 47 Hz to 63 Hz. 1U1, 1U2, 1V1, 1V2, 1W1, 1W2, PE Figure 2-9 Line reactor (example: 16 kW) Line/load connection... -

Page 47: Dimension Drawing

Line Connection Booksize 2.4 Line reactors 2.4.4 Dimension drawing Figure 2-10 Dimension drawing of line reactor Table 2-7 Dimensions of line reactor For active line module Order number L [mm] W [mm] h [mm] w [mm] [mm] [mm] 6SN1111- 16 kW 0AA00-0BA1 36 kW 0AA00-0CA1... -

Page 48: Technical Specifications

Line Connection Booksize 2.4 Line reactors 2.4.5 Technical specifications Table 2-9 Technical specifications of line reactors for the active line module 6SN1111–0AA00– 0BA1 0CA1 0DA1 1EA0 1FA0 Unit Output Voltage drop/phase 12.3 12.3 11.1 15.2 Rated current Phase inductance 0.27 0.23 Power loss See: Power Loss of Components in Rated Operation... -

Page 49: Line Modules Booksize

Line Modules Booksize Introduction Line modules generate a DC voltage that is used to power the motor modules from the connected supply voltage. General characteristics of the line modules • Connection voltage 380 V 3AC -10% to 480 V 3AC +10% (-15% <1 min) (47 to 63 Hz) •... - Page 50 Line Modules Booksize 3.1 Introduction Characteristics of the active line modules • Regulated DC link voltage via controlled rectifier • Regulated regenerative feedback capability • Operation without effect on supply system due to reduced line harmonics Characteristics of the smart line modules •...

-

Page 51: Active Line Modules Booksize Internal Air Cooling

Line Modules Booksize 3.2 Active line modules booksize internal air cooling Active line modules booksize internal air cooling 3.2.1 Description The motor modules are connected to the power supply network via the active line moduleswhich provide the motor modules with a constant DC link voltage. This ensures that they are not influenced by network fluctuations. -

Page 52: Safety Information

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.2 Safety information Warning After disconnecting all the supply voltages, a hazardous voltage will be present in all components for another 5 minutes. The protective cover must not be opened until this time has elapsed. -

Page 53: Interface Description

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.3 Interface description Terminals X200-X202 X202 DRIVE CLiQ X200 24 V terminal adapter Protective cover release Electronics power supply 1 (0.5 x 3.5) DC link busbars Protective cover LEDs PE conductor connection Line connection... - Page 54 Line Modules Booksize 3.2 Active line modules booksize internal air cooling ext. 24 V X200 X201 X202 Main circuit-breaker +Temp Fuses -Temp Active Line EP +24 V Module EP M 24 V DC Line contactor 3)4) Line filter READY DC LINK Line reactor 1) Leading contact t >10 ms 2) DI/DO controlled by control unit...

- Page 55 Line Modules Booksize 3.2 Active line modules booksize internal air cooling Line connection The active line module is rated for the voltage range 3AC 380 V -10% to 3AC 480 V +10% (-15% < 1min) at 47 Hz to 63 Hz. Table 3-1 Connection methods active line module Terminals...

- Page 56 Line Modules Booksize 3.2 Active line modules booksize internal air cooling EP terminals X21 Table 3-3 Terminal block X21 Terminal Designation Technical specifications Reserved, do not use Reserved, do not use EP +24 V (Enable Pulses) Voltage 24 V DC Current consumption: 10 mA EP M (Enable Pulses) Signal propagation times:...

- Page 57 (only when active line module is ready for operation). Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120, Installation and Start-Up Manual Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 58: Dimension Drawing

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.4 Dimension drawing 6 Nm W [mm] w [mm] Dimensions 6SL3130-7TE21-6Axx 6 Nm w [mm] Dimensions W [mm] 6SL3130-7TE23-6Axx 6SL3130-7TE25-5Axx Figure 3-4 Dimension drawings of the active line modules 16 kW, 36 kW, and 55 kW Booksize Power Sections 3-10 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... - Page 59 Line Modules Booksize 3.2 Active line modules booksize internal air cooling 6 Nm Order no. W [mm] w [mm] 6SL3130-7TE28-0Axx 6SL3130-7TE31-2Axx Figure 3-5 Dimension drawing of the active line modules 80 kW and 120 kW Booksize Power Sections 3-11 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 60: Installation

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.5 Installation Installing the fan on active line modules 80 kW and 120 kW 1) Tighten screws with M6 / 6 Nm 2) Connect fan power supply Figure 3-6 Installing the fan for 300 mm modules Booksize Power Sections 3-12... -

Page 61: Electrical Connection

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.6 Electrical connection Figure 3-7 Busbar connections for booksize components Booksize Power Sections 3-13 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 62: Technical Specifications

Line Modules Booksize 3.2 Active line modules booksize internal air cooling 3.2.7 Technical specifications Table 3-6 Technical specifications of active line modules Internal air cooling 6SL3130– 7TE21– 7TE23– 7TE25– 7TE28–0AAx 7TE31–2AAx 6AAx 6AAx 5AAx Rated power Powers Supply voltages: Rated power (S1)* kW (Pn) power rating kW (Ps6) - Page 63 Line Modules Booksize 3.2 Active line modules booksize internal air cooling Internal air cooling 6SL3130– 7TE21– 7TE23– 7TE25– 7TE28–0AAx 7TE31–2AAx 6AAx 6AAx 5AAx Rated power DC link μF 1 410 1 880 2 820 3 995 capacitance Charging limit μF 20 000 20 000 20 000...

