Siemens SINAMICS S120 Getting Started

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Quick Links

Table of Contents

Summary of Contents for Siemens SINAMICS S120

- Page 1 SINAMICS S120 Getting Started · 01/2013 SINAMICS...

- Page 3 ___________________ Getting Started Preface ___________________ Safety instructions SINAMICS S120 drive ___________________ system SINAMICS ___________________ Overview S120 ___________________ Getting Started Hardware components ___________________ Creating a drive object Getting Started ___________________ Configuring the drive object ___________________ Commissioning a drive ___________________ Appendix Valid as of: Firmware Version 4.6...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

Siemens' content, and adapt it for your own machine documentation: http://www.siemens.com/mdm Training Under the following link there is information on SITRAIN - training from Siemens for products, systems and automation engineering solutions: http://www.siemens.com/sitrain FAQs You can find Frequently Asked Questions in the Service&Support pages under Product Support: http://support.automation.siemens.com... - Page 6 Planning/configuration SIZER engineering tool • Configuration Manuals, Motors • Deciding/ordering SINAMICS S120 catalogs SIMOTION, SINAMICS S120 and Motors for Production Machines • (Catalog PM 21) SINAMICS and motors for single-axis drives (catalog D 31) • SINUMERIK & SINAMICS • Equipment for Machine Tools (Catalog NC 61) SINUMERIK 840D sl Type 1B •...

- Page 7 The EC Declaration of Conformity for the EMC Directive can be found on the Internet at: http://support.automation.siemens.com There – as a search term – enter the number 15257461 or contact your local Siemens office. Purpose of this document This documentation is aimed at beginners who want to find out more about the SINAMICS S120 drive system.

- Page 8 Preface Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

-

Page 9: Table Of Contents

Creating a drive project........................26 Configuring the drive object ........................29 Configuring the drive unit ......................29 Configuring the Motor Module......................33 Special issues with the SINAMICS S120 training case ...............34 Commissioning a drive ..........................37 Appendix..............................43 List of important alarms and faults ....................43 Restoring factory settings ......................45... - Page 10 Table of contents Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

-

Page 11: Safety Instructions

Safety instructions General safety instructions DANGER Danger to life when live parts are touched Death or serious injury can result when live parts are touched. • Only work on electrical devices when you are qualified for this job. • Always observe the country-specific safety rules. Generally, six steps apply when establishing safety: 1. - Page 12 Safety instructions 1.1 General safety instructions DANGER General safety notices • Commissioning is absolutely prohibited until it has been completely ensured that the machine, in which the components described here are to be installed, is in full compliance with the provisions of the EC Machinery Directive. •...

- Page 13 Safety instructions 1.1 General safety instructions NOTICE Material damage due to incorrect voltage tests • As part of routine tests, SINAMICS devices with three-phase motors are subject to a voltage test in accordance with EN 61800-5-1. Before the voltage test is performed on the electrical equipment of industrial machines in accordance with EN 60204-1, Section 18.4, all connectors of SINAMICS equipment must be disconnected/unplugged to prevent the equipment from being damaged.

-

Page 14: Handling Electrostatic Discharge Sensitive Devices

Safety instructions 1.2 Handling electrostatic discharge sensitive devices Handling electrostatic discharge sensitive devices Electrostatic sensitive devices (ESDs) are individual components, integrated circuits, modules or devices that may be damaged by either electrostatic fields or electrostatic discharge. NOTICE Damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can result in malfunctions as a result of damaged individual components, integrated circuits, modules or devices. -

