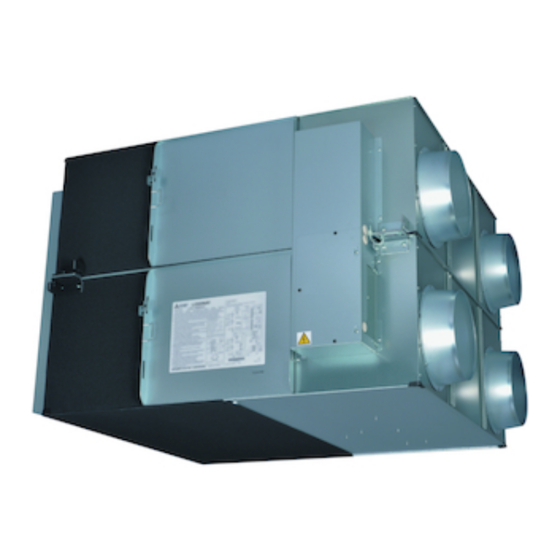

Mitsubishi Electric LOSSNAY LGH-F300RX5-E Handbook

Hide thumbs

Also See for LOSSNAY LGH-F300RX5-E:

- Technical manual (105 pages) ,

- Installation instructions manual (28 pages) ,

- Handbook (83 pages)

Table of Contents

Quick Links

Table of Contents

Summary of Contents for Mitsubishi Electric LOSSNAY LGH-F300RX5-E

- Page 1 January 2012 No. U181 LOSSNAY HAND BOOK FOR DEALERS Model: LGH-F300RX LGH-F470RX LGH-F600RX Nameplate LGH-F1200RX Nameplate Repair work must be performed by the manufacturer, its service agent or a similarly qualified person in order to avoid hazards.

-

Page 2: Table Of Contents

Contents 1. Safety precautions ............... 3 2. Specifications ................4-5 3. Outside dimensions ..............6-9 4. Electrical wiring diagrams ............. 10-12 5. Circuit board diagram ..............13 6. Fundamentals of operation ........... 14-36 7. Troubleshooting ..............37-57 8. Overhauling procedures ............58-60 9. -

Page 3: Safety Precautions

1. Safety precautions Be sure to read the following precautions thoroughly before the maintenance, and then inspect and repair the product in a safe manner. The types and levels of danger that may arise if the product is handled incorrectly are described with the warning symbols shown below. -

Page 4: Specifications

2. Specifications ─ 4 ─... - Page 5 ─ 5 ─...

-

Page 6: Outside Dimensions

3. Outside dimensions LGH-F300RX Unit: Inch ( mm ) ─ 6 ─... - Page 7 LGH-F470RX Unit: Inch ( mm ) ─ 7 ─...

- Page 8 LGH-F600RX Unit: Inch ( mm ) ─ 8 ─...

- Page 9 LGH-F1200RX Unit: Inch ( mm ) ─ 9 ─...

-

Page 10: Electrical Wiring Diagrams

4. Electrical wiring diagrams LGH-F300RX ─ 10 ─... - Page 11 LGH-F470RX -E, LGH-F600RX ─ 11 ─...

- Page 12 LGH-F1200RX ─ 12 ─...

-

Page 13: Circuit Board Diagram

5. Circuit board diagram Circuit board diagram and check points Common for SA * Fan drive output voltage: Each 208 to 230 V AC fan drive (TAB5) EA fan drive SA fan drive Transformer (CN9) (CN10) primary (input) Power supply Common for EA 208 to 230 V AC (CN1) -

Page 14: Fundamentals Of Operation

6. Fundamentals of operation Description of the circuit operation ( 1 ) System Configuration Lossnay operates through the following system. System Prepared System Diagram Features Parts Classification Details Basic 1 Lossnay • One remote controller oper- Lossnay Lossnay System unit ates one Lossnay unit. - Page 15 System Prepared System Diagram Features Parts Classification Details Systems Mitsubishi • Lossnay can be interlocked When using PZ-60DR-E inter- City Multi with a maximum of 16 air Lossnay City Multi locked air condi- conditioning units. Indoor unit Transmission M-NET Remote with tioner •...

- Page 16 Remote controller list 1 Remote controllers Rough Classification Fine Classification Product Model PZ-60DR-E For Lossnay independent control Lossnay remote controller PZ-41SLB-E For Lossnay M-NET control Lossnay remote controller PZ-52SF-E MA remote controller PAR-20/21MAA MA remote control- Wireless remote controller PAR-FA ( FL ) 31MA M-NET For City Multi air con- Compact remote controller PAC-YT51CRA...

