Siemens SINAMICS S120 Commissioning Manual

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 SINAMICS S120 Commissioning manual · 01/2012 SINAMICS...

- Page 3 ___________________ Commissioning Manual Preface ___________________ Preparation for commissioning ___________________ Commissioning SINAMICS ___________________ Diagnostics S120 ___________________ Commissioning Manual Appendix Commissioning Manual Applies to: Firmware version 4.5 (IH1), 01/2012 6SL3097-4AF00-0BP2...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

Siemens' content, and adapt it for your own machine documentation: http://www.siemens.com/mdm Training Under the following link there is information on SITRAIN - training from Siemens for products, systems and automation engineering solutions: http://www.siemens.com/sitrain FAQs You can find Frequently Asked Questions in the Service&Support pages under Product Support: http://support.automation.siemens.com... - Page 6 Equipment for Machine Tools (Catalog NC 61) SINUMERIK 840D sl Type 1B Equipment for Machine Tools (Catalog NC 62) Installation/assembly SINAMICS S120 Equipment Manual for Control Units and Additional System Components SINAMICS S120 Equipment Manual for Booksize Power ...

- Page 7 The EC Declaration of Conformity for the EMC Directive can be found on the Internet at: http://support.automation.siemens.com There – as a search term – enter the number 15257461 or contact your local Siemens office. The EC Declaration of Conformity for the Low Voltage Directive can be found on the Internet http://support.automation.siemens.com...

- Page 8 The Safety Integrated functions of SINAMICS components are generally certified by independent institutes. An up-to-date list of already certified components is available on request from your local Siemens office. If you have any questions relating to certifications that have not been completed, please ask your Siemens contact.

-

Page 9: Commissioning Manual Commissioning Manual, (Ih1), 01/2012, 6Sl3097-4Af00-0Bp2

Preface Explanation of symbols Table 2 Symbols Symbol Meaning Protective earth (PE) Ground (e.g. M 24 V) Functional ground Equipotential bonding Notation The following notation and abbreviations are used in this documentation: Notation for parameters (examples): ● p0918 Adjustable parameter 918 ●... - Page 10 Preface ESD Notes CAUTION Electrostatic sensitive devices (ESD) are single components, integrated circuits or devices that can be damaged by electrostatic fields or electrostatic discharges. Regulations for the ESD handling: During the handling of electronic components, pay attention to the grounding of the person, workplace and packaging! Electronic components may be touched by persons only when ...

- Page 11 Preface Safety notices DANGER Commissioning is absolutely prohibited until it has been completely ensured that the machine, in which the components described here are to be installed, is in full compliance with the provisions of the EC Machinery Directive. ...

- Page 12 Preface CAUTION The motors can have surface temperatures of over +80 °C. This is why temperature-sensitive components, e.g. cables or electronic components must not be in contact with or attached to the motor. When connecting up cables, please ensure that they –...

-

Page 13: Table Of Contents

Contents Preface ..............................3 Preparation for commissioning ........................ 15 Requirements for commissioning....................15 Check lists to commission SINAMICS S..................17 PROFIBUS components ......................20 PROFINET components ......................21 Rules for wiring with DRIVE-CLiQ ....................22 1.5.1 Binding DRIVE-CLiQ rules......................22 1.5.2 Recommended DRIVE-CLiQ rules ....................28 1.5.3 Notes on the number of controllable drives .................31 1.5.3.1 System sampling times and number of controllable drives ............32... - Page 14 Contents 2.5.2 Component wiring (example) ...................... 98 2.5.3 Signal flow of the commissioning example ................. 99 2.5.4 Commissioning with STARTER (example) ................100 First commissioning control mode vector U/f in booksize format..........106 2.6.1 Task............................106 2.6.2 Component wiring (example) ....................107 2.6.3 Signal flow of the commissioning example ................

- Page 15 Contents 3.1.2.7 Smart Line Module booksize compact format................200 3.1.2.8 Motor Module booksize compact format..................201 3.1.2.9 Control Interface Module in the Active Line Module chassis format..........202 3.1.2.10 Control Interface Module in the Basic Line Module chassis format...........203 3.1.2.11 Control Interface Module in the Smart Line Module chassis format ..........204 3.1.2.12 Control Interface Module in the Motor Module chassis format ..........205 3.1.2.13 Control Interface Module in the Power Module chassis format ..........206 3.1.3...

- Page 16 Contents Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 17: Preparation For Commissioning

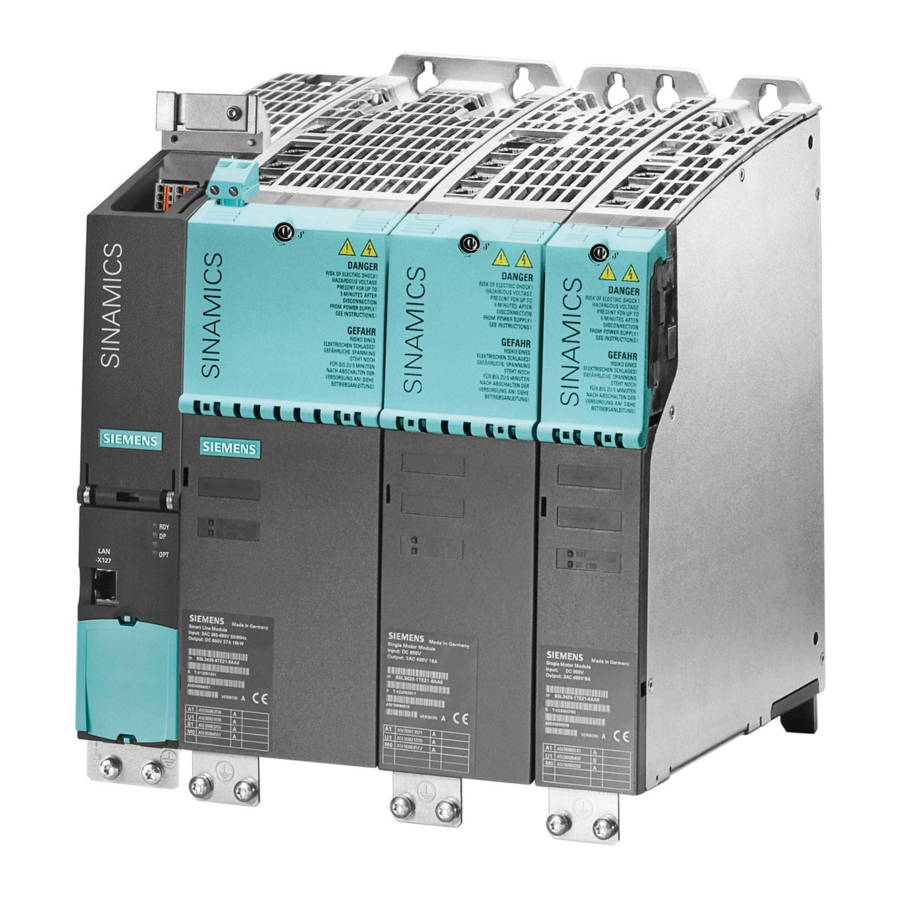

● A communication interface, e.g. PROFIBUS, PROFINET, Ethernet, CAN bus or USS (RS232-C) ● Completely wired-up drive line-up (see the SINAMICS S120 Manual) The following diagram shows a configuration example with booksize and chassis components, as well as with PROFIBUS and PROFINET communication... - Page 18 Preparation for commissioning 1.1 Requirements for commissioning Figure 1-1 Component configuration (example) Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 19: Check Lists To Commission Sinamics S

Preparation for commissioning 1.2 Check lists to commission SINAMICS S Check lists to commission SINAMICS S Checklist (1) for commissioning booksize power units The following checklist must be carefully observed. Read the safety instructions in the Manuals before starting any work. Table 1- 1 Checklist for commissioning (booksize) Check... - Page 20 Preparation for commissioning 1.2 Check lists to commission SINAMICS S Checklist (2) for commissioning chassis power units The following checklist must be carefully observed. Read the safety instructions in the Manuals before starting any work. Table 1- 2 Checklist for commissioning (chassis) Activity Are the environmental conditions in the permissible range? Are the components correctly installed in the cabinets?

- Page 21 Preparation for commissioning 1.2 Check lists to commission SINAMICS S Activity For operation on non-grounded supply systems: Has the connection bracket for the interference suppression at the Infeed Module or the Power Module been removed? Is the period from the date of manufacture to initial commissioning or the downtime of the power components less than two years Is the drive operated by higher-level controller/control room? Checklist (3) for commissioning blocksize Power Modules...

