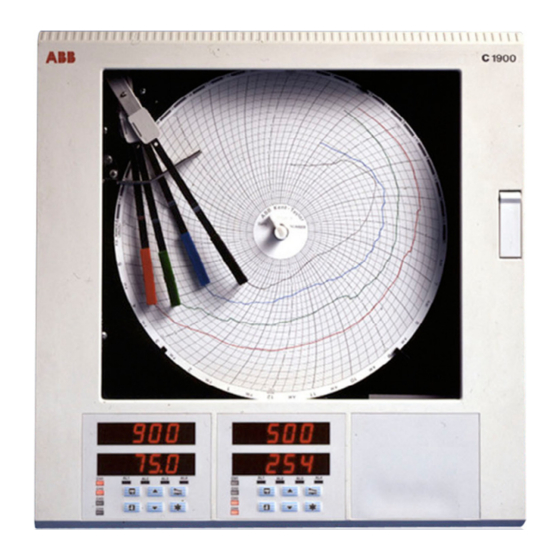

ABB C1900 Series Operating Manual

Circular chart recorder/controller

Hide thumbs

Also See for C1900 Series:

- Installation manual (28 pages) ,

- User manual (20 pages) ,

- Operating manual (20 pages)

Summary of Contents for ABB C1900 Series

- Page 1 Operating Guide IM/C1900-OGC Rev. H C1900 Series Circular Chart Recorder / Controllers...

- Page 2 Cert. No. Q 05907 As a part of ABB, a world leader in process automation technology, we offer customers EN 29001 (ISO 9001) application expertise, service and support worldwide.

-

Page 3: Table Of Contents

CONTENTS 1 INTRODUCTION Section Page The documentation for the C1900 series of circular chart recorders is shown in Fig. 1.1. The , including Standard Manuals the specification sheet, are supplied with all instruments. The INTRODUCTION ............1 supplied depend on the specification of Supplementary Manuals the instrument. -

Page 4: Setting Up

2 SETTING UP 2.1 Instrument Power-up – Fig. 2.1 and 2.2 1914 r Caution. Ensure that all connections, especially to the tESt earth stud, are made correctly. Instrument Test identifies the instrument type, e.g. a) Check that the input sensors are installed correctly. 1914r –... -

Page 5: Power-Up Error Codes

2 SETTING UP… 2.1.1 Power-up Error Codes If any of the power-up tests fail (see Fig. 2.2), error codes are displayed to identify the fault. Refer to Fig. 2.3 for error code interpretations. Configuration and battery-backed RAM errors Action Code Error No error None... -

Page 6: Fitting The Chart

…2 SETTING UP 2.2 Fitting the Chart – Fig. 2.4 2.3 Fitting the Pen Capsule(s) – Fig. 2.5 Raise pens Raise pens Lift the chart clamp and remove the chart Gently pull the arm off the bracket – see Note Fit new chart ensuring Note. -

Page 7: Displays & Controls

3 DISPLAYS & CONTROLS The displays, LED indicators and operation/programming controls are located on the faceplates on the front panel of the instrument – see Fig 3.1. 3.1 Displays and LED Indicators – Fig. 3.1 The displays comprise 2 rows of 6 characters. At the top of each programming page (the page header) both displays are used to describe the particular page selected. - Page 8 …3 DISPLAYS & CONTROLS… Used to program all Channels Instrument Identification Control Blank Blank 100. 3 100. 5 1911 Control Record Blank 100. 3 1912 100. 5 1913 Control Record Record 100. 3 1914 100. 5 Control Control Blank 100. 3 200.

