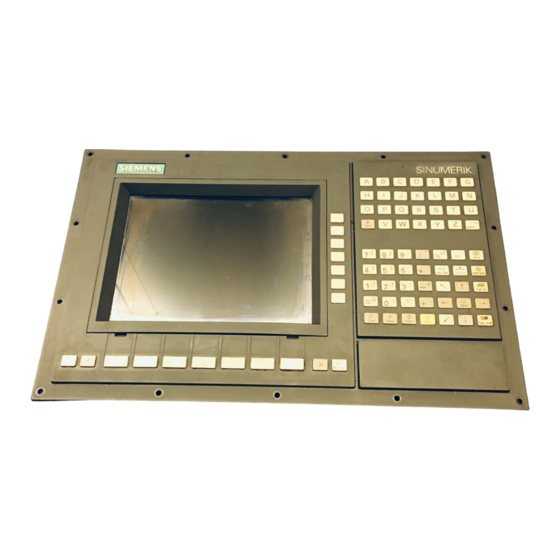

Siemens Sinumerik 840C Diagnostics Manual

Digital ana module

Hide thumbs

Also See for Sinumerik 840C:

- Installation instructions manual (1154 pages) ,

- Operator's manual (301 pages) ,

- Installation manual (189 pages)

Summary of Contents for Siemens Sinumerik 840C

- Page 1 SINUMERIK 840C SIMODRIVE 611-D Diagnostics Guide 09.2001 Edition User Documentation...

- Page 3 Alarms Diagnostics on the PLC SINUMERIK 840C SIMODRIVE 611–D Error Display on CPU Diagnostics Guide Errors with Function Macros Parameterization Errors Spindle/Axis Valid for Control Drive SINUMERIK 840C/CE SIMODRIVE 611–D (Standard/Export version) Software Version Software Version 09.2001 Edition...

- Page 4 , SINUMERIK and SIMODRIVE are trademarks of Siemens AG. All other product and system names are registered trademarks of their respective companies and must be treated accordingly. Other functions not decribed in this documentation might be executable in the control. This does not, however, represent an...

- Page 5 Notice This warning notice means that an undesired event or an undesired state can result if the appropriate notices are not observed. Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 6 12/93 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 7: Table Of Contents

Contents Alarms ..............1–1 Alarm groups . - Page 9 MMC alarms do not interrupt an active NC program. The alarms are acknowledged automatically provided the correct sequence of operations is adhered to or via softkeys. 1–1 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 10: Table Of Contents

20000 to 20309 Spindle-specific alarms 100000 to 169999 MMC alarms 200000 to 209999 PLC dialogs 210000 to 219999 Free area 300000 to 399999 611D alarms 1–2 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) -

Page 11: Alarm Numbers/Cancellation Of Alarms

POWER ON means switching off the control and switching it on again. Please note the information provided by the machine tool manufacturer. 1–3 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 12 5 characters for ordinal number max. 100 characters The ordinal number shows the order (for two-line alarm) in which the alarms have occurred. max. 6 characters for alarm number 1–4 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 13: Display Of The Alarms In The Alarm Line

Type C: Machine Parameter Programm. Services Diagnosis 6000 Hydraulic oil min. max. 4 characters for alarm number max. 47 characters for explanatory text (for single-line alarm) 1–5 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 14 There are 3 types of dialog box: Dialog box with The dialog must be acknowledged from a configured application. empty softkey bar Fig. 1.1 Example 1 dialog box 1–6 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 15: Display Of The Alarms As Dialog Box

The dialog box can either be acknowledged with the OK key or it can be OK softkey and with the HIDE softkey without being acknowledged. HIDE softkey Fig. 1.3 Example 3 dialog box 1–7 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) -

Page 16: Alarm Groups

Specifies in which state the alarm occurs. Effect: Specifies the sphere of influence of processing. Explanation: States the reasons for the alarm. Remedy: Instructions for eliminating the alarm state. 1–8 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) -