- Page 17 ( 3 ) Fan control 1 Fan speed control for each system The control indicated below can be performed according to the system that is paired. Up to two of the Lossnay remote controllers PZ-60DR-E, PZ-41SLB-E, and PZ-52SF-E can be used in the same group, but they cannot be used together with a different remote control- ler.

- Page 18 2 Fan speed control by function setting The following fan speed control can be set with PZ-60DR-E or the function selection switch (SW2) on the Lossnay circuit board. Setting Method PZ-60DR-E PZ-60DR-E Not Used Function Details ( Remote controller ( Function selec- function selection ) tion switch ) Extra High...

- Page 19 Setting Method PZ-60DR-E PZ-60DR-E Not Used Function Details ( Remote controller ( Function selec- function selection ) tion switch ) Fan motor When TM4 9, 0 output settings, and TM3 6, 7 output set- TM4 9, 0 output setting delay stop tings are set to operation monitor with delay function 1 or 2, “Operation monitor with delay ( Operation...

- Page 20 2 Damper control for each system The control indicated below can be performed according to the system that is paired. Up to two of the Lossnay remote controllers PZ-60DR-E, PZ-41SLB-E, and PZ-52SF-E can be used in the same group, but they cannot be used together with a different remote controller.

- Page 21 3 Bypass ventilation prohibited When the conditions described below are applicable, the ventilation mode will be fixed at Lossnay ventila- tion. When bypass ventilation has been set from the remote controller or the system controller, damper operation will be set to Lossnay ventilation, even though bypass ventilation is displayed on the ventilation mode display.

- Page 22 b. When there is no interlocking with Mr. Slim and City Multi indoor units Pattern 1. Normal ventilation mode When PZ-60DR-E is used, operation will be at the setting of automatic ventilation adjustment pattern “1” of the remote controller function selection. When PZ-60DR-E is not used, operation will be at the OFF setting of function selection switch ( SW2-7 ) on the Lossnay circuit board.

- Page 23 6 Ventilation mode change recommendation (RECOMMENDED, VENTILATION MODE) display When PZ-60DR-E is used and the ventilation mode is set to Lossnay ventilation or bypass ventilation, “RECOMMENDED” and “VENTILATION MODE” may be displayed alternately (for 10 minutes maximum). This function informs the user of the suitable ventilation mode according to the automatic ventilation algo- rithm.

- Page 24 2 Interlock mode Lossnay can set the following four types of interlock modes for the start/stop signal from the external device. Setting Method PZ-52SF-E or remote Interlock Other than pulse signal PZ-60DR-E PZ-41SLB-E Pulse signal input controller not used mode input ( Remote controller ( Interlock...

- Page 25 ( 6 ) External input/output terminals on the Lossnay circuit board Located on the Lossnay circuit board are terminals for the external output of the Lossnay operating condition, and input terminals for external switching of the Lossnay fan speed and ventilation mode. 1 Output terminals The function and contact rating of each output terminal are described below.

- Page 26 [1] For operating on High ( Extra High ) fan speed via external input Usually, ventilation is performed at Low/Extra Low fan speed, and there is automatic switching to High ( Extra High ) fan speed when dirty indoor air is detected by a CO sensor, etc.

- Page 27 b. Bypass ventilation switching input This is used to force a changeover of the ventilation mode to bypass ventilation by means of the input of an external switch, etc. During the input of bypass ventilation switching, the ventilation mode display of the remote Operation controller and the system controller will change to bypass ventilation.

- Page 28 ( 8 ) Trial operation function This function operates Lossnay without the need of a device ( such as a remote controller, or an external de- vice ) to control Lossnay. This function permits verification of the connection condition of the AC line and wiring when Lossnay has been set up.

- Page 29 Night Purge mode is active; no operation 1:00 A.M. The outdoor temperature (OA) setting can be selected either 62.6°F (17°C) or Outdoor 82.4°F (28°C) by using Dip-Switch (SW2-7) in the Lossnay control box. temperature 62.6°F (17°C)/ Refer to the remote controller installation manual for more information. 82.4°F (28°C) or more (within 24 hours) Temperature monitoring...

- Page 30 ( 10 ) Setting of function selection switches ( SW1, 2, and 5 ) The associated switches are as listed below. * This function can also be set from PZ-60DR-E. When the function has been switched from the remote con- troller later on, the system will operate according to the setting of the remote controller.

