Siemens Sinamics S120 Manual

Liquid-cooled chassis power units

Hide thumbs

Also See for Sinamics S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens Sinamics S120

- Page 3 ___________________ Preface Fundamental safety ___________________ instructions ___________________ SINAMICS System overview ___________________ Line-side power components S120 Liquid-cooled chassis power units ___________________ Power Modules ___________________ Line Modules Manual ___________________ Motor Modules ___________________ Motor-side power components ___________________ Cabinet design and EMC ___________ Cooling circuit, coolant properties and protection against condensation ___________________...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

Siemens' content, and adapt it for your own machine documentation: http://www.siemens.com/mdm Training Using the following link, you can find information on SITRAIN - training from Siemens for products, systems and drive technology solutions: http://www.siemens.com/sitrain FAQs You can find Frequently Asked Questions in the Service&Support pages under Product Support: https://support.industry.siemens.com/cs... - Page 6 (Catalog PM 21) SINAMICS S120 Chassis Units and Cabinet Modules, SINAMICS • S150 Converter Cabinet Units (Catalog D 21.3) Configuring/installation SINAMICS S120 Manual for Control Units and Additional System • Components SINAMICS S120 Manual for Booksize Power Units • SINAMICS S120 Manual for Chassis Power Units, Air-cooled •...

- Page 7 The EC Declaration of Conformity for the EMC Directive and the Low-Voltage Directive are available on the Internet at: https://support.industry.siemens.com/cs/ww/en/ps/13231/cert Alternatively, you can contact the Siemens office in your region in order to obtain the EC Declaration of Conformity. Note Complying with the low-voltage directive In the operational state –...

- Page 8 An up-to-date list of currently certified components is also available on request from your local Siemens office. If you have any questions relating to certifications that have not yet been completed, please ask your Siemens contact. Note on the design of a UL-approved system...

-

Page 9: Table Of Contents

Basic structure of a drive system with liquid-cooled SINAMICS S120 ........36 2.5.1 Structure of a drive system with liquid-cooled SINAMICS S120 and Power Module ..... 36 2.5.2 Structure of a drive system with liquid-cooled SINAMICS S120 and regulated infeed ..37 2.5.3... - Page 10 Table of contents 3.3.3.5 X530 neutral point grounding ....................56 3.3.3.6 X609 terminal strip ......................... 57 3.3.3.7 Meaning of the LED on the Voltage Sensing Module (VSM) in the Active Interface Module ........................... 58 3.3.4 Dimension drawing ........................ 59 3.3.5 Electrical connection ......................

- Page 11 Table of contents Technical specifications ......................127 4.7.1 Overload capability ....................... 128 4.7.2 Derating factors as a function of coolant temperature ............130 4.7.3 Derating factors as a function of the ambient temperature ........... 131 4.7.4 Derating factors as a function of installation altitude ............132 4.7.5 Current derating as a function of the pulse frequency ............

- Page 12 Table of contents Motor Modules ............................. 199 Description ........................... 199 Safety information ........................ 200 Interface description ......................203 6.3.1 Overview ..........................203 6.3.2 Connection example ......................207 6.3.3 DC link/motor connection ..................... 208 6.3.4 X9 terminal strip ........................208 6.3.5 X41 EP terminal / temperature sensor connection ..............

- Page 13 Table of contents 7.4.4 Connecting the dv/dt filter compact plus Voltage Peak Limiter ..........281 7.4.5 Dimension drawing for dv/dt filter compact plus Voltage Peak Limiter ......... 284 7.4.6 Technical data ........................290 Cabinet design and EMC ........................295 Notes ............................. 295 8.1.1 General ..........................

- Page 14 Table of contents 10.4.6 Replacing the Control Interface Module, Motor Module, frame size FXL ......360 10.4.7 Replacing the Control Interface Module, Active Line Module and Motor Module, frame size GXL ..........................363 10.4.8 Replacing the Control Interface Module, Active Line Module and Motor Module, frame size HXL ..........................

-

Page 15: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions DANGER Danger to life due to live parts and other energy sources Death or serious injury can result when live parts are touched. • Only work on electrical devices when you are qualified for this job. •... - Page 16 Fundamental safety instructions 1.1 General safety instructions WARNING Danger to life when live parts are touched on damaged devices Improper handling of devices can cause damage. For damaged devices, hazardous voltages can be present at the enclosure or at exposed components;...

- Page 17 Fundamental safety instructions 1.1 General safety instructions WARNING Danger to life due to fire spreading if housing is inadequate Fire and smoke development can cause severe personal injury or material damage. • Install devices without a protective enclosure in a metal control cabinet (or protect the device by another equivalent measure) in such a way that contact with fire is prevented.

- Page 18 Fundamental safety instructions 1.1 General safety instructions WARNING Danger of an accident occurring due to missing or illegible warning labels Missing or illegible warning labels can result in accidents involving death or serious injury. • Check that the warning labels are complete based on the documentation. •...

-

Page 19: Safety Instructions For Electromagnetic Fields (Emf)

Fundamental safety instructions 1.2 Safety instructions for electromagnetic fields (EMF) Safety instructions for electromagnetic fields (EMF) WARNING Danger to life from electromagnetic fields Electromagnetic fields (EMF) are generated by the operation of electrical power equipment such as transformers, converters or motors. People with pacemakers or implants are at a special risk in the immediate vicinity of these devices/systems. -

Page 20: Industrial Security

In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept. Siemens products and solutions represent only one component of such a concept. -

Page 21: Residual Risks Of Power Drive Systems

Fundamental safety instructions 1.5 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine or system-related risk in accordance with the respective local regulations (e.g. EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. - Page 22 Fundamental safety instructions 1.5 Residual risks of power drive systems Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 23: System Overview

The SINAMICS range of drives Field of application SINAMICS is the comprehensive family of drives from Siemens designed for machine and plant engineering applications. SINAMICS offers solutions for all drive tasks: ● Simple pump and fan applications in the process industry ●... - Page 24 System overview 2.1 The SINAMICS range of drives Variants Depending on the application, the SINAMICS range offers the ideal variant for any drive task. ● SINAMICS V From both the hardware perspective as well as the functionality, these converters focus on the essential issues.

- Page 25 2.1 The SINAMICS range of drives Totally Integrated Automation and communication SINAMICS is an integral component of Siemens Totally Integrated Automation. The integrated and seamless SINAMICS system covering engineering, data management, and communication at the automation level ensures solutions with low associated costs in conjunction with the SIMATIC, SIMOTION, and SINUMERIK control systems.

- Page 26 System overview 2.1 The SINAMICS range of drives Depending on the application, the appropriate converter can be selected and incorporated in the automation concept. With this in mind, the converters are clearly subdivided into their different applications. A wide range of communication options (depending on the drive type) are available for establishing a communication link to the automation system: ●...

-

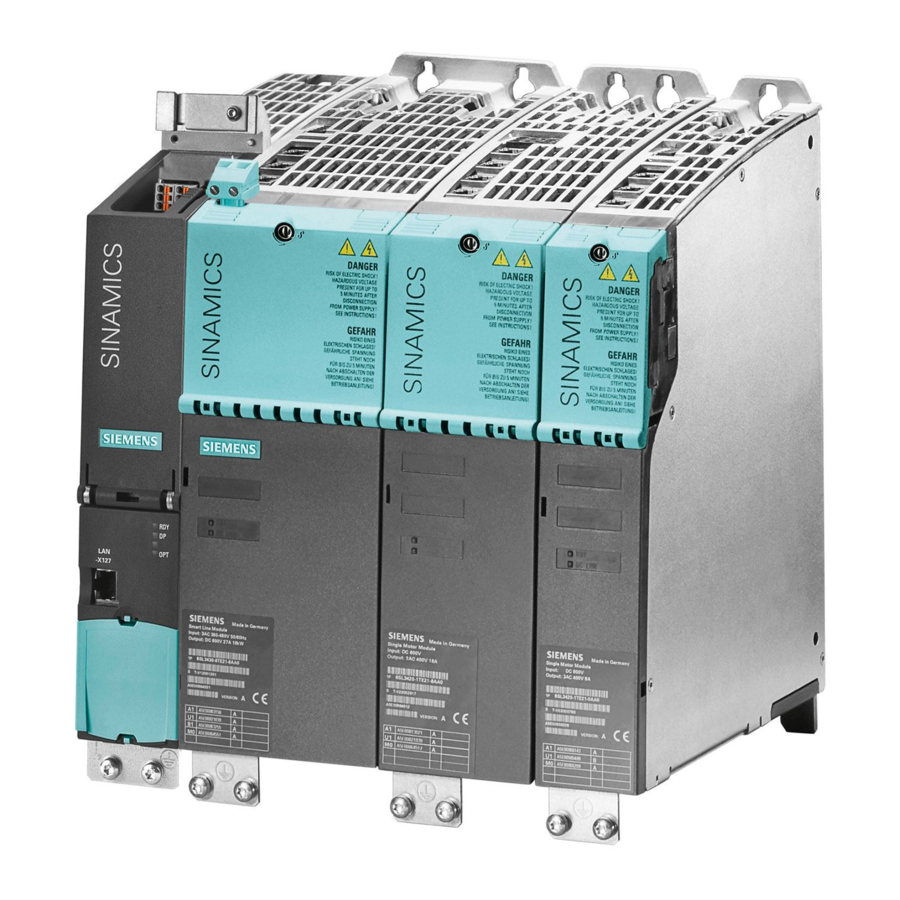

Page 27: Sinamics S120 Drive System

SINAMICS S120 drive system Overview SINAMICS S120 is the modular drive system with vector and servo control that is ideal for sophisticated drive tasks in plant and machine construction. Multi-axis drive solutions with higher-level motion control can be implemented with the modular SINAMICS S120 system just the same as solutions for single-axis drives. - Page 28 The electronic rating plate Electronic type plates in every component represent a digital link to the SINAMICS S120 drive system. They allow all drive components to be automatically identified via the DRIVE- CLiQ link.