-

Page 22: Profibus Components

Preparation for commissioning 1.3 PROFIBUS components PROFIBUS components For communication via PROFIBUS, the following components are necessary. ● A communication module for programming device/PC connection via the PROFIBUS interface: ● PROFIBUS connection to a programming device/PC via USB port (USB V2.0), e.g. with the PROFIBUS adapter CP5711. -

Page 23: Profinet Components

Preparation for commissioning 1.4 PROFINET components PROFINET components For communication via PROFINET, the following components are necessary: 1. A communication module for programming device/PC connection via the PROFINET interface. Note For commissioning with STARTER, the onboard Ethernet interface of the Control Unit can be used with a crossover cable from CAT5 and higher. -

Page 24: Rules For Wiring With Drive-Cliq

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Rules for wiring with DRIVE-CLiQ Rules apply for wiring components with DRIVE-CLiQ. A distinction is made between binding DRIVE-CLiQ rules, which must be unconditionally observed and recommended rules, which should then be maintained so that the topology, generated offline in STARTER, no longer has to be changed. - Page 25 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 5. Double wiring of components is not permitted. Figure 1-2 Example: DRIVE-CLiQ line connected to the X103 DRIVE-CLiQ connection of a Control Unit 6. DRIVE-CLiQ components of unknown type within a topology are functionally not supported.

- Page 26 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 11. Parallel operation of power units in chassis format: – A parallel connection of Infeed Modules as well as Motor Modules is only permitted for vector control or for V/f control. –...

- Page 27 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 19. At a drive object "SERVO" or "VECTOR", up to three encoder data sets can be created for each drive data set. The maximum number of encoder data sets depends on the quantity structure and the current controller clock cycle: –...

- Page 28 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 30. The maximum number of DRIVE-CLiQ nodes on a DRIVE-CLiQ line of the Control Unit 320-2 depends on the basic clock cycle of the DRIVE-CLiQ line: – For a current controller cycle of 31.25 µs, a maximum of 3 DRIVE-CLiQ nodes are permissible –...

- Page 29 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 35. Only components that have the same sampling time may be connected to DRIVE-CLiQ connections with a sampling time of T = 31.25 μs. The following components are permissible: – Sensor Modules –...

-

Page 30: Recommended Drive-Cliq Rules

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ For the CU310-2 Control Unit the following applies: 1. The CU310-2 is a 1-axis control module that is plugged on to a PM340 Power Module 2. When plugged on, in operation, current controller sampling times up to a minimum of 125.00 µs can be selected. - Page 31 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 7. Line Modules and Motor Modules in the chassis format should be connected to separate DRIVE-CLiQ lines. 8. Peripheral components (e.g. Terminal Module, TM) should be connected to DRIVE-CLiQ socket X103 of the Control Unit in a line. –...

- Page 32 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 16. A Power Module with the CUA31 should be connected to the end of the DRIVE-CLiQ line. Figure 1-3 Example: DRIVE-CLiQ line 17. Only one final node should be connected to free DRIVE-CLiQ sockets of components within a DRIVE-CLiQ line (e.g.

-

Page 33: Notes On The Number Of Controllable Drives

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Table 1- 5 VSM connection Component VSM connection Active Line Module booksize X202 Active Line Module chassis X402 Power Module chassis X402 Motor Module Chassis X402 (active with PEM encoderless and "Flying restart" function) 1.5.3 Notes on the number of controllable drives... -

Page 34: System Sampling Times And Number Of Controllable Drives

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.3.1 System sampling times and number of controllable drives This chapter lists the number of axes that can be operated with a Control Unit. The number of axes depends on the cycle times and the control mode. The other available remaining computation times are available for options (e.g. - Page 35 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Cycle times for vector control This following table lists the number of axes that can be operated with a Control Unit in the vector control mode. The number of axes is also dependent on the cycle times of the controller: Table 1- 7 Sampling time setting for vector control...

- Page 36 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Mixed operation of servo control and U/f open-loop control In mixed operation with servo control and U/f control, one axis in servo control at 125 µs uses exactly as much computing performance as two axes in U/f control at 500 µs. In conjunction with servo control, a maximum of 11 axes are permitted (1 servo plus 10 vector U/f).

- Page 37 ● 50 DCC blocks for 2 ms time slice correspond to 1.5 U/f axes with 500 μs. Using EPOS The following table lists the number of axes that can be operated with a SINAMICS S120 when using a basic positioning system (EPOS). The number of axes is dependent on the current controller clock cycle.

-

Page 38: Optimizing Drive-Cliq

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Using CUA31/CUA32 Information on using the Control Unit Adapter CUA31 or CUA32: ● CUA31/32 is the first component in the CUA31/32 topology: 5 axes ● CUA31/32 is not the first component in the CUA31/32 topology: 6 axes ●... -

Page 39: Default Settings For The Sampling Times

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.3.3 Default settings for the sampling times When commissioning for the first time, the current controller sampling times (p0115[0]) are automatically pre-set with factory setting values: Table 1- 13 Factory settings Construction type Number p0112... -

Page 40: Changing The Offline Topology In Starter

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.4 Changing the offline topology in STARTER The device topology can be changed in STARTER by shifting the components in the topology tree. Table 1- 14 Example: changing the DRIVE-CLiQ topology Topology tree view Comment Select the DRIVE-CLiQ component. -

Page 41: Modular Machine Concept: Offline Correction Of The Reference Topology

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.5 Modular machine concept: Offline correction of the reference topology Description The topology is based on a modular machine concept. The machine concept is created "Offline" in STARTER in the maximum version as reference topology. The maximum version is the maximum expansion of a particular machine type. - Page 42 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ ● Transfer the project with "Download to drive unit". ● Then execute a "Copy RAM to ROM". Figure 1-5 Example of a sub-topology Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

- Page 43 "1" to "0". The deactivated components remain inserted, however, they are deactivated. Errors are not displayed from deactivated components. Overview of important parameters (see SINAMICS S120/S150 List Manual) ● p0105 Activate/deactivate drive object ● r0106 Drive object active/inactive ●...

-

Page 44: Topology Example: Drives In Vector Control

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.6 Topology example: Drives in vector control Example 1 A drive line-up with three Motor Modules in chassis format with identical pulse frequencies or three Motor Modules in booksize format in vector control mode: The Motor Modules chassis format with identical pulse frequencies or the Motor Modules booksize format in vector control mode can be connected to one DRIVE-CLiQ interface on the Control Unit. - Page 45 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Drive line-up comprising four Motor Modules in the chassis format with different pulse frequencies It is advantageous to connect Motor Modules with different pulse frequencies to different DRIVE-CLiQ sockets of the Control Unit. They may also be connected at the same DRIVE- CLiQ line.

-

Page 46: Topology Example: Parallel Motor Modules In Vector Control

X100 or X101 socket. For further information on parallel connection, see the chapter "Parallel connection of power units" in the SINAMICS S120 Function Manual. Note This topology does not match the topology created offline by STARTER and must be changed manually. -

Page 47: Topology Example: Drives In U/F Control (Vector Control)

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.8 Topology example: Drives in U/f control (vector control) The following diagram shows the maximum number of controllable vector V/f drives with additional components. The sampling times of individual system components are: ●... -

Page 48: Topology Example: Drives In Servo Control

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.9 Topology example: Drives in servo control The following diagram shows the maximum number of controllable servo drives and extra components. The sampling times of individual system components are: ● Active Line Module: p0115[0] = 250 µs ●... -

Page 49: Topology Example: Power Modules

Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ 1.5.10 Topology example: Power Modules Blocksize Figure 1-11 Drive line-ups with Power Modules blocksize Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... - Page 50 Preparation for commissioning 1.5 Rules for wiring with DRIVE-CLiQ Chassis Figure 1-12 Drive line-up of a Power Module chassis Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 51: Powering-Up/Powering-Down The Drive System

Preparation for commissioning 1.6 Powering-up/powering-down the drive system Powering-up/powering-down the drive system Powering up the infeed Figure 1-13 Powering up the infeed Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... - Page 52 Preparation for commissioning 1.6 Powering-up/powering-down the drive system Powering up the drive Figure 1-14 Powering up the drive Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

- Page 53 Preparation for commissioning 1.6 Powering-up/powering-down the drive system Off responses ● OFF1 – n_set = 0 is input immediately to brake the drive along the deceleration ramp (p1121). – When zero speed is detected, the motor holding brake (if parameterized) is closed (p1215).

- Page 54 ZSWA.11 r0899.11 ZSW2.10 only available in Interface Mode p2038 = 0 Function diagrams (see SINAMICS S120/S150 List Manual) ● 2610 Sequence control - sequencer ● 2634 Missing enable signals, line contactor control ● 8732 Basic Infeed - sequencer ● 8832 Smart Infeed - sequencer ●...

