Summary of Contents for GE AquaTrans AT868

- Page 1 Sensing & Inspection Technologies AquaTrans™ AT868 Panametrics Liquid Flow Ultrasonic Transmitter Abridged Manual...

- Page 2 Sensing & Inspection Technologies AquaTrans™ AT8688 Panametrics Liquid Flow Ultrasonic Transmitter Abridged Manual 914-218D September 2004 The AquaTrans AT868 is a GE Panametrics product. GE Panametrics has joined other GE high-technology businesses under a new name—GE Sensing & Inspection Technologies.

- Page 3 GE Infrastructure Sensing, Inc. Fuses and batteries are specifically excluded from any liability. This warranty is effective from the date of delivery to the original purchaser. If GE Infrastructure Sensing, Inc. determines that the equipment was defective, the warranty period is: •...

- Page 4 If a GE Infrastructure Sensing, Inc. instrument malfunctions within the warranty period, the following procedure must be completed: 1. Notify GE Infrastructure Sensing, Inc., giving full details of the problem, and provide the model number and serial number of the instrument.

-

Page 5: Table Of Contents

September 2004 Table of Contents Chapter 1: Installation Introduction................1-1 Site Considerations . - Page 6 September 2004 Table of Contents (cont.) Entering Global System Data [GLOBL-SYSTM Menu] ........2-12 Selecting the GLOBL-SYSTM Units .

- Page 7 Chapter 1...

- Page 8 Installation Introduction........... . 1-1 Site Considerations .

-

Page 9: Introduction

Introduction To ensure safe and reliable operation of the AT868, the system must be installed and programmed in accordance with the guidelines established by GE. Those guidelines are explained in detail in this chapter. !WARNING! Be sure to follow all applicable local safety codes and regulations for installing electrical equipment. -

Page 10: Flowcell Location

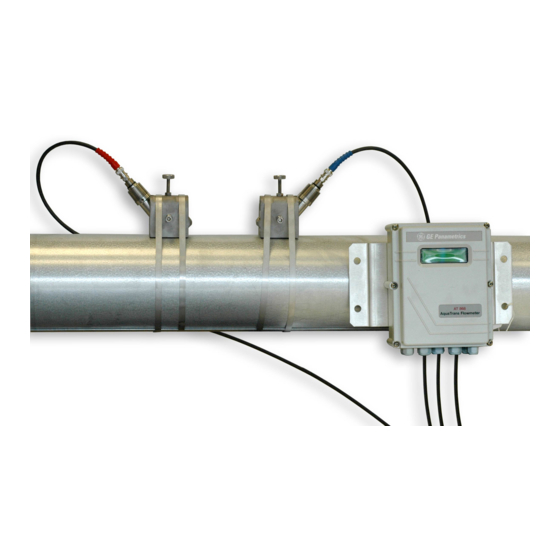

September 2004 Flowcell Location A flowcell is the section of pipe where the transducers are mounted. It can be created either by mounting the transducers on the existing pipeline or by mounting them on a spoolpiece. A spoolpiece is a separately manufactured pipe section, matched to the existing pipe, which contains ports for mounting the transducers. -

Page 11: Cable Lengths

Cable Lengths Locate the electronics enclosure as close as possible to the flowcell, preferably directly on the flowcell. However, GE can supply transducer cables up to 1,000 ft (300 m) in length for remote location of the electronics enclosure. If longer cables are required, consult the factory for assistance. -

Page 12: Ce Mark Compliance

September 2004 CE Mark Compliance For CE Mark compliance, the AT868 must meet both the EMC and LVD directives. IMPORTANT: CE Mark compliance is required for all units intended for use in EEC countries. EMC Compliance For EMC compliance, the electrical connections must be shielded and grounded as in Table 1-1 below. -

Page 13: Lvd Compliance

September 2004 LVD Compliance For compliance with the European Union’s Low Voltage Directive (73/23/EEC). the analyzer requires an external power disconnect device such as a switch or circuit breaker. The disconnect device must be marked as such, clearly visible, directly accessible, and located within 1.8 m (6 ft) of the unit. -

Page 14: Making Electrical Connections

September 2004 Making Electrical This section contains instructions for making all the necessary Connections electrical connections to the AT868 electronics console. Refer to Figure 1-5 on page 1-16 for a complete wiring diagram. !ATTENTION EUROPEAN CUSTOMERS! To meet CE Mark requirements, all cables must be installed as described in the previous section !WARNING! Always disconnect the line power from the AT868 before... -

Page 15: Wiring The Line Power

September 2004 Wiring the Line Power The AT868 may be purchased for operation with power inputs of 85-265 VAC or 12-28 VDC. The label on the side of the electronics enclosure lists the required line voltage and power rating. The fuse rating is listed on label located under the fuse. -

