Summary of Contents for Canon Finisher-AB1

- Page 1 Finisher-AB1 Saddle Finisher-AB2 SERVICE MANUAL DU7-1230-000 MAY 2007 REV. 0 COPYRIGHT ©2007 CANON INC. CANON Finisher-AB1 / Saddle Finisher-AB2 REV. 0 PRINTED IN U.S.A.

- Page 2 This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

- Page 3 Introduction Symbols Used This documentation uses the following symbols to indicate special information: Symbol Description Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to avoid combustion (fire). Indicates an item prohibiting disassembly to avoid electric shocks or problems.

- Page 4 Introduction The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between elec- trical and mechanical systems with reference to the timing of operation. In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow indicates the direction of the electric signal.

-

Page 5: Table Of Contents

Contents Contents Chapter 1 Specifications 1.1 Product Specifications..................1-1 1.1.1 Specifications (finisher) ..................... 1-1 1.2 Names of Parts....................1-4 1.2.1 External View......................1-4 1.2.2 Cross Section ......................1-5 Chapter 2 Installation 2.1 Making Pre-Checks................... 2-1 2.1.1 Checking the Contents....................2-1 2.2 Installation Procedure.................. - Page 6 Contents 3.4.1 Overview........................3-8 3.4.2 Basic Sequence of Operations ................3-11 3.4.3 Horizontal Registration Detection ................. 3-12 3.4.4 Horizontal Registration Correction/Alignment Operation ........3-14 3.4.5 Buffer Operation ...................... 3-17 3.4.6 Switching Over the Paper Path................3-19 3.5 Intermediate Process Tray Assembly............3-20 3.5.1 Overview........................

- Page 7 Contents 4.4.2 Process Tray Assembly ..................4-20 4.4.3 Process Tray ......................4-21 4.4.4 Feed Belt ........................4-22 4.4.5 Paddle Unit ........................4-24 4.4.6 Paddle ........................4-24 4.4.7 Tray Unit ........................4-24 4.5 Electrical System..................... 4-28 4.5.1 Finisher Controller PCB ..................4-28 4.5.2 Static Charge Eliminator ..................4-28 4.5.3 Horizontal Registration Sensor Unit ..............4-30 Chapter 5 Maintenance 5.1 User Maintenance .....................

- Page 8 Contents 5.3.2.13 Bufferless mode 2 ......................5-30 5.3.2.14 Assist stopper position adjustment................5-30 5.3.2.15 Staple inlet guide height adjustment ................5-32 5.3.2.16 Paddle height adjustment ....................5-34 5.3.2.17 Adjustment at poor tray stackability (when the upper curl occurs) ......5-36 5.3.2.18 Adjustment at poor tray stackability (when the lower curl occurs) ......

-

Page 9: Chapter 1 Specifications

Chapter 1 SPECIFICATIONS... - Page 10 Contents Contents 1.1 Product Specifications ..................1-1 1.1.1 Specifications (finisher)....................1-1 1.2 Names of Parts ...................... 1-4 1.2.1 External View ........................1-4 1.2.2 Cross Section .........................1-5...

-

Page 11: Product Specifications

Chapter 1 1.1 Product Specifications 1.1.1 Specifications (finisher) 0015-2057 T-1-1 Item Description Remarks Stacking tray A/B by tray lift mechanism Stacking orientation tray A face-down/face-up tray B face-down Stack size tray A A3,A4,A4R,A5R,B4,B5,B5R,Jpn postcard in feed direction, 182 to 487.7 mm; R,279.4mmx432.8mm(11x17),LGL,LTR,EXE,LT in cross-feed direction,139.7 to RR,STMTR,EXER... - Page 12 Chapter 1 1: The number of sheets refers to the result of conversion based on paper of 80g/m2 2: A sheet of paper may be grouped into the following: -large-size; A3,B4,279.4mmx432.8mm(11x17),LGL -small-size; A4,A5,B5,EXE,LTR,STMT,postcard,A4R,B5R,LTRR T-1-2 Item Description Remarks Staple accommodation in special staple cartridge (5000 staples) Detection of staples an alert condition identified at 0 to 40...

- Page 13 Chapter 1 Staple Position 1-Point Stapling (front) 5 2.0 5 2.0 A3, B4, A4, B5, / 11"x17", LTR A4R / LGL, LTRR 1-Point Stapling (rear) 5 2.0 5 2.0 A3, B4, A4, B5, / 11"x17", LTR A4R / LGL, LTRR 2-Point Stapling A3, A4 B4, B5...

-

Page 14: Names Of Parts

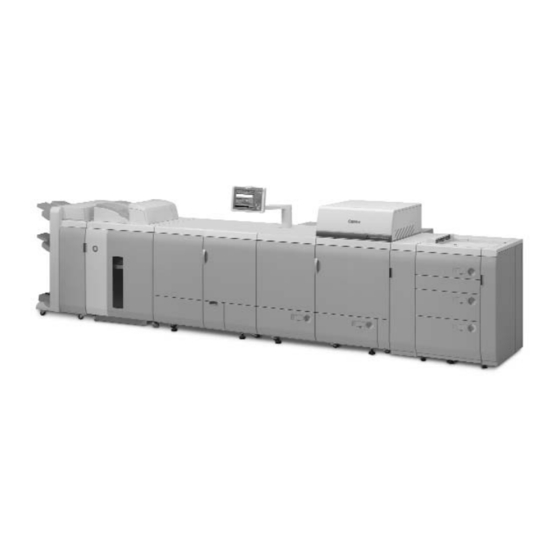

Chapter 1 1.2 Names of Parts 1.2.1 External View 0015-2060 F-1-1 [1]Tray B [5]Upper cover [2]Tray A [6]Inlet transport unit [3]Top delivery outlet [7]Front cover [4]Bottom delivery outlet... -

Page 15: Cross Section

Chapter 1 1.2.2 Cross Section 0015-2062 [10] [12] [11] [13] [14] [15] [16] [17] [18] [19] F-1-2 [1]Transport belt [8]Delivery roller [14]Assist roller 2 [2]Stack delivery roller [9]Buffer roller 2 [15]Shift roller 2 [3]Swing guide [10]Assist roller 3 [16]Shift roller 1 [4]Paddle [11]Buffer roller 3 [17]Assist roller 1... -

Page 16: Chapter 2 Installation

Chapter 2 INSTALLATION... - Page 17 Contents Contents 2.1 Making Pre-Checks................... 2-1 2.1.1 Checking the Contents....................2-1 2.2 Installation Procedure..................2-3 2.2.1 Points to Note When Turning ON/OFF the power of Host Machine ....2-3 2.2.2 Before Installing Finisher ..................2-3 2.2.3 Connecting with Machine..................2-4 2.2.4 Connecting with High-Capacity Stacker ..............