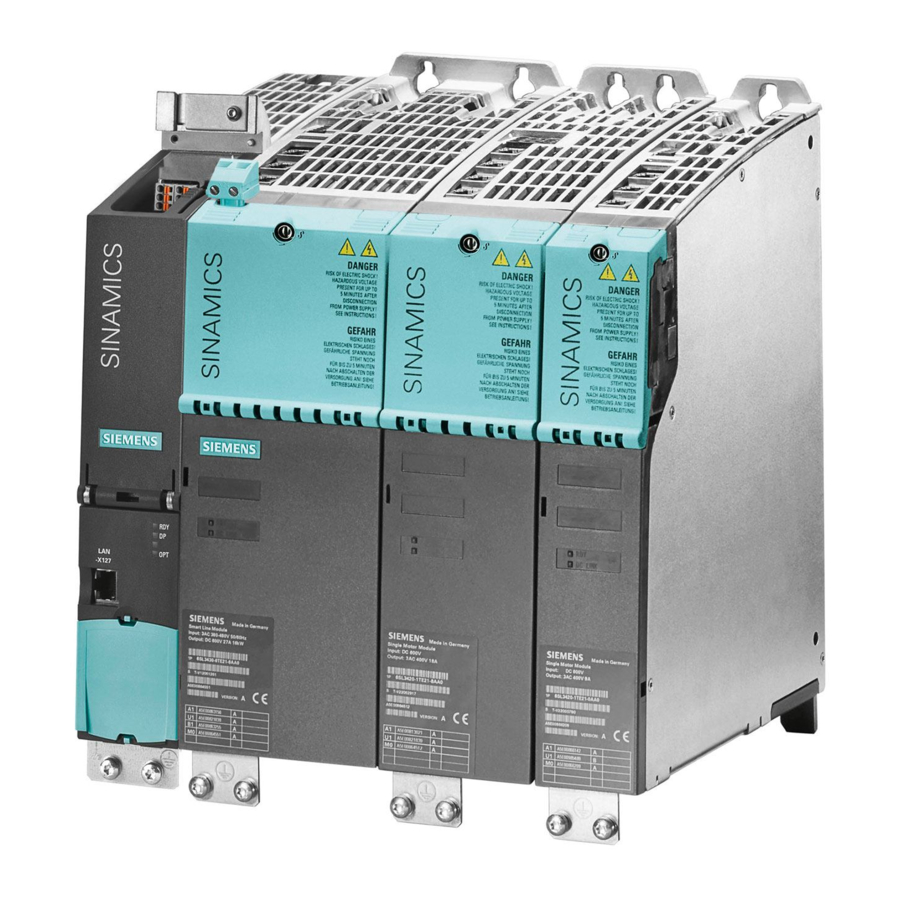

Page 15: Sinamics S120 Drive System

SINAMICS S120 drive system Modular system for sophisticated drive tasks SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Users can choose from many different harmonized components and functions to create a solution that best meets their requirements. - Page 16 SINAMICS S120 drive system System overview The SINAMICS S120 drive system consists of a variety of different modules. It is constructed of infeeds, filters, motor power units, modules for additional functions, Control Units plus standard and special versions of rotating and linear motors.

-

Page 17: Overview

Overview This manual provides instructions on how to commission a simple SINAMICS S120 drive based on a sample project. To create a sample project the following points are explained: 1. Which hardware components do you need for the sample project? 2. - Page 18 Overview Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

-

Page 19: Hardware Components

Hardware components Components of the example configuration The following components are contained within the example configuration: ● CU320-2 DP from firmware version 4.5 with integrated Ethernet interface ● Smart Line Module (supply module) ● Line filter ● Double Motor Module ●... -

Page 20: System Data Of The Sinamics S120 Training Case

Hardware components 4.2 System data of the SINAMICS S120 training case System data of the SINAMICS S120 training case The example configuration is performed on a SINAMICS S120 training case. Figure 4-1 Training case The following technical data applies to the training case used:... - Page 21 Hardware components 4.2 System data of the SINAMICS S120 training case The training case is supplied ready-to-use with a demo project on the memory card and documentation. Technical data Degree of protection in accordance with IP20 DIN VDE 0470 Part 1/ EN 60529/IEC 529...