Page 17: Alarm Description

The power failure protection integrated in the software could not be executed correctly because of a hardware fault. Explanation Data loss in the NCK unit. Obligatory re-installation is activated. Remedy The whole NCK unit must be re-installed. Eliminate hardware fault. 1–9 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 18 In the UMS, an altered system area has been configured that exceeds the memory area. Remedy Configure UMS properly Note Applies as from SW 4 1–10 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 19 (no spaces, no CR, etc.) Remedy Divide the block into two or more blocks. The number of the faulty block is displayed. Note Applies up to SW 2 only 1–11 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 20 Part programs or subroutines are not defined or concluded correctly (check header) Remedy Check the program to be read in. The number of the faulty block is displayed. Note Applies up to SW 2 only 1–12 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 21 “Extended tool parameter for type 50..59” selected: 10 – 32 Remedy Correct machine data Format user memory or, in General Reset mode, format the area for the TO data 1–13 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 22 Interlocking of NC Ready, NC Start, Mode Group Ready, NC Stop Explanation Internal software error or ring programming for GI or gantry axes. Remedy Eliminate ring programming for GI or gantry axes Notify service 1–14 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 23 The machine data MD 60013 (memory for real axes) is not within the permissible range or has been set too small. Remedy Correct axis-specific machine data bits 564*. Correct MD 60013. 1–15 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 24 Check and correct machine data for axis assignment and spindle assignment. Remedy Check and correct machine data for “Axis valid in mode group” Perform POWER ON 1–16 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 25 The leading axis is defined as a coupled axis Remedy Correct machine data using the “Coupled motion” function and perform a warm restart (see Start-up Guide). 1–17 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 26 The programmed ID number in the UMS header, which is evaluated by the system software, is incorrect or has been read incorrectly because the UMS submodules were plugged in incorrectly. Remedy Check WS 800A software version. Note Applies up to SW 3 only 1–18 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 27 User is advised to replace the backup battery to avoid the risk of data loss – see alarm 1. Remedy Replace battery when control is switched on 1–19 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 28 Alarm 105 is output only if appropriately configured by the machine manufacturer. An error has occured in the safety NCK–FB. For more information and remedy, refer to the manufacturer’s documentation. Applies as from SW 5.4 1–20 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 29 38803 – 38815 (monitoring relation). Remedy Correct machine data and execute POWER ON. Note Applies as from SW 6 1–21 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 30 NC machine data “Zero speed monitoring delay” must be large enough for the following error of the individual axis to be removed within the time entered Check actual values (encoder) and position control direction 1–22 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 31 Example: MD3840 = 01090000; the 1st measuring circuit module is a HMS module with submodule slot 2 empty. Measuring circuit module removed or defective. Remedy Compare and correct MD200x or MD384x with hardware configuration. 1–23 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 32 Remedy Traverse away from the limit switch in the opposite direction in JOG mode. Check the values in machine data for software limit switches. 1–24 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 33 The control enable is removed after the time stored in NC machine data “Control enable cutout delay” has elapsed Follow-up operation Explanation The axis-specific controller enable has been removed by the PLC during a traversing movement. Remedy Check the PLC program 1–25 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 34 The machine limit switch in the minus direction has been approached or has been activated by other errors. Remedy Travel away in the opposite direction in JOG mode Check limit switches Check PLC user program 1–26 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 35 Remedy Define CRC plane and length compensations with G16! Note Applies as from SW 4 Note Alarm is displayed with reference to block and channel 1–27 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 36 The entered acceleration data are too small. Remedy Program a smaller path feedrate Check interpolation combinations in the part program block Note Channel-specific 1–28 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 37 Programming fictitious axes with transformation deselected Selecting transformation although transformation has already been selected Programming traversing movements in the selection block of transformation Remedy Correct program Note Channel-specific 1–29 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 38 The axis/spindle converter function has been programmed which is not included in the function set of the control. Remedy Correct program Check NC–MD Have Service Dept. check function options Note Alarm is displayed with reference to channel 1–30 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 39 The unit and working diameter factor is ZERO Remedy Check program block Check machine data Note Alarm is displayed with reference to block and channel 1–31 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 40 Correct program block whose block number and channel number are specified in the alarm display Cancel alarm using RESET Note Alarm is displayed with reference to block and channel 1–32 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 41 The programmed end point of the block is beyond the working area limitation. Remedy Correct program Note Alarm is displayed with reference to block and channel 1–33 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 42 Value of angle for the contour described is meaningless Remedy Check and correct program settings Cancel alarm using “RESET” Note Alarm is displayed with reference to block and channel 1–34 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 43 G33, G34, G35, G58, G59, G92, @714 and all the functions that trigger an @714. e.g. G74, G200 Remedy Program G40 beforehand Deselection of TRC with G41, G42 D00 Note Alarm is displayed with reference to block and channel 1–35 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 44 Remedy Note the valid range of values for scale factor: (P = 0.00001 to 99.99999) Note Alarm is displayed with reference to block and channel 1–36 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 45 Explanation M function for C axis ON/OFF (MD 260, MD 261) has been given a value reserved by the system. Remedy Enter the correct value 1–37 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 46 A spindle has been programmed in C axis mode or a C axis has been programmed in spindle mode Remedy Change C axis/spindle mode Note Applies up to SW 2 1–38 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 47 If a program with the same program no. as the program to be processed externally is already in the part pro- gram memory. Remedy Rename or delete the program which already exists Note Channel-specific 1–39 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 48 G511/G522 block collide functionally. Remedy Select another target block. Note Channel–specific reset alarm (as from SW 5.4), alarm is displayed with reference to channel 1–40 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 49 3000 N0010 General programming error Alarm number Channel number Block number ”N10” which contains errors Alarm text Note Alarm is displayed with reference to channel 1–41 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 50 If possible the cursor is positioned in front of the faulty word The number of the faulty block is after the alarm number in the alarm line 1–42 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 51 Number of axes selected too high (max. 3 axes permitted per block) No axis name programmed (0) Note Alarm is displayed with reference to block and channel 1–43 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 52 The number of the faulty block is after the alarm number in the alarm line Re G511/G522 – Place the F word immediately after G511/G522 – Delete G511/G522 F... Note Alarm is displayed with reference to block and channel 1–44 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 53 Stock removal path circular R parameter number not available Remedy Check program in which contour is stored. Note Alarm is displayed with reference to block and channel 1–45 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 54 No main block was found in front of the target block during an automatic block search. Remedy Check target block Use another block search Note Channel-specific Applies up to SW 2 only 1–46 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 55 A function not included or not enabled in the control has been programmed or selected. Remedy Have function option retrofitted or set function enable bit. Note Alarm is displayed with reference to channel 1–47 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 56 Block increment for the extended table display is incorrect (must always be 1 for absolute display) Remedy Check the display description with the NC workstation, in particular the information for data group, data type and format. 1–48 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 57 The programmed variable display part of the display description is too large. Remedy Check display with NC workstation, and if necessary regenerate Reduce variable display part 1–49 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 58 User windows can be defined in the UMS. These must lie within the configuring area, otherwise an alarm is given. Remedy Check and correct user window in the UMS. 1–50 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 59 An error has occurred during transmission of fixed texts e.g.: delete window, fixed texts, etc. from NCK to MMC. Remedy Activate notebook for I code and send message to System Support (system program change required) 1–51 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 60 Look at the complete listing of alarm displays and check off alarm numbers without text. With cycle alarms, program an appropriate text. With system alarms, notify your Systems Support. Note Applies to SW 1 only 1–52 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 61 An illegal value has been transferred from the PLC via the command channel. Evaluation is in the error byte in the PLC. Remedy Check PLC user program 1–53 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 62 Program a lower path speed or check override Check NC machine data “Maximum speed” Program a smaller spindle speed with G95 Note Channel-specific Applies up to SW 2 1–54 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 63 G27 programmed with active DRF Setting data 564* not provided with values Effect Interlocking of NC START Remedy Deselect DRF Note Alarm is displayed with reference to channel 1–55 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 64 When G160 and G161 commands are not programmed alone in a block Effect Interlocking of NC START Remedy Alter the part program Note Applies to SW 2 only 1–56 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 65 Scan On selecting via softkey in a configured display Effect None Explanation Configured field shows a non-existent PLC number; SINUMERIK 840C has only 1 PLC. Remedy Check assignments using NC workstation and correct 3159 There is no data block Acknowledgement key...