-

Page 55: Commissioning

Note The design guidelines and safety information in the Equipment Manuals must be carefully observed (refer to the documentation SINAMICS S120, Equipment Manual GH1 and GH2). Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... - Page 56 Commissioning 2.1 Procedure when commissioning CAUTION In STARTER, after the changeover of the axis type via p9302/p9502 and subsequent POWER ON, the units that depend on the axis type are only updated after a project upload. DANGER Vdc control with Basic Line Modules If several Motor Modules are supplied from a non-regenerative infeed unit (e.g.

-

Page 57: Starter Commissioning Tool

Commissioning 2.2 STARTER commissioning tool STARTER commissioning tool The STARTER commissioning tool is used to parameterize and commission drive units from the SINAMICS product family. STARTER can be used for the following: ● Commissioning ● Testing (via the control panel) ●... - Page 58 In the following prompt window you can select as to whether you also wish to save the factory setting in the ROM. 2. Click on "OK" to acknowledge. More information on how to use STARTER can be found in the SINAMICS S120 Getting Started manual. Operating support using wizards Wizards are integrated in STARTER for various functions to support operation.

- Page 59 Commissioning 2.2 STARTER commissioning tool Copy volatile data from the RAM to a ROM You can use this function to save volatile Control Unit data to the non-volatile memory (memory card). After backing up, the data are also kept if the 24 V Control Unit supply has been switched off.

- Page 60 2. Double-click the function entry "Safety Integrated". Additional information about how to use Safety Integrated Functions is provided in the SINAMICS S120 Safety Integrated Function Manual. Activate write protection Write protection prevents settings from being inadvertently changed. No password is required for write protection.

-

Page 61: Activating Online Operation: Starter Via Profibus

Commissioning 2.2 STARTER commissioning tool 2.2.2 Activating online operation: STARTER via PROFIBUS The programming device (PG/PC), on which STARTER is activated, is connected to PROFIBUS using a PROFIBUS adapter. STARTER via PROFIBUS (example with 2 CU320-2 DP) Figure 2-1 Connecting the programming device to the target device via PROFIBUS Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... - Page 62 Commissioning 2.2 STARTER commissioning tool STARTER settings for PROFIBUS The following settings are required in STARTER for communication via PROFIBUS: ● "Tools > Set PG/PC interface..." Select, Install/remove interfaces ● "Tools > Set PG/PC interface... > Properties" Activate/deactivate "PG/PC is the only master on the bus". Note PROFIBUS setting ...

-

Page 63: Activating Online Operation: Starter Via Ethernet

Commissioning 2.2 STARTER commissioning tool 2.2.3 Activating online operation: STARTER via Ethernet The Control Unit can be commissioned with the programming device (PG/PC) via the integrated Ethernet Interface. This interface is provided for commissioning purposes only and cannot be used to control the drive in operation. Routing with a possibly inserted CBE20 expansion card is not possible. - Page 64 Commissioning 2.2 STARTER commissioning tool Setting the IP address in Windows XP 1. On the desktop, click on the symbol "Network Environment" and click the right mouse button to open the "Properties" shortcut menu. 2. Double-click the appropriate network card and then click "Properties". 3.

- Page 65 Commissioning 2.2 STARTER commissioning tool Settings in STARTER In STARTER, set the communication via Ethernet as follows (in our example, we are using the Ethernet interface "Belkin F5D 5055"): 1. Call the menu "Tools > Set PG/PC interface ...". 2. Select the "Access point of the application", and therefore the interface parameter assignment (in the example we use the access point "S7ONLINE (STEP7)"...

- Page 66 Commissioning 2.2 STARTER commissioning tool 3. Click on button "Select". Figure 2-5 Setting the interface 4. In the selection list on the left-hand side, select the module that you want to use as the interface. 5. Click the "Install" button. The selected module is then listed in the "Installed"...

- Page 67 Commissioning 2.2 STARTER commissioning tool 7. Select the drive unit and call the shortcut menu "Target device > Online access ...". 8. Then click on the "Address module" tab. Figure 2-6 Setting the online access Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

- Page 68 Commissioning 2.2 STARTER commissioning tool Assigning the IP address and the name Note When assigning names to IO devices (e.g. a Control Unit) in Ethernet (SINAMICS components), then ST conventions (Structured Text) must be complied with. The names must be unique within Ethernet. "-" and "." are not permitted in the name of an IO device. Note The IP address and device name for the Control Unit are stored on the memory card (non- volatile).

- Page 69 Commissioning 2.2 STARTER commissioning tool 8. Click on the "View/Refresh (F5)" button to display the IP address and the NameOfStation = "The assigned name" in the entry for the bus node. Note If these two pieces of information are not be displayed in the entry for the bus node, close the "Accessible nodes"...

-

Page 70: Activating Online Operation: Starter Via Profinet Io

Commissioning 2.2 STARTER commissioning tool 2.2.4 Activating online operation: STARTER via PROFINET IO Online operation with PROFINET IO is implemented using TCP/IP. Preconditions ● STARTER commissioning tool from version 4.1.5 or higher ● Control Unit CU320-2 PN ● Communication Board CBE 20 in the Control Unit STARTER via PROFINET IO (example) Figure 2-7 Connecting the programming device to the target device via PROFINET (example) - Page 71 Commissioning 2.2 STARTER commissioning tool Setting the IP address in Windows XP 1. On the desktop, click on the symbol "Network Environment" and click the right mouse button to open the "Properties" shortcut menu. 2. Double-click the appropriate network card and then click "Properties". 3.

- Page 72 Commissioning 2.2 STARTER commissioning tool Interface settings in the STARTER commissioning tool In STARTER, you set communication via PROFINET as follows: 1. Call the menu "Tools > Set PG/PC interface ...". 2. Select the "Access point of the application", and therefore the interface parameter assignment (in the example we use the access point "S7ONLINE (STEP7)"...

- Page 73 Commissioning 2.2 STARTER commissioning tool 3. Click on button "Select". Figure 2-10 Setting the interface 4. In the selection list on the left-hand side, select the module that you want to use as the interface. 5. Click the "Install" button. The selected module is then listed in the "Installed"...

- Page 74 Commissioning 2.2 STARTER commissioning tool 7. Select the drive unit and call the shortcut menu "Target device > Online access ...". 8. Then click on the "Address module" tab. The IP address that you set must be located under "Connect to target station". Figure 2-11 Setting online access Assigning an IP address and a name to the drive unit...

- Page 75 Commissioning 2.2 STARTER commissioning tool 4. Call the menu "Project > Accessible nodes" or click on the symbol "Accessible nodes". – The search is performed for available nodes connected to PROFINET. – The Control Unit is identified and displayed under "Accessible nodes" as the bus node with the IP address 0.0.0.0, without any type information.

-

Page 76: Basic Operator Panel 20 (Bop20)

Commissioning 2.3 Basic Operator Panel 20 (BOP20) 12. Close the "Edit Ethernet node" window. Note ST (Structured Text) conventions must be satisfied for the name assignment of IO devices in PROFINET (SINAMICS components). The names must be unique within PROFINET. The characters "-"... -

Page 77: Operation With Bop20 (Basic Operator Panel 20)

Commissioning 2.3 Basic Operator Panel 20 (BOP20) 2.3.1 Operation with BOP20 (Basic Operator Panel 20) 2.3.1.1 General information about the BOP20 The BOP20 can be used to switch on and switch off drives during the commissioning phase as well as to display and modify parameters. Faults can be diagnosed as well as acknowledged. - Page 78 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Information on the displays Table 2- 2 Display Meaning top left The active drive object of the BOP is displayed here. 2 positions The displays and key operations always refer to this drive object. Lit if at least one drive in the drive line-up is in the RUN state (in operation).

- Page 79 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Information on the keys Table 2- 3 Keys Name Meaning Powering up the drives for which the command "ON/OFF1" should come from the BOP. Binector output r0019.0 is set using this key. Powering down the drives for which the commands "ON/OFF1", "OFF2" or "OFF3" should come from the BOP.

- Page 80 Commissioning 2.3 Basic Operator Panel 20 (BOP20) BOP20 functions Table 2- 4 Functions Name Description Backlighting The backlighting can be set using p0007 in such a way that it switches itself off automatically after the set time if no actions are carried out. Changeover active drive From the BOP perspective the active drive is defined using p0008 or using the keys "FN"...

- Page 81 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Overview of important parameters (see SINAMICS S120/S150 List Manual) All drive objects ● p0005 BOP operating display selection ● p0006 BOP operating display mode ● p0013 BOP user-defined list ● p0971 Drive object, save parameters Drive object, Control Unit ●...