-

Page 22: Wiring The Components

Hardware components 4.3 Wiring the components Wiring the components The components of this example are assembled and wired into the SINAMICS training case. No changes to this wiring are permitted. For the purpose of commissioning this project example, it is not permissible to connect other components or drive loads to the motor. Figure 4-2 Wiring principle Note... -

Page 23: Creating A Drive Object

For data exchange between the programming device (PG/PC) and the Control Unit (CU), an Ethernet interface is used in the example, which is integrated into each SINAMICS S120 device. With PROFIBUS or PROFINET interfaces, commissioning happens in a similar way. -

Page 24: Setting The Communication Interfaces

Creating a drive object 5.2 Setting the communication interfaces Setting the communication interfaces 5.2.1 Setting up the Ethernet interface For the commissioning, the programming device (PG/PC) can be connected to the Control Unit via an Ethernet interface. However, the communications interface of the programming device must first be set up. -

Page 25: Calling Starter

Creating a drive object 5.2 Setting the communication interfaces 5. Set the IP address of the access interface of the PG/PC to the Control Unit to 169.254.11.1 and the subnet mask to 255.255.0.0. Figure 5-1 IP address of PG/PC 6. Click "OK" and close the Windows-specific window of the network connections. 5.2.2 Calling STARTER 1. -

Page 26: Assigning The Ethernet Interface In Starter

Creating a drive object 5.2 Setting the communication interfaces 5.2.3 Assigning the Ethernet interface in STARTER Assigning the communication interface 1. In STARTER, go through the menu items "Tools > Set PG/PC interface...". The "Set PG/PC interface" window opens: Figure 5-2 Creating an access point 2. - Page 27 Creating a drive object 5.2 Setting the communication interfaces 3. If the desired adapter is in the list, continue as described in point 6. If the required adapter is not included in the list, you must add the appropriate entry. To do so, click on the "Selection..."...

-

Page 28: Creating A Drive Project

Creating a drive object 5.3 Creating a drive project Creating a drive project In STARTER, the project wizard will guide you through all the steps necessary to create and set up a new drive project. Procedure 1. In STARTER, click on the menu items "Project > New with Wizard." The start window of the project wizard is opened. - Page 29 Creating a drive object 5.3 Creating a drive project 4. Click on "Continue >". In step 2, the project wizard opens the "Set PG/PC interface" window. Figure 5-6 Setting the PG/PC Interface 5. In this window, you can check the settings of the communication interface made in the previous chapter, i.e.

- Page 30 Creating a drive object 5.3 Creating a drive project 6. Click on "Continue >". The project wizard continues to step 4 to display a summary of your project settings. Figure 5-8 Summary 7. Click on button "Complete". The project wizard closes the window. In the project navigator, the found drive unit "S120_CU320_2_DP"...

-

Page 31: Configuring The Drive Object

Configuring the drive object Configuring the drive unit In the example configuration, the "S120_CU320_2_DP" drive unit is configured for operation in the online mode. Through automatic configuration, the drive is initially switched to the "Factory settings" state and then provided with a standard configuration. Procedure 1. - Page 32 (the training case), but which are missing in the newly created project in STARTER (see section Special issues with the SINAMICS S120 training case (Page 34) and section Commissioning a drive (Page 37)).

- Page 33 Configuring the drive object 6.1 Configuring the drive unit 4. Double-click on option "Automatic configuration" in the project navigator. The following window opens: Figure 6-3 Automatic configuration is prepared 5. Start the automatic configuration of the drive unit by clicking on the "Configure" button. The programming device (PG/PC) searches the DRIVE-CLiQ bus for connected objects.

- Page 34 Configuring the drive object 6.1 Configuring the drive unit 7. Click on button "Create". The automatic configuration process commences. When the process has been completed, a window with the message "Automatic configuration is complete" opens. Figure 6-5 Automatic configuration, stay online Note The above message appears because two drives are integrated in the training case.