- Page 66 One or more command parameters violate the permitted lower and upper limit values Remedy Correct the faulty command Note Alarm is displayed with reference to block and channel 1–58 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 67 The plane assignment (cube) and the axis definitions in the channel do not correspond. Remedy Check NC MD 548* 550*552* Note Alarm is displayed with reference to channel 1–59 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 68 Check the incorrect block in the “Correction block” display. The cursor is positioned in front of the incorrect word, if possible. Note Alarm is displayed with reference to block and channel 1–60 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 69 Remedy Perform no programming or check MD parameterization. Note Applies as from SW 4 Note Alarm is displayed with reference to channel 1–61 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 70 ”following error” that has been built up in the meantime is reduced again. The ”reduction” is executed with the modification limit of the IKA. Note Applies as from SW 6, the IKA number will be shown in the block number. 1–62 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 71 Delete alarm 4220 Parallel straight lines This area is reserved for measuring cycle messages. The messages are listed in the publication SINUMERIK 840C MEASURING CYCLES. 1–63 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 72 Alarm causes machining stop Explanation Speed alarm limit has been reached Remedy Check current controller Set speed control loop to a slower rate Increase parameters Check mechanical parts 1–64 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 73: Parameterization Errors Spindle/Axis

1808*, bit 0, the absolute position is requested by the control on POWER ON. If it is not possible to transmit an absolute position from the encoder without any errors, this alarm is released. 1–65 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 74 Explanation A digital setpoint output which does not exist has been assigned Remedy Check the setpoint assignment machine data Note Applies as from SW 3 1–66 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 75 Overlaid offset of following axis although the PLC interface signal “Enable FA overlay” has not been set. Remedy Traverse the following axis with the fictitious leading axis or set PLC interface signal “Enable FA overlay” Note Applies as from SW 3 1–67 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 76 Remedy For example, specified positions through the GI input display. Note Applies as from SW 4.4 1–68 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 77 RECONFIGURATION is only possible after DELETE CONFIGURATION. Program a new configuration block (G401); following axis already exists. Remedy First set LINK OFF for the GI grouping in question. Note Applies as from SW 3 1–69 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 78 JOG mode still possible. Explanation The link factor default setting must not be changed (MD 1844*). Remedy Change default setting if necessary. Note Applies as from SW 3 1–70 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 79 Interlocking of NC START; NC STOP, channel stopped: JOG mode still possible. Explanation The GI positions cannot be overwritten (enable with MD 1844*, bit 3) Remedy Correct input Note Applies as from SW 3 1–71 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 80 NC MD when alarm 87 was triggered. Remedy Check software limit switch machine data and correct if necessary. Note Applies as from SW 3 1–72 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 81 The alarm is triggered if the fixed stop is moved away from by more than the tolerance set in MD 1284*. Remedy Check parameter settings Note Applies as from SW 3 1–73 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 82 A C axis has been programmed in spindle mode. The alarm is only output if MD 5025.5 is set. Remedy Switch C axis to C axis mode. 1–74 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 83 Remedy the error, and press the RESET key. The program is aborted. If safe monitoring was active, STOP B was also initiated automatically. In this case, it is necessary to switch the control off and on (POWER ON). Note Applies as from SW 5.4. 1–75 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 84 MD 4264* and MD 1351 are not identical Enter the same MD values Tolerance time/ SGE switch- MD 4260* and MD 1350 are not identical Enter the same MD values over 1–76 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 85 – SG correction factor 13 MD 1301 bit 5 is not 0 – SG correction factor 14 MD 1301 bit 5 is not 0 – 1–77 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 86 If the value 12 is stored in this value, the cross–comparison has detected a difference in the MD for lower limit SE1 in the NCK and drive monitoring channel. 1–78 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 87 Remedy the causes of ”safe speed exceeded” or ”safe end position exceeded” (see description of the alarms). Continuation Remedy the error and press the RESET key (the program is aborted and must be restarted). Note Applies as from SW 5.4. 1–79 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 88 NC Start Explanation Overlap of two protection zones has been recognized Remedy Travel free and trigger mode group reset Note Applies as from SW 6. 1–80 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 89 An incorrect feedback polarity has been parameterized in the spindle positioning mode (sign error). Remedy Traverse at slower speed Check the actual values (encoder) Check NC MD “Max. speed setpoint (DAC)” Check the drive actuator 1–81 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 90 The measuring circuit short circuit connector can be slotted in to check whether the measuring circuit module is functioning correctly. Check the difference signals with the oscilloscope Replace the encoder/cable 1–82 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 91 NC has risen to above approx. 500 mV. Remedy Check whether the drift has been compensated for correctly at the driving unit. 1–83 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 92 Interlocking of NC START Alarm causes machining to stop Explanation Speed controller limitation triggered Remedy Check current control. Set speed control loop slower. Check SIMODRIVE Check machine 1–84 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 93 “M19 S...” has been programmed in the part program although this function is not implemented in the control. Explanation Check program Remedy Check NC MD 1–85 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 94 Servo enable removed after time set in NC MD “Switchoff delay servo enable” has passed Follow-up mode Remedy Additional detailed information about the cause is given in the MMC diagnosis display Note Applies as from SW 3 1–86 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 95 Maximum value programmed for the following spindle has been exceeded. Synchronism is at risk. Remedy Reduce the acceleration of the leading spindles Check the acceleration limit value Check the link factors Note Applies as from SW 3 1–87 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 96 The link factor default setting must not be changed (MD 525*, bit 2). Remedy Change default setting if necessary. Note Applies as from SW 3 1–88 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 97 Channel is stopped: JOG mode still possible Explanation The link factor must not be switched over from the default setting (MD525*). Remedy Change default setting if necessary. 1–89 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 98 Stop channel: JOG mode is still possible Explanation A GI grouping with the stated axis as a leading axis does not exist Remedy Correct input. Note Applies as from SW 3 1–90 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 99 If an input/output value is specified with G410/G411/G412 that does not correspond to the configuration or is not permissible, this alarm is triggered. Remedy Specify input/output correctly or omit I/O designation with G410. 1–91 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 100 Alarm description see 1364* 2094* Tolerance for safe standstill exceeded POWER ON Note Alarm description see 1324* 2095* Safe speed exceeded Reset key Note Alarm description see 1328* 1–92 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 101 Area ... could not be terminated OK softkey Scan – Effect The application has not been terminated Explanation Application is still active Remedy Terminate application 1–93 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 102 This message is output if the workpiece to be loaded is not found (e.g. workpiece has been deleted on the MMC disk or incorrect network connection). Remedy Copy workpiece back to the MMC disk or establish network connection. Note Alarm from SW 6.4 1–94 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 103 Check parameters. Permitted parameters are workpiece, program, transmission direction (IN, OUT). Combining the parameters ”IN” and device type ”Printer” is not allowed. Note Alarm from SW 6.3 1–95 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 104 An unknown object type was discovered Remedy Correct the data type (correct syntax must be observed, e.g. MPF, SPF, TEA1 ...) Note Alarm from SW 6.3 1–96 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 105 PLC system being loaded Scan When PLC system is being loaded Effect None Explanation Message appears in the red bar when the system is being loaded Remedy – 1–97 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 106 NCK is not powering-up: MMC powers up without NCK Explanation Software error in transport protocol Faulty loaded file Remedy POWER ON Replace hardware, reinstall software 1–98 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 107 UMS is not loaded. Explanation The UMS (of customer or Siemens) cannot be loaded with the current memory configuration because it is larger than the setting in NC MD 60000 (from SW 4; fixed setting 512 KB until SW 3) Remedy Change memory configuration (from SW 4);...