- Page 29 ● Additional system components that enhance functionality and offer different interfaces for encoders and process signals. SINAMICS S120 components were developed for installation in cabinets. They have the following features and characteristics: ● Easy to handle, simple installation and wiring ●...

-

Page 30: Technical Specifications

System overview 2.3 Technical specifications Technical specifications Technical data Unless specified otherwise, the following technical specifications are valid for all the following components of the SINAMICS S120 drive system, liquid-cooled. Table 2- 1 General technical data Electrical data Line supply voltage 3 AC 380 V -10% (-15% <... - Page 31 System overview 2.3 Technical specifications Ambient conditions Degree of protection IP00 according to EN 60529 (IP20, without taking into account the connecting busbars) Protection class Class I (with protective conductor system) and class III (PELV) according to EN 61800-5-1 Touch protection EN 50274 and DGUV regulation 3 when used for the intended purpose Cooling method according to Power Modules, Basic Line Modules, Active Line Modules, Motor Modules:...

- Page 32 System overview 2.3 Technical specifications Environmental class/harmful chemical substances Storage Class 1C2 according to EN 60721-3-1 • • Transport Class 2C2 according to EN 60721-3-2 • • Operation Class 3C2 according to EN 60721-3-3 • • Organic/biological influences Storage Class 1B1 according to EN 60721-3-1 •...

-

Page 33: Standards

System overview 2.4 Standards Standards Note Information on the listed standards The standards listed in the table below are non-binding and do not in any way claim to be complete. The standards listed do not represent a guaranteed property of the product. Only the statements made in the Declaration of Conformity shall be deemed binding. - Page 34 System overview 2.4 Standards Standards* Title EN 60269-1 Low-voltage fuses; IEC 60269-1 Part 1: General requirements DIN EN 60269-1 VDE 0636-1 IEC 60287-1 to -3 Cables - Calculation of the current carrying capacity Part 1: Current carrying capacity equations (100 % load factor) and calculating the losses Part 2: Thermal resistance - Part 3: Main sections for operating conditions HD 60364-x-x...

- Page 35 System overview 2.4 Standards Standards* Title EN 61800-3 Adjustable-speed electrical power drive systems; IEC 61800-3 Part 3: EMC - Requirements and specific test methods DIN EN 61800-3 VDE 0160-103 EN 61800-5-x Adjustable-speed electrical power drive systems; IEC 61800-5-x Part 5: Safety requirements; DIN EN 61800-5-x Main section 1: Electrical, thermal and energy requirements VDE 0160-105-x...

-

Page 36: Basic Structure Of A Drive System With Liquid-Cooled Sinamics S120

Basic structure of a drive system with liquid-cooled SINAMICS S120 2.5.1 Structure of a drive system with liquid-cooled SINAMICS S120 and Power Module Figure 2-3 Basic structure of a drive system with liquid-cooled SINAMICS S120 and Power Module Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 37: Structure Of A Drive System With Liquid-Cooled Sinamics S120 And Regulated Infeed

2.5 Basic structure of a drive system with liquid-cooled SINAMICS S120 2.5.2 Structure of a drive system with liquid-cooled SINAMICS S120 and regulated infeed Figure 2-4 Basic structure of a drive system with liquid-cooled SINAMICS S120 and regulated infeed Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 38: Structure Of A Drive System With Liquid-Cooled Sinamics S120 And Unregulated Infeed

2.5 Basic structure of a drive system with liquid-cooled SINAMICS S120 2.5.3 Structure of a drive system with liquid-cooled SINAMICS S120 and unregulated infeed Figure 2-5 Basic structure of a drive system with liquid-cooled SINAMICS S120 and unregulated infeed Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 39: Line-Side Power Components

Line-side power components Line reactors for Power Modules 3.1.1 Description The line reactors limit low-frequency line harmonics and reduce the load on the semiconductors in the Power Modules. A line reactor is not required where the effective supply impedance equals uk > 3 %. 3.1.2 Safety information WARNING... - Page 40 Line-side power components 3.1 Line reactors for Power Modules NOTICE Damage to the system caused by the use of inappropriate and not approved line reactors Inappropriate and not approved line reactors can damage the Power Modules. Line harmonics that damage/disturb other loads connected to the same line supply can also occur.

-

Page 41: Dimension Drawing

Line-side power components 3.1 Line reactors for Power Modules 3.1.3 Dimension drawing Figure 3-1 Dimension drawing of line reactor for Power Modules Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 42: Technical Data

Line-side power components 3.1 Line reactors for Power Modules Table 3- 1 Dimensions of line reactors for Power Modules (all data in mm) 6SL3000- 0CE32-3AA0 0CE32-8AA0 0CE33-3AA0 0CE35-1AA0 12.5 12.5 12.5 212.5 84.5 84.5 84.5 Lengths n1 and n2 correspond to the distance between holes 3.1.4 Technical data Table 3- 2... -

Page 43: Line Reactors For Basic Line Modules

Line-side power components 3.2 Line reactors for Basic Line Modules Line reactors for Basic Line Modules 3.2.1 Description Line reactors limit low-frequency line harmonics and reduce the load on the semiconductors in the Basic Line Modules. A line reactor must be used if several Basic Line Modules are operated in parallel. A line reactor is not required if a single Basic Line Module is used and the effective supply impedance equals uk >... - Page 44 Line-side power components 3.2 Line reactors for Basic Line Modules Note Malfunctions through magnetic fields Reactors produce magnetic fields that can disturb or damage components and cables. • Arrange the components and cables at a suitable distance (at least 200 mm) or shield the magnetic fields appropriately.

-

Page 45: Dimension Drawing

Line-side power components 3.2 Line reactors for Basic Line Modules 3.2.3 Dimension drawing Figure 3-2 Dimension drawing of line reactors for Basic Line Modules Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 46 Line-side power components 3.2 Line reactors for Basic Line Modules Table 3- 3 Dimensions of line reactors for Basic Line Modules, 380 V ... 480 V 3 AC (all values in mm) 6SL3000- 0CE36-3AA0 0CE41-0AA0 0CE41-5AA0 18 x 14 152.5 212.5 211.5 Lengths n1 and n2 correspond to the distance between holes...

-

Page 47: Technical Data

Line-side power components 3.2 Line reactors for Basic Line Modules 3.2.4 Technical data Table 3- 5 Technical data, line reactors for Basic Line Modules, 380 ... 480 V 3 AC Article number 6SL3000- 0CE36-3AA0 0CE41-0AA0 0CE41-5AA0 Suitable for 6SL3335- 1TE37-4AAx 1TE41-2AAx 1TE41-7AAx Basic Line Module... -

Page 48: Active Interface Modules, Air-Cooled

Line-side power components 3.3 Active Interface Modules, air-cooled Active Interface Modules, air-cooled 3.3.1 Description Air-cooled Active Interface Modules are used in conjunction with liquid-cooled Active Line Modules in chassis format. The air-cooled Active Interface Modules contain a Clean Power Filter with basic RI suppression, the pre-charging circuit for the Active Line Module, the line voltage sensing circuit and monitoring sensors. -

Page 49: Safety Information

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.2 Safety information WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed The non-observance of the fundamental safety instructions and residual risks stated in Chapter 1 can result in accidents with severe injuries or death. •... - Page 50 Line-side power components 3.3 Active Interface Modules, air-cooled WARNING Danger of an accident due to missing warning labels in the national language. Missing warning labels in the national language can result in death or serious injury. • Attach the component warning labels in the national language. Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 51: Interface Description

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3 Interface description 3.3.3.1 Overview Figure 3-3 Interface overview in the Active Interface Module, frame size GI Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 52 Line-side power components 3.3 Active Interface Modules, air-cooled Figure 3-4 Interface overview in the Active Interface Module, frame size HI Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 53: Connection Example

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3.2 Connection example Figure 3-5 Connection example Active Interface Module, frame size GI Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 54 Line-side power components 3.3 Active Interface Modules, air-cooled Figure 3-6 Connection example Active Interface Module, frame size HI NOTICE Damage to the device through different phase sequence in the pre-charging and main circuits Different phase sequences in the pre-charging and main circuits can overload and destroy the pre-charging resistors of the Active Interface Module during the brief overlap period, where both contactors are simultaneously closed.