-

Page 82: Displays And Using The Bop20

Commissioning 2.3 Basic Operator Panel 20 (BOP20) 2.3.1.2 Displays and using the BOP20 Features ● Status indicator ● Changing the active drive object ● Displaying/changing parameters ● Displaying/acknowledging faults and alarms ● Controlling the drive using the BOP20 Status indicator The operating display for each drive object can be set using p0005 and p0006. - Page 83 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Parameter display The parameters are selected in the BOP20 using the number. The parameter display is reached from the operating display by pressing the "P" key. Parameters can be searched for using the arrow keys. The parameter value is displayed by pressing the "P" key again. You can toggle between the drive objects by simultaneously pressing the "FN"...

- Page 84 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Value display To switch from the parameter display to the value display, press the "P" key. In the value display, the values of the adjustable parameters can be increased and decreased using the arrow.

- Page 85 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Example: Changing a parameter Precondition: The appropriate access level is set (for this particular example, p0003 = 3). Figure 2-16 Example: Changing p0013[4] from 0 to 300 Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

- Page 86 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Example: Changing binector and connector input parameters For the binector input p0840[0] (OFF1) of drive object 2 binector output r0019.0 of the Control Unit (drive object 1) is interconnected. Figure 2-17 Example: Changing indexed binector parameters Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 87: Fault And Alarm Displays

Commissioning 2.3 Basic Operator Panel 20 (BOP20) 2.3.1.3 Fault and alarm displays Displaying faults Figure 2-18 Faults Displaying alarms Figure 2-19 Alarms Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 88: Controlling The Drive Using The Bop20

Commissioning 2.3 Basic Operator Panel 20 (BOP20) 2.3.1.4 Controlling the drive using the BOP20 When commissioning the drive, it can be controlled via the BOP20. A control word is available on the Control Unit drive object (r0019) for this purpose, which can be interconnected with the appropriate binector inputs of e.g. - Page 89 Commissioning 2.3 Basic Operator Panel 20 (BOP20) Copy RAM to ROM You can initiate the saving of all parameters to the non-volatile memory (memory card) in the drive object CU: ● Press the P key for 3 seconds, ● p0009 = 0 ●...

-

Page 90: Creating A Project In Starter

Commissioning 2.4 Creating a project in STARTER Creating a project in STARTER 2.4.1 Creating a project offline PROFIBUS To create a project offline, you need the PROFIBUS address, the device type and the device version, e.g. firmware version 4.5 or higher. Table 2- 6 Example of a sequence for creating a project in STARTER What to do? - Page 91 Commissioning 2.4 Creating a project in STARTER What to do? How to do it? Comment 2. Add individual drive Information about the bus 1. Double-click in the project tree on "Insert single address: drive unit". The following settings are preassigned: The PROFIBUS address of the Control Unit must be set for initial –...

- Page 92 Commissioning 2.4 Creating a project in STARTER PROFINET To create a project offline, you need the PROFINET address, the device type and the device version, e.g. firmware version 4.5 or higher. What to do? How to do it? Comment Create a new project The project is created offline and 1.

- Page 93 Commissioning 2.4 Creating a project in STARTER What to do? How to do it? Comment Add individual drive Information about the bus 1. Double-click in the project tree on "Insert single address: drive unit". The following settings are preassigned: The PROFINET address of the Control Unit must not be set for –...

-

Page 94: Creating A Project Online

Commissioning 2.4 Creating a project in STARTER 2.4.2 Creating a project online In order to search online for bus nodes via PROFIBUS or PROFINET, the drive unit must be connected with the programming device (PG/PC) via PROFIBUS or PROFINET. Table 2- 7 Example of search sequence with STARTER What to do? How to do it? - Page 95 Commissioning 2.4 Creating a project in STARTER What to do? How to do it? Enter the project 1. Enter the following project data: data. – Project name: Project_1, can be freely selected – Author: Any – Storage location: Any – Comment: Any 2.

- Page 96 Commissioning 2.4 Creating a project in STARTER What to do? How to do it? Selecting the The target device can be accessed via STARTER or via STEP 7. access point 1. For step 2, click on "Access point". 2. Select the access point for the accessible nodes. Selecting the In this window, the interface can be selected, set and tested.

- Page 97 Commissioning 2.4 Creating a project in STARTER What to do? How to do it? Insert drives The nodes are shown here in the preview. Use the button "Refresh view" to update the preview. Summary You have now created the project. 1.

-

Page 98: First Commissioning, Servo Control Mode, Booksize Format

Commissioning 2.5 First commissioning, servo control mode, booksize format First commissioning, servo control mode, booksize format An example provided in this chapter explains all the configuration and parameter settings, as well as tests that are required for initial commissioning. Commissioning is carried out using the STARTER commissioning tool. -

Page 99: Task

Standard telegram 4: Speed control, 2 position encoders ● Enable signals for drive 2 Standard telegram 3: Speed control, 1 position encoder Note For more information about telegram types, see Function Manual SINAMICS S120 or SINAMICS S120/S150 List Manual. Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 100: Component Wiring (Example)

Commissioning 2.5 First commissioning, servo control mode, booksize format 2.5.2 Component wiring (example) The following diagram shows the structure of the components and the appropriate wiring. The DRIVE-CLiQ wiring is highlighted in bold. Figure 2-20 Component wiring (example) For more information on wiring and connecting the encoder system, see the Equipment Manual. -

Page 101: Signal Flow Of The Commissioning Example

Commissioning 2.5 First commissioning, servo control mode, booksize format 2.5.3 Signal flow of the commissioning example Figure 2-21 Signal flow of the commissioning example - servo - Part 1 Figure 2-22 Signal flow of the commissioning example - servo - Part 2 Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 102: Commissioning With Starter (Example)

Commissioning 2.5 First commissioning, servo control mode, booksize format 2.5.4 Commissioning with STARTER (example) The table below describes the steps for commissioning a drive using the STARTER commissioning tool. Table 2- 9 Sequence for commissioning with STARTER (example) What to do? How to do it? Comment Creating a new... - Page 103 Commissioning 2.5 First commissioning, servo control mode, booksize format What to do? How to do it? Comment Configure the Infeed 1. Call the menu "Project > Disconnect from target system" in infeed order to change to offline mode. 2. Double-click in the project tree on "Infeeds". 3.

- Page 104 Commissioning 2.5 First commissioning, servo control mode, booksize format What to do? How to do it? Comment Configuration of You must individually configure the drives in the offline mode. The the drives wizard displays the data determined automatically from the electronic type plate.

- Page 105 Commissioning 2.5 First commissioning, servo control mode, booksize format What to do? How to do it? Comment 1. If your motor is not in the default list, select "Enter motor data" and jump to point 5.2. 2. Click on your motor type in the "Motor type" list. 3.

- Page 106 Commissioning 2.5 First commissioning, servo control mode, booksize format What to do? How to do it? Comment Entering encoder Enter additional encoders 1. Enter the encoder data into the input screen form and click on data in the same way as "OK".

- Page 107 The control panel supplies the control word 1 (STW1) and speed setpoint 1 (NSOLL). For more information about line/DC link identification, see the SINAMICS S120 Function Manual. STARTER diagnostic options Under Component -> Diagnostics -> Control/status words ● Control/status words ● Status parameters ●...

-

Page 108: First Commissioning Control Mode Vector U/F In Booksize Format

Commissioning 2.6 First commissioning control mode vector U/f in booksize format First commissioning control mode vector U/f in booksize format An example provided in this chapter explains all the configuration and parameter settings, as well as tests that are required for initial commissioning. Commissioning is carried out using the STARTER commissioning tool. -

Page 109: Component Wiring (Example)

Commissioning 2.6 First commissioning control mode vector U/f in booksize format 2.6.2 Component wiring (example) The following diagram shows the structure of the components and the appropriate wiring. The DRIVE-CLiQ wiring is highlighted in bold. Figure 2-23 Component wiring (example) For more information on wiring and connecting the encoder system, see the Equipment Manual. -

Page 110: Signal Flow Of The Commissioning Example

Commissioning 2.6 First commissioning control mode vector U/f in booksize format 2.6.3 Signal flow of the commissioning example Figure 2-24 Signal flow diagram of the example vector U/f control mode in the booksize format Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 111: Commissioning With Starter (Example)

Commissioning 2.6 First commissioning control mode vector U/f in booksize format 2.6.4 Commissioning with STARTER (example) The table below describes the steps for commissioning the example using the STARTER commissioning tool. Table 2- 11 Sequence for commissioning with STARTER (example) What to do? How to do it? Comment... - Page 112 Commissioning 2.6 First commissioning control mode vector U/f in booksize format What to do? How to do it? Comment Configure the 1. Call the menu "Project > Disconnect from target system" in infeed order to change to offline mode. 2. Double-click in the project tree on "Infeeds". 3.

- Page 113 Commissioning 2.6 First commissioning control mode vector U/f in booksize format What to do? How to do it? Comment Configuration of You must individually configure the drives in the offline mode. the drives The wizard displays the data determined automatically from the electronic type plate.