- Page 108 By operator action the ASCII editor is requested to paste from the clipboard into the file processed. The clipboard, however, is empty, not available or faulty. Possibly an operating error Remedy Other operator action Fill clipboard 1–100 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 109 When saving file Effect File is not saved Explanation File is still open somewhere else (e.g. execution from harddisk) Remedy Wait until execution has ended 1–101 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 110 NCK RESET must be initiated at a suitable time. An NCK system error has occurred. For more detailed diagnosis refer to messages 105003 or 105020. Remedy Initiate NCK RESET 1–102 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 111 UMS does not load Explanation The UMS (customer or Siemens UMS) cannot be loaded with the current memory configuration because it is set greater than in NC–MD 60000 (as from SW 4; up to SW 3, 512 kB fixed). Remedy Change the memory configuration (as from SW 4);...

- Page 112 Power up Effect The MMC system boots up without NCK Explanation The Siemens configuration file NCMEMCFG.020 does not exist. When transferring the standard configuration, an error occurred or the NCK signals an error in memory configuration. Remedy New system software...

- Page 113 Error during conversion of ASCII files. A message has a reference to a message line description greater than or equal to the number of message line descriptions. Remedy Eliminate error in the alarm configuration Note SW 5 and higher 1–105 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 114 Binary files have been read from the Siemens branch. Explanation Error during conversion of ASCII files. The converter could not interpret the message attribute/message text files. The binary files from the Siemens branch have been read in. Remedy Eliminate error in the alarm configuration.

- Page 115 Explanation The existing log (alarm log = 1, service log = 2) could no longer be accessed. Remedy – Note Applies as from SW 4 1–107 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 116 A data block read in from harddisk (so-called punched tape format) contains an error. Remedy Correct the error as far as possible and repeat the process. Note Applies as from SW 4 1–108 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 117 Name ... already exists OK softkey Scan COPY / PASTE Effect – Explanation The entered name already exists for the data type Remedy Enter a different name 1–109 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 118 OK softkey Scan – Effect The interface is not parameterized and can therefore not be used. Explanation See above Remedy Select or create valid interface 1–110 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 119 (INSERT NEXT DISKETTE) OK DATA IN-OUT / FORMAT / OK Effect – Explanation There is no diskette in the floppy disk drive Remedy Insert diskette 1–111 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 120 DATA IN-OUT / DATA OUTPUT / ARCHIVE LIST Effect No data are being read out Explanation No object in the archive list can be accessed Remedy Check archive list 1–112 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 121 DATA IN-OUT / DEVICES / SELECTION Effect Interface selection still being executed Explanation Interface selection not possible during output (e.g. printing) Remedy Delete print jobs or wait 1–113 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 122 DATA IN-OUT / DATA OUTPUT / WORKPIECES / START Effect Data are not archived/loaded into the NC Explanation Syntax error in job list Remedy Correct 1–114 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 123 Check other station and cable, reselect interface 110046 System error ... OK softkey Scan None Effect The last action has not been executed correctly Explanation None Remedy Inform system service 1–115 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 124 DATA IN-OUT / ... / ... / START Effect Data are not read-in/written or only partially Explanation E.g. end of data without M02 or end identifier Remedy Check other station and cable 1–116 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 125 The file could not be entered in the current directory (not possible, no authorization, file opened from PC editor) Remedy Paste from clipboard into the desired archive location 1–117 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 126 Remedy Wait until the save operation has been concluded in the ASCII editor. Note Applies as from SW 4.4 110066 Data in Siemens branch cannot be stored OK softkey Scan Data management / new Data management / insert from archive...

- Page 127 No read only / write rights for the set user class, e.g. because PLC is in stop or keyswitch not processed in PLC Remedy Turn keyswitch to position < 3 or set password 1–119 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 128 OK softkey Scan SAVE NC / NC SOURCE / START Effect SPF0 is not saved Explanation The name SPF0 is not permissible Remedy Deselect from SPF1 1–120 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 129 SAVE NC /. .. / START Effect No data transmission The channel number must be 0 4 ( 6 as from SW 4) Explanation Remedy – 1–121 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 130 Alarm from SW 6.3 110124 Conversion warning in workpiece <%1> Same as 110123 except a program error is evaluated as a warning. Note Alarm from SW 6.3 1–122 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 131 The value indicates a data transfer error if the cause cannot be output as a plaintext message. Remedy Check settings on NC and check input fields and restart transmission. 1–123 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 132 Check path setting of data selector in SIIEMENS branch; the path must also exist in the user branch. 120008 No data storage possible here OK softkey Scan No NC/PPLC data can be stored in the SIEMENS area. Effect None Explanation Only data transfer from the NCK in the user areas of the MMC is possible.