-

Page 55: Line/Load Connection

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3.3 Line/load connection Table 3- 8 Connections for the Active Interface Module Terminals Designations X1: L1, L2, L3 Voltage: X2: U2, V2, W2 3 AC 380 V -10 % (-15 % < 1 min) ... 3 AC 480 V +10 % •... -

Page 56: X530 Neutral Point Grounding

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3.5 X530 neutral point grounding Table 3- 10 Neutral point grounding X530 Terminal Designation Technical data Neutral point of the Jumper inserted: Grounded measurement voltage sensing Jumper not inserted: isolated measurement Ground potential The Voltage Sensing Module is supplied with inserted jumper. -

Page 57: X609 Terminal Strip

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3.6 X609 terminal strip Table 3- 11 Terminal strip X609 Terminal Designation Technical data External 24 V DC supply Voltage: 24 VDC (20.4 ... 28.5 V) Current consumption: Max. 0.25 A Voltage: 230 VAC (195.5 ... 264.5 V) Current consumption: Max. -

Page 58: Meaning Of The Led On The Voltage Sensing Module (Vsm) In The Active Interface

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.3.7 Meaning of the LED on the Voltage Sensing Module (VSM) in the Active Interface Module Table 3- 12 Description of the LED on the Voltage Sensing Module (VSM) in the Active Interface Module Color Status Description... -

Page 59: Dimension Drawing

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.4 Dimension drawing Dimension drawing, frame size GI The mandatory cooling clearances are indicated by the dotted line. Figure 3-8 Dimension drawing for Active Interface Module, frame size GI Side view, front view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 60 Line-side power components 3.3 Active Interface Modules, air-cooled Dimension drawing, frame size HI The mandatory cooling clearances are indicated by the dotted line. Figure 3-9 Dimension drawing for Active Interface Module, frame size HI Side view, rear view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 61: Electrical Connection

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.5 Electrical connection The Active Interface Module is electrically connected in accordance with the connection examples shown in section "Interface description". Operating an Active Interface Module on a non-grounded line supply (IT system) When the device is operated on a non-grounded line supply (IT system), the integrated basic interference suppression modules must be deactivated by removing a connection clip. - Page 62 Line-side power components 3.3 Active Interface Modules, air-cooled Figure 3-11 Removing the connection clip to the basic interference suppression module in the Active Interface Module for frame size GI Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 63 Line-side power components 3.3 Active Interface Modules, air-cooled Figure 3-12 Removing the connection clip to the basic interference suppression module in the Active Interface Module for frame size HI Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 64 Line-side power components 3.3 Active Interface Modules, air-cooled NOTICE Damage to the device through not removing the connection clip with a non-grounded line supply Failure to remove the connection clip to the basic interference suppression module on a non-grounded line supply (IT system) can cause significant damage to the device. •...

-

Page 65: Technical Data

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.6 Technical data Table 3- 13 Technical data for Active Interface Modules, 380 V ... 480 V 3 AC Article number 6SL3300– 7TE35–0AA1 Suitable for Active Line Module 6SL3335- 7TE35-0AA3 Rated power of Active Line Module Rated current Supply voltages... - Page 66 Line-side power components 3.3 Active Interface Modules, air-cooled Table 3- 14 Technical data for Active Interface Modules, 500 V ... 690 V 3 AC Article number 6SL3300– 7TG35–8AA1 Suitable for Active Line Module 6SL3335- 7TG35-8AA3 Rated power of Active Line Module Rated current Supply voltages - Line voltage...

-

Page 67: Derating Factors As A Function Of Installation Altitude And Ambient Temperature

Line-side power components 3.3 Active Interface Modules, air-cooled 3.3.7 Derating factors as a function of installation altitude and ambient temperature Chassis units and the associated system components are rated for an ambient temperature of 40 °C and installation altitudes up to 2000 m above sea level. At ambient temperatures >... -

Page 68: Active Interface Modules, Liquid-Cooled

Line-side power components 3.4 Active Interface Modules, liquid-cooled Active Interface Modules, liquid-cooled 3.4.1 Description Liquid-cooled Active Interface Modules are used in conjunction with liquid-cooled Active Line Modules in chassis format. The liquid-cooled Active Interface Modules contain a Clean Power Filter with basic RI suppression, the pre-charging circuit for the Active Line Module, the line voltage sensing circuit and monitoring sensors. -

Page 69: Safety Information

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.2 Safety information WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed The non-observance of the fundamental safety instructions and residual risks stated in Chapter 1 can result in accidents with severe injuries or death. •... - Page 70 Line-side power components 3.4 Active Interface Modules, liquid-cooled WARNING Danger of an accident due to missing warning labels in the national language. Missing warning labels in the national language can result in death or serious injury. • Attach the component warning labels in the national language. CAUTION Risk of burns due to high surface temperature of the filter reactor The filter reactors can become very hot.

-

Page 71: Interface Description

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3 Interface description 3.4.3.1 Overview Figure 3-13 Interface overview filter reactor, size JIL, valid for article numbers 6SL3005-0DE38-4AA0, 6SL3005-0DG37-4AA0 and 6SL3005-0DG41-3AA0 Figure 3-14 Interface overview filter reactor, frame size JIL, valid for article numbers 6SL3005-0DE41-4AA0 and 6SL3005-0DG41-6AA0 Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 72 Line-side power components 3.4 Active Interface Modules, liquid-cooled Figure 3-15 Interface overview filter reactor, frame size JIL, valid for article numbers 6SL3005-0FE38-4AA5, 6SL3005-0FG37-4AA5, 6SL3005-0FG41-0AA5 and 6SL3005-0FG41-3AA5 Figure 3-16 Interface overview filter reactor, frame size JIL, valid for article numbers 6SL3005-0FE41-4AA5 and 6SL3005-0FG41-6AA5 Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 73: Connection Example

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3.2 Connection example Figure 3-17 Connection example of liquid-cooled Active Interface Module, frame size JIL, valid for article numbers 6SL3305-7TE38-4AA5, 6SL3305-7TG37-4AA5, 6SL3305-7TG41-0AA5 and 6SL3305-7TG41-3AA5 Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 74 Line-side power components 3.4 Active Interface Modules, liquid-cooled Figure 3-18 Connection example of liquid-cooled Active Interface Module, frame size JIL, valid for article numbers 6SL3305-7TE41-4AA5 and 6SL3305-7TG41-6AA5 NOTICE Damage to the device through different phase sequence in the pre-charging and main circuits Different phase sequences in the pre-charging and main circuits can overload and destroy the pre-charging resistors of the Active Interface Module during the brief overlap period,...

-

Page 75: Line/Load Connection

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3.3 Line/load connection Table 3- 17 Filter reactor connections Terminals Designations Line connection: Voltage: U1, V1, W1 3 AC 380 V -10% (-15% < 1 min) ... 3 AC 480 V +10% •... -

Page 76: X530 Neutral Point Grounding

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3.5 X530 neutral point grounding Table 3- 20 Neutral point grounding X530 Terminal Designation Technical data Neutral point of the Jumper inserted: Grounded measurement voltage sensing Jumper not inserted: isolated measurement Ground potential The Voltage Sensing Module is supplied with inserted jumper. -

Page 77: X609 Terminal Strip

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3.6 X609 terminal strip Table 3- 21 Terminal strip X609 Terminal Designation Technical data PE connection External 24 V DC supply Voltage: 24 V DC (20.4 ... 28.5 V) Current consumption: max. 0.25 A Voltage: 230 V AC (195.5 ... -

Page 78: Meaning Of The Led On The Voltage Sensing Module (Vsm) In The Active Interface

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.3.8 Meaning of the LED on the Voltage Sensing Module (VSM) in the Active Interface Module Table 3- 23 Description of the LED on the Voltage Sensing Module (VSM) in the Active Interface Module Color Status Description... -