- Page 64 Line Modules Booksize 3.2 Active line modules booksize internal air cooling Derating as a function of the ambient temperature Permissible output current [°C] Ambient temperature Figure 3-9 Derating as a function of the ambient temperature Derating as a function of the installation altitude Permissible output power 1000 2000...

-

Page 65: Smart Line Module Booksize Internal Air Cooling

Line Modules Booksize 3.3 Smart line module booksize internal air cooling Smart line module booksize internal air cooling 3.3.1 Description The motor modules are connected to the power supply network via the smart line moduleswhich provide the motor modules with an unregulated DC link voltage. Smart line modules are unregulated feed/feedback units with 100% regenerative feedback capability. -

Page 66: Safety Information

Line Modules Booksize 3.3 Smart line module booksize internal air cooling 3.3.2 Safety information Warning After disconnecting all the supply voltages, a hazardous voltage will be present in all components for another 5 minutes. The protective cover must not be opened until this time has elapsed. -

Page 67: Interface Description

Line Modules Booksize 3.3 Smart line module booksize internal air cooling 3.3.3 Interface description X21/X22 Terminals 24 V terminal adapter Protective cover release Electronics power supply DC link busbars Protective cover LEDs Line connection PE conductor connection M5 / 3Nm Figure 3-11 Smart line module (example: 5 kW) Booksize Power Sections... - Page 68 Line Modules Booksize 3.3 Smart line module booksize internal air cooling ext. 24 V Main circuit-breaker Smart Line 24 V Module Line contactor 3)4) CU 2) DO, Ready DO, Warning I*t EP +24 V EP M Line filter READY DC LINK + 24 V DI, Disable DI, Reset...

- Page 69 Line Modules Booksize 3.3 Smart line module booksize internal air cooling Line connection The smart line module is rated for a voltage range from 380 V 3AC -10% to 480 V 3AC +10% (-15% <1 min) at 47 Hz to 63 Hz. Table 3-7 Connection methods for the smart line module Terminals...

- Page 70 DC link voltage outside permissible tolerance range Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120, Installation and Start-Up Manual Booksize Power Sections 3-22 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 71: Dimension Drawing

Line Modules Booksize 3.3 Smart line module booksize internal air cooling 3.3.4 Dimension drawing 6 Nm Figure 3-13 Dimension drawing of the smart line module Table 3-12 Dimensions Line module type Order number W [mm] w [mm] Smart line module: Internal air cooling 5 kW 6SL3130-6AE15-0AAx 10 kW... -

Page 72: Electrical Connection

Line Modules Booksize 3.3 Smart line module booksize internal air cooling 3.3.5 Electrical connection Figure 3-14 Busbar connections for booksize components Booksize Power Sections 3-24 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 73: Technical Specification

Line Modules Booksize 3.3 Smart line module booksize internal air cooling 3.3.6 Technical specification Table 3-13 Technical specifications for smart line modules in booksize format with internal air cooling Internal air cooling 6SL3130– 6AE15–0AAx 6AE21–0AAx Rated power Supply voltages: Rated power (S1)* kW (Pn) S6 infeed Power rating (S6-40%) - Page 74 Line Modules Booksize 3.3 Smart line module booksize internal air cooling Internal air cooling 6SL3130– 6AE15–0AAx 6AE21–0AAx Rated power Sound pressure level dB(A) <60 <60 Cooling air requirement 29.6 29.6 Rated voltage for rated data 3 AC 380 V Weight 4.68 4.78 * These values apply to 380 V and not 380 V -10%...

- Page 75 Line Modules Booksize 3.3 Smart line module booksize internal air cooling Derating as a function of the ambient temperature Permissible output power [°C] Ambient temperature Figure 3-16 Derating as a function of the ambient temperature Derating as a function of the installation altitude Permissible output power 1000 2000...

-

Page 77: Motor Modules Booksize

Motor Modules Booksize Introduction The motor modules in the SINAMICS S system in “booksize” format are inverters. The control information is generated in the control unit and distributed to the individual motor modules via DRIVE-CLiQ. Depending on the type (single or double), each motor module has one or two DRIVE-CLiQ interfaces for connecting the motor encoder evaluation (sensor modules). -

Page 78: Motor Modules Booksize Internal Air Cooling

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Characteristics of the motor modules: • Single type from 3 A to 200 A • Double type from 2x3 A to 2x18 A • Internal air cooling • Short-circuit/ground-fault-proof • Integrated DC link and electronics current busbar connection •... -

Page 79: Safety Information

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.2 Safety information Warning After disconnecting all the supply voltages, a hazardous voltage will be present in all components for another 5 minutes. The protective cover must not be opened until this time has elapsed. -

Page 80: Interface Description

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.3 Interface description X21/X22 Terminals X200-X203 X203 DRIVE-CLiQ X200 Protective cover release Electronics power supply 1 (0.5 x 3.5) DC link busbars Protective cover LEDs Rating plate Motor connection PE conductor connection Motor connection Figure 4-2... - Page 81 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling X200 X201 X202 DRIVE-CLiQ socket 2 +Temp -Temp READY EP +24 V DC LINK EP M1 Additionally for double motor modules X203 DRIVE-CLiQ socket 3 +Temp -Temp EP +24 V EP M1 smm_3a_30a_a.vsd 1) Required for Safety...