- Page 31 Type Name Specification Exhaust fan stop at outdoor air ON : Both Supply air fan and Exhaust air fan stop OFF: Exhaust air fan operation ( Only Supply air fan stopped ) ( Factory temperature of 5°F (-15°C) or setting ) lower * Type setting LGH-F300 to F600 types : Fixed at OFF...

- Page 32 1 Function selection mode The following functions can be changed with PZ-60DR-E function selection mode. Please change the set- tings as needed. Intermediate Dot matrix Selection Major items Function Notes items ( Names ) display display Change English display Dot matrix display characters English ( Factory setting ) Language...

- Page 33 *2: When the 24 hour ventilation setting is ON, “24HR VENTILATION” is displayed during Extra Low fan speed operation. When the pulse input setting is ON, the 24 hour ventilation setting is not permitted. When two remote controllers are used, the 24 hour ventilation setting is not permitted from the “Sub” remote controller.

- Page 34 Intermediate Dot matrix Selection Major items Function Notes items ( Names ) display display ON/OFF interlocked ( Factory setting ) Interlocking Interlock mode onoF item setting selection ON interlocked OFF interlocked External input signal priority Pulse input set- Without pulse input ( Factory setting ) ting With pulse input Without delay operation ( Factory setting )

- Page 35 Total operation hours, Maintenance items display Dot display ON/OFF button button CLEAR button MENU (MONITOR/SET) button Back button Intermediate Dot matrix Major items Function Notes items ( Names ) display Total opera- Total operation Displays the total Lossnay operation hours. ( The 10,000 and 100,000 hours digits are displayed in tion hours hours display...

- Page 36 ( 12 ) Operation sequence flowchart Power On System with System without Selection Lossnay remote controller Lossnay remote controller switch input Is there a Lossnay remote controller? Data input Data input Temperature data Temperature data (Outdoor air temperature/Indoor (Outdoor air temperature/Indoor temperature) temperature) Diverse error detection...

-

Page 37: Troubleshooting

7. Troubleshooting Work precautions • When removing or touching a transformer, printed circuit board or other parts, make sure to turn off the power supply isolator. • When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force to the surface mounted parts. - Page 38 7-2 Checklist ( 1 ) Troubleshooting 1: The system will not start properly. Initialization checklist from installation to operation ( Table 1-1 ) After checking the system, verify the checkpoints listed below. Power supply ( Table 1-1-1 ) Checkpoint Action Is the main power supply on? Turn on the main power supply.

- Page 39 Signal cables from external devices ( Table 1-1-3 ) Check the following checkpoints when connecting with level signal/pulse signal output devices, and Mr. Slim units. Checkpoint Action Do the transmission cables meet regulations? ( Type, diameter ) Use specified cables. Is the signal cable wired at least 2 in.

- Page 40 Signal cables to external devices ( Table 1-1-4 ) Check the following checkpoints when outputting the operation monitor, air supply fan operation monitor, mal- function monitor, bypass operation monitor, and operation monitor with delay function. Checkpoint Action Do the signal cables meet regulations? ( Type, diameter ) Use specified cables.

- Page 41 System checklist ( Table 1-2 ) When using PZ-60DR-E, PZ-41SLB-E, or interlocking with external devices ( Table 1-2-1 ) Error Cause Action • Remote controller Power is not supplied to the Lossnay, or power Check the power supply to the Lossnay.

- Page 42 Error Cause Action The interlock mode is set to “ ON Interlocked ” Interlock operation Check the Interlock mode setting or “ OFF Interlocked ” with the remote controller with the remote controller ( PZ- with external device ( PZ-60DR-E ) .

- Page 43 Error Cause Action Cannot perform group Power is not supplied to Lossnay, or power Check the power supply to Lossnay settings for the Lossnay that does not follow specifications is used. and perform the registration again. using MELANS, ME ...

- Page 44 Error Cause Action The remote controller The specified power is not supplied to Lossnay. Check the power to Lossnay. PZ-52SF-E continues Group setting of the PZ-52SF-E address Check the address registration of to blink “ HO ” when the has not been performed with MELANS.

- Page 45 ( 2 ) Troubleshooting 2 An error code displays on the remote controller. The LED on the Lossnay circuit board is blinking or lit up. An error code displayed on the remote controller ( PZ-60DR-E, PZ-41SLB-E, PZ-52SF-E ) or the M-NET control- ler, and blinking or illumination of LED1 ( green ) or LED2 ( red ) on the circuit board shows the type of an error.