Page 79: Dimension Drawing

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.4 Dimension drawing Dimension drawing, filter reactor Figure 3-20 Dimension drawing, filter reactor frame size JIL Table 3- 24 Dimensions of the filter reactors (all values in mm) 6SL3005- 0DE38-4AA0 0DE41-4AA0 0DG37-4AA0 0DG41-3AA0 0DG41-6AA0 <575... - Page 80 Line-side power components 3.4 Active Interface Modules, liquid-cooled Dimension drawing, filter module Figure 3-21 Dimension drawing, filter module, frame size JIL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 81: Installation

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.5 Installation Transport fixtures for the filter reactor There are lifting eyes on the top of the filter reactor to facilitate transporting it. NOTICE Damage to the device due to improper transport Improper transport can mechanically stress the housing of the filter reactor that can damage it. -

Page 82: Notes On Installation In A Control Cabinet

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.6 Notes on installation in a control cabinet A typical control cabinet design is shown in the following that shows the mounting of the main components (filter reactor and filter module) with the supplied pressure hoses and connecting cables. - Page 83 Line-side power components 3.4 Active Interface Modules, liquid-cooled Control cabinet example, valid for article numbers 6SL3305-7TE38-4AA5, 6SL3305-7TG37-4AA5, 6SL3305-7TG41-0AA5 and 6SL3305-7TG41-3AA5 Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 84 Line-side power components 3.4 Active Interface Modules, liquid-cooled ① Connections (U1, V1, W1) at the filter module to establish the connection to the line side of the filter reactor (U1, V1, W1) ② Partition plate (not included in the scope of supply) to shield the power loss of the filter reactor from the filter module ③...

- Page 85 Line-side power components 3.4 Active Interface Modules, liquid-cooled ① Connections (U1, V1, W1) at the filter module to establish the connection to the line side of the filter reactor (U1, V1, W1) ② Partition plate (not included in the scope of supply) to shield the power loss of the filter reactor from the filter module ③...

- Page 86 Line-side power components 3.4 Active Interface Modules, liquid-cooled There must be a minimum clearance of 970 mm between the lower edge of the transport ⑦ plate ( ) and the lower edge of the filter module. The dimensions of the typical cabinet (Rittal TS8) are (width x height x depth) 600 mm x 2200 mm x 600 mm The insulating mat between the filter reactor and the filter module is made of "AF/Armaflex AF-19MM/EA"...

- Page 87 Line-side power components 3.4 Active Interface Modules, liquid-cooled WARNING Risk of fire due to ground fault/short-circuit Inadequate installation of the cables between the filter reactor and the filter module can result in a ground fault/short-circuit and place persons at risk as a result of the associated smoke and fire.

- Page 88 Line-side power components 3.4 Active Interface Modules, liquid-cooled Control cabinet example, valid for article number 6SL3305-7TE41-4AA5 and 6SL3305-7TG41-6AA5 Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 89 Line-side power components 3.4 Active Interface Modules, liquid-cooled ① Connections (U1, V1, W1) at the filter module to establish the connection to the line side of the filter reactor (U1, V1, W1) ② Partition plate (not included in the scope of supply) to stabilize the thermally insulating mat be- ⑬...

- Page 90 Line-side power components 3.4 Active Interface Modules, liquid-cooled ① Connections (U1, V1, W1) at the filter module to establish the connection to the line side of the filter reactor (U1, V1, W1) ② Partition plate (not included in the scope of supply) to stabilize the thermally insulating mat between the filter reactor ⑬...

- Page 91 Line-side power components 3.4 Active Interface Modules, liquid-cooled There must be a minimum clearance of 970 mm between the lower edge of the transport ⑦ plate ( ) and the lower edge of the filter module. The dimensions of the typical cabinet (Rittal TS8) are (width x height x depth) 600 mm x 2200 mm x 600 mm The insulating mat between the filter reactor and the filter module is made of "AF/Armaflex AF-19MM/EA"...

-

Page 92: Cooling Circuit Connections

Line-side power components 3.4 Active Interface Modules, liquid-cooled WARNING Risk of fire due to ground fault/short-circuit Inadequate installation of the cables between the filter reactor and the filter module can result in a ground fault/short-circuit and place persons at risk as a result of the associated smoke and fire. - Page 93 Line-side power components 3.4 Active Interface Modules, liquid-cooled Article numbers 6SL3305-7TE41-4AA5 and 6SL3305-7TG41-6AA5: The hose connections must be fastened with the gaskets with a tightening torque of 30 Nm: ● The straight hose connections are intended for P1, P5 and P6. ●...

-

Page 94: Electrical Connection

Line-side power components 3.4 Active Interface Modules, liquid-cooled Note Replacement seal The seals for the screwed connections can be used only once when the cooling circuit is first assembled. The seals must be replaced if the circuit is disassembled and assembled again. The replacement seal is commercially available as flat Viton polymer seal with hardness 75 (+/-5) Shore A (Viton is the commercial name for elastomers with the abbreviations FPM and FKM). - Page 95 Line-side power components 3.4 Active Interface Modules, liquid-cooled WARNING Risk of fire and damage to equipment due to short-circuit / ground fault The cables to the filter module must be routed so that a ground fault or short-circuit can be ruled out.

- Page 96 Line-side power components 3.4 Active Interface Modules, liquid-cooled Figure 3-29 Connection clip at the filter module NOTICE Damage to the device through not removing the connection clip with a non-grounded line supply Failure to remove the connection clip to the basic interference suppression module on a non-grounded line supply (IT system) can cause significant damage to the device.

- Page 97 Line-side power components 3.4 Active Interface Modules, liquid-cooled Removing the connector jumper in the VSM10 Voltage Sensing Module When operating the Active Interface Module on a non-grounded line supply (IT system), at the Voltage Sensing Module (VSM10), remove the plug-in jumper in terminal X530 at the lower side of the component.

-

Page 98: Technical Data

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.9 Technical data Table 3- 25 Technical data for Active Interface Modules, 380 V ... 480 V 3 AC Article number 6SL3305– 7TE38–4AA5 7TE41–4AA5 Suitable for Active Line Module 6SL3335- 7TE38-4AA3 7TE41-4AA3 Rated power of Active Line Module 6SL3335-... - Page 99 Line-side power components 3.4 Active Interface Modules, liquid-cooled Article number 6SL3305– 7TE38–4AA5 7TE41–4AA5 Max. connection cross-section - line connection (U1, V1, W1) mm² 1500 1500 - load connection (U2, V2, W2) mm² 1500 1500 - to the filter Module (U1, V1, W1) mm²...

- Page 100 Line-side power components 3.4 Active Interface Modules, liquid-cooled Table 3- 26 Technical data for Active Interface Modules, 500 V ... 690 V 3 AC Article number 6SL3305– 7TG37–4AA5 7TG41–0AA5 7TG41–3AA5 7TG41–6AA5 Suitable for Active Line Module 6SL3335- 7TG37-4AA3 7TG38-1AA3 7TG41-3AA3 7TG41-6AA3 Rated power of 1400...

- Page 101 Line-side power components 3.4 Active Interface Modules, liquid-cooled Article number 6SL3305– 7TG37–4AA5 7TG41–0AA5 7TG41–3AA5 7TG41–6AA5 Max. connection cross-section - line connection (U1, V1, W1) mm² 1000 1500 1500 1500 - load connection (U2, V2, W2) mm² 1000 1500 1500 1500 - to the filter Module (U1, V1, W1) mm²...

-

Page 102: Derating Factors As A Function Of Coolant Temperature

3.4 Active Interface Modules, liquid-cooled 3.4.9.1 Derating factors as a function of coolant temperature The SINAMICS S120 liquid -cooled devices are suitable for H O or a mixture of H O and an antifreeze as coolant, corresponding to Section Antifreeze, biocides, inhibitors (Page 335). -

Page 103: Derating Factors As A Function Of The Ambient Temperature

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.9.2 Derating factors as a function of the ambient temperature The units can supply 100 % output current at an ambient air temperature of between 0 °C and 45 °C. The maximum output current decreases linearly to 90 % at ambient air temperatures of between 45 °C and 50 °C. -

Page 104: Derating Factors As A Function Of Installation Altitude

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.9.3 Derating factors as a function of installation altitude When the units are operated at an installation altitude with reduced air pressure, the derating characteristic shown below applies to the output current or the ambient air temperature. Figure 3-32 Maximum ambient temperature as a function of installation altitude At installation altitudes above 2000 m (6562 ft), the line voltage must not exceed certain... - Page 105 Line-side power components 3.4 Active Interface Modules, liquid-cooled Figure 3-33 Voltage correction factor K as a function of the installation altitude Note Rated voltage Refer to the maximum line voltage under "Connection voltages" in the technical data for details of the rated voltage. Note Input voltage range that can be actually used The dashed line represents a theoretical characteristic of the correction factor.