-

Page 18: Making Pre-Checks

Chapter 2 2.1 Making Pre-Checks 2.1.1 Checking the Contents 0016-0898 [10] M_ _ ________ ___ _________ ___________ __ _____ ____________. M_ _ ________ ___ _________ ___________ __ _____ ____________. P_ _ ______ ___ __________ _____ ____________ ___ _____________. P_ _ ______ ___ __________ _____ ____________ ___ _____________. J_ ____ ____________ ___ ________ _____ ___ _______ _____________ _________. - Page 19 Chapter 2 [1]*1 Finisher Latch plate (for front) Latch plate (for rear) Positioning Pin ARCNET cable coaxial connector Shunt Cable Wire Saddle Screws (RS tight; M4X10) 10pc [10] Screw (Bind; M4X8) [11]*2 Guide map label [12]*3 Guide map label [13] Staple label [14]*3 LED Lamp Label (products for China, Korea and...

-

Page 20: Installation Procedure

Chapter 2 2.2 Installation Procedure 2.2.2 Before Installing Finisher 0016-0901 1) Open the front cover of the finisher. 2.2.1 Points to Note When Turning 2) Remove 1 screw [2] from the front latch retainer ON/OFF the power of Host [1]. Machine 0016-5236 Power-On Order for Turning On the... -

Page 21: Connecting With Machine

Chapter 2 4) Remove 1 screw [1] on the rear latch retainer and pull the hinge [2] forward and downward. F-2-5 2) Fit the positioning pin [1]. - 2 screws (RS tight; M4X10) [2] F-2-4 2.2.3 Connecting with Machine 0016-0903 Check the power on the host machine is surely turned off and the power supply cable is unplugged. - Page 22 Chapter 2 3) While lifting up the front latch plate [1], fit the 4) Fix the front latch retainer. positioning pin on the machine side [2] to the - 1 screw [2] (Use the screw removed in the step finisher's positioning hole [3]. Connect the 2 of "Before Installing Finisher") finisher with the machine.

-

Page 23: Connecting With High-Capacity Stacker

Chapter 2 7) Attach the rear small cover. left side of the high-capacity stacker. 8) Remove 1 screw [1] on the rear lower cover of the - 4 screws (RS tight; M4X10) finisher. Confirm the mark engraved on each latch plate when attaching. -

Page 24

Chapter 2 2) Fit the positioning pin [1] of the high-capacity

stacker to the position [A]. - 2 screws [2] F-2-16 4) Fix the front latch plate (front) [1]. - 1 screw [2] (Use the screw removed in step 2 of "Before Installing Finisher") F-2-14 3) While lifting up the front latch support [1], fit the... -

Page 25: After Installation

Chapter 2 6) Lift up the rear latch plate [1] to fit the pin and fix 9) Connect the shunt cable [1]. - 1 screw (Use the ones removed in step 8.) - 1 screw [2] (Use the screw removed in step 4 of - 1 screw (Use the included screw for the high- "Before Installing Finisher") capacity stacker.) - Page 26 Chapter 2 2) Connect the ARCNET cable [1] to the terminal [2] at sub station, and then turn the finger grip [3] in the direction of the arrow to connect. Be sure to turn off the host machine and unplug the power supply cable when connecting the ARCNET cable.

- Page 27 Chapter 2 6) Connect the power supply plug of the finisher. (Perform only for EUR) After setting the connection sequence, the host machine should be turned off and on to enable the setting. Power-On Order for Turning On the Power When Pickup/Delivery Accessories are Connected F-2-26 Be sure to turn on the power in the correct...

-

Page 28: Making Adjustments

Chapter 2 2.3 Making Adjustments 2.3.1 Height Adjustment 0016-1444 Depending on the floor condition of an installation site, you should adjust the height of the finisher. If not properly adjusted, paper might be jammed more frequently in the feeder assembly. Follow the steps below to adjust the height when it is necessary. - Page 29 Chapter 2 3) For Finisher AB1, detach the caster front cover. - 1 screw [2] F-2-32 6) Measure the height [A] from the floor to the bottom of the machine to check the figure is in the F-2-30 range of 84.6+ -0.5mm. 4) For Saddle Finisher, detach the saddle inner cover (lower) [1].

- Page 30 Chapter 2 9) Tighten the fixing nut [1] in the direction of [B]. When loosening the fixing nut on the front caster of the saddle finisher, insert the wrench [3] into the opening just below the saddle bottom plate [2]. F-2-36 10) Repeat the steps above to adjust the height of other 3 casters.

-

Page 31: Attaching The Labels Etc

Chapter 2 2.4 Attaching the Labels etc. 4) For Saddle Finisher AB2 (product for China, Korea and Taiwan), affix the LED lamp label [2] on the label [1] found in the saddle lower inner 2.4.1 Affixing Labels cover. 0016-1445 1) Open the front cover of the finisher. 2) Affix the Guide map label [1] to the inside of the front cover. - Page 32 Chapter 2 6) Affix the jam removal label [2] in the local language on the position of [A] on the shift guide. F-2-41 7) Attach the parts removed in the previous steps in the following order. - The shift guide - upper cover 8) Close the front cover of the finisher.

-

Page 33: Chapter 3 Functions

Chapter 3 FUNCTIONS... - Page 34 Contents Contents 3.1 Basic Construction .................... 3-1 3.1.1 Overview........................3-1 3.2 Electrical Control Unit ..................3-2 3.2.1 Overview........................3-2 3.2.2 Finisher Controller PCB .................... 3-3 3.3 Stacking Unit...................... 3-4 3.3.1 Overview........................3-4 3.3.2 Tray Ascent/Descent Control ................... 3-5 3.3.3 Auxiliary Tray Lift Control..................3-6 3.3.4 Tray Paper Surface Detection..................