- Page 114 Commissioning 2.6 First commissioning control mode vector U/f in booksize format What to do? How to do it? Comment Drive setting You can select the motor standard (IEC/NEMA) and power unit application (duty cycles). Configuring the You can select a standard 1.

- Page 115 Commissioning 2.6 First commissioning control mode vector U/f in booksize format What to do? How to do it? Comment Configuring an When using an encoder You can connect up to 3 encoders. encoder that is not in the list, after 1.

- Page 116 Commissioning 2.6 First commissioning control mode vector U/f in booksize format What to do? How to do it? Comment Enable signals and The enable signals for the infeed and the two drives must be BICO realized via the digital inputs on the Control Unit. interconnections 1.

- Page 117 Save the Position cursor on drive 1. Select the drive unit in the project tree. parameters on the unit (SINAMICS S120) and 2. Call the "Connect target device" shortcut menu. device right-click. 3. Call the "Target device > Load to target device" shortcut menu.

-

Page 118: First Commissioning, Vector Control Mode In The Chassis Format

Commissioning 2.7 First commissioning, vector control mode in the chassis format STARTER diagnostic options Under Component -> Diagnostics -> Control/status words ● Control/status words ● Status parameters ● Missing enable signals First commissioning, vector control mode in the chassis format An example provided in this chapter explains all the configuration and parameter settings, as well as tests that are required for initial commissioning. -

Page 119: Task

Commissioning 2.7 First commissioning, vector control mode in the chassis format 2.7.1 Task A drive in the "chassis" format in the "Vector" control mode with the following components is to be commissioned for the first time: Table 2- 12 Component overview Designation Component Order number... -

Page 120: Component Wiring (Example)

Commissioning 2.7 First commissioning, vector control mode in the chassis format 2.7.2 Component wiring (example) The following diagram shows the structure of the components and the appropriate wiring. The DRIVE-CLiQ wiring is highlighted in bold. Figure 2-25 Component wiring (example) 1) X500 at the Voltage Sensing Module For more information on wiring and connecting the encoder system, see the Equipment Manual. -

Page 121: Signal Flow Of The Commissioning Example

Commissioning 2.7 First commissioning, vector control mode in the chassis format 2.7.3 Signal flow of the commissioning example Figure 2-26 Signal flow of the commissioning example chassis Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 122: Commissioning With Starter (Example)

Commissioning 2.7 First commissioning, vector control mode in the chassis format 2.7.4 Commissioning with STARTER (example) The table below describes the steps for commissioning a drive using the STARTER commissioning tool. Table 2- 13 Sequence for commissioning with STARTER (example) What to do? How to do it? Comment... - Page 123 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment Configure the Infeed 1. Call the menu "Project > Disconnect from target system" in infeed order to change to offline mode. 2.

- Page 124 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment Configuration of You must individually configure the drives in the offline mode. the drives The wizard displays the data determined automatically from the electronic type plate.

- Page 125 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment 1. If your motor is not in the default list, select Enter motor data and jump to point 5.2. 2. Click on your motor type in the "Motor type" list. 3.

- Page 126 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment Configuring For communication, you can select the PROFIdrive telegram process data from various telegrams. exchange 1. For the example, select "[ 999] Free telegram configuration with BICO".

- Page 127 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment Enable Motor See function diagram Enable signals for the Motor Module (drive_1): Module [2501] p0840 = 722.0 ON/OFF1 p0844 = 722.1 1. OFF2 p0845 = 1 2.

- Page 128 Commissioning 2.7 First commissioning, vector control mode in the chassis format What to do? How to do it? Comment Setpoint A setpoint of 0 (0 signal) or Specify setpoint: configuration 40 (1 signal) is defaulted p1001 = 0 Fixed setpoint 1 via digital input 7.

- Page 129 SINAMICS S120 Function Manual. Diagnostics parameters (see the SINAMICS S120/S150 List Manual) ● r0002 Infeed/drive operating display ● r0046 Missing enable signals (for more information, see Chapter, "Diagnostics") Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 130: 2.8 First Commissioning, Control Mode Vector Ac Drive In The Booksize Format

Commissioning 2.8 First commissioning, control mode vector AC Drive in the booksize format First commissioning, control mode vector AC Drive in the booksize format An example provided in this chapter explains all the configuration and parameter settings, as well as tests that are required for initial commissioning. Commissioning is carried out using the STARTER commissioning tool. -

Page 131: Component Wiring (Example)

Commissioning 2.8 First commissioning, control mode vector AC Drive in the booksize format 2.8.2 Component wiring (example) The following diagram shows the structure of the components and the appropriate wiring. Figure 2-27 Component wiring (example) For more information on wiring, see the Equipment Manual. Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2... -

Page 132: Quick Commissioning Using The Bop (Example)

Commissioning 2.8 First commissioning, control mode vector AC Drive in the booksize format 2.8.3 Quick commissioning using the BOP (example) Table 2- 14 Quick commissioning for a vector drive without a DRIVE-CLiQ interface Procedure Description Factory setting Restore the drive to the factory setting: p0009 = 30 Device commissioning parameter filter * 0 Ready... - Page 133 Commissioning 2.8 First commissioning, control mode vector AC Drive in the booksize format Procedure Description Factory setting p0100 = 0 IEC/NEMA motor standard 0 IEC motor (SI units, e.g. kW) Preset: Rated motor frequency (p0310): 50 Hz Specification of the power factor cos φ (p0308) 1 NEMA motor (US units, e.g.

- Page 134 * These parameters offer more setting options than the ones described here. For further setting options see SINAMICS S120/S150 List Manual [CDS] Parameter depends on command data sets (CDS). Data set 0 is preset. [DDS] Parameter depends on drive data sets (DDS). Data set 0 is preset.

-

Page 135: First Commissioning, Control Mode Servo Ac Drive In The Booksize Format

Commissioning 2.9 First commissioning, control mode servo AC Drive in the booksize format First commissioning, control mode servo AC Drive in the booksize format An example provided in this chapter explains all the configuration and parameter settings, as well as tests that are required for initial commissioning. Commissioning is carried out using the STARTER commissioning tool. -

Page 136: Component Wiring (Example)

Commissioning 2.9 First commissioning, control mode servo AC Drive in the booksize format 2.9.2 Component wiring (example) The following diagram shows the structure of the components and the appropriate wiring. Figure 2-28 Component wiring with integrated Sensor Module (example) For more information on wiring and connecting the encoder system, see the Equipment Manual. -

Page 137: Quick Commissioning Using The Bop (Example)

Commissioning 2.9 First commissioning, control mode servo AC Drive in the booksize format 2.9.3 Quick commissioning using the BOP (example) Table 2- 15 Quick commissioning of a servo drive with a DRIVE-CLiQ interface Procedure Description Factory setting Note: Before commissioning for the first time, in the drive mode DO = 1, the drive is restored to the factory setting. p0009 = 30 Device commissioning parameter filter 0 Ready... - Page 138 Commissioning 2.9 First commissioning, control mode servo AC Drive in the booksize format Procedure Description Factory setting p0009 = 0 Device commissioning parameter filter * 0 Ready 1 Device configuration 30 Parameter reset Note: Wait until the RDY-LED changes from orange to green. To save the setting in the ROM, press about 5 seconds on the "P" key until the BOP display flashes, then wait until flashing has stopped.

-

Page 139: Commissioning Of Power Units Connected In Parallel

31 - and the drive is now ready. 10 is displayed in DO = 1. * These parameters offer more setting options than the ones described here. For further setting options see SINAMICS S120/S150 List Manual [CDS] Parameter depends on command data sets (CDS). Data set 0 is preset. - Page 140 Commissioning 2.10 Commissioning of power units connected in parallel Parallel connection of infeeds in STARTER Figure 2-29 Example of parallel connection of 3 Active Line Modules (chassis type) You need to specify the number of infeeds to be connected in parallel in the appropriate field (maximum 4 infeeds).

- Page 141 Commissioning 2.10 Commissioning of power units connected in parallel Parallel connection of Motor Modules in STARTER Figure 2-30 Example of a parallel connection of 3 Motor Modules (chassis format, in vector control) Select the number of Motor Modules connected in parallel in the drop-down list, "Number of parallel modules"...

- Page 142 Parallel connection is indicated with a "P" in front of the value shown on the parameter value display. Other parameters relevant for the operation and parameterization of power units can be taken from the SINAMICS S120/S150 List Manual from parameter r7002 or from p0125 onwards. Commissioning Manual...

- Page 143 Commissioning 2.10 Commissioning of power units connected in parallel Parallel connection with one or two Control Units If an infeed is deactivated, the pre-charging must be able to charge the remaining infeeds in the DC link. For example, the charging time is doubled, if only one of the two infeeds connected in parallel is activated.