Page 16: Wiring Transducers

September 2004 Wiring the Line Power 5. Leaving a bit of slack, secure the power line with the cable clamp. (cont.) Caution! Do not apply power to the AT868 until after the transducers have been properly wired. 6. Do one of the following: •... -

Page 17: Wiring Standard 0/4-20 Ma Analog Outputs

September 2004 Wiring Transducers (cont.) 4. For a 2-Channel AT868, repeat steps 1-3 to connect the CH2 transducers to the DN and UP terminal block for Channel 2. Note: It is not required that both channels of a 2-Channel unit be connected. -

Page 18: Wiring The Totalizer/Frequency Output

September 2004 Wiring the The AT868 also provides a second output for each channel Totalizer/Frequency (designated as Output B and Output D) that can be configured as a totalizer or frequency output using the Instrument Data Manager Output (IDM) software. These outputs can be configured independently. Typically, Output B is used for Channel 1 and Output D is used for Channel 2. -

Page 19: Wiring The Serial Port

*For standard GE cables 704-659, -660, -661 and -662. Note: Signal names that imply direction (e.g., transmit and receive) are named from the point of view of the DTE device (the GE meter is usually considered the DTE device). When the RS232 standard is strictly followed, these signals are labeled with the same name and pin # on the DCE device side. - Page 20 September 2004 Wiring an RS232 Interface 2. Route the flying leads end of the cable through the conduit hole (cont.) and wire the leads to the COMMUNICATION terminal block as shown in Figure 1-5 on page 1-16. Connect the other end of the cable to the printer, ANSI terminal or personal computer.

- Page 21 September 2004 Using an INMAC Converter To wire the RS485 serial port using an INMAC converter, refer to Figure 1-5 on page 1-16 and complete the following steps: 1. Route one end of the cable through the conduit hole and wire the leads to the COMMUNICATION terminal block as shown in Figure 1-5 on page 1-16.

-

Page 22: Wiring An External Totalizer Reset Switch

September 2004 Wiring an External The AT868 can be wired with an external switch for resetting the Totalizer Reset Switch totalizer values. When properly configured, pressing the switch will reset the totalizer values to zero for both Channel 1 and Channel 2. IMPORTANT: The AT868 has the capability to use a reset switch, but the user must supply all the hardware. - Page 23 September 2004 Note: 1. All dimensions are in inches (millimeters). 10.00 9.00 (254.0) (228.6) 2.86 (72.6) Ø .41 (10.40) 4.11 (104.4) 4 Holes 5.88 (149.3) Installation 1-15...

- Page 24 September 2004 Contrast Adjustment Backlight Adjustment TB3: 0/4-20 mA Analog Outputs TB3: RS232/RS485 Serial Port NOTE: For compliance with the European Pin No. Description Pin No. Color* Description Union's Low Voltage Directive (73/23/EEC), 7 OUT1- Output 1 RTN (-) 5 DTR White Data Terminal Ready this unit requires an external power disconnect...

- Page 25 Chapter 2...

- Page 26 Programming Site Data Introduction........... . 2-1 Activating a Channel [CHx-ACTIV Menu].

-

Page 27: Introduction

September 2004 Introduction The AT868 has a user program that provides access to the various programmable features of the unit. To program the AT868 you can use either the internal keypad or Panaview™, which is a PC-based, non-resident software program that communicates with the AT868 through its serial port. -

Page 28: Accessing The Activ Submenu

September 2004 Accessing the ACTIV 1. Press [ESC] , [ENTER] , [ESC] in sequence to enter the user program. Submenu 2. Press [ ] until PROG appears and press [ENTER] . 3. Press [ ] until the desired channel appears. Press [ENTER] at CH1 or CH2 . -

Page 29: Selecting The Volumetric Units

September 2004 Selecting the Volumetric 1. Use the arrow keys to select the desired volumetric units for the flow rate display and press [ENTER] . Units 2. Use the arrow keys to select the desired number of digits to the right of the decimal point in the volumetric flow rate display and press [ENTER] . -

Page 30: Entering Transducer And Pipe Parameters [Chx-Pipe Menu]

September 2004 Entering Transducer and Enter the transducer and pipe parameters via the submenu (see PIPE Pipe Parameters Figure A-1 on page A-1). [CHx-PIPE Menu] Accessing the PIPE 1. Press [ESC] , [ENTER] , [ESC] in sequence to enter the user program. Submenu 2. -

Page 31: Special Transducers

If special wetted transducers are being used, proceed to Pipe Outside Diameter on page 2-7. 1. Enter the wedge angle (supplied by GE) of the transducer by using the arrow keys. Press [ and [ ] to move the cursor to the... -

Page 32: Pipe Material

September 2004 Pipe Material If a standard or special clamp-on transducer is being used, the programming sequence should be rejoined here. 1. Press [ and [ ] to select the pipe material and press [ENTER] . Some of the pipe materials require additional selections. See a complete list of choices in Table 2-1 below. -