- Page 82 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling X200 X201 Motor Module X202 DRIVE-CLiQ socket 2 +Temp -Temp READY EP +24 V DC LINK EP M1 2) Additionally for motor modules 132 A to 200 A smm_45a_200a_a.vsd 1) Required for Safety Figure 4-4 Example connection of single motor modules 45 A to 200 A Booksize Power Sections...

- Page 83 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Motor/brake connection Table 4-1 Connection methods Motor connection terminals Designations Double motor module with a rated output current of Motor: X1/X2, (U2, V2, W2) 2 x 3 A of 2 x 18 A Brake: X1/X2, (1:24 V, 2: Ground) Motor connector, 5–pin Threaded hole for PE: M5...

- Page 84 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Brake connector X11 Table 4-2 Terminal block X11 Terminal Function Technical specifications BR + Brake connection + Voltage 24 V DC BR+ BR- Max. load current 2 A Brake connection - The brake connector is part of the prefabricated cable Max.

- Page 85 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling X21/X22 EP terminals / temperature sensor connection motor module Table 4-3 Terminal block X21/X22 Terminal Function Technical specifications + Temp Temperature sensor connection KTY84–1C130 - Temp EP +24 V (Enable Pulses) Supply voltage: 24 V DC (20.4 V –...

- Page 86 DC link voltage outside permissible tolerance range (only when ready for operation). Cause and rectification of faults The following reference contains information about the cause and rectification of faults: Reference: /IH1/ SINAMICS S120, Installation and Start-Up Manual Booksize Power Sections 4-10 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 87: Dimension Drawings

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.4 Dimension drawings 6 Nm Figure 4-5 Dimension drawing of motor modules 3 A to 30 A and 2 x 3 A to 2 x 18 A Booksize Power Sections 4-11 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... - Page 88 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Table 4-6 Dimensions Order number W [mm] [mm] [mm] 6SL3120-1TE13-0AAx 6SL3120-1TE21-0AAx 6SL3120-1TE21-8AAx 6SL3120-1TE23-0AAx 6SL3120-2TE13-0AAx 6SL3120-2TE15-0AAx 6SL3120-2TE21-0AAx 6SL3120-2TE21-8AAx Booksize Power Sections 4-12 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

- Page 89 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 6 Nm Figure 4-6 Dimension drawing of motor module < 45 to 85 A Table 4-7 Dimensions Order number W [mm] w [mm] 6SL3120-1TE24-5AAx 6SL3120-1TE26-0AAx 6SL3120-1TE28-5AAx Booksize Power Sections 4-13 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

- Page 90 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 6 Nm Figure 4-7 Dimension drawing of motor module 132 A and 200 A Table 4-8 Dimensions Order number W [mm] w [mm] 6SL3120-1TE31-3AAx 6SL3120-1TE32-0AAx Booksize Power Sections 4-14 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 91: Installation

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.5 Installation 1) Tighten screws with M6 / 6 Nm 2) Connect fan power supply Figure 4-8 Installing the fan for 300 mm modules Booksize Power Sections 4-15 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 92: Electrical Connection

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.6 Electrical connection Shield contact for the terminals Figure 4-9 Shield contact for the terminals Internet address: Weidmüller: http://www.weidmueller.com Booksize Power Sections 4-16 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 93: Technical Specifications

Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 4.2.7 Technical specifications Table 4-9 Technical specifications for single motor modules booksize (3 to 30 A) Internal air 6SL3120– 1TE13-0AA0 1TE15-0AA0 1TE21–0AAx 1TE21–8AAx 1TE23-0AAx cooling Rated current Voltage Supply voltages: DC link voltage 510 –... - Page 94 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Internal air 6SL3120– 1TE13-0AA0 1TE15-0AA0 1TE21–0AAx 1TE21–8AAx 1TE23-0AAx cooling Rated current Max. pulse frequency with derating Max. ambient °C temperature without derating Max. ambient °C temperature with derating DC link μF capacitance Efficiency...

- Page 95 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Internal air 6SL3120– 1TE24-5AAx 1TE26-0AAx 1TE28-5AAx 1TE31-3AAx 1TE32-0AAx cooling Rated current Intermittent ACrms duty current ) 40% Peak current ACrms DC link busbar current capacity 24 V busbar current capacity Rated power (DC link voltage 600 V...

- Page 96 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Table 4-11 Technical specifications for double motor modules booksize (2x3 to 2x18A) Internal air cooling 6SL3120- 2TE13-0AA0 2TE15-0AA0 2TE21-0AA0 2TE21-8AA0 Rated current 2x18 Voltage Supply voltages: DC link voltage 510 – 750 Electronics power 24 (20.4 –...

- Page 97 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Internal air cooling 6SL3120- 2TE13-0AA0 2TE15-0AA0 2TE21-0AA0 2TE21-8AA0 Rated current 2x18 Cooling air 29.6 29.6 29.6 requirement Weight Rated duty cycles of motor modules booksize 0.25 s 10 s Figure 4-10 Peak current duty cycle with prior loading 2.65 s 10 s...

- Page 98 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Imax 4 min 0.7 x I 10 min Figure 4-12 S6 current duty cycle with prior loading 0.7 I 10 s 60 s Figure 4-13 S6 peak current duty cycle with prior loading 1.5 x I base base...

- Page 99 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling 1.76 x I base base 30 s Base load current (with overload capacity) 300 s Figure 4-15 Current duty cycle with prior loading Derating as a function of the ambient temperature Permissible output power [°C] Ambient temperature...