-

Page 144: Learn Devices

Configuration of power units connected in parallel Information on the hardware configuration and wiring the power units is provided in the SINAMICS S120 Equipment Manual Chassis Power Units. You can find information on configuration in "SINAMICS Configuration Manual G130, G150, S120 Chassis, S120 Cabinet Modules, S150". - Page 145 Commissioning 2.11 Learn devices SSP (SINAMICS Support Package) An SSP contains only description files of the devices and drive objects. By installing an SSP, new drive objects and devices can be added to an existing STARTER installation, without changing its program code. After installation, all the functions of the new SINAMICS version can be configured with the expert list.

-

Page 146: Selection And Configuration Of Encoders

2. Select a standard encoder from a list (also possible via the motor order number for encoder 1/motor encoder). Every encoder type on the list has a code number (see SINAMICS S120/S150 List Manual), that can also be assigned using parameter p0400 (encoder type selection). - Page 147 Commissioning 2.12 Selection and configuration of encoders Encoder type Encoder code Encoder evaluation procedure Evaluation module Linear Incremental 2110 4000 nm, 1 Vpp, A/B R distance-coded SMC20, SMI20, encoder linear 2111 20000 nm, 1 Vpp, A/B R distance-coded SME20 2112 40000 nm, 1 Vpp, A/B R distance-coded 2151 16000 nm, 1 Vpp, A/B, EnDat, resolution...

- Page 148 Commissioning 2.12 Selection and configuration of encoders Encoder configuration You can configure the encoders using an input screen in STARTER. 1. If you mark the appropriate check box option, encoders with a DRIVE-CLiQ interface are automatically identified on the encoder configuration screen. Figure 2-32 Identifying DRIVE-CLiQ encoders Commissioning Manual...

- Page 149 Figure 2-33 Standard encoder option When configuring the drive you can select the standard encoders offered by Siemens from a list under "encoder". When the encoder type is chosen, all necessary parameterizations are simultaneously and automatically transferred into the encoder configuration.

- Page 150 Commissioning 2.12 Selection and configuration of encoders 3. Manually entering user-defined encoder data. In this case, the encoder can be configured using the encoder-specific input screens in STARTER. Figure 2-34 User-defined encoder option To do this, select the option "Enter data" and press the "Encoder data" button. The following window for encoder data opens: Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

- Page 151 Commissioning 2.12 Selection and configuration of encoders Figure 2-35 Rotary encoder types In this window, you can select between "rotary" and "linear" encoders. For rotary encoders you can select the following encoder types: – Resolver – Incremental encoder with sin/cos signal –...

- Page 152 Commissioning 2.12 Selection and configuration of encoders The drop-down list for linear encoders offers the following encoder types: Figure 2-36 Linear encoder types For linear encoders, you can configure the following encoder types: – Absolute encoder with EnDat protocol – Incremental encoder with sin/cos signal –...

- Page 153 Commissioning 2.12 Selection and configuration of encoders Encoders with a DRIVE-CLiQ interface Encoder evaluation units with DRIVE-CLiQ interface are available in the following versions: ● Sensor Module Cabinet-Mounted (SMCx) for rail mounting ● Sensor Module External (SMEx) to be incorporated in the feeder cable ●...

- Page 154 The newly defined codes are not stored in the DRIVE-CLiQ encoder. Replacing a SINAMICS Sensor Module Integrated If a defect occurs in a SINAMICS Sensor Module Integrated (SMI) or in a DRIVE-CLiQ Sensor Integrated (DQI), contact your local Siemens office for a repair. Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 155: Commissioning Linear Motors (Servo)

Commissioning 2.13 Commissioning linear motors (servo) 2.13 Commissioning linear motors (servo) 2.13.1 General information on commissioning linear motors Before commissioning motors, the following questions must be answered: 1. Are the preconditions for commissioning (Page 15) fulfilled? 2. Have the commissioning checklists (Page 17) been completed and are all of the points fulfilled? Detailed information on linear motors, encoders and power connection, configuring and mounting can be found in the Configuration Manual of the 1FN1, 1FN3 or 1FN6 linear... - Page 156 – Hanging (suspended) axis: If weight equalizing is used for the axis is this functioning? – Brake: If a brake is being used, is it correctly controlled (see the SINAMICS S120 Function Manual)? – Traversing range limiting: Are the mechanical end stops available and tightly bolted to both ends of the traversing path? –...

- Page 157 Commissioning 2.13 Commissioning linear motors (servo) 4. Wiring – Power unit (connect UVW, phase sequence, clockwise rotating field) – Protective conductor connected? – Shield connected? – Temperature monitoring circuits: Are the cables connected to the terminal block of the shield connecting plate? Temperature sensor (Temp-F): With the temperature sensor (Temp-F), the average absolute winding temperature can be measured.

-

Page 158: Commissioning: Linear Motor With One Primary Section

Commissioning 2.13 Commissioning linear motors (servo) 2.13.2 Commissioning: Linear motor with one primary section Commissioning with STARTER DANGER Linear drives can achieve significantly higher rates of acceleration and velocities than conventional drives. The traversing range must always be kept clear in order to avoid any potential danger for man or machine. - Page 159 Commissioning 2.13 Commissioning linear motors (servo) 2. Enter motor data The following motor data must be entered for third-party motors: Parameter Description Comment p0305 Rated motor current p0311 Motor rated velocity p0315 Motor pole pair width p0316 Motor force constant p0322 Maximum motor velocity p0323...

-

Page 160: Commissioning: Linear Motor With Several Identical Primary Sections

Commissioning 2.13 Commissioning linear motors (servo) 3. User-defined encoder data For linear motors, the encoder is configured using the "User-defined encoder data" screen form. Figure 2-38 Encoder data screen in STARTER WARNING When linear motors are configured for the first time, the commutation angle offset (p0431) must be adjusted. - Page 161 Commissioning 2.13 Commissioning linear motors (servo) The linear motors are connected individually in sequence to the drive, and are commissioned as a single motor (1FNx ...). The angular commutation offset is automatically determined and noted for each motor. Finally, the measured angular commutation offset of the motors are compared with each other.

-

Page 162: Thermal Motor Protection

Commissioning 2.13 Commissioning linear motors (servo) 2.13.4 Thermal motor protection Temperature monitoring circuits Temp-F and Temp-S The motors are supplied with two temperature monitoring circuits: Temp - F and Temp - S. Temp-F is to monitor and evaluate the temperature characteristic in the motor being used. Temp-S is used to activate the motor protection in the event of overheating in the motor windings. - Page 163 ● SME120 for incremental position measurement systems ● SME125 for absolute position measurement systems You will find further information on the SME12x in the SINAMICS S120 Equipment Manual, Control Units and Additional System Components, in the chapter Encoder System Connection.

-

Page 164: Measuring System

U, V, W) coincides with the positive counting direction of the measuring system. Note The data to determine the drive direction is only valid for Siemens motors (1FNx motors). If the positive direction of the drive and positive counting direction of the measuring system do not match, the actual speed value (P0410.0) must be inverted in the "Encoder... - Page 165 Commissioning 2.13 Commissioning linear motors (servo) Determining the drive direction The direction of the drive is positive if the primary section moves relative to the secondary section in the opposite direction to the cable outlet direction. Figure 2-39 Determining the positive direction of the drive Determining the counting direction of the measuring system The counting direction is determined depending on the measuring system.

-

Page 166: Checking The Linear Motor By Taking Measurements

Commissioning 2.13 Commissioning linear motors (servo) Measuring systems from Renishaw (e.g. RGH22B) As the reference mark for the Renishaw RGH22B has a direction-dependent position, with control cables BID and DIR, the encoder must be parameterized, so that the reference mark is only output in one direction. - Page 167 Commissioning 2.13 Commissioning linear motors (servo) Taking the necessary measurements ● Disconnect the drive line-up from the power supply. ● Notice: Wait until the DC link has been discharged! ● Disconnect the power cables from the drive. Disconnect any primary components connected in parallel. ●...

- Page 168 Commissioning 2.13 Commissioning linear motors (servo) Determining the commutation angle using an oscilloscope Once the oscilloscope has been connected, the drive must first pass the zero mark so that fine synchronization can be carried out. The angular, commutation offset can be determined by measuring the EMF and normalized electrical pole position via an analog output.

-

Page 169: Notes On Commissioning Ssi Encoders

● SMC30 Sensor Module Cabinet-Mounted ● CU320-2 Control Unit Types of encoder that can be connected Table 2- 19 Overview of encoder types that can be connected depending on the SIEMENS evaluation module Encoder Incremental tracks Absolute position Power supply for... - Page 170 Commissioning 2.14 Notes on commissioning SSI encoders Note Only encoders that support a transfer rate of 100 kHz and that have a high level in idle state may be used. The monoflop time should be parameterized such that it is greater than or equal to the specified monoflop time of the encoder.