- Page 46 LED1 LED2 Error code Error Cause Action ( green ) ( red ) LC 3602 Damper re- Damper board operation is not Remove the rod, and check SLC 3602 blinks lated error correct. whether the damper board can be moved manually. Connectors for the damper unit Check the connection of the lead wire are not correctly connected.

- Page 47 Checklist of error codes displayed on PZ-60DR-E ( when using M-NET ) , PZ-52SF-E or M-NET controllers, and LED displays ( Table 2-2 ) Error code LED1 LED2 Error Cause Action ( green ) ( red ) 6600 Multiple There is another unit with the same Check the addresses of devices in blinks address error...

- Page 48 LED1 LED2 Error code Error Cause Action ( green ) ( red ) 6603 Transmission Power is supplied to the same Adjust the wiring of the power sup- blinks cable error transmission cable from two or ply unit. more power supply units. The power supply unit is connect- ed to the TB3 side of the power supply expansion unit.

- Page 49 ( 3 ) Troubleshooting 3: The remote controller operation is disabled or irregular. Checklist for PZ-60DR-E or PZ-41SLB-E ( Table 3-1 ) Error Cause Action 1 Nothing displays on the Transmission cable is connected to the Check the transmission cable con- LCD.

- Page 50 Error Cause Action 7 The ventilation mode The bypass ventilation switching external Check the bypass ventilation cannot be switched with input (CN16) is set to ON. switching input (CN16). (Refer to the remote controller. page 27) 8 When the main power ...

- Page 51 Checklist for PZ-52SF-E ( Table 3-2 ) Error Cause Action 1 Nothing displays on the Transmission cable is connected to the Check the transmission cable LCD. wrong terminal block. connection (TB5 A , B for M-NET transmission cables). ...

- Page 52 ( 4 ) Troubleshooting 4: The Lossnay operation is disabled or irregular. Lossnay checklist ( Table 4 ) Error Cause Action 1 The fan does not oper- Connectors for the fan or connectors for the Check the lead wire connectors ate.

- Page 53 Error Cause Action When PZ-60DR-E is used, “ RECOVERY 4 Lossnay operates when Check the power supply ON/ the main power is turned SETTING ” is set to “ on ” or “ AUTo ” with the OFF/AUTO setting with the PZ- 60DR-E function selection.

- Page 54 Error Cause Action 8 The damper board does The outdoor air temperature is 46.4°F (8°C) Check the outdoor air tempera- not operate. or lower. ture. The bypass ventilation switching external Check the bypass ventilation input ( CN16 ) is set to ON. switching input ( CN16 ) .

- Page 55 It is normal in the following cases. Error Cause Reference 1 Immediately after turning on LED1 blinks at 1 second intervals during starting operation (maximum Page the main power, LED1 (green) of 45 seconds). on the Lossnay circuit board blinks. 2 LED1 (green) on the Lossnay LED1 will be lit during the delay operation when the delay operation Page...

- Page 56 Error Cause Reference 12 When PZ-41SLB-E is used, The settings will be disabled for switches (SW2-6, SW5-1, SW5-4, Page the operation will not be in SW5-5, SW5-7, and SW5-8). accordance with the setting of the function selection switch on the Lossnay circuit board. 13 When PZ-60DR-E is used, Page In the following circumstances “...

- Page 57 Temperatures and thermistor resistance table Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance ( °F ) value ( kΩ ) ( °F ) value ( kΩ ) ( °F ) value ( kΩ ) ( °F ) value ( kΩ ) ( °F ) value ( kΩ...

-

Page 58: Overhauling Procedures

8. Overhauling procedures Work precautions • When touching the electric components such as circuit boards and fan motors, do not touch the components for more than 5 minutes after power-off, and then start working. • Before replacing parts, repair troubled sections according to the instructions described in the troubleshoot- ing. - Page 59 3 Unscrew the fixing screws (two special screws 4×22.5, indicated by ), and remove the core guides (left and right). Core guide 4 Slide the connector covers (with the connector) toward the Lossnay core side, and then take them off from the unit.

- Page 60 6 Take off the separators. Separator 7 Unscrew the screws (four PTT screws 5×10, indicated Motor ( for supply air ) by ) for the motor fix plate (SA side). (Remove the EA side motor in the same way.) Motor fix plate When reassembling Reassemble the unit in the reverse order of disassembly.