-

Page 35: Basic Construction

Chapter 3 3.1 Basic Construction 3.1.1 Overview 0015-2067 The machine consists of the following 5 blocks: electrical control block, stacking block, transport block, intermediary tray, and saddle stitcher block (Note). Electrical control block Transport block Stacking block To host machine Intermediary tray block Saddle stitcher block... -

Page 36: Electrical Control Unit

Chapter 3 3.2 Electrical Control Unit 3.2.1 Overview 0015-2068 The electrical control block governs all the control mechanisms of the machine, i.e., stacking block, transport block, intermediary tray block, and saddle stitcher block. The electrical control block consists of 2 entities: finisher controller PCB and saddle stitcher controller PCB (Note). -

Page 37: Finisher Controller Pcb

Chapter 3 3.2.2 Finisher Controller PCB 0015-2069 The finisher controller PCB drives the various loads (motors, solenoids) of the machine in response to the commands from the host machine (copier), and indicates the states of the sensors and switches to the host machine. -

Page 38: Stacking Unit

Chapter 3 3.3 Stacking Unit 3.3.1 Overview 0015-2072 The stacking block moves up and down the 2 delivery trays according to the instructions from the finisher controller PCB. Finisher controller PCB [10] [11] UN15 Tray A UN16 PS32 UN17 PS34 UN18 Tray B PS33... -

Page 39: Tray Ascent/Descent Control

Chapter 3 3.3.2 Tray Ascent/Descent Control 0015-2073 The tray A/B is moved up or down by controlling 2 motors (M22, M23) in response to the instructions from the finisher controller. The machine uses 2 sensors (PS34, PS35) to check for faults in these motors. The sensor monitors the rotation of the motors;... -

Page 40: Auxiliary Tray Lift Control

Chapter 3 3.3.3 Auxiliary Tray Lift Control 0015-2074 In response to an increase in the number of folded sheets in the tray, the auxiliary tray is moved up to prevent a delivery jam associated with the tray B (memo) by making sure that the lead and trail edges of the stacks deposited in the tray will be even. -

Page 41: Tray Paper Surface Detection

Chapter 3 3.3.4 Tray Paper Surface Detection 0015-2075 The machine is equipped with a mechanism to detect the position of the top of the stack deposited in its 2 trays. The trays are each fitted with a sensor PCB that consists of a light-emitting segment (UN15, UN17) and a light- receiving segment (UN16, UN18). -

Page 42: Feeding Unit

Chapter 3 3.4 Feeding Unit 3.4.1 Overview 0015-2076 The machine's transport block serves to move paper to the stacking block or the saddle stitcher block according to the instructions from the finisher controller PCB. It also is used in conjunction with horizontal registration adjustment and alignment operation. - Page 43 Chapter 3 [1]Saddle path switch solenoid drive signal [9]Assist roller 2 shift solenoid drive signal [2]Delivery motor drive signal [10]Horizontal registration motor drive signal [3]Upper path switch solenoid drive signal [11]Shift transport motor drive signal [4]Buffer motor drive signal [12]Assist roller 1 shift solenoid drive signal [5]Assist roller 3 shift solenoid drive signal [13]Horizontal registration detection unit shift motor drive signal [6]Buffer path switch solenoid...

- Page 44 Chapter 3 Finisher controller PCB From inserter To tray A UN13 UN14 UN24 To tray B From host machine From saddle stitcher unit F-3-9 [1]Lower delivery sensor signal [5]Buffer path 1 sensor signal [2]Lower path sensor signal [6]Inlet sensor signal [3]Upper delivery sensor signal [4]Buffer path 2 sensor signal PS3:inlet sensor...

-

Page 45: Basic Sequence Of Operations

Chapter 3 3.4.2 Basic Sequence of Operations 0015-2077 The transport block uses a sequence of operations that consists of the following 5: 1. Horizontal Registration Detection [1] Detects the position of the paper. 2. Horizontal Registration Correction [2] Corrects the position of the paper with reference to the result of horizontal registration detection. 3. -

Page 46: Horizontal Registration Detection

Chapter 3 3.4.3 Horizontal Registration Detection 0015-2078 1) About 150 msec after the lead edge of paper has moved past the inlet sensor (PS3), the finisher controller PCB causes the horizontal registration detection unit shift motor (M6) to rotate clockwise so that the horizontal registration sensor (UN12) moves to its standby position (paper edge) from home position. - Page 47 Chapter 3 2)The finisher controller PCB causes M6 to rotate clockwise so that UN12 moves to horizontal registration detection position (11 mm toward the inside from standby position), during which UN12 detects the edge of paper to be moved. The finisher controller PCB uses the results of the detection to compute the horizontal registration value.

-

Page 48: Horizontal Registration Correction/Alignment Operation

Chapter 3 3.4.4 Horizontal Registration Correction/Alignment Operation 0015-2079 1) About 200 msec after the inlet sensor (PS3) detects the lead edge of paper, the finisher controller PCB causes the transport motor (M2) to rotate clockwise, thereby causing the roller inside the shift roller unit to rotate. 2) The finisher controller PCB computes the horizontal registration correction value with reference to the result of horizontal registration detection. - Page 49 Chapter 3 After Correction Before Correction UN13 UN13 F-3-14 [1]Correct position [2]Paper [3]Shift roller unit 3-15...

- Page 50 Chapter 3 3) If the machine is in job offset mode, the shift roller unit is moved to the front or the rear as in the case of horizontal registration correction operation (Note), thereby offsetting the stacks of sheets discharged to the delivery tray.

-

Page 51: Buffer Operation

Chapter 3 3.4.5 Buffer Operation 0015-2080 The finisher controller PCB keeps a sheet of paper in the paper path and forwards it together with the subsequent sheet of paper using the buffer motor (M4) and the buffer path switching solenoid (SL1) with the help of the buffer path 1 sensor and the buffer path 2 sensor (UN13,UN14). - Page 52 Chapter 3 UN13 UN13 UN13 UN14 UN14 UN14 UN13 UN13 UN13 UN14 UN14 UN14 UN13 UN14 F-3-17 3-18...