- Page 100 Motor Modules Booksize 4.2 Motor modules booksize internal air cooling Derating as a function of the pulse frequency Permissible output current [kHz] Pulse frequency Figure 4-17 Derating as a function of the pulse frequency Derating as a function of the installation altitude Permissible output current 1000 2000...

-

Page 101: Dc Link Components Booksize

DC Link Components Booksize Braking module booksize 5.1.1 Description Braking modules can be used to reduce the DC link energy in supply systems without regenerative feedback capability (diesel generator) during controlled braking (e.g. emergency retraction) or for fast discharging of the DC link. The DC link energy is converted to heat loss in an external braking resistor. -

Page 102: Safety Information

The connection to the braking resistors must be made using a shielded cable. The tightening torque of the DC link busbar screws (1.8 Nm) must be checked before startup. Note Using braking resistors not approved by SIEMENS for SINAMICS 6SL31 can destroy them. Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 103: Interface Descriptions

DC Link Components Booksize 5.1 Braking module booksize 5.1.3 Interface descriptions Terminals Protective cover release Electronics power supply 1 (0.5 x 3.5) DC link busbars Protective cover LEDs Rating plate Braking resistor PE conductor connection connection Figure 5-1 Interface description braking module Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... - Page 104 DC Link Components Booksize 5.1 Braking module booksize Braking Module Max. cable length: 10 m DI, inhibit braking module DI, link quick discharge DO, "0 V" = prewarning I*t shutdown DO, "0 V" = fault/braking module inhibited Braking resistor Ground Ground braking_module_a.vsd Figure 5-2...

- Page 105 The prewarning for I*t monitoring is output as a high level on reaching 80% of the maximum braking resistor ON time. Only braking resistors approved by Siemens for this component are identified automatically. Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

- Page 106 DC Link Components Booksize 5.1 Braking module booksize Meaning of the LEDs on the braking module Table 5-3 Meaning of the LEDs on the braking module Color State Description Electronics power supply outside permissible tolerance range. READY Braking module deactivated via terminal. Green Continuous The component is ready for operation.

-

Page 107: Dimension Drawing

DC Link Components Booksize 5.1 Braking module booksize 5.1.4 Dimension drawing Figure 5-3 Dimension drawing of the braking module Booksize Power Sections Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 108: Mounting

DC Link Components Booksize 5.1 Braking module booksize 5.1.5 Mounting After the spacer element has been removed, the braking module has the mounting depth of the external air cooling system. The system is supplied with a fitted spacer element, which means it has the mounting depth for a drive line-up with an internal air... -

Page 109: Technical Specifications

DC Link Components Booksize 5.1 Braking module booksize 5.1.6 Technical specifications Table 5-4 Technical specifications Braking module booksize Voltages Supply voltages: DC link voltage 510 - 750 ON threshold Electronics power supply 24 (20.4 – 28.8) Electronics current consumption (at 24 V DC) 26 V DC busbar Current capacity 26 V DC busbar... -

Page 110: Braking Resistors

DC Link Components Booksize 5.2 Braking resistors Braking resistors Braking resistor 0.3 kW / 25 kW Braking resistor 1.5 kW / 100 kW 52.8 4 x Ø 6.5 Ø 5 Front view Side view Side view Top view Figure 5-5 Dimension drawings of braking resistors Caution The surface temperature of the braking resistors may exceed 80 °C. - Page 111 DC Link Components Booksize 5.2 Braking resistors P (kW) 0 kW 0 kW t (s) Figure 5-6 Duty cycle for braking resistors T [s] period duration of braking duty cycle A [s] load duration [W] continuous braking power of braking resistor [W] peak braking power of braking resistor Table 5-5 Example of duty cycles...

-

Page 112: Capacitor Module Booksize

DC Link Components Booksize 5.3 Capacitor module booksize Capacitor module booksize 5.3.1 Description Capacitor modules are used to increase the DC link capacitance to bridge momentary power losses. Capacitor modules are connected to the DC link voltage via the integrated DC link busbars. Capacitor modules function autonomously. -

Page 113: Interface Description

DC Link Components Booksize 5.3 Capacitor module booksize 5.3.3 Interface description Protective cover release Electronics power supply 1 (0.5 x 3.5) DC link busbars Protective cover PE conductor connection Figure 5-7 Interface description of the capacitor module Booksize Power Sections 5-13 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 114: Dimension Drawing

DC Link Components Booksize 5.3 Capacitor module booksize 5.3.4 Dimension drawing Figure 5-8 Dimension drawing of the capacitor module Booksize Power Sections 5-14 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 115: Installation

DC Link Components Booksize 5.3 Capacitor module booksize 5.3.5 Installation After the spacer The system is supplied with element has been a fitted spacer element, removed, the capacitor which means it has the module has the mounting depth for a drive mounting depth of the line-up with an internal air external air cooling... -

Page 116: Technical Specification

DC Link Components Booksize 5.3 Capacitor module booksize 5.3.6 Technical specification Table 5-6 Technical specifications Capacitor module Connection voltages: Line voltage 3AC 380 -10% to 3AC 480 +10% (-15% < 1 min) ACrams Line frequency 47 to 63 Hz Electronics power supply 24 (20.4 –... -

Page 117: Control Supply Module (Available Soon)