- Page 133 No write access at this point OK softkey Scan You have tried to store a file in the SIEMENS branch, or to store NC data in the user branch when keyswitch not in position 1 or 2. Effect Data cannot be stored.

- Page 134 Effect File has not been transferred or only partially. Explanation The NC part program is full. Remedy If necessary, delete part programs from the memory. 1–126 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 135 Option not available OK softkey Scan When activating the PG function Effect S5 package for programming functions cannot be called up. Explanation None Remedy Activate option 1–127 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 136 Explanation Cursor is positioned on “..” or “–”, the file that can be processed has not been selected Remedy Select a file with the cursor 1–128 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 137 Workpiece cannot be processed Explanation Cursor positioned on “..”, a workpiece has been selected which cannot be processed Remedy Position the cursor on a workpiece name 1–129 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 138 Workpiece cannot be processed Explanation Incorrect keyswitch setting No authorization for processing workpiece Remedy Turn keyswitch to setting 1 or 2; enter password in DIAGNOSIS 1–130 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 139 Press ABORT softkey if further changes are to be made in the edit mode. Press OK softkey if the changes are to be lost. Note Applies as from SW 4.4 1–131 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 140 ”No workholder available !” 142004 ”Error on loading machine data !” 142005 ”Error on loading R parameters” 142006 ”Error on loading the ZOA data !” 1–132 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 141 ”Radius too small for programmed circle” 144100 ”Wrong input for contour definition !” 144101 ”No intersection possible !” 144102 ”Angle value not allowed !” 144103 ”Radius value not allowed !” 1–133 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 142 144350 ”Axis %1 not possible. Only 3 axes at present” 144351 ”Axis %2 not permitted in channel %1!” 144352 ”Axis %2 disabled in channel %3!” 1–134 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 143 ”Too many SPFs: SPF%1 not opened” 146006 ”M17 not allowed in MPF” 146007 ”M02/M30 not allowed in SPF” 146010 ”Comments/program coordination nested” 146011 ”End of line in comments/program coordination” 1–135 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 144 ”M function of Group %1 already programmed” 146068 ”Meaning of P word not defined” 146069 ”The block no. is not at the beginning of line” 1–136 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 145 146135 ”Value must be an integer here” 146136 ”Value overflow” 146137 ”Value must be a bit pattern here” 146138 ”Not enough parameters for @ function” 1–137 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 146 ”@ position in block invalid” 146200 ”The axis is disabled according to axis MD” 146201 ”G16 block allows only signs in axis word” 146202 ”Axis already programmed in block” 1–138 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 147 ”Rapid traverse block was generated” 146254 ”G15 is not simulated” Simulation must be cancelled and a corrected set of machine data activated with the load list by reselec- ting. 1–139 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 148 ”Context: approach reference point” 146303 ”Context: pole specification” 146304 ”Context: spline interpolation is selected” 146305 ”Context: block preprocessing stop by @714” 146307 ”Context: G200 block” 1–140 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 149 ”G%1: 1 axis or 2 axes are expected” 146416 ”G%1: thread lead must be positive” 146417 ”G%1: no axis programmed” 146418 ”G%1: thread lead change F is missing” 1–141 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 150 ”G%1: plane axes are identical” 146472 ”G16: max. 4 axes can be simulated” 146480 ”Axis prog. –> C axis on/off ignored” 146481 ”M19 S: other M functions ignored” 1–142 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 151 146555 ”G92 P: axis is not a rotary axis” 146556 ”G%1: axes for working area limit. are missing” 146557 ”G%1: axis or angle is missing” 1–143 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 152 ”Block with G92 S: too much info in block” 146707 ”Block with M19 S: too much info in block” 146708 ”Block with @710: too much info. in block” 1–144 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 153 Drive module is not configured or incorrectly OK softkey Scan Startup application Effect Startup function is not executed Explanation Selected drive number is not available Remedy Select available drive module 1–145 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 154 When function generator is started Effect Function generator is not started Explanation Only function generator at a time can be active Remedy Stop active function generator and repeat procedure 1–146 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 155 Scan Parameterization/starting startup functions Effect The startup function cannot be started Explanation See machine data description Remedy Check/correct machine data for speed controller scan time 1–147 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 156 OK softkey Scan When starting DAC output Effect DAC output cannot be started Explanation Offset value is outside the permissible range Remedy Correct offset value 1–148 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 157 Selecting menu for DAC output Effect Startup menu for DAC is disabled Explanation Menu for DAC output needs at least one 611D module Remedy – 1–149 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 158 Recorded measured values cannot be used Remedy Check measuring parameters and repeat procedure. A higher amplitude must be selected most especially for path frequency response measurement 1–150 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 159 End application and restart 160050 Data not available OK softkey Scan Startup application Effect Function aborted Explanation Error on internal data access Remedy End application and restart 1–151 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 160 160058 Job could not be processed OK softkey Scan Startup application Effect Function aborted Explanation Error on internal consistency check Remedy End application and restart 1–152 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 161 OK softkey Scan Startup application Effect Startup function is not executed Explanation Application has no access rights for required data Remedy Enter password/alter keyswitch position 1–153 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 162 Illegal limitation OK softkey Scan Function generator/measuring function parameterization Effect The function cannot be started Explanation – Remedy Enter a lower value not equal to zero 1–154 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 163 Illegal traversing range limits OK softkey Scan Function generator/measuring function parameterization Effect The function cannot be started Explanation – Remedy Enter lower value; “0” means no monitoring 1–155 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 164 Enter a smaller value in the function parameter max. acceleration. Enter a value between 0 and 1% (resolution 0.001%). Enter a valid value in the fine quantization. Enter a valid value. 