-

Page 9: Use Of Controls

3 DISPLAYS & CONTROLS 3.2 Use of Controls – Fig. 3.3(a) to (g) Page 1 Page 2 Lift/Lower pen on alternate operations Frame 1 Frame 1 Frame 2 Frame 2 Frame 3 Frame 3 Note. If is selected in the 'Auto Pen Drop' Set Up Chart Return from... -

Page 10: General Operation

4 GENERAL OPERATION Note. The pages are displayed only if an alarm is active. Alarm Acknowledge Fig. 4.1 Summary of Operating Levels for Different Faceplate Types... -

Page 11: Input Error Messages

4 GENERAL OPERATION The instrument has dedicated Operating Pages – see Fig. 4.1. These pages are used for general monitoring of the process measurements and are not affected by the security system which inhibits access to the programming and control pages only – see Section 5.5 on page 18. -

Page 12: Control Operation

5 CONTROL OPERATION Note. The pages are displayed only if an alarm is active. Alarm Acknowledge Fig. 5.1 Summary of Operating Level Frames (Standard Control) - Page 13 5 CONTROL OPERATION… Note. The pages are displayed only if an alarm is active. Alarm Acknowledge Fig. 5.2 Summary of Operating Level Frames (Heat/Cool Control)

-

Page 14: Operating

…5 CONTROL OPERATION 5.1 Operating Page Introduction 5.1.4 Cascade Control The master in a cascade set-up is always channel 1 and the 5.1.1 Set Point Tracking slave is always channel 2. If the slave is switched to manual With set point tracking enabled ( control with cascade set point selected, the slave's set point Set Points Page, CONTROL ) the local set point value tracks the... -

Page 15: Operating

5 CONTROL OPERATION… 5.2 Operating Page Displays Process Variable 100. 3 Control Set Point 110. 5 The set point in use is displayed (Local, Remote, Dual or Cascade). If the Local or Dual set point is displayed it can be adjusted using the keys, providing adjustment is enabled in the Set Up Operating Page... - Page 16 …5 CONTROL OPERATION …5.2 Operating Page Displays 100. 3 r50. 0 Process Variable 100. 3 Temperature Units dEG F NONE The units are set in the Display is blank if ' ' is BASIC CONFIGURATION LEVEL. selected. Set Point Type Selection LOCAL rEMOtE displays show the difference between the...

- Page 17 5 CONTROL OPERATION… …5.2 Operating Page Displays Profile Option bIAS 0. 0 Profile Program Selected Profile Status: rAMP StOP rAMP StOP – waiting for run command, profile is inactive rAMP – program is running and ramping SOAK SOAK – program is running and soaking HOLd HOLd –...

-

Page 18: Alarm Acknowledge Page

…5 CONTROL OPERATION 5.3 Alarm Acknowledge Page 5.3.3 Using the Alarm Acknowledge Page No Alarm Active 5.3.1 Alarm Indications – Fig. 5.5 No LED indicators illuminated. The definitions for alarm states (on, off or flashing) are detailed in Fig. 5.5. 5.3.2 Acknowledging Alarms Unacknowledged alarms can be acknowledged from the faceplates on the front of the instrument in two ways:... -

Page 19: Totals Page Displays

5 CONTROL OPERATION… 5.4 Totals Page Displays This page is omitted from both faceplates if the is not fitted. The page is also omitted from faceplate 1 if is set Totalizer Option Total 1 and from faceplate 2 if is set to –... -

Page 20: Access To Configuration Levels

…5 CONTROL OPERATION 5.5 Access to Configuration Levels A security system is used to prevent tampering with the program parameters by utilizing a Tune password and a configuration password. A Tune password can be assigned to controller faceplates giving access to that faceplates controller settings. A Configuration password gives access to all controller settings and programming pages –... -

Page 21: Profile States Page

5 CONTROL OPERATION… 5.6 Profile States Page Page Header – Profile States PrOFLE StAtES key can be programmed to jump to this frame ( Set Up Function Keys Page ). If the key is used, the display reverts ADVANCED CONFIGURATION LEVEL automatically to the first frame of the when leaving this page. -