- Page 171 Commissioning 2.14 Notes on commissioning SSI encoders Parameterization Predefined encoders Various predefined SSI encoders are available for commissioning. These can be selected from the STARTER commissioning windows. User-defined encoders If there are no predefined entries for the encoder used, user-defined encoder data can be entered via windows using the commissioning wizard.

-

Page 172: Notes On The Commissioning Of A 2-Pole Resolver As Absolute Encoder

Commissioning 2.15 Notes on the commissioning of a 2-pole resolver as absolute encoder Diagnostics Example 1 An SSI encoder without incremental tracks is used. The encoder has a singleturn resolution of 16 bits and a multiturn resolution of 14 bits. The fine resolution p0418[x] and p0419[x] is set to the value 2. -

Page 173: Temperature Sensors For Sinamics Components

Commissioning 2.16 Temperature sensors for SINAMICS components Position tracking You can also activate position tracking for a 2-pole resolver. Please note, however, that the resolver may not be moved more than half an encoder revolution (pole width) when switched off. The activation and configuration of the position tracking is described in the chapter "Position tracking". - Page 174 Commissioning 2.16 Temperature sensors for SINAMICS components Table 2- 20 Temperature sensor connections for SINAMICS components Module Interface Signal name Technical specifications SMC10/SMC20 X520 (sub D) +Temp Temperature sensor - Temp KTY84-1C130 / PTC SMC30 X520 (sub D) +Temp Temperature sensor Temperature - Temp KTY84-1C130 / PTC / bimetallic...

- Page 175 Commissioning 2.16 Temperature sensors for SINAMICS components Module Interface Signal name Technical specifications X535 +Temp - Temp +Temp - Temp X536 +Temp - Temp +Temp - Temp SME20 Measuring system - Temp Temperature sensor interface +Temp KTY84-1C130 / PTC connection cable order number 6FX8002-2CA88- xxxx necessary SME120 / X200 (connector)

- Page 176 Commissioning 2.16 Temperature sensors for SINAMICS components Commissioning information The index [0..n] used in the following identifies either the motor data set or the encoder data set. SMC10/SMC20 You can use the STARTER screen (\signals and monitoring \ motor temperature) to parameterize the motor temperature evaluation via SUB-D socket X520.

- Page 177 Commissioning 2.16 Temperature sensors for SINAMICS components CU310-2 DP / CU310-2 PN The Control Unit 310-2 has an integrated SMC30 encoder interface. This encoder interface is accessed via the 15-pin Sub-D-contact X23 and is evaluated as temperature channel 1. There are three options available to evaluate the temperature: 1.

- Page 178 The parameterization of the temperature evaluation via terminal X210 or sub D socket X220 is performed using two temperature channels. p0600 = 11: Temperature sensor via Motor Module For the SINAMICS S120 AC Drive (AC/AC) and if Control Unit Adapter CUA31/CUA32 is used, the temperature sensor connection is on the adapter (X210). TM31 A Terminal Module 31 (TM31) is used when additional digital and analog inputs/outputs required.

- Page 179 To do this, short-circuit the sensor cable as close as possible to the sensor. The procedure is described in the SINAMICS S120/150 List Manual under p4109[0...11]. The measured cable resistance is then taken into account when evaluating the temperature.

- Page 180 3 and 4. The measuring cable is connected to terminals 1 and 2. You can find additional information in function diagram 9626 in the SINAMICS S120/S150 List Manual and in the SINAMICS S120 Function Manual in Chapter "Thermal motor protection".

- Page 181 Commissioning 2.16 Temperature sensors for SINAMICS components SME120/SME125 For modules with several temperature sensor connections (SME Modules), the temperature sensor is selected depending on encoder data set n via parameters p4601[0..n]..p4603[0..n]. A maximum of three motor temperature sensors can be evaluated simultaneously via terminal X200.

- Page 182 If an SME Module is used (p0601 = 10), parameter r949 displays the number of the sensor channel that has triggered the message. Function diagrams (see SINAMICS S120/S150 List Manual) ● 8016 Signals and monitoring - Thermal monitoring of motor...

- Page 183 Commissioning 2.16 Temperature sensors for SINAMICS components Overview of important parameters (see SINAMICS S120/S150 List Manual) ● r0035 CO: Motor temperature ● r0458[0...2] Sensor Module properties ● p0600[0..n] Motor temperature sensor for monitoring ● p0601[0..n] Motor temperature sensor type ● p0601 Motor temperature sensor type ●...

- Page 184 Commissioning 2.16 Temperature sensors for SINAMICS components Commissioning Manual Commissioning Manual, (IH1), 01/2012, 6SL3097-4AF00-0BP2...

-

Page 185: Diagnostics

Diagnostics This chapter describes the following diagnostic features of the SINAMICS S drive system: ● Diagnostics via LEDs ● Diagnostics via STARTER ● Diagnostic buffer ● Diagnostics of uncommissioned axes ● Fault and alarm messages ● Encoder troubleshooting Diagnostics via LEDs 3.1.1 Control Units 3.1.1.1... - Page 186 Diagnostics 3.1 Diagnostics via LEDs Control Unit 320-2 DP while powering up Table 3- 2 Load software State Comment Orange Orange Reset Hardware reset RDY LED lights up red, all other LEDs light up orange BIOS loaded – BIOS error Error occurred while loading the BIOS ...

- Page 187 Diagnostics 3.1 Diagnostics via LEDs Control Unit 320-2 DP in operation Table 3- 4 Control Unit CU320-2 DP – Description of the LEDs after booting Color State Description, cause Remedy RDY (READY) Electronic power supply is missing or outside Check power supply permissible tolerance range.

- Page 188 Diagnostics 3.1 Diagnostics via LEDs Color State Description, cause Remedy Flashing PROFIBUS master is sending wrong Adapt configuration between light parameterization/configuration data master/controller and CU 0.5 Hz Flashing Cyclic bus communication has been interrupted Remedy fault light or could not be established 2 Hz –...

- Page 189 Diagnostics 3.1 Diagnostics via LEDs Control Unit 320-2 PN while powering up Table 3- 5 Load software State Comment Orange Orange Reset Hardware reset RDY LED lights up red, all other LEDs light up orange BIOS loaded – BIOS error Error occurred while loading the BIOS ...

- Page 190 Diagnostics 3.1 Diagnostics via LEDs Control Unit 320-2 PN in operation Table 3- 7 Control Unit CU320-2 PN – Description of the LEDs after booting Color Status Description, cause Remedy RDY (READY) Electronics power supply is missing or outside Check power supply the permissible tolerance range.

-

Page 191: Description Of The Led States Of A Cu 310-2

Diagnostics 3.1 Diagnostics via LEDs Color Status Description, cause Remedy 0.5 Hz Bus error, Adapt configuration between flashing incorrect parameter assignment/configuration controller and devices light 2 Hz Cyclic bus communication has been interrupted Remove fault flashing or could not be established light –... - Page 192 Diagnostics 3.1 Diagnostics via LEDs Control Unit 310-2 DP while powering up Table 3- 9 Load software State Comment OUT>5V Orange Orange Orange Orange POWER ON All LEDs light up for approx. 1 s Hardware reset After pressing the RESET button the LEDs light up for approx.

- Page 193 Diagnostics 3.1 Diagnostics via LEDs Color State Description / cause Remedy Flashing light General errors Check parameter 2 Hz assignment / configuration Red / green Flashing light The Control Unit is ready for operation, but there Install the missing 0.5 Hz are no software licenses.

- Page 194 Diagnostics 3.1 Diagnostics via LEDs Control Unit 310-2 PN while powering up Table 3- 12 Load software State Comment OUT>5V Orange Orange Orange Orange POWER ON All LEDs light up for approx. 1 s Hardware reset After pressing the RESET button the LEDs light up for approx.

- Page 195 Diagnostics 3.1 Diagnostics via LEDs Color State Description / cause Remedy Flashing light General errors Check parameter 2 Hz assignment / configuration Red / green Flashing light The control unit is ready for operation, but there Install the missing 0.5 Hz are no software licenses.