1–156 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 165 Startup application file services (read only) Effect The read data set is not complete Explanation Contents of file were not transferred completely Remedy Repeat procedure 1–157 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 166 Repeat procedure 160100 File ... not saved OK softkey Scan Startup application file services (write) Effect Data set is not stored Explanation – Remedy Repeat procedure 1–158 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 167 Start-up application at start of circle form test Effect The function cannot be started Explanation Two real axes must be configured Remedy Configure axes Note Applies as from SW 4 1–159 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 168 Start-up application at start of SERVO TRACE function Effect SERVO trace is not started Explanation Segment address is illegal Remedy Specify legal segment address Note Applies as from SW 4 1–160 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 169 Start-up application when converting the TRACE buffer Effect Signal values in the Trace buffer could not be converted Explanation – Remedy – Note Applies as from SW 4 1–161 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 170 Measurement function is not started. Explanation Trace buffer is already assigned by Servo Trace Remedy Stop Servo Trace and restart measurement function Note Applies as from SW 4 1–162 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 171 “No PLC enable” “SERVO mode change” “MF on SERVO aborted” “Reset” Axis/spindle not in stop state” Spindle ramp-up encoder stop from PLC” Remedy End application and restart 1–163 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 172 OK softkey Scan Startup application Effect Current measurement aborted Explanation Current measurement aborted because of system error Remedy Start up control/drive again and repeat procedure 1–164 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 173 161008 Measurement position control loop in progress Scan Startup application position controller measuring function Effect – Explanation Position controller measuring function operational message Remedy – 1–165 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 174 Start-up application after recording has started within the control for all active Trace buffers Effect – Explanation The selected Trace signals are recorded Remedy – Note Applies as from SW 4 1–166 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 175 Saving, loading MD files Effect Function is not executed Explanation The link PC to NC is busy. Remedy Wait, startup end, NCK reset or Power On 1–167 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 176 Drive MD/FDD/motor selection Effect No default possible for motor Explanation There is no system file Remedy Please notify Siemens Service Note Applies as from SW 4 1–168 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 177 File cannot be edited OK softkey Scan Selecting Edit or Edit new Effect Function is not executed Explanation BOOT files cannot be edited. Remedy – 1–169 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 178 Edit new, saving, inserting MD files Effect Function is not executed Explanation This name cannot be used for user files Remedy Enter a different name 1–170 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 179 The alarm can also occur when drive MD are being transmitted if a boot file already exists. Remedy Repeat operation, press softkey ”General reset” in the initial clear mode and reload the drive data. Note Applies as from SW 5.4. 1–171 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 180 Effect Function is not performed Explanation Standard or on-line configuration selected accidentally. Remedy Select user setting under “File functions” Note Applies as from SW 4 1–172 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 181 The data block just edited cannot be modified even if password is set (e.g. standard data block) Remedy Select another data block Note Applies as from SW 4 1–173 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 182 The NQFK data for the stated axis have not been saved. Explanation The stated axis may have been incorrectly parameterized. Remedy Check parameterization and repeat procedure. Note Alarm in SW 5 and higher 1–174 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 183 The function has possibly been performed incompletely, data may be inconsistent. Explanation – Remedy If necessary, first start up the drive. Note Applies as from SW 5.4 1–175 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 184 The pole pair no. (ratio rated frequency (MD 1134 and MD 2134) /rated speed (MD 1400 and MD 2400)) is illegal. Remedy Correct value, repeat function. Note Applies as from SW 5.4 1–176 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 185 The value 0 has been entered for the rated frequency (MD 1134 and MD 2134). Remedy If necessary, correct value and repeat function. Note Applies as from SW 5.4 1–177 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 186 The ratio maximum current (MD 1104) no-load current (MD 1118) exceeds 900. Remedy If necessary, correct value and repeat function. Note Applies as from SW 5.4 1–178 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 187 Management overflow on transmitting of Contact service acknowledgements 0x0406 – Management overflow on receiving orders Contact service 0x0407 – Management overflow on receiving Contact service acknowledgements 1–179 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 188 SW ver- sions below SW 5 0x0607 Invalid DCM interrupt (no timeout, no CRC) Replace NC hardware 0x0608 Reserved 0x0610 Reserved 1–180 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 189 Invalid status Replace hardware: lese_alarm_status() control module 611D, NC module 0x0632 Invalid status Replace hardware: with drive alarm processing control module 611D, (al_status) NC module 1–181 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 190 Unknown order Contact service (internal communication servo, drive) 0x0706 Function no. Unknown acknowledgement Contact service (internal communication servo, drive) Note Applies as from SW 3. 1–182 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 191 In addition, both error registers from the DCM are displayed for further information on the alarm. If the information from the error registers is not sufficient to determine a drive number, the alarm is output for the first drive available. 1–183 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 192 If the alarm is triggered while the boot file is being transferred to the drive, the only means of acknowledgement is NCK POWER ON. Note Applies as from SW 6 1–184 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 193 NC and this information is pas- sed on to the drive, faults in com- munication by the drive bus could be the cause. 1–185 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 194 SERVO on STF handshake 0x61; error dur- ing RAM check 0x62; transport checksum does not correspond to that of SERVO 1–186 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 195 The endless loop for processing Replace servo control module. FDD / MSD communication has been exited. Presumably caused by a hardware fault on the servo control module. 1–187 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 196 / xx An illegal interrupt of the processor Check drive bus cable and connec- FDD / MSD has occurred. tor. Replace servo control module. 1–188 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 197 F041 xx / xx An illegal number of speed setpoint Correct number of speed setpoint FDD / MSD filters (>2) has been entered. filters MD1500. 