-

Page 53: Switching Over The Paper Path

Chapter 3 3.4.6 Switching Over the Paper Path 0015-2081 1) The finisher controller PCB turns off or on the2 flappers (upper delivery flapper, lower delivery flapper) to switch over the destination of paper. F-3-18 [1]From the host machine [5]Lower delivery flapper [2]Paper [6]To tray B [3]To tray A... -

Page 54: Intermediate Process Tray Assembly

Chapter 3 3.5 Intermediate Process Tray Assembly 3.5.1 Overview 0015-2083 The intermediary tray block serves to shift or staple a stack of sheets in response to the instructions from the finisher controller PCB, and then sends the result to the stacking block. The paper path is fitted with 2 sensors for detection of a jam. - Page 55 Chapter 3 [1]Front alignment motor drive signal/rear alignment motor signal [7]Paper trail edge retaining motor drive signal [2]Stack delivery auxiliary motor drive signal [8]Delivery motor drive signal [3]Stack delivery motor drive signal [9]Transport belt motor drive signal [4]Swing guide motor drive signal [10]Assist motor drive signal [5]Paddle rotation motor drive signal [11]Staple motor drive signal...

- Page 56 Chapter 3 Finisher controller PCB PS17 F-3-20 [1]Lower delivery sensor signal [2]Handling tray sensor signal PS6:lower delivery sensor PS17:processing tray sensor 3-22...

-

Page 57: Basic Sequence Of Operations

Chapter 3 3.5.2 Basic Sequence of Operations 0015-2085 The intermediary tray block uses the following 4 sequences of operations: 1.Stacking Operation [1] Deposits sheets coming front the transport block in the intermediary tray. 2.Aligning Operation [2] Switches over the point of depositing stacks between the front and the rear of the tray. (in shift mode) 3.Stapling Operation [3] Staples a stack of sheets at a specific point. -

Page 58: Stacking Operation

Chapter 3 3.5.3 Stacking Operation 0015-2086 1) When the sheet coming from the transport block reaches the lower delivery sensor (PS6), the machine moves the transport belt in the direction of the arrow, and rotates the delivery roller in the direction of the arrow. As a result, the transport belt rotates to move the paper in the direction of the tray. - Page 59 Chapter 3 2) When the trail edge of paper moves past PS6, the stack delivery roller and the paddle rotate in the direction of the arrow, thereby pulling the paper back into the machine. F-3-23 [1]Paper [4]Assist stopper [2]Stack delivery roller [5]Transport belt [3]Sort delivery roller [6]Paddle...

- Page 60 Chapter 3 3)When the trail edge of paper reaches the process stopper, the machine stops the rotation of the stack delivery roller and the paddle. The swing guide [7] is moved up. F-3-24 [1]Paper [5]Transport belt [2]Stack delivery roller [6]Paddle [3]Sort delivery roller [7]Swing guide [4]Processing stopper...

- Page 61 Chapter 3 Stacks Subject to Misalignment Tray Stacks Free of Misalignment Tray F-3-25 [1]Stack [4]Variation present among lead edges of sheets [2]Tray auxiliary plate [5]Variation absent among trail edges of sheets [3]Processing stopper 3-27...

-

Page 62: Alignment

Chapter 3 3.5.4 Alignment 0015-2087 1) At the end of stacking, the swing guide is moved up, and then the aligning plate is operated as part of an alignment operation (Note), causing the stack of sheets to move to the rear or to the front. The foregoing sequence of operations applies only to the Tray B. - Page 63 Chapter 3 lignment Mechanism (shift) The machine’s alignment mechanism operates either of its 2 aligning plates to switch over (offset) the point of depositing individual stacks of sheets. Shifting to the Front Shifting to the Rear F-3-27 [1]Tray [4]Rear aligning plate [2]Front aligning plate [5]Existing stacks [3]Paper...

-

Page 64: Stapling Operation

Chapter 3 3.5.5 Stapling Operation 0015-2088 1)At the end of alignment operation, the machine moves down the swing guide and performs stapling (Note). F-3-28 [1]Swing guide [4]Stapler [2]Stapled stack of sheets [5]Aligning plate [3]Stack delivery roller 3-30... - Page 65 Chapter 3 2) As needed, the staple unit is moved to empty itself of the waste staples in the waste staple case. The machine's stapling sequence consists of the following operations: driving a staple, cutting the staple tips, clinching the staple. F-3-29 [1]Stack of sheets [4]Cutting the staple tips...

-

Page 66: Delivery Operation

Chapter 3 3.5.6 Delivery Operation 0015-2089 1) The machine starts delivery of the stack at the end of alignment or stapling by rotating the delivery roller in the direction of the arrow. 2) When a stack has 11 or more sheets, the assist stopper moves in the direction of the arrow in synchronization with the stack delivery roller so that the paper delivery operation is smoothly performed. -

Page 67: Detecting Jams

Chapter 3 3.6 Detecting Jams 3.6.1 Jam Detection in the Finisher Assembly 0015-2098 The machine is equipped with the following sensors to check the presence/absence of paper and to see if paper is moving properly: - inlet sensor - shift unit sensor - upper delivery sensor - lower delivery sensor - buffer path 1 sensor... - Page 68 Chapter 3 The presence of a jam, on the other hand, is checked by the finisher controller PCB, running a check at such times as programmed in advance. When the finisher controller PCB finds a jam, it will cause the stitcher controller PCB to suspend the ongoing transport/delivery operation and communicate the presence of a jam to the host machine.

-

Page 69: Power Supply

Chapter 3 3.7 Power Supply 3.7.1 Overview 0015-2100 The machine's power supply mechanism converts the AC power from the power outlet into DC for supply to its various loads. The AC power is supplied to the circuit when the power switch (SW1) is turned on. It is then converted by the circuit into the following DC power supplies;... -

Page 70: Protective Mechanism

Chapter 3 3.7.2 Protective Mechanism 0015-2101 The machine is equipped with protective mechanisms that will automatically shut off the output voltage to prevent damage to the power supply circuit in the event of over-current or over-voltage caused, for example, by a short-circuit in any of its loads. -

Page 71: Chapter 4 Parts Replacement Procedure

Chapter 4 PARTS REPLACEMENT PROCEDURE... - Page 72 Contents Contents 4.1 Removing from the Host Machine ..............4-1 4.1.1 Finisher Assembly ......................4-1 4.2 External Covers ....................4-2 4.2.1 Rear Lower Cover ......................4-2 4.2.2 Rear Upper Cover ......................4-2 4.2.3 Upper Cover Unit .......................4-3 4.2.4 Delivery Tray .......................4-4 4.2.5 Stack Wall (Upper) .....................4-5 4.2.6 Stack Wall (Lower) .....................4-5 4.2.7 Rear Middle Cover .....................4-6 4.2.8 Inside Cover (Upper) ....................4-6...