-

Page 106: Parameterization

Line-side power components 3.4 Active Interface Modules, liquid-cooled 3.4.9.4 Parameterization The thresholds for the temperature monitoring must be parameterized correctly for safe operation: ● Alarm threshold p3667: 60 °C ● Trip threshold p3668: 70 °C Note Note regarding STARTER V4.4.1 The product is supported from STARTER version V4.4.1. -

Page 107: Power Modules

Power Modules Description A Power Module is a power unit (frequency converter) that provides the power supply for the connected motor. The power from the 3-phase system is supplied via the 6-pulse rectifier. The output inverter produces a 3-phase, variable-voltage, variable-frequency system. A Power Module must be connected to a Control Unit via DRIVE-CLiQ. - Page 108 Power Modules 4.1 Description Characteristics of Power Modules ● Design for 380 V 3 AC to 480 V 3 AC from 210 A to 490 A ● Suitable for TN, TT, and IT supply systems ● Liquid cooling ● Short-circuit/ground-fault-proof ●...

-

Page 109: Safety Information

Power Modules 4.2 Safety information Safety information WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed The non-observance of the fundamental safety instructions and residual risks stated in Chapter 1 can result in accidents with severe injuries or death. •... - Page 110 Power Modules 4.2 Safety information WARNING Danger to life due to high leakage currents caused by an interrupted external protective conductor The drive components conduct a high leakage current via the protective conductor. Touching conductive parts when the protective conductor is interrupted can result in death or serious injury.

- Page 111 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

-

Page 112: Interface Description

Power Modules 4.3 Interface description Interface description 4.3.1 Overview Figure 4-1 Power Module, frame size FL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 113 Power Modules 4.3 Interface description Figure 4-2 Power Module, frame size GL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 114: Connection Example

Power Modules 4.3 Interface description 4.3.2 Connection example Figure 4-3 Connection example for Power module Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 115: Line/Dc Link/Motor Connection

Power Modules 4.3 Interface description 4.3.3 Line/DC link/motor connection Table 4- 2 Line/DC link/motor connection for Power Module Terminals Technical specifications U1/L1, V1/L2, W1/L3 Voltage: 3 AC 380 V -10 % (-15 % < 1 min) ... 3 AC 480 V +10 % 3 AC power input Frequency: 47 ... -

Page 116: X41 Ep Terminal / Temperature Sensor Connection

Power Modules 4.3 Interface description Note Looping through the supply voltage The two "P24 V" or "M" terminals are jumpered in the connector. This ensures that the supply voltage is looped through, even when the connector is removed. 4.3.5 X41 EP terminal / temperature sensor connection Table 4- 4 Terminal strip X41 Terminal... -

Page 117: X42 Terminal Strip

Power Modules 4.3 Interface description NOTICE Damage to motor in the event of incorrectly connected KTY temperature sensor If a KTY temperature sensor is connected with incorrect polarity, it is not possible to detect when the motor overheats. Overheating can cause damage to the motor. •... -

Page 118: X46 Brake Control And Monitoring

Power Modules 4.3 Interface description 4.3.7 X46 Brake control and monitoring Table 4- 6 Terminal strip X46 brake control and monitoring Terminal Function Technical data BR output + Brake connection Supply voltage: 24 V DC BR output - Max. load current: 0.2 mA FB input + FB input - Max. -

Page 119: Cooling Circuit Connections

Power Modules 4.3 Interface description 4.3.9 Cooling circuit connections Table 4- 8 Cooling circuit connections Connection Technical data Coolant connection A: Intake Pipe thread ISO 228 - G 3/4 B (external thread 3/4", flat-sealing) Coolant connection B: Return Tightening torque 60 Nm Note Replacement seal... -

Page 120: Meaning Of The Leds On The Control Interface Module In The Power Module

Flashing There is a fault. If the LED continues to flash after you have performed light a POWER ON, please contact your Siemens service center. WARNING Danger of death when live parts of the DC link are touched Hazardous DC link voltages may be present at any time regardless of the status of the "DC LINK"... -

Page 121: Dimension Drawing

Power Modules 4.4 Dimension drawing Dimension drawing Dimension drawing for frame size FL The mandatory cooling clearances are indicated by the dotted line. Figure 4-4 Dimension drawing Power Module, frame size FL, front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 122 Power Modules 4.4 Dimension drawing Dimension drawing for frame size GL The mandatory cooling clearances are indicated by the dotted line. Figure 4-5 Dimension drawing Power Module, frame size GL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 123: Installation

Power Modules 4.5 Installation Installation Figure 4-6 Crane lifting lugs / screw coupling points for mechanical support Crane lifting lugs Power Modules are fitted with crane lifting lugs as standard when shipped. The units can be hoisted using these lugs and transported from the pallet to the installation location. Note Transport in the horizontal position Transport in the horizontal position is permissible. - Page 124 Power Modules 4.5 Installation NOTICE Damage to the device due to improper transport Improper transport can cause mechanical loads on the housing or busbars which can result in damage to the device. • Use a lifting harness with vertical ropes or chains during transport. •...

-

Page 125: Electrical Connection

Power Modules 4.6 Electrical connection Figure 4-7 Protection guard Electrical connection Operating a Power Module on a non-grounded supply system/IT system If the device is operated on a non-grounded line supply (IT system), the connection clip to the basic interference suppression module must be removed. To do so, loosen the two screws ("1"... - Page 126 Power Modules 4.6 Electrical connection Figure 4-8 Removing the connection clip to the basic interference suppression module NOTICE Damage to the device through not removing the connection clip with a non-grounded line supply Failure to remove the connection clip to the basic interference suppression module on a non-grounded line supply (IT system) can cause significant damage to the device.

-

Page 127: Technical Specifications

Power Modules 4.7 Technical specifications Technical specifications Table 4- 11 Technical data, Power Modules, 380 V ... 480 V 3 AC Article number 6SL3315– 1TE32-1AA3 1TE32–6AA3 1TE33–1AA3 1TE35–0AA3 Type rating - Based on I (50 Hz 400 V) - Based on I (50 Hz 400 V) - Based on I (60 Hz 460 V) -

Page 128: Overload Capability

Power Modules 4.7 Technical specifications Article number 6SL3315– 1TE32-1AA3 1TE32–6AA3 1TE33–1AA3 1TE35–0AA3 Degree of protection IP00 IP00 IP00 IP00 Dimensions - Width - Height - Depth Frame size Weight Recommended fuse 3NE1230-2 3NE1331-2 3NE1333-2 3NE1230-2 - Number per phase (connected in parallel) - Rated current - Frame size acc. - Page 129 Power Modules 4.7 Technical specifications Low overload The base load current for low overload (I ) is based on a load duty cycle of 110% for 60 s or 150% for 10 s. Figure 4-9 Low overload High overload The base load current for a high overload I is based on a duty cycle of 150% for 60 s or 160% for 10 s.

-

Page 130: Derating Factors As A Function Of Coolant Temperature

4.7 Technical specifications 4.7.2 Derating factors as a function of coolant temperature The SINAMICS S120 liquid -cooled devices are suitable for H O or a mixture of H O and an antifreeze as coolant, corresponding to Section Antifreeze, biocides, inhibitors (Page 335). -

Page 131: Derating Factors As A Function Of The Ambient Temperature

Power Modules 4.7 Technical specifications 4.7.3 Derating factors as a function of the ambient temperature The units can supply 100 % output current at an ambient air temperature of between 0 °C and 45 °C. The maximum output current decreases linearly to 90 % at ambient air temperatures of between 45 °C and 50 °C. -

Page 132: Derating Factors As A Function Of Installation Altitude

Power Modules 4.7 Technical specifications 4.7.4 Derating factors as a function of installation altitude When the units are operated at an installation altitude with reduced air pressure, the derating characteristic shown below applies to the output current or the ambient air temperature. Figure 4-13 Maximum ambient temperature as a function of installation altitude At installation altitudes above 2000 m (6562 ft), the line voltage must not exceed certain... - Page 133 Power Modules 4.7 Technical specifications Figure 4-14 Voltage correction factor K as a function of the installation altitude Note Rated voltage Refer to the maximum line voltage under "Connection voltages" in the technical data for details of the rated voltage. Note Input voltage range that can be actually used The dashed line represents a theoretical characteristic of the correction factor.

-

Page 134: Current Derating As A Function Of The Pulse Frequency

Power Modules 4.7 Technical specifications 4.7.5 Current derating as a function of the pulse frequency When the pulse frequency is increased, the derating factor of the output current must be taken into account. This derating factor must be applied to the currents specified in the technical data. Table 4- 12 Derating factor of the output current as a function of the pulse frequency Article No. -

Page 135: Line Modules

Line Modules Introduction The drive line-up is connected to the power supply network via the Line Modules. Line Infeeds comprise a Line Module and the associated line connection. They generate a DC voltage from the connected line voltage that is used to supply the connected Motor Modules. -

Page 136: Basic Line Modules

Line Modules 5.2 Basic Line Modules Basic Line Modules 5.2.1 Description Basic Line Modules are used for the power infeed into the DC link. They are suitable for applications in which no regenerative energy is produced, or in which the energy exchange takes place between the motor- and the generator-driven axes in the DC link. - Page 137 Line Modules 5.2 Basic Line Modules Components of the Basic infeed A Basic Infeed comprises a Basic Line Module and an external line connection, which comprises a line reactor. Operating principle One or more Motor Modules can be connected to the power supply network via the Basic Line Module.