DC Link Components Booksize 5.4 Control supply module (available soon) Control supply module (available soon) 5.4.1 Description The control supply module provides the electronics with power via the supply system or DC link. During emergency retraction, the control supply module provides a 24 V supply independently of the line voltage. -

Page 118: Safety Information

DC Link Components Booksize 5.4 Control supply module (available soon) 5.4.2 Safety information Warning After disconnecting all the supply voltages, a hazardous voltage will be present in all components for another 5 minutes. The protective cover must not be opened until this time has elapsed. -

Page 119: Interface Description

DC Link Components Booksize 5.4 Control supply module (available soon) 5.4.3 Interface description Further loads Main circuit-breaker RCCB 1 to n motor modules Fuses Motor I > I > I > circuit-breaker Control Line Motor Supply Module Modules Module 24 V DC Line contactor Line filter... - Page 120 DC Link Components Booksize 5.4 Control supply module (available soon) 24 V terminal adapter Spacer element Protective cover release Electronics power supply Protective cover DC link busbars LEDs Rating plate PE conductor Line connection connection M5 / 3Nm Figure 5-11 Interface description control supply module Booksize Power Sections 5-20...

- Page 121 DC Link Components Booksize 5.4 Control supply module (available soon) Table 5-7 Control supply module - description of the LEDs Color State Description READY Electronics power supply outside permissible tolerance range. Green Continuous Ready for operation. Output voltage within tolerance range. Continuous Overcurrent tripping or overtemperature.

-

Page 122: Dimension Drawing

DC Link Components Booksize 5.4 Control supply module (available soon) 5.4.4 Dimension drawing Figure 5-12 Dimension drawing of the control supply module Booksize Power Sections 5-22 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0... -

Page 123: Technical Specification

DC Link Components Booksize 5.4 Control supply module (available soon) 5.4.5 Technical specification Table 5-8 Technical specifications Control supply module Unit Value Input data Line voltage 3AC 380 -10% to 3AC 480 +10% (-15% < 1 min) Line frequency 47 to 63 Connection currents Rated value Approx. -

Page 125: Cabinet Configuration And Emc Booksize

Cabinet Configuration and EMC Booksize Information 6.1.1 General SINAMICS S series components are designed for mounting in an enclosure, for example because of the required degree of shock protection. Cabinets are the type of enclosure normally used but other mounting compartments affording protection against shock and harmful environmental influences may be used. -

Page 126: Safety Information

To ensure that the encoder system works properly, you are advised to use the original Siemens accessories from catalogs D21.2 and NC Z. Only motors with a safe electrically isolated holding brake may be connected. The brake conductors must also be safely electrically isolated. -

Page 127: Directives And Standards

Cabinet Configuration and EMC Booksize 6.1 Information 6.1.3 Directives and standards The following directives and standards apply within the European Union: Table 6-1 Directives Directive Description 73/23/EEC Directive of the Council of February 19, 1973, on the approximation of the laws of the member states relating to electrical equipment designed for use within certain voltage limits Low-Voltage Directive 98/37/EC... -

Page 128: Selection Of Devices Required For Operation Of Sinamics

Cabinet Configuration and EMC Booksize 6.2 Selection of devices required for operation of SINAMICS Standard Description EN 60439-1 Low-voltage switchgear and controlgear assemblies Part 1: Type-tested and partially type-tested assemblies EN 60529 Degrees of protection provided by enclosures EN 61000-6-2 Electromagnetic compatibility (EMC) Part 2: Generic standard immunity, industrial environments EN 61800–3... -

Page 129: Overcurrent Protection By Line Fuse Or Circuit-Breaker

Cabinet Configuration and EMC Booksize 6.2 Selection of devices required for operation of SINAMICS 6.2.3 Overcurrent protection by line fuse or circuit-breaker The cables for the drive line-up power supply must be protected against overcurrent. LV HBC, D-type, and DO-type fuses with a gL characteristic or suitable circuit-breakers can be used. -

Page 130: Line Contactors

Cabinet Configuration and EMC Booksize 6.2 Selection of devices required for operation of SINAMICS 6.2.4 Line contactors Line contactors are required for electrical isolation of the drive line-up from the power supply network. For selection of the line contactor, the characteristic values in the technical specifications apply. -

Page 131: Dc Supply Voltage

Cabinet Configuration and EMC Booksize 6.3 24 V DC supply voltage 24 V DC supply voltage 6.3.1 General The 24 V DC voltage is required for the power supply of 1. The electronics of the SINAMICS components via the integrated 24-V busbar 2. -

Page 132: Selection Of Power Supply Units

Cabinet Configuration and EMC Booksize 6.3 24 V DC supply voltage 6.3.2 Selection of power supply units You are advised to use the devices in the following table. These devices meet the applicable requirements of EN 60204-1. Table 6-5 Recommended SITOP Power Rated output current [A] Input voltage range [V] Short-circuit current [A]... -

Page 133: Typical 24-V Component Power Consumption

Cabinet Configuration and EMC Booksize 6.3 24 V DC supply voltage 6.3.3 Typical 24-V component power consumption The following table can be used to calculate the 24 V DC power supply for the components. Table 6-7 Overview of 24 V DC current consumption with internal cooling Component Current consumption [A CU320 without load... -

Page 134: Overcurrent Protection

The recommended overcurrent protection devices on the primary side are circuit-breakers as specified in Siemens catalog NSK. The recommended overcurrent protection devices on the secondary side are MCBs. The MCBs can be selected according to Siemens catalog I1.2. The 24 V DC power supply of booksize • Line modules •... - Page 135 Cabinet Configuration and EMC Booksize 6.3 24 V DC supply voltage 24 V DC 24 V DC 2.5 mm2 6 mm2 CU320 Line Motor Motor module module module Figure 6-1 Example of 24 V DC fuse protection The following conditions apply to the cables when the MCBs are selected from the following table: •...