-

Page 61: Parts Catalog

9. Parts catalog Please note the following when using the parts catalog. 1. When ordering parts, always indicate the part number, part name, and the number of parts required. 2. Parts are not always available, and it may take time for you to receive them. 3. -

Page 62: Lgh-F300Rx 5 -E

LGH-F300RX 16 pcs. shows accessory parts. ─ 62 ─ LGH-F300RX... - Page 63 Model LGH-F300RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 1. R50 541 045 Special screw 4×22.5 2. R50 521 710 Filter stopper 3. R50 542 383 Core guide (left) 4. H00 000 244 PT screw 6×12 5.

- Page 64 Air supply fan assembly Air exhaust fan assembly ─ 64 ─ LGH-F300RX...

- Page 65 Model LGH-F300RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 21. R50 331 067 Special nut (8) Left-handed 22. M34 398 077 Tab washer 23. R50 542 480 Centrifugal fan φ220 24. R50 542 707 Fan base 25.

- Page 66 shows accessory parts. ─ 66 ─ LGH-F300RX...

- Page 67 Model LGH-F300RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 51. R50 533 693 Fix piece 52. Y50 151 706 Damper motor cover 53. Y50 115 225 Bush 54. Y50 061 260 Damper motor (GM) AC220・240V 55.

-

Page 68: Lgh-F470Rx 5 -E

LGH-F470RX 16 pcs. shows accessory parts. ─ 68 ─ LGH-F470RX... - Page 69 Model LGH-F470RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 1. R50 541 045 Special screw 4×22.5 2. R50 522 710 Filter stopper 3. R50 543 383 Core guide (left) 4. R50 543 704 Cover 5. H00 000 244 PT screw 6×12 6.

- Page 70 Air exhaust fan assembly Air supply fan assembly ─ 70 ─ LGH-F470RX...

- Page 71 Model LGH-F470RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 21. R50 218 067 Special nut (12) Left-handed 22. K83 466 113 Washer (12) 23. R50 543 480 Centrifugal fan φ245 24. R50 543 709 Fan base 25.

- Page 72 shows accessory parts. ─ 72 ─ LGH-F470RX...

- Page 73 Model LGH-F470RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 51. R50 533 693 Fix piece 52. Y50 151 706 Damper motor cover 53. Y50 115 225 Bush 54. Y50 061 260 Damper motor (GM) AC220・240V 55.

-

Page 74: Lgh-F600Rx 5 -E

LGH-F600RX 16 pcs. shows accessory parts. ─ 74 ─ LGH-F600RX... - Page 75 Model LGH-F600RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 1. R50 541 045 Special screw 4×22.5 2. R50 522 710 Filter stopper 3. R50 544 381 Core guide (left) 4. H00 000 244 PT screw 6×12 5.

- Page 76 Air exhaust fan assembly Air supply fan assembly ─ 76 ─ LGH-F600RX...

- Page 77 Model LGH-F600RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 21. R50 218 067 Special nut (12) Left-handed 22. K83 466 113 Washer (12) 23. R50 543 480 Centrifugal fan φ245 24. R50 543 709 Fan base 25.

- Page 78 shows accessory parts. ─ 78 ─ LGH-F600RX...

- Page 79 Model LGH-F600RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 51. R50 533 693 Fix piece 52. Y50 151 706 Damper motor cover 53. Y50 115 225 Bush 54. Y50 061 260 Damper motor (GM) AC220・240V 55.

-

Page 80: Lgh-F1200Rx 5 -E

LGH-F1200RX 16 pcs. shows accessory parts. ─ 80 ─ LGH-F1200RX... - Page 81 Model LGH-F1200RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 1. R50 543 487 Maintenance cover 2. R50 541 045 Special screw 4×22.5 3. R50 522 710 Filter stopper 4. R50 544 381 Core guide (left) 5.

- Page 82 Air exhaust fan assembly Air supply fan assembly ─ 82 ─ LGH-F1200RX...

- Page 83 Model LGH-F1200RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 21. R50 218 067 Special nut (12) Left-handed 22. K83 466 113 Washer (12) 23. R50 543 480 Centrifugal fan φ245 24. R50 543 709 Fan base 25.

- Page 84 shows accessory parts. ─ 84 ─ LGH-F1200RX...

- Page 85 Model LGH-F1200RX5-E Parts No. Name of part Q'ty Critical Remarks Price pcs/unit for safety 51. Y50 151 706 Damper motor cover 52. H00 000 349 PT screw 4×8 53. Y50 115 225 Bush 54. Y50 154 260 Damper motor GM (assy) 55.