-

Page 138: Safety Information

Line Modules 5.2 Basic Line Modules 5.2.2 Safety information WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed The non-observance of the fundamental safety instructions and residual risks stated in Chapter 1 can result in accidents with severe injuries or death. •... - Page 139 Line Modules 5.2 Basic Line Modules WARNING Danger to life due to high leakage currents caused by an interrupted external protective conductor The drive components conduct a high leakage current via the protective conductor. Touching conductive parts when the protective conductor is interrupted can result in death or serious injury.

- Page 140 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

-

Page 141: Interface Description

Line Modules 5.2 Basic Line Modules 5.2.3 Interface description 5.2.3.1 Overview Figure 5-1 Basic Line Module, frame size FBL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 142 Line Modules 5.2 Basic Line Modules Figure 5-2 Basic Line Module, frame size GBL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 143: Connection Example

Line Modules 5.2 Basic Line Modules 5.2.3.2 Connection example Figure 5-3 Connection example for Basic Line Modules Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 144: Line/Load Connection

Line Modules 5.2 Basic Line Modules 5.2.3.3 Line/load connection Table 5- 2 Line/load connection of the Basic Line Module Terminals Technical specifications U1, V1, W1 Voltage: 3 AC power input 3 AC 380 V -10 % (-15 % < 1 min) ... 3 AC 480 V +10 % •... -

Page 145: X41 Ep Terminal / Temperature Sensor Connection

Line Modules 5.2 Basic Line Modules 5.2.3.5 X41 EP terminal / temperature sensor connection Table 5- 4 Terminal strip X41 Terminal Function Technical data EP M1 (Enable Pulses) Connected to terminal -X9:8 EP +24 V (Enable Pulses) Connected to terminal -X9:7 - Temp Temperature sensor connection KTY84- 1C130 / PT1000 / PTC... -

Page 146: X42 Terminal Strip

Line Modules 5.2 Basic Line Modules Note The temperature sensor connection can be used for motors that are equipped with a KTY84- 1C130, PT1000 or PTC measuring sensor in the stator windings. Note Connection to terminal strip -X9 A cable harness is used to connect terminals -X41:1 and -X41:2 to terminals -X9:8 and -X9:7. -

Page 147: Drive-Cliq Interfaces X400, X401, X402

Line Modules 5.2 Basic Line Modules 5.2.3.7 DRIVE-CLiQ interfaces X400, X401, X402 Table 5- 6 DRIVE-CLiQ interfaces X400, X401, X402 Signal name Technical data Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 148: Meaning Of The Leds On The Control Interface Module In The Basic Line Module

Flashing There is a fault. If the LED continues to flash after you have performed light a POWER ON, please contact your Siemens service center. WARNING Danger of death when live parts of the DC link are touched Hazardous DC link voltages may be present at any time regardless of the status of the "DC LINK"... -

Page 149: Dimension Drawing

Line Modules 5.2 Basic Line Modules 5.2.4 Dimension drawing Dimension drawing, frame size FBL The mandatory cooling clearances are indicated by the dotted line. Figure 5-4 Dimension drawing, Basic Line Module, frame size GBL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 150 Line Modules 5.2 Basic Line Modules Dimension drawing, frame size GBL The mandatory cooling clearances are indicated by the dotted line. Figure 5-5 Dimension drawing, Basic Line Module, frame size GBL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 151: Installation

Line Modules 5.2 Basic Line Modules 5.2.5 Installation Figure 5-6 Lifting lugs / screw coupling points for mechanical support Lifting lugs Basic Line Modules are fitted with lifting lugs as standard when shipped. The units can be lifted from these lugs by a crane and transported from the pallet to the installation location. Note Transport in the horizontal position Transport in the horizontal position is permissible. - Page 152 Line Modules 5.2 Basic Line Modules NOTICE Damage to the device due to improper transport Improper transport can cause mechanical loads on the housing or busbars which can result in damage to the device. • Use a lifting harness with vertical ropes or chains during transport. •...

-

Page 153: Electrical Connection

Line Modules 5.2 Basic Line Modules Figure 5-7 Protection guard 5.2.6 Electrical connection Operating a Basic Line Module on a non-grounded line supply (IT system) If the device is operated on a non-grounded line supply (IT system), the connection clip to the basic interference suppression module must be removed. - Page 154 Line Modules 5.2 Basic Line Modules Figure 5-8 Removing the connection clip to the basic interference suppression module NOTICE Damage to the device through not removing the connection clip with a non-grounded line supply Failure to remove the connection clip to the basic interference suppression module on a non-grounded line supply (IT system) can cause significant damage to the device.

-

Page 155: Technical Specifications

Line Modules 5.2 Basic Line Modules 5.2.7 Technical specifications Table 5- 10 Technical data for Basic Line Modules, 380 ... 480 V 3 AC Article number 6SL3335– 1TE37–4AA3 1TE41–2AA3 1TE41–7AA3 Rated power - At I (50Hz 400V) L DC - At I (50Hz 400V) H DC - At I... - Page 156 Line Modules 5.2 Basic Line Modules Article number 6SL3335– 1TE37–4AA3 1TE41–2AA3 1TE41–7AA3 Degree of protection IP00 IP00 IP00 Dimensions - Width - Height 1137 1137 1562 - Depth Frame size Weight Recommended fuse 3NE1333-2 3NE1435-2 3NE1438-2 - Number per phase (connected in parallel) - Rated current - Frame size acc.

- Page 157 Line Modules 5.2 Basic Line Modules Table 5- 11 Technical data for Basic Line Modules, 500 ... 690 V 3 AC Article number 6SL3335– 1TG34–2AA3 1TG37–3AA3 1TG41–3AA3 1TG41–7AA3 Rated power - At I (50Hz 690V) 1100 1370 L DC - At I (50Hz 690V) 1070 H DC...

- Page 158 Line Modules 5.2 Basic Line Modules Article number 6SL3335– 1TG34–2AA3 1TG37–3AA3 1TG41–3AA3 1TG41–7AA3 Max. cable length (total of all motor cables and DC link) - Shielded 1500 1500 2250 2250 - Unshielded 2250 2250 3375 3375 Degree of protection IP00 IP00 IP00 IP00...

-

Page 159: Derating Factors As A Function Of Coolant Temperature

5.2 Basic Line Modules 5.2.7.1 Derating factors as a function of coolant temperature The SINAMICS S120 liquid -cooled devices are suitable for H O or a mixture of H O and an antifreeze as coolant, corresponding to Section Antifreeze, biocides, inhibitors (Page 335). -

Page 160: Derating Factors As A Function Of The Ambient Temperature

Line Modules 5.2 Basic Line Modules 5.2.7.2 Derating factors as a function of the ambient temperature The units can supply 100 % output current at an ambient air temperature of between 0 °C and 45 °C. The maximum output current decreases linearly to 90 % at ambient air temperatures of between 45 °C and 50 °C. -

Page 161: Derating Factors As A Function Of Installation Altitude

Line Modules 5.2 Basic Line Modules 5.2.7.3 Derating factors as a function of installation altitude When the units are operated at an installation altitude with reduced air pressure, the derating characteristic shown below applies to the output current or the ambient air temperature. Figure 5-11 Maximum ambient temperature as a function of installation altitude At installation altitudes above 2000 m (6562 ft), the line voltage must not exceed certain... - Page 162 Line Modules 5.2 Basic Line Modules Figure 5-12 Voltage correction factor K as a function of the installation altitude Note Rated voltage Refer to the maximum line voltage under "Connection voltages" in the technical data for details of the rated voltage. Note Input voltage range that can be actually used The dashed line represents a theoretical characteristic of the correction factor.

-

Page 163: Active Line Modules

Line Modules 5.3 Active Line Modules Active Line Modules 5.3.1 Description The self-commutating infeed / regenerative feedback units act as step-up converters and generate a stabilized DC link voltage that is 1.5x greater (factory setting) than the rated line supply voltage. In this way, the connected Motor Modules are isolated from the line voltage. This improves the dynamic response and control quality because line tolerances and fluctuations do not affect the motor voltage. - Page 164 Line Modules 5.3 Active Line Modules Active Infeed components An Active Infeed comprises an Active Interface Module and an Active Line Module. The bypass contactor is fitted in the relevant Active Interface Module on Active Infeeds which feature an Active Line Module of frame size GXL. Active Interface Modules in these frame sizes have degree of protection IP20;...