Page 22: Auto-Tuning Introduction

…5 CONTROL OPERATION 5.7 Auto-tuning Introduction Information. • On demand user-activated tuning. • Two types of auto-tuning – initial 'Start-up' and when close to Set Point. • Tuning for P, PI or PID control can be selected. • Tuning for 1/4 wave damped or minimum overshoot can be selected. •... -

Page 23: Auto-Tuning Page

5 CONTROL OPERATION… 5.7.1 Auto-tuning Page Information on Initial Conditions. • 'Start-up' Tuning – the controller is placed in the Manual control mode with the control output value set to give a stable process variable at least 10% of the engineering range below the control set point. •... - Page 24 …5 CONTROL OPERATION …5.7.1 Auto-tuning Page Hysteresis Value HYSt The hysteresis value is entered in engineering units and is used to determine when to change the controller output value. 10. 0 – when the process variable crosses the hysteresis band 'At Set Point' Tuning only Start-up (plus and minus the hysteresis value), the controller output changes by plus and...

- Page 25 5 CONTROL OPERATION… …5.7.1 Auto-tuning Page Auto-tune Status/Enable At–OFF StArt StArt Select to enable auto-tune cycle. The 'AT' (auto-tune) LED is illuminated. The time taken for completion of auto-tuning is dependent on the speed of response of the controlled process. AUtO Note.

-

Page 26: Auto-Tune Diagnostic Messages

…5 CONTROL OPERATION 5.8 Auto-tune Diagnostic Messages Message Explanation Action Flashing The auto-tune process has selected a Because of the process characteristics, A–tUNE Pb–INt with proportional band or integral action time re-trying the auto-tuning process is CAUtN HI– LMt above the high limits of these parameters unlikely to improve the calculated so the high value has been used. -

Page 27: Introduction To Standard Control

5 CONTROL OPERATION… 5.9 Introduction to Standard Control Engineering Range –500 1000 1500 Point Proportional Band 200% Proportional Band Settings Control Set Point Examples shown with a Proportional Band Offset of 50% Manual Reset Settings Information. Proportional control gives an output that is proportional to the deviation of the process variable Information. - Page 28 …5 CONTROL OPERATION …5.9 Introduction to Standard Control Proportional Band Settings Set Point Integral Step = 100 Proportional Step = 100 Time Approach Band Settings Derivative Action Time Bandwidth = Seconds Approach Band x Proportional Band Example shows an Integral Action Time of 30 seconds Information.

- Page 29 5 CONTROL OPERATION… …5.9 Introduction to Standard Control Example shows a Cycle Time of 20 seconds 50% Offset Mark Mark Space Space Set Point 1000 Cycle Time Cycle Time % Proportional Band 0% Offset % Output = x 100 % Output = x 100 % Output = 50% % Output = 25%...

- Page 30 …5 CONTROL OPERATION …5.9 Introduction to Standard Control Initial Settings • Proportional Band = 100% • Integral Action Time = OFF • Derivative Action Time = OFF • Adjust the set point a small amount • Hold the set point at the new value until Decrease Proportional Band Increase Proportional Band the process begins to move...

- Page 31 5 CONTROL OPERATION… …5.9 Introduction to Standard Control Effect Of Response Settings Response Contributions Too High Too Low Hysteresis too high Process swings Helps to prevent rapid Output switches On/Off Hysteresis too far above and switching of output too rapidly below set point Hysteresis too Low High Prop.

-

Page 32: Control Page (Standard Control)

…5 CONTROL OPERATION 5.9.1 Control Page (Standard Control) Page Header – Control Page CONtrL PAGE Cycle Time (applicable only for control using relay output) CYCt 300. 0 This setting can be ignored for analog control outputs. 1. 0 1. 0 Set the required cycle time for time proportioning control, from 1.0 to 300.0 in 0.1 second increments (300 seconds = 5 minutes) –... -