-

Page 73: Removing From The Host Machine

Chapter 4 4.1 Removing from the Host 3) Remove the rear small cover [1]. - 4 screws [2] Machine 4.1.1 Finisher Assembly 4.1.1.1 Disconnecting from the Host Machine 0015-2102 Check to make sure that the machine is off and the power plug is not connected to the power outlet. -

Page 74: External Covers

Chapter 4 4.2 External Covers 5) Open the front cover. 6) Remove the screw [2] from the latch base (front) [1]. 4.2.1 Rear Lower Cover 4.2.1.1 Removing the Low Rear Cover 0015-2104 1) Remove the lower rear cover [1]. - 8 screws [2] F-4-5 7) While lifting the latch base (front) [1], disconnect the finisher from the host machine. -

Page 75: Upper Cover Unit

Chapter 4 4.2.2.2 Before Removing the Upper Rear 4.2.3.2 Removing the Upper Cover Unit Cover (left) 0015-2110 1) Disconnect the cable [1]. - 4 clamps [1] 0015-2106 1) Remove the upper rear cover (right). (page 4- - 1 connector [3] 2)Reference[Removing the Upper Rear Cover - 2 screws [4] (right)]... -

Page 76: Delivery Tray

Chapter 4 4) Open the upper cover unit [1]. F-4-14 F-4-12 4.2.4 Delivery Tray 5) Open the upper cover unit so that the damper shaft [1] becomes loose; then, detach it. 4.2.4.1 Position of the Tray B at Power-On 0015-2111 At power-on, the tray B [1] must never be above the tray B paper sensor [2], which will cause an error during detection of the tray B position. -

Page 77: Stack Wall (Upper)

Chapter 4 4.2.5 Stack Wall (Upper) 4.2.6 Stack Wall (Lower) 4.2.5.1 Removing the Stacking Wall 4.2.6.1 Before Removing the Stacking (upper) Wall (lower) 0015-2112 0015-2113 1) Remove the stacking wall (upper). (page 4- 1) While supporting the tray from below, insert a screwdriver [2] in the hole [1] of the lower face to 5)Reference[Removing Stacking... -

Page 78: Rear Middle Cover

Chapter 4 4.2.7 Rear Middle Cover 4.2.6.3 Mounting the Stacking Wall (lower) 4.2.7.1 Removing the Middle Rear Cover 0015-2115 1) Turn the shutter drive shaft [2] so that the shutter 0015-2118 1) Remove the middle rear cover [1]. drive roll [1] is directly below. - 4 screws [2] F-4-20 2) Mount the stacking wall (lower) so that the shutter... -

Page 79: Inside Cover (Lower)

Chapter 4 4.2.9 Inside Cover (Lower) 2) Push in the stapler unit [1] until it is as shown. 4.2.9.1 Removing the Inside Cover (lower) 0015-2122 1) Open the front cover. 2) Remove the inside cover (lower) [1]. - 2 screws [2] F-4-26 3) Remove the stapler unit [1]. -

Page 80: Front Alignment Motor

Chapter 4 4.3.2 Front Alignment Motor 3) Remove the handling tray plate unit [1]. - 1 screw [2] (loosen) - 1 belt [3] 4.3.2.1 Before Removing the Alignment - 6 screws [4] Motor (frontÅj - 2 positioning plates [5] 0015-2128 1) Remove the stacking wall (upper). -

Page 81: Rear Alignment Motor

Chapter 4 5) Remove the handling tray (front) [1]. - 2 screws [2] F-4-32 6) Loosen the screw [1], and free the belt [2] from the gear [3]. F-4-34 4.3.3 Rear Alignment Motor 4.3.3.1 Before Removing the Alignment Motor (rear) 0015-2302 1) Remove the stacking wall (upper). - Page 82 Chapter 4 2) Free the cable [2] connected to the 2 clamps [1], 4) Remove the handling tray aligning plate (rear). and disconnect the connector [3]. - 1 screw [2] - 1 claw [3] F-4-36 F-4-38 3) Remove the handling plate unit [1]. 5) Remove the handling tray (front) [1].

-

Page 83: Tray Shift Motor

Chapter 4 7) Remove the aligning motor (rear) [1]. 2) While supporting the tray from below, release the (page 5-11)Reference[Adjusting the Angle of roll [1] in the direction of the arrow; then, move it the Aligning Plate (orthogonal)] down until it stops. (page 5-13)Reference[Adjusting the Aligning Plate Width] - 1 clamp [2]... -

Page 84: Shift Motor

Chapter 4 5) Remove the tray A/B lift motor. 2) Remove the transport stay (upper right) [1]. - 2 screws [2] - 4 screws [2] - 1 belt [3] F-4-46 4.3.5 Shift Motor 4.3.5.1 Before Removing the Shift Motor 0015-2305 1) Disconnect the machine from the host machine side. - Page 85 Chapter 4 4) Disconnect the 2 connectors [1], and remove the 2 6) Remove the cable retainer [1], and disconnect the screws [2]. connector [2]; then, free the cable [3] from the cable guide [4]. F-4-52 7) Insert a screwdriver [1] into the hole [1]. F-4-50 5) Remove the detection drive assembly [1].

- Page 86 Chapter 4 9) Detach the belt [1] from the gear [2]. F-4-57 F-4-55 12) Disconnect the connector [1], and free the cable 10) Remove the 2 slide shafts [1] in the direction of [2] from the clamp [3] and the 2 edge saddles [4]. the arrow.