- Page 165 Line Modules 5.3 Active Line Modules Operating principle One or more Motor Modules can be connected to the power supply network via the Active Line Module. The Active Line Module provides a constant DC link voltage for the Motor Modules. This ensures that they are not influenced by line voltage fluctuations. The regenerative feedback capability of the Active Line Module can be deactivated by parameterization.

-

Page 166: Safety Information

Line Modules 5.3 Active Line Modules 5.3.2 Safety information WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed The non-observance of the fundamental safety instructions and residual risks stated in Chapter 1 can result in accidents with severe injuries or death. •... - Page 167 Line Modules 5.3 Active Line Modules WARNING Danger to life due to high leakage currents caused by an interrupted external protective conductor The drive components conduct a high leakage current via the protective conductor. Touching conductive parts when the protective conductor is interrupted can result in death or serious injury.

- Page 168 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

-

Page 169: Interface Description

Line Modules 5.3 Active Line Modules 5.3.3 Interface description 5.3.3.1 Overview Figure 5-15 Active Line Module, frame size GXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 170 Line Modules 5.3 Active Line Modules Figure 5-16 Active Line Module, frame size HXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 171 Line Modules 5.3 Active Line Modules Figure 5-17 Active Line Module, frame size JXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 172: Connection Example

Line Modules 5.3 Active Line Modules 5.3.3.2 Connection example Figure 5-18 Example connection of Active Line Module Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 173: Line/Load Connection

Line Modules 5.3 Active Line Modules 5.3.3.3 Line/load connection Table 5- 13 Line/load connection of the Active Line Module Terminals Technical specifications U1, V1, W1 Voltage: 3 AC power input 3 AC 380 V -10 % (-15 % < 1 min) ... 3 AC 480 V +10 % •... -

Page 174: X41 Ep Terminal / Temperature Sensor Connection

Line Modules 5.3 Active Line Modules Note Connection to terminals 7 and 8 For operation, 24 V DC must be connected to terminal 7 and ground to terminal 8. Pulse suppression is activated when removed. Note Looping through the supply voltage The two "P24 V"... - Page 175 Line Modules 5.3 Active Line Modules NOTICE Device failure as a result of unshielded or incorrectly routed cables to temperature sensors Unshielded or incorrectly routed cables to temperature sensors can result in interference being coupled into the signal processing electronics from the power side. This can result in significant disturbance of all signals (fault messages) up to failure of individual components (destruction of the devices).

-

Page 176: X42 Terminal Strip

Line Modules 5.3 Active Line Modules 5.3.3.6 X42 terminal strip Table 5- 16 Terminal strip X42 voltage supply for Control Unit, Sensor Module and Terminal Module Terminal Function Technical data P24L Power supply for Control Unit, Sensor Module and Terminal Module (18 ... 28.8 V) maximum load current: 3 A Max. -

Page 177: Cooling Circuit Connections

Line Modules 5.3 Active Line Modules 5.3.3.8 Cooling circuit connections Table 5- 18 Cooling circuit connections Connection Technical data Coolant connection A: Intake Pipe thread ISO 228 - G 3/4 B (external thread 3/4", flat-sealing) Coolant connection B: Return Tightening torque 60 Nm Note Replacement seal... -

Page 178: Meaning Of The Leds On The Control Interface Module In The Active Line Module

Flashing There is a fault. If the LED continues to flash after you have performed light a POWER ON, please contact your Siemens service center. WARNING Danger of death when live parts of the DC link are touched Hazardous DC link voltages may be present at any time regardless of the status of the "DC LINK"... -

Page 179: Dimension Drawing

Line Modules 5.3 Active Line Modules 5.3.4 Dimension drawing Dimension drawing for frame size GXL The mandatory cooling clearances are indicated by the dotted line. Figure 5-19 Dimension drawing Active Line Module, frame size GXL Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 180 Line Modules 5.3 Active Line Modules Dimension drawing, frame size HXL The mandatory cooling clearances are indicated by the dotted line. Figure 5-20 Dimension drawing Active Line Module, frame size HXL Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 181 Line Modules 5.3 Active Line Modules Dimension drawing for frame size JXL The mandatory cooling clearances are indicated by the dotted line. Figure 5-21 Dimension drawing Active Line Module, frame size JXL, article numbers 6SL3335- 7TE41-0AA3, 6SL3335-7TE41-4AA3, 6SL3335-7TG41-0AA3, 6SL3335-7TG41-3AA3. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 182 Line Modules 5.3 Active Line Modules Figure 5-22 Dimension drawing Active Line Module, frame size JXL, article number 6SL3335-7TG41- 6AA3. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 183: Installation

Line Modules 5.3 Active Line Modules 5.3.5 Installation Figure 5-23 Crane lifting lugs / screw coupling points for mechanical support Crane lifting lugs Active Line Modules are fitted with crane lifting lugs as standard when shipped. The units can be hoisted using these lugs and transported from the pallet to the installation location. Note Transport in the horizontal position Transport in the horizontal position is permissible. - Page 184 Line Modules 5.3 Active Line Modules NOTICE Damage to the device due to improper transport Improper transport can cause mechanical loads on the housing or busbars which can result in damage to the device. • Use a lifting harness with vertical ropes or chains during transport. •...

- Page 185 Line Modules 5.3 Active Line Modules Figure 5-24 Protection guard Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 186: Technical Specifications

Line Modules 5.3 Active Line Modules 5.3.6 Technical specifications Table 5- 21 Technical data for Active Line Modules, 3 AC 380 ... 480 V, Part 1 Article number 6SL3335– 7TE35–0AA3 7TE36–1AA3 7TE38–4AA3 7TE41–0AA3 Rated power - At I (50Hz 400V) L DC - At I (50Hz 400V) - Page 187 Line Modules 5.3 Active Line Modules Article number 6SL3335– 7TE35–0AA3 7TE36–1AA3 7TE38–4AA3 7TE41–0AA3 Max. cable length (total of all motor cables and DC link) - Shielded 2700 3900 3900 3900 - Unshielded 4050 5850 5850 5850 Degree of protection IP00 IP00 IP00 IP00...

- Page 188 Line Modules 5.3 Active Line Modules Table 5- 22 Technical data for Active Line Modules, 3 AC 380 ... 480 V, Part 2 Article number 6SL3335– 7TE41–4AA3 Rated power - At I (50Hz 400V) L DC - At I (50Hz 400V) H DC - At I (60Hz 460V)

- Page 189 Line Modules 5.3 Active Line Modules Article number 6SL3335– 7TE41–4AA3 Degree of protection IP00 Dimensions - Width - Height 1516 - Depth Frame size Weight Recommended fuse 3NE1448-2 - Number per phase (connected in parallel) - Rated current - Frame size acc. to IEC 60269 Minimum short-circuit current 21000 Valid for a 5s duty cycle (overload duration) and a duty cycle duration of 300s based on the rated DC-link current.

- Page 190 Line Modules 5.3 Active Line Modules Table 5- 23 Technical data for Active Line Modules, 3 AC 500 ... 690 V, Part 1 Article number 6SL3335– 7TG35–8AA3 7TG37-4AA3 7TG38-1AA3 7TG41–0AA3 Rated power - At I (50Hz 690V) 1100 L DC - At I (50Hz 690V) 1000...

- Page 191 Line Modules 5.3 Active Line Modules Article number 6SL3335– 7TG35–8AA3 7TG37-4AA3 7TG38-1AA3 7TG41–0AA3 Max. cable length (total of all motor cables and DC link) - Shielded 2250 2250 2250 2250 - Unshielded 3375 3375 3375 3375 Degree of protection IP00 IP00 IP00 IP00...

- Page 192 Line Modules 5.3 Active Line Modules Table 5- 24 Technical data for Active Line Modules, 3 AC 500 ... 690 V, Part 2 Article number 6SL3335– 7TG41–3AA3 7TG41-6AA3 Rated power - At I (50Hz 690V) 1400 1700 L DC - At I (50Hz 690V) 1215 1490...

- Page 193 Line Modules 5.3 Active Line Modules Article number 6SL3335– 7TG41–3AA3 7TG41-6AA3 Max. cable length (total of all motor cables and DC link) - Shielded 2250 2250 - Unshielded 3375 3375 Degree of protection IP00 IP00 Dimensions - Width - Height 1516 1516 - Depth...