Page 33: Pipe Outside Diameter

September 2004 Pipe Outside Diameter The programming sequence should be rejoined here for all transducers. 1. Press [ ] to move the cursor to the outside diameter units. Press to select the desired units and press [ENTER] . 2. Measure either the pipe outside diameter (OD) or circumference at the transducer installation site. -

Page 34: Lining

September 2004 Lining 1. Press [ and [ ] to select if your pipe has a lining or your pipe does not have a lining. Then, press [ENTER] . 2. Do one of the following: • If you selected No , proceed to Setting Up a Tracking Window below. -

Page 35: Fluid Type

September 2004 Fluid Type 1. The selections for fluid type vary depending on whether the Tracking Window is enabled or disabled. Press [ and [ ] to select the desired fluid and press [ENTER] . Refer to Table 2-2 below for a list of available fluids. Table 2-2: Fluid Types Tracking Window = NO Tracking Window = YES... -

Page 36: Kv Input Selection

September 2004 KV Input Selection 1. Press [ and [ ] to enter a static kinematic viscosity or a table of values and press [ENTER] . 2. Do one of the following: • If you selected Table , enter the Calibration Factor by using the arrow keys. -

Page 37: Entering The Zero Cutoff Value [Chx-I/O Menu]

September 2004 Entering the Zero Cutoff Near a zero flow rate, the AT868 readings may fluctuate due to small Value [CHx-I/O Menu] offsets caused by thermal drift or similar factors. To force a zero display reading when there is minimal flow, enter a zero cutoff value as described below (see Figure A-1 on page A-1): 1. -

Page 38: Entering Global System Data [Globl-Systm Menu]

September 2004 Entering Global System Refer to Figure A-2 on page A-2, and complete the steps below to Data [GLOBL-SYSTM enter system information in the menu. GLOBL Menu] Selecting the 1. Press [ESC] , [ENTER] , [ESC] in sequence to enter the user program. GLOBL-SYSTM Units 2. -

Page 39: Setting Up The External Totalizer Reset Switch

September 2004 Setting Up the External If you have installed an external totalizer reset switch as described in Chapter 1, Installation, the GATE OPTION enables you to configure Totalizer Reset Switch the switch. 1. At the GATE OPTION prompt, press [ ] to select one of the following and press [ENTER] . -

Page 40: Setting Up The Outputs [Globl-I/O Menu]

September 2004 Setting Up the Outputs To set up the AT868 analog outputs and totalizer/frequency outputs, [GLOBL-I/O Menu] refer to Figure A-2 on page A-2 and follow the instructions in this section. Accessing the Analog Output A and Output C are analog outputs that can be configured Outputs independently. -

Page 41: Accessing The Totalizer/Frequency Outputs

September 2004 Setting Up the Analog 6. At , enter a flow rate value for the high end of the analog FULL Output Scale (cont.) output range by using the arrow keys. Press [ and [ ] to move the cursor to the desired location and press increase or decrease the number. -

Page 42: Setting Up A Frequency Output

September 2004 Setting Up a Frequency 1. At Output B or D , select OFF or FREQ and press [ENTER] . Output 2. Do one of the following: • If you selected OFF , the meter returns to the Global I/O menu. Go to Setting Up a Totalizer Output on the next page. -

Page 43: Setting Up A Totalizer Output

September 2004 Setting Up a Totalizer 1. At Output B or D , select OFF or TTLZR and press [ENTER] . Output 2. Do one of the following: • If you selected OFF , the meter returns to the Global I/O menu. Go to Configuring the Communications Port on the next page. -

Page 44: Configuring The Communications Port [Globl-Comm]

Then press [ENTER] . Note: A meter address is only necessary for communication with the GE Panaview software. See the Panaview User’s Manual for more information. 6. Press [ ] to select a baud rate and press [ENTER] . - Page 45 Chapter 3...

- Page 46 Displaying Data Introduction........... . 3-1 Adjusting LCD Contrast and Brightness .

-

Page 47: Introduction

September 2004 Introduction The AT868 is equipped with a Liquid Crystal Display (LCD), which may be programmed to display up to four variables in sequence. Both the brightness and the contrast of the LCD are easily adjusted by following the instructions in this chapter. In addition, instructions are provided for resetting the totalizers and pausing the measurements. -

Page 48: Setting Up The Display

September 2004 Setting Up the Display Follow the instructions in this section to display the desired data on the display screen (see Figure A-2 on page A-2 in Appendix A, Menu Maps Accessing the Display 1. Press [ESC] , [ENTER] , [ESC] in sequence to enter the user program. Submenu 2. -

Page 49: Resetting The Totalizers

September 2004 Resetting the Totalizers To reset the totalizers, you can use either the internal keypad or an external switch. When resetting the totalizers, the totals for both channels are reset. Use the appropriate section below to reset the totalizers. Resetting Totalizers Using See Figure A-4 on page A-4 in Appendix A, Menu Maps. - Page 50 Chapter 4...