-

Page 87: Belt Controller Unit

Chapter 4 4.3.6.2 Removing the Belt Controller Unit 13) Remove the shift motor unit [1]. - 3 screws [2] 0015-2310 1) Loosen the screw [1]. F-4-61 F-4-59 2) Free the cable from the 4 clamps [1] and the edge 14) Remove the shift motor [1]. saddle [2];... - Page 88 Chapter 4 3) Remove the 2 screws [1] found at the rear of the machine. F-4-63 4) Remove the 2 screws [1] found at the front of the machine. F-4-65 The belt [4] tends to slip off. Take care not to lose it. 6) Shift the belt variable lever [1] in the direction of the arrow.

- Page 89 Chapter 4 7) Release the 2 roll guides [1] in the direction of the 9) Remove the E-ring [1] and the bushing [2]. arrow, and detach the 2 belts [2] from the belt variable lever [3]. F-4-69 10) Remove the belt controller unit [1]. - 2 screws [2] F-4-67 8) Remove the 3 E-rings [1], shift [2], and bushing...

-

Page 90: Document Feeding System

Chapter 4 4.4 Document Feeding System 4.4.1 Stack Delivery Roller Unite the guide side [3] of a guide lever (before) [1] 4.4.1.1 Before Removing the Stack and a guide lever (after) [2]. After that, it is a belt Delivery Upper Roller [4]. - Page 91 Chapter 4 3) Remove the belt [1], E-ring [2], gear [3], parallel 5) Remove the ball bearing [1] in downward pin [4], and plate [5]. direction, detaching the delivery roller [2] at the same time. F-4-74 4) Remove the ball bearing [1], washer [2]; E-ring F-4-76 [3], and ball bearing [4].

-

Page 92: Process Tray Assembly

Chapter 4 4.4.2 Process Tray Assembly 2) Turn the knob [1] clockwise so that the rear edge drop guide [2] is at its lowest position. 4.4.2.1 Before Removing the Handling Tray Unit 0015-2165 1) Remove the stacking wall (upper). (page 4- 5)Reference[Removing Stacking Wall... -

Page 93: Process Tray

Chapter 4 A guide [2] is attached so that it may not run aground on a lever [1]. F-4-82 2) Remove the handling tray (front) [1]. - 2 screws [2] F-4-81 4.4.3 Process Tray F-4-83 4.4.3.1 Before Removing the Handling Tray (front/rear) 0015-2167 1) Remove the stacking wall (upper). -

Page 94: Feed Belt

Chapter 4 4.4.4 Feed Belt 4.4.3.3 Removing the Handling Tray (rear) 4.4.4.1 Before Removing the Transport 0015-2169 1) Shift the handling tray aligning plate (rear) [1] in the direction of the arrow; then, remove the screw Belt [2] and the claw [3] to detach the handling tray aligning plate (rear). - Page 95 Chapter 4 3) Turn the coupling (front) [1] so that the screw is at 5) Release the roll guide [1], and detach the transport the front; then, loosen the screw, and shift the roll [2] from the shaft together with the belt. coupling (front) to the right.

-

Page 96: Paddle Unit

Chapter 4 4.4.5 Paddle Unit 4.4.6.2 Removing the Paddle 4.4.5.1 Before Removing the Paddle Unit 0015-2175 1) Release the 2 claws [1], and detach the paddle retaining roll [2] to detach the paddle [3]. 0015-2172 1) Remove the stacking wall (upper). (page 4- 5)Reference[Removing Stacking Wall... - Page 97 Chapter 4 3) Remove the stopper[1] 1. Removing the Tray A Unit - screw [2] 1) Remove the support cover [1]. - claw [2] F-4-96 4) Remove the screw [1], and disconnect the 2 connectors [2]. F-4-94 2) Remove the support plate [1]. - 4 screws [2] F-4-95 F-4-97...

- Page 98 Chapter 4 5) Remove the 2 screws [1], and lead out the cable [2] in the direction of the arrow. 2. Removing the Tray B Unit 1) Remove the stopper (lower) [1]. - 1 screw [2] F-4-98 6) Remove the tray A cover [1] - 4 screws [2] F-4-101 2) Remove the screw [1], and disconnect the...

- Page 99 Chapter 4 4.4.7.3 Points to Note About the Tray A/B 3) Remove the 2 screws [1], and lead out the cable [2] in the direction of the arrow. Cable 0015-2178 When mounting the tray A/B unit, take care so that the cables will not become tangled.

-

Page 100: Electrical System

Chapter 4 4.5 Electrical System 4.5.2 Static Charge Eliminator 4.5.2.1 Removing the Stack Edging Roller 4.5.1 Finisher Controller PCB Static Eliminator 4.5.1.1 Finisher Controller PCB 0015-2194 1) Remove the 2 stack edging roller stack eliminators 4.5.1.1.1 Before Removing the Finisher [1]. - Page 101 Chapter 4 4.5.2.3 Removing the Stack Eliminator 3) Remove the handling tray unit. (page 4- 20)Reference[Removing the Handling Tray (upper delivery slot) Unit] 0015-2196 4.5.2.5 Removing the Stack Eliminator 1) Remove the buffer upper cover assembly [1]. - 1 reuse band [2] (inside delivery guide) - 4 screws [3] 0015-2198...

-

Page 102: Horizontal Registration Sensor Unit

Chapter 4 4.5.3 Horizontal Registration Sensor 4.5.2.7 Removing the Static Eliminator (T2) Unit 0015-2203 4.5.3.1 Before Removing the Horizontal 1) Open the front cover. 2) Slide out the saddle unit. Registration Sensor Unit 3) Remove the static eliminator (T2) [1] - 2 screws [2] 0015-2205 1) Separate the machine from the host machine side. - Page 103 Chapter 4 2) Disconnect the 2 connectors [1], and remove the 2 4) Disconnect the connector [1], and free the cable screws [2]. [2] from the 3 cable guides [3] and the edge saddle [4]. 5) Remove the 2 screws [5]. F-4-117 3) Remove the detection drive assembly [1].