- Page 136 Cabinet Configuration and EMC Booksize 6.3 24 V DC supply voltage Table 6-8 MCBs by conductor cross-section and temperature Conductor cross-section Max. value up to 40 °C Max. value up to 55 °C 1.5 mm 10 A 10 A 2.5 mm 20 A 10 A 4 mm...

-

Page 137: Arrangement Of Components And Devices

Cabinet Configuration and EMC Booksize 6.4 Arrangement of components and devices Arrangement of components and devices 6.4.1 General The arrangement of the components and equipment takes account of • Space requirements • Cable routing • Heat dissipation • EMC Components are usually located centrally in a cabinet. 6.4.2 Drive line-up Due to the current capacity of the DC link busbars and their function, the components must... - Page 138 Cabinet Configuration and EMC Booksize 6.4 Arrangement of components and devices Motor module (3 - 18 A) Motor module (30 A) Braking module Active line module (55 kW) Control unit 320 Figure 6-2 Example of a drive line-up Note When the power supply input is on the right-hand side of the drive line-up (e.g. in a multiple- tier configuration), the above rules apply in reverse.

- Page 139 Cabinet Configuration and EMC Booksize 6.4 Arrangement of components and devices The components of the drive line-up should preferably be installed on a conductive mounting surface to ensure low impedance between the component and the mounting surface. Mounting plates with a galvanized surface are suitable. The components can be arranged in one or more tiers.

- Page 140 Cabinet Configuration and EMC Booksize 6.4 Arrangement of components and devices Two-tier configuration Shielded Figure 6-4 Example of a two-tier configuration with modules between 200 and 300 mm wide The distance between the two module rows depends on the wiring and cable cross-section. For modules with a width of between 50 and 100 mm, the distance between the upper and lower module row must be at least 300 mm.

-

Page 141: Information About Electromagnetic Compatibility (Emc) And Cable Laying

The cable shields The cable shields must be connected as close to the conductor terminal connections as possible to ensure a low-impedance connection with cabinet ground. For Siemens power cables in which the shield is connected to the connector shell (see relevant catalog), this is a sufficiently good shield contact. - Page 142 Cabinet Configuration and EMC Booksize 6.5 Information about electromagnetic compatibility (EMC) and cable laying With components that do not have any special shield connection or where the shield connection is not sufficient, the cable shields can be connected to the metal mounting plate using hose clamps and toothed rails.

-

Page 143: Equipotential Bonding

Cabinet Configuration and EMC Booksize 6.5 Information about electromagnetic compatibility (EMC) and cable laying 6.5.3 Equipotential bonding The SINAMICS S booksize drive system is designed for use in cabinets with a PE conductor connection. If the drive line-up is arranged on a common unpainted metal-surfaced mounting plate, e.g. with a galvanized surface, no additional equipotential bonding is needed within the drive line- up as •... -

Page 144: Connection Methods

Cabinet Configuration and EMC Booksize 6.6 Connection methods Connection methods 6.6.1 Spring-loaded terminals/screw terminals Connectable conductor cross-sections of spring-loaded terminals Table 6-11 Spring-loaded terminals Spring-loaded terminal type Connectable conductor cross- Flexible 0.14 mm to 1.5 mm sections With wire end ferrule, without plastic sleeve 0.25 mm to 1.5 mm With wire end ferrule, with plastic sleeve... - Page 145 Cabinet Configuration and EMC Booksize 6.6 Connection methods Screw terminal type Connectable conductor cross- Flexible 0.2 mm to 4 mm sections With wire end ferrule, without plastic sleeve 0.25 mm to 4 mm With wire end ferrule, with plastic sleeve 0.25 mm to 4 mm Insulation stripping length...

-

Page 146: Motor Connector

Cabinet Configuration and EMC Booksize 6.6 Connection methods 6.6.2 Motor connector The diagram below shows you how to remove the motor connectorusing a pair of engineer's pliers, for example, to pull the cable through narrow cable bushings. Figure 6-6 Removing the motor connector The following figure shows how the motor connector is coded to prevent incorrect connection (especially relevant for double motor modules). -

Page 147: 24-V Terminal Adapter

Cabinet Configuration and EMC Booksize 6.6 Connection methods Coding plugs Coding plugs Motor connector Coding plugs Coding plugs Coding plugs cod_motorst.vsd Figure 6-7 Coding the motor connector The coding plugs are supplied with the motor cables. 6.6.3 24-V terminal adapter 24 V terminal adapter for 6mm²... -

Page 148: Information About Heat Dissipation

Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Information about heat dissipation 6.7.1 General The following devices are available as cooling equipment: • Filtered fans • Heat exchangers or • Cooling units The decision in favor of one of these methods will depend on the prevailing ambient conditions and the cooling power required. - Page 149 Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Table 6-13 Ventilation clearances above and below the components Component Order number Clearance [mm] CU320 6SL3040-0MA00-0AAx SMCxx 6SL3055-0AA00-5xAx TM31 6SL3055-0AA00-3AAx Line filter for line module 5 kW – 120 kW 6SL3000-0BExx-xAAx Line reactor for active line module 16 kW –...