Page 33: Introduction To Heat/Cool Control

5 CONTROL OPERATION… 5.10 Introduction to Heat/Cool Control Q Heater = 1.5kW Q Cooler = 0.75kW Max. Heat Output = 88%* Max. Cool Output = 75%* Cool Heat Output Output Output Off Hysteresis Band =15%* Crossover Value (33%) *User definable limits PID Output (%) 100% Proportional Band... -

Page 34: Control Page (Heat/Cool Control)

…5 CONTROL OPERATION 5.10.1 Control Page (Heat/Cool Control) Page Header – Control Page CONtrL PAGE Cycle Time (heat output) CYCt h 300. 0 This setting can be ignored for analog control outputs. 1. 0 1. 0 Set the required cycle time for time proportioning control, from 1.0 to 300.0 in 0.1 second increments (300 seconds = 5 minutes). -

Page 35: Calculating The Crossover Value

5 CONTROL OPERATION …5.10.1 Control Page (Heat/Cool Control) Manual Reset (cool output) MrESEt c 100. 0 Set the required proportional band offset, between 0.0 and 100.0% of the 50. 0 0. 0 engineering range span in 0.1% increments. Integral 999. 0 Derivative Action Time dErIV 0. -

Page 36: Record Operation

6 RECORD OPERATION Display Channels 2 and 3 Display Channels 3 and 4 Record Faceplate 2 Record Faceplate 3 If all Totalizers are If all Totalizers are off or Totalizer off or Totalizer See Note See Note option not fitted option not fitted Totals Page Totals Page... -

Page 37: Operating

6 RECORD OPERATION… 6.1 Operating Page Displays Faceplate 2 for channels 2 and 3 Faceplate 3 for channels 3 and 4 Process Variable 2 (PV2) Process Variable 3 (PV3) 200. 3 300. 3 Process Variable 3 (PV3)* Process Variable 4 (PV4)* 300. -

Page 38: Alarm Acknowledge Page

…6 RECORD OPERATION 6.2 Alarm Acknowledge Page 6.2.3 Using the Alarm Acknowledge Page No Alarm Active 6.2.1 Alarm Indications – Fig. 6.2 No LED indicators illuminated. The definitions for alarm states (on, off or flashing) are detailed in Fig. 6.2. 6.2.2 Acknowledging Alarms Unacknowledged alarms can be acknowledged from the faceplate controls on the front panel in two ways:... -

Page 39: Totals Page Displays

6 RECORD OPERATION 6.3 Totals Page Displays This page is omitted from both faceplates if the is not fitted. The page is also omitted from faceplate 2 if both Totals Totalizer Option 2 and 3 are set to and from faceplate 3 if both Totals 3 and 4 are set to –... -

Page 40: Simple Fault Finding

7 SIMPLE FAULT FINDING Symptom Possible Cause Action Does not power up a) Internal fuse (if fitted) is blown a) Check wiring, rectify fault and replace fuse b) Internal power switch (if fitted) is OFF b) Turn power switch ON c) Power supply connections are incorrect c) Check connections Chart does not appear to move... -

Page 41: Spares List

8 SPARES LIST Item Part No. Pen Capsules (pack of 3) Black C1900/0119 Blue C1900/0120 C1900/0121 Green C1900/0122 Violet* C1900/0123 Pen Arm Assemblies ER/C Type Chart (J or R in Code Number) – Standard Pen C1900/0076 ER/C Type Chart (J or R in Code Number) – Event Pen C1900/0078 PX105 and PXR105 Type Chart (K or S in Code Number) –... - Page 42 NOTES...

- Page 43 — Food & Beverage offices for details on your nearest Service and Repair Centre. — Manufacturing — Metals and Minerals — Oil, Gas & Petrochemical ABB Limited — Pulp and Paper Tel: +44 (0)1453 826661 Drives and Motors Fax: +44 (0)1453 829671 —...

- Page 44 For more product information visit: notice. With regard to purchase orders, the agreed www.abb.com particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document. We reserve all rights in this document and in the subject matter and illustrations contained therein.