1–189 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 198 Defective actual current value circuit Remedy Check maximum power section current MD1107; replace 611D hardware if necessary Note Applies up to SW 4 (611–D: up to SW 2.6) 1–190 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 199 Motor encoder cable faulty Module faulty Consider MD1023 (IMS) and MD1033 (DMS) Remedy Eliminate cause; replace motor/611D hardware if necessary Note Applies as from SW 3 1–191 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 200 Reference with BERO deselect. Check encoder cable, encoder cable connection or grounding, because EMC problems might have occurred. Replace motor/611D if necessary. Note Applies as from SW 4 As from SW 5, alarm cannot be configured 1–192 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 201 SIMODRIVE_READY and DRIVE_READY are cancelled. Power On error Explanation Speed too high at center frequency measurement Remedy Reduce speed Note Applies as from SW 4 1–193 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 202 Motor either not connected or phase missing Remedy Check motor – converter connecting cable. Note Alarm in SW 5 and higher (611–D: SW 3.1 and higher) 1–194 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 203 Motor encoder cable defective or not fastened properly Motor encoder cable screen not connected Drive module defective Remedy Eliminate cause Note Applies as from SW 4 1–195 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 204 Fault between turns motor Remedy Eliminate cause or operate at MSD fixed temperature Note: Temperature monitoring not active with fixed temperature Note Applies as from SW 4 1–196 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 205 Drive only ramps up to ramp-up state 2 Explanation Speed controller clock pulse MD 1001 is invalid. Remedy Change speed controller clock pulse Note Applies as from SW 3 1–197 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 206 On 2-axis modules, the position controller clock pulse must be identical for both axes. Remedy Set the position controller clock pulse to be identical for both axes. Note Applies as from SW 3 1–198 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 207 The maximum current of the power section MD 1107 has a value that is less than or equal to 0. Remedy Enter a valid value in machine data MD 1107 “Maximum current of power section”. Note Applies as from SW 3 1–199 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 208 Maximum motor speed MD 1401 of speed controller clock pulse MD 1001 have too great a value. Remedy Reduce maximum motor speed MD 1401 or set a smaller speed controller clock pulse MD 1001. Note Applies for SW 3 only 1–200 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 209 The voltage constant MD 1114 has a value less than or equal to zero. Remedy Eliminate error on inputting the voltage constant MD 1114. Note Applies as from SW 4 1–201 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 210 Rated motor speed MD 1140 is less than or equal to zero. Remedy Eliminate error on inputting the rated motor speed MD 1140. Note Applies as from SW 4 1–202 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 211 Division error has occurred because of illegal parameter combination Additional information: none Remedy Check parameters and correct Save BOOT Repeat ramp-up Note Applies as from SW 3 1–203 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 212 Error occurred when last saved; data from last save operation are used. Additional information: none Remedy Check parameters and save BOOT again Note Applies for SW 3 only 1–204 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 213 Set the monitoring cycle in MD 1300 to n * NC position control cycle, where n must be 1. Note Applies as from SW 5.4. 1–205 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 214 MD 1322 (for the use of a gearbox) The motor type and axis type are defined in MD 1302. Note Applies as from SW 5.4 1–206 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 215 The blocking frequency MD 1210, MD 1213, MD 1216, MD 1219 for each current filter must be greater than the reciprocal value of two current controller clock pulses MD 1000. Note Applies as from SW 3 1–207 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 216 MD 1012.4 = 0: 300755 MD 1012.4 = 1: 300855 Explanation V/f operation: at initialization, the motor turns. Remedy Stop the motor. Note Applies as from SW 4 1–208 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 217 MD1631 + MD1632 exceeds that in MD1633. Remedy Eliminate error on inputting MD 1631, MD 1632 and MD 1633. Note Applies as from SW 4 1–209 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 218 Minimum speed generator axis MD 1635 is greater than or equal to the maximum speed MD 1146. Remedy Eliminate error on inputting MD 1635 or MD 1146. Note Applies as from SW 4 1–210 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 219 Enter the value zero into machine data MD 1161 or order new hardware version (hardware components: drive control with Order No. 6SN1 118–0Dx1x–0AA0). Note Applies as from SW 4 1–211 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 220 Current setpoint filter 1: MD 1214 < 1 / (2MD 100031.25 microsec) Current setpoint filter 2: MD 1217 < 1 / (2MD 100031.25 microsec) Note Alarm in SW 5 and higher 1–212 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 221 Speed setpoint filter 1: MD 1516 x 2MD 1514 Speed setpoint filter 2: MD 1519 x 2MD 1517 Note Alarm in SW 5 and higher 1–213 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 222 The calculated filter coefficients for a band-stop filter cannot be represented in the internal format. Remedy Alter filter setting Note Alarm in SW 5 and higher 1–214 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 223 A current higher than that permissible for the motor and for the power section used has been parameterized in MD 1019. Remedy Reduce current via MD 1019. Note Applies as from SW 6 1–215 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 224 The stator reactance MD 1139 or rotor reactance MD 1140 or main field reactance MD 1141 is smaller than or equal to zero. Remedy Correct error when entering MD 1139, MD 1140 or MD 1141. Note Applies as from SW 6 1–216 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 225 Field weakening speed MD 1142 is smaller than or equal to zero. Remedy Correct the error when entering the field weakening speed MD 1142. Note Applies as from SW 6 1–217 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 226 Alarm description see 300759 300860 Excessive emergency retraction speed Note Alarm description see 300760 300861 Minimum generator speed too high Note Alarm description see 300761 1–218 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 227 über die beim Bremsen nachgeführte Geschwindigkeitsgrenze und die in MMMMD_SB_STOP_N_TOL (Toleranz Istgeschwindigkeit für SBR) eingetragene Toleranz angestiegen. Remedy Eingabewert des Maschinendatums MD_SB_STOP_N_TOL überprüfen. Note Applies as from SW 6 1–219 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 228 CPU, such as a corrupt memory cell. This error can be transient (remedied by POWER ON) or per- manent (reoccurs after POWER ON, in this case replace the hardware). Note Applies as from SW 5.4 1–220 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 229 SGE, the alarm is deactivated. Remedy If STOP A was triggered, it is only possible to restart by POWER ON. Note Applies as from SW 5.4 1–221 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 230 Deselect actual value synchronization with drift/slip or safe limit position and/or cam monitoring in MD 1301: ”En- able safety functions”. Note Alarm from SW 6.2 1–222 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 231 Remove “Cycle disable” (editing, copying, etc.) interface signal CYCLE IN THE EPROM Information while handling –– cycles DATA TRANSMISSION Editing part programs Stop interface RUNNING 1–223 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 232: Dialog Text