- Page 150 Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Mounting surface Air out Cold air Figure 6-8 Ventilation clearances for booksize drive line-up Booksize Power Sections 6-26 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

- Page 151 Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Air out Mounting surface Ventilation clearances Cold air 50 mm Figure 6-9 Ventilation clearances for 300 mm modules Booksize Power Sections 6-27 Equipment Manual, (GH2), 04.2004 Edition, 6SL3097-2AC00-0BP0...

-

Page 152: Information About Ventilation

Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Mounting surface Air out DIN rail Cold air Figure 6-10 Ventilation clearances for DIN rail modules 6.7.2 Information about ventilation The SINAMICS equipment is ventilated separately by means of integrated fans and is in some cases cooled by means of natural convection. - Page 153 Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Cooling unit Cabinet Figure 6-11 Examples of cabinet ventilation Caution The air guidance and arrangement of the cooling equipment must be chosen in such a way as to prevent condensation from forming. If necessary, cabinet enclosure heating may have to be installed.

-

Page 154: Power Loss Of Components In Rated Operation

Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation 6.7.3 Power loss of components in rated operation The following table shows the power loss for components with internal cooling. The characteristic values apply for the following conditions: • Line voltage for line modules 400 V •... - Page 155 Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation Unit Power loss Smart line modules 5 kW Available soon 10 kW Available soon Single motor modules 18 A 30 A 85 A 200 A 2050 Double motor modules 2x3 A 2x5 A 2x9 A 2x18 A...

-

Page 156: Information About Calculating Power Loss

Cabinet Configuration and EMC Booksize 6.7 Information about heat dissipation 6.7.4 Information about calculating power loss Cabinet manufacturers provide calculation programs for selecting climate control equipment. It is always necessary to know the power loss of the components and equipment installed in the cabinet. -

Page 157: Service And Support Booksize

A&D Technical Support Tel.: +49 (0) 180 5050 – 222 Fax: +49 (0) 180 5050 – 223 email: [email protected] Please send any questions about the documentation (suggestions for improvement, corrections, and so on) to the following fax number or e-mail address: Fax: +49 (0) 9131 98 –... -

Page 158: Replacing Fans

Service and Support Booksize 7.2 Replacing fans Replacing fans Notice When replacing the fan, you must observe the ESD regulations. Parts must only be replaced by trained personnel (danger of damage to sensitive components due to static electricity)! Removing the fan: 1. - Page 159 Service and Support Booksize 7.2 Replacing fans Installing the fan: 1. Before installing the fan, check the through-flow direction (the arrow on the fan must point towards the fins) 2. Insert the connector fully. 3. Insert the fan fully. Do not squash the connection cables! 4.

-

Page 160: List Of Spare Parts

Service and Support Booksize 7.3 List of spare parts List of spare parts Table 7-1 List of spare parts for SINAMICS S120 (as at: October 08, 2003) Component Order number Control Unit 320 6SL3040-0MA00-0AA1 24 V DC 4-pin tee unit (X124) - Page 161 Service and Support Booksize 7.3 List of spare parts Component Order number Safe standstill/KTY84 terminal block, 4-pin (X21) 6SL3162-2EA00-0AA0 24 V terminal adapter (X24) 6SL3162-2AA00-0AA0 Plastic inserts (CU<>line module) 6SL3064-3DB00-0AA0 Fan for 100mm line/motor module (incl. fan cover) 6SL3162-0AD00-0AA0 DC link cover for 100mm line/motor module 6SL3162-3AD00-0AA0 36kW smart line module (150mm) 6SL3130-6TE23-6AA0...

- Page 162 Service and Support Booksize 7.3 List of spare parts Component Order number 24 V jumper 6SL3162-2AA01-0AA0 Fan for 50mm line/motor module (incl. fan cover) 6SL3162-0AB00-0AA0 DC link cover for 50mm line/motor module 6SL3162-3AB00-0AA0 30A single motor module (100mm) 6SL3120-1TE23-0AA1 18A double motor module (100mm) 6SL3120-2TE21-8AA0 DRIVE-CLiQ cable, IP20/IP20, without 24 V DC, 6SL3060-4AD00-0AA0...

- Page 163 Service and Support Booksize 7.3 List of spare parts Component Order number DC link cover for 50mm line/motor module 6SL3162-3AB00-0AA0 Capacitor module (100mm) 24 V jumper 6SL3162-2AA01-0AA0 DC link cover for 100mm line/motor module 6SL3162-3AD00-0AA0 Control supply module (50mm) 24 V terminal adapter (X24) 6SL3162-2AA00-0AA0 24 V jumper 6SL3162-2AA01-0AA0...

- Page 165 Appendix A List of abbreviations Table A-1 List of abbreviations Abbreviation English A... Alarm Alternating Current Analog Digital Converter Analog Input Analog Output Advanced Operator Panel ASCII American Standard Code for Information Interchange Operating condition BERO Tradename for a type of proximity switch Binector Input Berufsgenossenschaftliches Institut für...