-

Page 51: Chapter 4: Calibration

Calibration Introduction........... . 4-1 Calibrating and Testing the Analog Outputs . -

Page 52: Introduction

September 2004 Introduction Follow the instructions in this chapter to calibrate and test the AT868 analog and totalizer/frequency outputs. Refer to Figure A-4 on page A-4 in Appendix A, Menu Maps, while following the calibration instructions. Calibrating and Testing The AT868 includes one built-in analog output per channel with a resolution of 5.0 μA (0.03% full scale). -

Page 53: Testing Linearity

3. When the desired reading is achieved, select STORE . If the ammeter reading cannot be adjusted with ±5.0 μA of the 4 mA setting, select ABORT to end the calibration and contact GE for assistance. Calibrating the High Point 1. - Page 54 Then, repeat the low and high end calibrations. If the analog output still does not pass the linearity test, contact GE for assistance. 8. Repeat Step 2 for a different output percentage (0-100%). Check the ammeter reading at this setting and press [ENTER] when done.

-

Page 55: Calibrating The Totalizer/Frequency Outputs

September 2004 Calibrating the Prepare for the calibration procedure by connecting a frequency Totalizer/Frequency counter to the appropriate terminal blocks (see Figure 1-5 on page 1-16). Outputs Note: Outputs 1 and 2 in the wiring diagram correspond to Outputs B and D in the AT868 software. Calibrating the Frequency To calibrate the frequency outputs, complete the following steps: Outputs... - Page 56 Appendix A...

- Page 57 Menu Maps The CHx ACTIV, SYSTM, PIPE and I/O Menu Map ... . A-1 The GLOBL Menu Map........A-2 The CHx SETUP Menu Map .

-

Page 58: Appendix A: Menu Maps

September 2004 To enter the User Program press ENTER PROG RESET CALIB (*for 2-Channel meters only) CH2* GLOBL ACTIV SYSTEM PIPE SETUP SYSTM COMM ZERO CUTOFF CHANNEL LABEL (See Figure A-3) See Figure A-2 TRANSDUCER NUMBER SITE/CHANNEL MESSAGE (English) VOLUMETRIC UNITS (Metric) TRANS SPEC... - Page 59 September 2004 To enter the User Program press Keypad Program ENTER PROG RESET CALIB (*for 2-Channel meters only) CH2* GLOBL (See Figure A-1) SYSTEM COMM METER MESSAGE Meter Address SYSTEM UNITS BAUD RATE METRIC 1200 2400 4800 9600 19200 GATE OPTION RESET HOLD 1 CHANNEL UNITS...

- Page 60 September 2004 To enter the User Program press ENTER PROG RESET CALIB (*for 2-Channel meters only) CH2* GLOBL ACTIV SYSTEM PIPE SETUP SYSTM COMM (See Figure A-1) (See Figure A-1) (See Figure A-1) (See Figure A-1) See Figure A-2 SIGNL AVRG INIT ADVAN...

- Page 61 September 2004 To enter the User Program press ENTER PROG RESET CALIB RESET TOTALS? SLOT0 Slot 0 Outputs Totals are NOT Reset Totals are Reset A or C B or D TIME (usec) ANALOG OUTPUT PULSES 4 mA 20 mA TEST EXIT % Full Scale...

- Page 62 Appendix B...

-

Page 63: Appendix B: Measuring P And L Dimensions

Measuring P and L Dimensions Measuring P and L ..........B-1... - Page 64 September 2004 Measuring P and L If you are using wetted transducers, the AT868 requires you to enter the path length (P) and the axial dimension (L). P is the transducer face-to-face distance, and L is the axial projection of P in the flow stream.

- Page 65 September 2004 Measuring P and L (cont.) Use Figure B-2 below to properly measure the pipe coupling length. Typically, the transducer face is positioned just outside the inside diameter (ID) of the pipe, or slightly retracted inside the coupling. Figure B-2: Determining the Pipe Coupling Length Then, use the following formula to determine the P dimension: 2 WT ---------------------------------- -...

- Page 66 DECLARATION Sensing CONFORMITY Panametrics Limited Shannon Industrial Estate Shannon, County Clare Ireland declare under our sole responsibility that the AquaTrans™ AT868 Liquid Flow Ultrasonic Transmitter UPT868-P UltraPure Flow™ Measurement System to which this declaration relates, are in conformity with the following standards: •...

- Page 67 1100 Technology Park Drive Billerica, MA 01821-4111 Web: www.gesensing.com Ireland Sensing House Shannon Free Zone East Shannon, Co. Clare...