“Reset” MDA MEMORY In “MDA” mode Max. 500 characters may OVERFLOW be entered NO CORRECTION With “Correction block” Correction block cannot be BLOCK function selected 1–224 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 233 SOURCE PROGRAM Appears when reading out A bit has flipped in the part a part program program just read (parity DEFECTIVE error). 1–225 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 234 2nd NUMBER 2ND DECIMAL POINT Taking over an input value Input value has the wrong (e.g. with the input key) format END OF SECTION 1–226 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 235: Diagnostics On The Plc

Call for an illegal OB (OB No. 0...39) *) Call for a non-existent page (command “ACR”) *) *) Additional information is given on this error in additional fields (see Section 2.2) 2–1 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 236 I/O configuration: Multiple addressing for outputs *) I/O modules changed Unassigned *) Additional information is given on this error in additional fields (see Section 2.2) 2–2 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 237 EUs or DMP modules not switched on or incorrectly jumpered (rotary switch) *) *) Additional information is given on this error in additional fields (see Section 2.2) 1) SW 3 and higher 2–3 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 238 Timeout with LPB/LPW/TPB/TPW commands *) Timeout with a substitution command *) *) Additional information is given on this error in additional fields (see Section 2.2) 2–4 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 239 DB to be opened not available DB to be opened not in line with paragraph *) Additional information is given on this error in additional fields (see Section 2.2) 2–5 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 240: Errors With Function Macros

OUTPUT ISTACK. For more details on errors see FB descriptions. *) Additional information is given on this error in additional fields (see Section 2.2) 2–6 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) -

Page 241: Additional Error Information (Accu 3 Low Byte, Db 1 Dw 161–163)

OB number where STS occurred F0002 –– F0003 –– F0000 Error number processing time delay F0001 OB number where processing time delay occurred F0002 –– F0003 –– 2–7 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 242 F0003 Submodule number (when F0001=01) F0004 Line number (when F0001=01) F0000 Distributed interrupt byte not available F0001 Byte number (BCD format) F0002 –– F0003 –– 2–8 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 243 5B, 5C, 5D, F0002 Offset address (byte-oriented) of fault block (segment and offset point to the 5E, 60, 61, synchronization pattern) 70, 71 F0003 –– 2–9 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 244 000C: ADS error (e.g. no communication with MMC) F0002 When F0001 = 0001: 0001: User program memory empty 0002: Boot not completely finished or data loss 1) SW 3 and higher 2–10 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 245 Type identifier of the timeout **) **) Type identifier of timeout: 0001 = Internal timeout 0002 = Link bus timeout 0003 = Local bus timeout 2–11 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 246 Current OB No. (No. of processing level) F0002 –– F0003 –– **) Type identifier of timeout: 0001 = Internal timeout 0002 = Link bus timeout 0003 = Local bus timeout 2–12 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 247 PLC MD “2nd machine control panel” set – output missing Reserved Reserved PLC MD for error and operational messages (DB58) set Reserved Reserved Reserved Reserved 2–13 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 248 Error on reserving a transmit buffer 0400 Error on transmitting a receive buffer 0500 Reserved 0600 ADS interface between PLC and IF PLC faulty END OF SECTION 2–14 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

-

Page 249: Error Display On Cpu

Meaning Driver not loaded Driver loaded but ADS power-up not yet performed Jump ADS interface power-up ADS interface power-up, MMC waits for ‘0’ from NC 3–1 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA) - Page 250 Wrong file started as last in the loading list (no starting information) Link area between boot EPROM and loaded system was illegally overwritten (presumably software error in the loaded system program). Remedy: Reboot END OF SECTION 3–2 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 251 Target DB No. = 0 Target or source DB not available Target DB too short Target DB in EPROM Source DB too short Incorrect TYQU parameter Incorrect TYZI parameter 4–1 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 252 Source or target DB too short Parameter limit of flag area exceeded PII or PIQ limits exceeded Illegal source or target parameter type (not I, Q, F) 4–2 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 253 Reading of block start address Block type not permitted Address list does not exist Address list insufficient Symmetrical tool search No messages END OF SECTION 4–3 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 254 04/96 4 Errors with Function Macros 4–4 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 255 564* Position control cycle LA/LS is not the same 1396* MD 466* Position control cycle FA/FS Incorrect LA/LS/FA/FS number parameterized 1) SW 3 and higher 5–1 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 256 1) or position control resolution (spindle) = position control resolution (axis) 2) or mode group (spindle) = mode group (axis) 5–2 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 257 4200* 4200* 4244* 4244* 4248* 4248* 4260* 4260* 4180* 4180* Evaluate detailed informa- tion in the SI SERVICE SCREEN (service data 1000). END OF SECTION 5–3 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 258 04/96 5 Parameterization Errors Spindle/Axis 5–4 Siemens AG 2001 All rights reserved 6FC5198–jAB40 SINUMERIK 840C / SIMODRIVE 611–D (DA)

- Page 259 Siemens AG Suggestions A&D MC BMS Corrections P.O. Box 3180 For Publication/Manual D–91050 Erlangen SINUMERIK 840 C Federal Republic of Germany SIMODRIVE 611–D Tel. ++49 – (0) 180 / 5050–222 [Hotline] Fax ++49 –(0) 9131 / 98–2176 email: [email protected] User Documentation...

- Page 260 Overview of SINUMERIK 840C Documentation / OEM Version for Windows User/Manufacturer/ General Documentation User Documentation Service Documentation SINUMERIK SINUMERIK SINUMERIK SINUMERIK SINUMERIK ACR 20/ 840C 840C Accessories 840C 805SM/840C Brochure Catalog NC 36 Catalog NC Z Link to SINEC L2–DP with Module Diagnostics Guide –...