-

Page 166: A.1 List Of Abbreviations

Appendix A A.1 List of abbreviations Abbreviation English Central Processing Unit Cyclic Redundancy Check Constant Torque Control Unit Digital Analog Converter Direct Current Direct Current Negative Direct Current Positive Drive Data Set Digital Input DI/DO Bidirectional Digital Input/Output DRIVE-CLiQ Module Cabinet (Hub) Digital Output Drive Object DPRAM... - Page 167 Appendix A A.1 List of abbreviations Abbreviation English High Frequency High frequency reactor Ramp-function generator Human Machine Interface High Threshold Logic Hardware In preparation: In preparation: this feature is currently not available Commissioning Input/Output Identifier International Electrotechnical Commission IGBT Insulated Gate Bipolar Transistor Insulated three-phase supply network Jogging Data cross-checking...

- Page 168 Appendix A A.1 List of abbreviations Abbreviation English N. C. Not Connected NEMA National Electrical Manufacturers Association Zero mark Normally Open (contact) Original Equipment Manufacturer Optical Link Plug Option Module Interface p ... Adjustable parameter Power Module Data Set Protective Earth PELV Protective Extra Low Voltage Programming terminal...

- Page 169 Appendix A A.1 List of abbreviations Abbreviation English Safe Brake Control Safe input signal Safe standstill Safety Integrated Safety Integrity Level SLVC Sensorless Vector Control Sensor Module Sensor Module Cabinet Setpoint Channel Programmable Logic Controller (PLC) PROFIBUS control word Terminal Board Totally Integrated Automation Terminal Module Grounded three-phase supply network...

-

Page 171: References

Order no.: E86060-K5151-A121-A3-7600 2. /D11/ SINAMICS G150 Drive Converter 75 – 560 kW Cabinet Units Order no.: E86060-K5511-A101-A1-7600 3. /D21.1/ SINAMICS S120 Vector Control Drive system Order no.: (in preparation) 4. /D21.2/ SINAMICS S120 Servo Control Drive system (incl. servo motors) Order no.: (in preparation) - Page 172 Appendix B B.1 References 3. /GH2/ SINAMICS S120 Equipment Manual for Booksize Power Sections Order no.: 6SL3097-2AC00-0BP0, edition: 01.2004 4. /GH3/ SINAMICS S120 Equipment Manual for Chassis Power Sections Order no.: 6SL3097-2AE00-0BP0, edition: 01.2004 5. /GS1/ SINAMICS S120 Getting Started Order no.: 6SL3097-2AG00-0BP0, edition: 01.2004...

- Page 173 SIMOTION Engineering System SCOUT Order no.: 6AU1 900-0AD30-0BA0, edition: 02.2003 6. DRIVE ES Basic V5.1 Function Description Engineering System for Drives from the Siemens A&D Product Range Order no.: 6SW1 700-0JA00-0BA0, edition: 08.2001 PROFIBUS documentation 1. /IKPI/ Catalog IK PI 2002/2003 Industrial Communication and Field Equipment Order no.: E86060-K6710-A101-B2-7600 (bound edition)

- Page 174 Function Description SINUMERIK Safety Integrated Order no.: 6FC5297-6AB80-0BP2, edition: 09.2003 5. /SIAH/ Safety Integrated The Safety Program for International Industry Application Manual, 4th edition, Siemens AG Automation and Drives Order no.: 6ZB5000-0AA01-0BA0, edition: 01.2003 6. /SICD/ Safety Integrated The Fully Integrated Safety System CD-ROM Order no.: E20001-D10-M103-X-7400-7600...

-

Page 175: Index

Index Motor Module with Internal Air Cooling, 4-11 Smart Line Modules with Internal Air Cooling, 3-23 Drive Line-Up, 6-13 Active line module, 3-3 Applications, 1-1 Autotransformer, 2-5 Electrical Connections Active Line Modules with Internal Air Cooling, 3-13 Motor Module with Internal Air Cooling, 4-16 Smart Line Modules with Internal Air Cooling, 3-24 Booksize EMC Directive, 6-17... - Page 176 Index Line Filters, 2-14 Line Reactors, 2-18 Motor Connector, 6-22 Motor modules with internal air cooling, 4-17 Motor Module with Internal Air Cooling, 4-2 Smart Line Modules with Internal Air Cooling, 3-25 Motor/brake connection, 4-7 Technical Support, 7-1 Terminal adapter, 6-23 Totally Integrated Automation, 1-3 Overcurrent, 6-10 Overcurrent Protection, 6-5...

- Page 177 Overview of SINAMICS Documentation (01.2004) General Documentation / Catalogs MICRO- SINAMICS SINAMICS MASTER SINAMICS SINAMICS 410/420/ G110/ S150 S120 S120 430/440 G130/ G150 DA 51.2 D 21.2 D 21.3 D 21.1 Converter Servo Control Converter Vector Control Vector Control 0.12–250kW Drive System 0.12–3kW Blocksize Units Cabin Units...

- Page 179 Suggestions SIEMENS AG Corrections A&D MC BMS For Publication/Manual: P.O. Box 3180 SINAMICS S120 D-91050 Erlangen, Germany Equipment Manual (GH2) Phone: +49-(0)180-5050-222 (Hotline) Fax: +49-(0)9131-98-2176 (Documentation) Manufacturer/Service Documentation Email: [email protected] From Equipment Manual Name Order No.: 6SL3097-2AC00-0BP0 Company/Dept. Edition: 04.04...

- Page 182 Siemens AG Automation & Drives Motion Control Systems © Siemens AG, 2004 P.O. Box 3180, D-91050 Erlangen Subject to change without prior notice Germany Order No.: 6SL3097-2AC00-0BP0 Printed in Germany www.siemens.com/motioncontrol...