-

Page 35: Configuring The Motor Module

Configuring the drive object 6.2 Configuring the Motor Module Configuring the Motor Module The Control Unit has detected the connected Motor Module and the SMI motor during the automatic configuration process. The device data have been transferred to the Control Unit. The Control Unit has automatically entered the correct device data into the parameters required to operate the components. -

Page 36: Special Issues With The Sinamics S120 Training Case

6.3 Special issues with the SINAMICS S120 training case Special issues with the SINAMICS S120 training case If you use the SINAMICS S120 training case (which is customary with SITRAIN), as in the example case, pay attention to the following special issues: Motor used in the example configuration In this example, we only put the motor with the DRIVE-CLiQ interface into operation. - Page 37 Configuring the drive object 6.3 Special issues with the SINAMICS S120 training case 5. There, click on the "0" button in the expert list. The following configuration dialog is opened: Figure 6-7 Infeed operation 6. Click on row "1" and then click on "OK".

- Page 38 Configuring the drive object 6.3 Special issues with the SINAMICS S120 training case Device supply voltage You must reduce the device supply voltage so that you can commission the drive. 1. Scroll through the expert list of the drive to parameter p0210 (device supply voltage)

-

Page 39: Commissioning A Drive

(STOP), and (TIP), and various diagnostic functions are available. You can find more information about these functions in the SINAMICS S120 Drive Functions Function Manual. ON/OFF enable 1. In the project navigator, click on the "+" symbol before the entry "S120_CU320_2_DP". - Page 40 Commissioning a drive 5. There, click on the "0" button. The configuration dialog for the ON/OFF signal is opened: Figure 7-2 On/off configuration 6. Click on row "1" and then click on "OK". Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

- Page 41 Commissioning a drive Commission with the control panel 1. Double-click on the entries "S120_CU320_2_DP" > "Drives" > "SERVO_02" > "Commissioning" > "Control Panel" in the project navigator. Figure 7-3 Calling up the control panel The control panel is opened. Figure 7-4 Control panel displayed 2.

- Page 42 Commissioning a drive The "Assume control priority" window opens. Figure 7-5 Assuming control priority 3. Click on button "Safety notes". The "Safety notes" window opens. Figure 7-6 Safety instructions 4. Read and take note of the safety notes and then close the window. 5.

- Page 43 Commissioning a drive 6. Activate the check box "Enable signals". The symbols are active. 7. Enter a suitable speed for the motor in input field "n = ", e.g. "1,000." Figure 7-8 Control panel motor running 8. Click on the symbol The motor accelerates to the selected example speed of 1000 rpm.

- Page 44 Commissioning a drive Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

-

Page 45: Appendix

Appendix List of important alarms and faults Axxxxx: Alarm Fyyyyy: Fault Table A- 1 The most important alarms and faults Number Cause Remedy F07085 Control parameters were compulsorily changed for the Not necessary. following reasons: No parameter change is necessary as the parameters have already been limited to a reasonable level. - Page 46 Appendix A.1 List of important alarms and faults Number Cause Remedy F07840 The "Infeed operation" signal is not available, though Put infeed into operation. • the enables for the drive have already been pending for Check the interconnection of the binector input for •...

-

Page 47: Restoring Factory Settings

Appendix A.2 Restoring factory settings Restoring factory settings In rare cases, it may be necessary to revert the target device (the training case) back to factory settings. The simulated drive in the training case thus obtains a defined state once again and you can then restart the configuration on a secure basis. - Page 48 Appendix A.2 Restoring factory settings 3. Activate the check box " S120_CU320_2_DP ", and click on "OK." The PG/PC establishes the link to the Control Unit. It then performs an "Online/offline comparison". The result is displayed in the following dialog "Online/offline comparison". Example: Figure A-2 Online/offline comparison...

-

Page 49: Documentation Overview

Appendix A.3 Documentation overview Documentation overview Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2... - Page 50 Appendix A.3 Documentation overview Getting Started Getting Started, 01/2013, 6SL3097-4AG00-0BP2...

- Page 52 Siemens AG Subject to change without prior notice Industry Sector © Siemens AG, 2004 - 2013 Drive Technologies Motion Control Systems PO Box 3180 91050 ERLANGEN GERMANY www.siemens.com/motioncontrol...