-

Page 104: Chapter 5 Maintenance

Chapter 5 MAINTENANCE... - Page 105 Contents Contents 5.1 User Maintenance ..................... 5-1 5.1.1 User Maintenance Items (finisher) ................5-1 5.2 Maintenance and Inspection ................5-1 5.2.1 Periodically Replaced Parts ..................5-1 5.2.1.1 Periodically Replaced Parts in the Finisher..............5-1 5.2.2 Durables ........................5-1 5.2.2.1 Durables in the Finisher ...................... 5-1 5.2.2.2 Durables in the Saddle Stitcher..................

-

Page 106

Contents 5.3.2.23 The amount of sending of a saddle disengage roller adjustment......5-49 5.3.2.24 Saddle staple position adjustment................. 5-51 5.3.3 Other ......................... 5-53 5.3.3.1 Service Mode (by DIP switch)

................ 5-53 5.4 Troubleshooting ....................5-56 5.4.1 Malfunction ....................... 5-56 5.4.1.1 Malfunction/Faulty Detection .................... 5-56 5.5 Outline of Electrical Components .............. -

Page 107: User Maintenance

Chapter 5 5.1 User Maintenance 5.1.1 User Maintenance Items (finisher) 0015-2208 T-5-1 Item Timing staple cartridge (replacement) when prompted (in host machine control panel) waste staple (disposal) when prompted (in host machine control panel) 5.2 Maintenance and Inspection 5.2.1 Periodically Replaced Parts 5.2.1.1 Periodically Replaced Parts in the Finisher 0015-2211 The finisher does not have a part that requires periodical replacement. -

Page 108: Durables In The Saddle Stitcher

Chapter 5 5.2.2.2 Durables in the Saddle Stitcher 0015-2214 Some parts of the machine may require replacement once or more over the period of product warranty because of deterioration or damage. Replace them as necessary. T-5-3 as of November 2005 Parts name Parts number Q'ty Life... -

Page 109: Adjustment

Chapter 5 5.3 Adjustment 5.3.1 Basic Adjustment 5.3.1.1 Adjusting the Height 0015-2219 If jams start to occur often, adjust the height of the machine as follows: 1. Checking the Height 1) Check the height of the finisher and the host machine. - Page 110 Chapter 5 3) In the case of the Finisher-AB1, remove the caster 5) Remove the 2 caster covers [1] from the left side. cover [1]. (The illustration shows the saddle finisher.) - 1 screw [2] - 2 screws [2] F-5-6...

- Page 111 Chapter 5 7) Loosen the fixing nut [1] of the scanner by turning the spanner (large) [2] in the direction of [A]. F-5-10 F-5-8 9) Tighten the fixing nut [1] in the direction of [B]. When loosening the caster fixing nut [1] on the front of the saddle finisher, be sure to fit the spanner [3] through the gap below the saddle assembly base plate [2].

-

Page 112: Adjusting The Horizontal Registration/Angle

Chapter 5 5.3.1.2 Adjusting the Horizontal 4) Set the DIP switch SW382 [1] on the switch PCB as shown (1, 4, 6, and 8 at ON), and press the Registration/Angle enter button (SW385) [2]; in response, the LED [3] will flash '0'. 0015-2221 If the vibration is excessive (i.e., the horizontal registration unit shifts excessively), or the skew is... -

Page 113: Adjusting The Horizontal Registration/Angle

Chapter 5 7) Press the enter button to end adjustment mode. 3. Adjusting the Angle 8) Turn off the host machine and then the finisher in If the angle is as indicated, start with step 7). sequence. 1) Lift the upper cover [1], and detach the inside cover (upper) [2]. -

Page 114: Adjusting The Sensor Intensity

Chapter 5 5) Loosen the 2 screws [2] on the latch base (rear) [1]. 6) If the value recorded is on the + side, move the base in the direction of [A] and tighten the screw Make sure that the total of the indexes over which the [2]. - Page 115 Chapter 5 Be sure to lower the tray A/B [2] until it does not block the tray sensor (front/rear) [1]. F-5-21 3) Insert a screwdriver [2] through the hole [1] in the bottom face of the tray; then, disengage the tray in the direction of [A], and lower the tray A/B in the direction of [B].

-

Page 116: Adjustment At Time Of Parts Replacement

Chapter 5 5) Set the DIP switch SW382 [1] of the switch PCB T-5-4 as shown (1: ON), and press the enter button Code Sensor Name (SW385) [2] to start sensor intensity adjustment. Buffer path 1 sensor PCB(UN13) Buffer path 2 sensor PCB(UN14) Lower path sensor PCB(UN24) Horizontal sensor PCB(UN12) SW382... -

Page 117: Adjusting The Angle Of The Aligning Plate (Orthogonal)

Chapter 5 5.3.2.2 Adjusting the Angle of the Aligning 3) Place A4 paper [1] in the intermediate handling tray in the direction of the arrow. Make adjustments Plate (orthogonal) so that there is no gap between the paper edge [1] and the aligning plate [2];... -

Page 118: Adjusting The Stapler Position

Chapter 5 5.3.2.3 Adjusting the Stapler Position 5.3.2.4 Adjusting the Speed of the Swing Guide 0015-2227 Go through the following steps if you have replaced the stapler unit found in the intermediate handling 0015-2229 Go through the following steps if you have replaced tray assembly: the swing guide motor or the EEPROM of the 1) Mark the position [1] of the stapler unit before... -

Page 119: Adjusting The Aligning Plate Width

Chapter 5 5.3.2.5 Adjusting the Aligning Plate Width 5) Set the DIP switch SW382 [1] on the switch PCB as follows: 0015-2230 Go through the following steps if you have replaced the front alignment motor or the rear alignment motor or the EEPROM of the controller PCB: 1) Turn on the finisher. - Page 120 Chapter 5 5) Set the DIP switch SW382 [1] on the switch PCB as follows: for A-Series, SW382 SW381 SW382 SW383 SW384 SW385 SW381 ENTER SW383 SW384 SW385 F-5-40 7) Place A4 paper [1] in the intermediate handling ENTER tray. (Be sure to butt the paper against the rear of the handling tray.) F-5-38 for L-Series,...

- Page 121 Chapter 5 8) Press the push switch SW383 [1] or SW384 [2] to 9) Press the push switch SW385 [1] to store the store the new value. distance of travel of the front aligning plate. A single press on SW383 will cause the LED [3] to indicate '-1', moving the front aligning plate [4] by about 0.2 mm toward the front.