-

Page 196: Power Units

Diagnostics 3.1 Diagnostics via LEDs 3.1.2 Power units 3.1.2.1 Active Line Module booksize Table 3- 15 Meaning of the LEDs on the Active Line Module State Description, cause Remedy Ready DC link Electronic power supply is missing or outside – permissible tolerance range. -

Page 197: Basic Line Module Booksize

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.2 Basic Line Module booksize Table 3- 16 Meaning of the LEDs on the Basic Line Module State Description, cause Remedy Ready DC link Electronic power supply is missing or outside – permissible tolerance range. Green The component is ready for operation and cyclic DRIVE- –... -

Page 198: Smart Line Modules Booksize 5 Kw And 10 Kw

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.3 Smart Line Modules booksize 5 kW and 10 kW Table 3- 17 Meaning of the LEDs at the Smart Line Modules 5 kW and 10 kW Color State Description, cause Remedy READY – Electronic power supply is missing or outside –... -

Page 199: Smart Line Modules Booksize 16 Kw To 55 Kw

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.4 Smart Line Modules booksize 16 kW to 55 kW Table 3- 18 Meaning of the LEDs at the Smart Line Modules ≥ 16 kW State Description, cause Remedy Ready DC link Electronic power supply is missing or outside –... -

Page 200: Single Motor Module / Double Motor Module / Power Module

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.5 Single Motor Module / Double Motor Module / Power Module Table 3- 19 Meaning of the LEDs on the Motor Module State Description, cause Remedy Ready DC link Electronic power supply is missing or outside –... -

Page 201: Braking Modules Booksize Format

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.6 Braking Modules booksize format Table 3- 20 Meaning of the LEDs on the Braking Module booksize Color State Description, cause Remedy READY Electronic power supply is missing or outside permissible – tolerance range. Component deactivated via terminal. Green Continuous Component is ready to operate. -

Page 202: Smart Line Module Booksize Compact Format

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.7 Smart Line Module booksize compact format Table 3- 21 Meaning of the LEDs on the Smart Line Module booksize compact State Description, cause Remedy DC LINK Electronic power supply is missing or outside – permissible tolerance range. -

Page 203: Motor Module Booksize Compact Format

Diagnostics 3.1 Diagnostics via LEDs 3.1.2.8 Motor Module booksize compact format Table 3- 22 Meaning of the LEDs on the Motor Module booksize compact State Description, cause Remedy DC LINK Electronic power supply is missing or outside – permissible tolerance range. Green The component is ready for operation and cyclic DRIVE- –... -

Page 204: Control Interface Module In The Active Line Module Chassis Format

There is a fault. If the LED continues to flash after you have performed a light POWER ON, please contact your Siemens service center. WARNING Hazardous DC link voltages may be present at any time regardless of the state of the "DC link"... -

Page 205: Control Interface Module In The Basic Line Module Chassis Format

There is a fault. If the LED continues to flash after you have performed a light POWER ON, please contact your Siemens service center. WARNING Hazardous DC link voltages may be present at any time regardless of the state of the "DC link"... -

Page 206: Control Interface Module In The Smart Line Module Chassis Format

There is a fault. If the LED continues to flash after you have performed a light POWER ON, please contact your Siemens service center. WARNING Hazardous DC link voltages may be present at any time regardless of the state of the "DC LINK"... -

Page 207: Control Interface Module In The Motor Module Chassis Format

There is a fault. If the LED continues to flash after you have performed a light POWER ON, please contact your Siemens service center. WARNING Hazardous DC link voltages may be present at any time regardless of the state of the "DC link"... -

Page 208: Control Interface Module In The Power Module Chassis Format

There is a fault. If the LED continues to flash after you have performed a light POWER ON, please contact your Siemens service center. WARNING Hazardous DC link voltages may be present at any time regardless of the state of the "DC LINK"... -

Page 209: Additional Modules

Diagnostics 3.1 Diagnostics via LEDs 3.1.3 Additional modules 3.1.3.1 Control Supply Module Table 3- 33 Control Supply Module – description of the LEDs Color Status Description, cause Remedy READY Electronics power supply is missing or outside permissible – tolerance range. Green Continuous Component is ready to operate. -

Page 210: Meaning Of Leds On The Sensor Module Cabinet-Mounted Smc30

Diagnostics 3.1 Diagnostics via LEDs 3.1.3.3 Meaning of LEDs on the Sensor Module Cabinet-Mounted SMC30 Table 3- 35 Meaning of LEDs on the Sensor Module Cabinet SMC30 Color Status Description, cause Remedy Electronics power supply is missing or outside permissible –... -

Page 211: Communication Board Cbc10 For Canopen

Diagnostics 3.1 Diagnostics via LEDs 3.1.3.4 Communication Board CBC10 for CANopen Table 3- 36 Meaning of the LEDs on the Communication Board CAN CBC10 Color Status Description, cause Remedy OPT on the – Electronics power supply is missing or outside permissible –... -

Page 212: Communication Board Ethernet Cbe20

Diagnostics 3.1 Diagnostics via LEDs 3.1.3.5 Communication Board Ethernet CBE20 Meaning of the LEDs on the CBE20 Communication Board Ethernet Table 3- 37 Meaning of the LEDs at ports 1 to 4 of the X1400 interface Color Status Description Link port Electronics power supply is missing or outside permissible tolerance range (link missing or defective). - Page 213 Diagnostics 3.1 Diagnostics via LEDs Table 3- 39 Meaning of the OPT LED on the Control Unit Color Status Description, cause Remedy – Electronics power supply is missing or outside permissible – tolerance range. Communication Board either defective or not inserted. Green Continuous Communication Board is ready and cyclic communication...

-

Page 214: Voltage Sensing Module Vsm10

Diagnostics 3.1 Diagnostics via LEDs 3.1.3.6 Voltage Sensing Module VSM10 Table 3- 40 Meanings of the LEDs on the Voltage Sensing Module VSM10 Color Status Description, cause Remedy READY Electronics power supply is missing or outside the – permissible tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE-... -

Page 215: Terminal Module

Diagnostics 3.1 Diagnostics via LEDs 3.1.4 Terminal Module 3.1.4.1 Terminal Module TM15 Table 3- 42 Meanings of the LEDs on the Terminal Module TM15 Color Status Description, cause Remedy READY Electronics power supply is missing or outside permissible – tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE-... -

Page 216: Terminal Module Tm31

Diagnostics 3.1 Diagnostics via LEDs 3.1.4.2 Terminal Module TM31 Table 3- 43 Meanings of the LEDs on the Terminal Module TM31 Color Status Description, cause Remedy READY Electronics power supply is missing or outside the – permissible tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE- –... -

Page 217: Terminal Module Tm150

Diagnostics 3.1 Diagnostics via LEDs 3.1.4.4 Terminal Module TM150 Table 3- 45 Meaning of the LEDs at the Terminal Module TM150 Color State Description, cause Remedy Electronic power supply is missing or outside permissible Check power supply tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE-CLiQ light... -

Page 218: Terminal Module Tm41

Diagnostics 3.1 Diagnostics via LEDs 3.1.4.5 Terminal Module TM41 Table 3- 46 Meaning of the LEDs on the Terminal Module TM41 Color Status Description, cause Remedy READY Electronics power supply is missing or outside the – permissible tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE- –... -

Page 219: Terminal Module Tm54F

Diagnostics 3.1 Diagnostics via LEDs 3.1.4.6 Terminal Module TM54F Table 3- 47 Meaning of the LEDs on the Terminal Module TM54F Color Status Description, cause Remedy READY Electronics power supply is missing or outside the – permissible tolerance range. Green Continuous The component is ready for operation and cyclic DRIVE- –... -

Page 220: Diagnostics Via Starter

Diagnostics 3.2 Diagnostics via STARTER Color Status Description, cause Remedy Inputs x+1 (DI 1+, 3+, .. 19+) can be set individually via parameter p10040 (TM54F). p10040 (TM54F) = 0: Input x+1 is an NC contact. p10040 (TM54F) = 1: Input x+1 is NO contact. Factory setting: p10040 (TM54F) = 0 for all inputs x+1. -

Page 221: Function Generator

Diagnostics 3.2 Diagnostics via STARTER 3.2.1 Function generator Description The function generator is part of the STARTER commissioning tool. The ramp-function generator can be used, for example, for the following tasks: ● To measure and optimize control loops. ● To compare the dynamic response of coupled drives. ●... - Page 222 Diagnostics 3.2 Diagnostics via STARTER Injection points of the ramp-function generator Figure 3-1 Injection points of the ramp-function generator Further signal shapes Additional signal waveforms can be generated. Example: The "triangular" signal form can be parameterized with "upper limitation" to produce a triangle with no peak.

- Page 223 Diagnostics 3.2 Diagnostics via STARTER Parameterizing and operating the ramp-function generator You operate and parameterize the function generator using the STARTER commissioning tool. Figure 3-3 Function generator Note Please refer to the online help for more information about parameterizing and operation. Starting/stopping the ramp-function generator CAUTION With the corresponding ramp-function generator parameter settings (e.g.

- Page 224 Diagnostics 3.2 Diagnostics via STARTER Start function generator: 1. Load the function generator. – Click on the symbol – In the project navigator, double-click on "Drives" > "Drive_xy" > "Commissioning" > "Function generator". 2. Select "Function generator as a commissioning tool". 3.

-

Page 225: Trace Function