-

Page 194: Derating Factors As A Function Of Coolant Temperature

5.3 Active Line Modules 5.3.6.1 Derating factors as a function of coolant temperature The SINAMICS S120 liquid -cooled devices are suitable for H O or a mixture of H O and an antifreeze as coolant, corresponding to Section Antifreeze, biocides, inhibitors (Page 335). -

Page 195: Derating Factors As A Function Of The Ambient Temperature

Line Modules 5.3 Active Line Modules 5.3.6.2 Derating factors as a function of the ambient temperature The units can supply 100 % output current at an ambient air temperature of between 0 °C and 45 °C. The maximum output current decreases linearly to 90 % at ambient air temperatures of between 45 °C and 50 °C. -

Page 196: Derating Factors As A Function Of Installation Altitude

Line Modules 5.3 Active Line Modules 5.3.6.3 Derating factors as a function of installation altitude When the units are operated at an installation altitude with reduced air pressure, the derating characteristic shown below applies to the output current or the ambient air temperature. Figure 5-27 Maximum ambient temperature as a function of installation altitude At installation altitudes above 2000 m (6562 ft), the line voltage must not exceed certain... - Page 197 Line Modules 5.3 Active Line Modules Figure 5-28 Voltage correction factor K as a function of the installation altitude Note Rated voltage Refer to the maximum line voltage under "Connection voltages" in the technical data for details of the rated voltage. Note Input voltage range that can be actually used The dashed line represents a theoretical characteristic of the correction factor.

- Page 198 Line Modules 5.3 Active Line Modules Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 199: Motor Modules

Motor Modules Description A Motor Module is a power unit (DC-AC inverter) that provides the power supply for the motor connected to it. Power is supplied by means of the DC link of the drive unit. A Motor Module must be connected to a Control Unit via DRIVE-CLiQ. The open-loop and closed- loop control functions are stored in the Control Unit. -

Page 200: Safety Information

Motor Modules 6.2 Safety information Characteristics of the Motor Modules ● Version for 510 ... 720 V DC (line voltage 380 ... 480 V 3 AC) from 210 to 1405 A Version for 675 ... 1035 V DC (line voltage 500 ... 690 V 3 AC) from 100 to 1560 A ●... - Page 201 Motor Modules 6.2 Safety information DANGER Danger to life through electric shock due to the residual charge of the DC-link capacitors Because of the DC-link capacitors, a hazardous voltage is present for up to five minutes after the power supply has been switched off. Contact with live parts can result in death or serious injury.

- Page 202 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

-

Page 203: Interface Description

Motor Modules 6.3 Interface description Interface description 6.3.1 Overview Figure 6-1 Motor Module, frame size FXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 204 Motor Modules 6.3 Interface description Figure 6-2 Motor Module, frame size GXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 205 Motor Modules 6.3 Interface description Figure 6-3 Motor Module, frame size HXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 206 Motor Modules 6.3 Interface description Figure 6-4 Motor Module, frame size JXL Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 207: Connection Example

Motor Modules 6.3 Interface description 6.3.2 Connection example Figure 6-5 Connection example Motor Module Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... -

Page 208: Dc Link/Motor Connection

Motor Modules 6.3 Interface description 6.3.3 DC link/motor connection Table 6- 2 DC link/motor connection of the Motor Module Terminals Technical data DCP, DCN Voltage: DC power input 510 ... 720 VDC • 675 ... 1035 VDC • Connecting lugs: d = 13 mm (M12/50 Nm) for busbar connection U2, V2, W2 Voltage: 3 AC power output... -

Page 209: X41 Ep Terminal / Temperature Sensor Connection

Motor Modules 6.3 Interface description Note EP terminals only for Safety Integrated Basic Functions The function of the EP terminals is only available when Safety Integrated Basic Functions are enabled. Note Looping through the supply voltage The two "P24 V" or "M" terminals are jumpered in the connector. This ensures that the supply voltage is looped through, even when the connector is removed. - Page 210 Motor Modules 6.3 Interface description NOTICE Device failure as a result of unshielded or incorrectly routed cables to temperature sensors Unshielded or incorrectly routed cables to temperature sensors can result in interference being coupled into the signal processing electronics from the power side. This can result in significant disturbance of all signals (fault messages) up to failure of individual components (destruction of the devices).

-

Page 211: X42 Terminal Strip

Motor Modules 6.3 Interface description 6.3.6 X42 terminal strip Table 6- 5 Terminal strip X42 voltage supply for Control Unit, Sensor Module and Terminal Module Terminal Function Technical data P24L Power supply for Control Unit, Sensor Module and Terminal Module (18 ... 28.8 V) maximum load current: 3 A Max. -

Page 212: Drive-Cliq Interfaces X400, X401, X402

Motor Modules 6.3 Interface description 6.3.8 DRIVE-CLiQ interfaces X400, X401, X402 Table 6- 7 DRIVE-CLiQ interfaces X400, X401, X402 Signal name Technical data Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 213: Meaning Of The Leds On The Control Interface Module In The Motor Module

Flashing There is a fault. If the LED continues to flash after you have performed light a POWER ON, please contact your Siemens service center. WARNING Danger of death when live parts of the DC link are touched Hazardous DC link voltages may be present at any time regardless of the status of the "DC LINK"... -

Page 214: Dimension Drawing

Motor Modules 6.4 Dimension drawing Dimension drawing Dimension drawing, frame size FXL The mandatory cooling clearances are indicated by the dotted line. Figure 6-6 Dimension drawing Motor Module, frame size FXL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7... - Page 215 Motor Modules 6.4 Dimension drawing Dimension drawing for frame size GXL The mandatory cooling clearances are indicated by the dotted line. Figure 6-7 Dimension drawing Motor Module, frame size GXL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 216 Motor Modules 6.4 Dimension drawing Dimension drawing, frame size HXL The mandatory cooling clearances are indicated by the dotted line. Figure 6-8 Dimension drawing Motor Module, frame size HXL. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 217 Motor Modules 6.4 Dimension drawing Dimension drawing for frame size JXL The mandatory cooling clearances are indicated by the dotted line. Figure 6-9 Dimension drawing Motor Module, frame size JXL, article numbers 6SL3325-1TE41- 0AA3, 6SL3325-1TE41-4AA3, 6SL3325-1TG38-1AA3, 6SL3325-1TG41-0AA3, 6SL3325-1TG41-2AA3, 6SL3325-1TG41-3AA3. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

- Page 218 Motor Modules 6.4 Dimension drawing Figure 6-10 Dimension drawing Motor Module, frame size JXL, article numbers 6SL3325-1TE41- 4AS3, 6SL3325-1TG41-6AA3. Front view, side view Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 219: Installation

Motor Modules 6.5 Installation Installation Figure 6-11 Crane lifting lugs / screw coupling points for mechanical support Crane lifting lugs Motor Modules are fitted with crane lifting lugs as standard when shipped. The units can be hoisted using these lugs and transported from the pallet to the installation location. Note Transport in the horizontal position Transport in the horizontal position is permissible. - Page 220 Motor Modules 6.5 Installation NOTICE Damage to the device due to improper transport Improper transport can cause mechanical loads on the housing or busbars which can result in damage to the device. • Use a lifting harness with vertical ropes or chains during transport. •...

- Page 221 Motor Modules 6.5 Installation Figure 6-12 Protection guard Liquid-cooled chassis power units Manual, (GH7), 11/2016, 6SL3097-4AM00-0BP7...

-

Page 222: Technical Specifications

Motor Modules 6.6 Technical specifications Technical specifications Table 6- 11 Technical data for Motor Modules, 510 ... 720 V DC (line voltage 380 ... 480 V3 AC), Part 1 Article number 6SL3325– 1TE32-1AA3 1TE32–6AA3 1TE33-1AA3 1TE35–0AA3 Type rating - Based on I (50 Hz 400 V) - Based on I (50 Hz 400 V) - Page 223 Motor Modules 6.6 Technical specifications Article number 6SL3325– 1TE32-1AA3 1TE32–6AA3 1TE33-1AA3 1TE35–0AA3 DC link/motor connection Flat connection for M12 screw Max. conductor cross-sections - DC link connection (DCP, DCN) mm² Busbar Busbar Busbar Busbar - Motor connection (U2, V2, W2) mm²...

- Page 224 Motor Modules 6.6 Technical specifications Table 6- 12 Technical data for Motor Modules, 510 ... 720 V DC (line voltage 380 ... 480 V3 AC), Part 2 Article number 6SL3325– 1TE36-1AA3 1TE37-5AA3 1TE38–4AA3 1TE41-0AA3 Type rating - Based on I (50 Hz 400 V) - Based on I (50 Hz 400 V)

- Page 225 Motor Modules 6.6 Technical specifications Article number 6SL3325– 1TE36-1AA3 1TE37-5AA3 1TE38–4AA3 1TE41-0AA3 DC link/motor connection Flat connection for M12 screw Max. conductor cross-sections - DC link connection (DCP, DCN) mm² Busbar Busbar Busbar Busbar - Motor connection (U2, V2, W2) mm²...