-

Page 122: Adjusting The Transport Belt Position

Chapter 5 5.3.2.6 Adjusting the Transport Belt 5) Set the DIP switch SW382 [1] on the switch PCB as follows: Position 0015-2231 Go through the following steps if you have replaced the transport belt of the intermediate tray or there is displacement among the sheets of a delivered stack: 1) Turn on the finisher. -

Page 123: Adjusting The Stapling Position (Rear 1-Point)

Chapter 5 Reference: 1. If wear has occurred on the transport belt or recycled paper (i.e., with high surface resistance) is used, select a negative adjustment value (-1 to - 4) to increase the retention. 2. If dents have occurred in the edge of paper, select a positive adjustment value (+1 to +4) to SW382 decrease the retention. - Page 124 Chapter 5 4) Remove the screw [2], and detach the switch cover [1]. SW382 SW381 SW383 SW384 SW385 ENTER F-5-54 F-5-52 for L-Series, 5) Set the DIP switch SW382 [1] of the switch PCB as follows: SW382 SW382 SW381 SW381 SW383 SW384 SW385 SW383...

- Page 125 Chapter 5 7) Press the push switch SW383 [1] or SW384 [2] to execute stapling. store the adjustment value. A single press on SW383 will cause the LED [3] to indicate '-1', moving the stapling position toward the rear. On the other hand, a single press on SW384 will cause the LED [3] to indicate '+1', moving the stapling position toward the front.

-

Page 126: Adjusting The Stapling Position (Front 1-Point)

Chapter 5 5.3.2.8 Adjusting the Stapling Position (front 1-point) 0015-2233 Go through the following steps if the stapling position (front 1-point) is displaced or if you have replaced the EEPROM of the finisher controller SW382 PCB: 1) Turn on the finisher. 2) Turn on the host machine so that it will be in a standby state. - Page 127 Chapter 5 6) Press the push switch SW385 [1] to start 8) Press the push switch SW385 [1] to move the adjustment of the stapling position (front 1- stapler toward the front. point). SW382 SW382 SW381 SW381 SW383 SW384 SW385 SW383 SW384 SW385 ENTER...

-

Page 128: Adjusting The Stapling Position (2-Point)

Chapter 5 5.3.2.9 Adjusting the Stapling Position (2- 10) Check to make sure that the stapling position is 5 +/-2 mm [1] as a result of the foregoing steps. point) Otherwise, go back to step 6). 0015-2237 Go through the following steps if there is displacement in stapling position (2-point) or if you have replaced the EEPROM of the finisher controller PCB:... - Page 129 Chapter 5 5) Set the DIP switch SW382 [1] on the switch PCB 6) Press the push switch SW385 [1] to start as follows: adjustment of stapling position (2-point). for A-Series, SW382 SW382 SW381 SW383 SW384 SW385 SW381 ENTER SW383 SW384 SW385 F-5-73 ENTER...

- Page 130 Chapter 5 7) Press the push switch SW383 [1] or SW384 [2] to 8) Press the push switch SW385 [1] to move the store the new adjustment value. stapler to the 2-point stapling position. A single press on SW383 will cause the LED [3] to indicate '-1', moving the stapling position (2- point) upward.

-

Page 131: Adjusting The Delivery Of Stapled Stacks (Lower Delivery)

Chapter 5 10) Check to see that the stapling position is as follows [1] as the result of the foregoing steps: for A-Series, 86.3 +/-4 mm; for L-Series, 73.7 +/-4 mm. Otherwise, go back to step 6). F-5-77 F-5-79 5) Set the DIP switch SW382 [1] on the switch PCB as follows: If the LED indicates other than '0', the adjustment is likely to have failed. - Page 132 Chapter 5 6) Press the push switch SW385 [1] so that the LED [2] flashes '0', indicating that the machine is ready for adjustment. SW382 SW381 SW383 SW384 SW385 ENTER F-5-81 7) Place 3 originals in the ADF, and set as follows on the control panel: A4, 1 set (staple sort).

-

Page 133: Adjustment Of Eeprom (Ic107) On The Finisher Controller Pcb After Replacement

Chapter 5 10) If A (between 1st and 2nd sheets) or B (between 2nd and 3rd sheets) is not as indicated, go through the following: Press the push switch SW385 [1] so that the machine is in adjustment mode for A (between 1st and 2nd sheets). - Page 134 Chapter 5 5) Set the DIP SW382 [1] on the Switch PCB as shown in the figure below. EEPROM is initialized by pressing the switches in the order of SW385,SW384,SW383, once for each. SW382 SW381 F-5-86 SW383 SW384 SW385 4) Detach the switch cover [1] by removing the screw [2].

-

Page 135: Bufferless Mode 1

Chapter 5 5.3.2.12 Bufferless mode 1 5) Set the DIP switch SW382 [1] on the switch PCB as follows: 0016-4794 This mode is selected when the conditions listed below are satisfied. - When poor alignment has occurred in cases where a multiple number of copies has been made - When the corners of the sheets are creased - When a buffer path 2 sensor stationary jam (jam... -

Page 136: Assist Stopper Position Adjustment

Chapter 5 5) Set the DIP switch SW382 [1] on the switch PCB as follows: 5.3.2.13 Bufferless mode 2 0016-4795 This mode is selected when the conditions listed below are satisfied. - When poor alignment has occurred in cases where a multiple number of copies has been made using coated sheets for the originals SW382... - Page 137 Chapter 5 3) Place the A4 or letter size sheets [1] in the 4) Remove the 2 screws [2], and remove the assist intermediate processing tray in the direction of the stopper [1]. arrow. Then, measure the degree of displacement [A] between the paper edge stopper [2] and the assist stopper [3].

-

Page 138: Staple Inlet Guide Height Adjustment

Chapter 5 6) Attach the assist stopper [1] using the 2 screws [2]. F-5-101 F-5-99 4) Remove the screw [2], and detach the switch cover [1]. 5.3.2.15 Staple inlet guide height adjustment 0016-4796 This adjustment is performed either when poor tray stacking occurs with thin papers shown in the figure below or when the EEPROM (IC107) on the finisher controller PCB is replaced. - Page 139 Chapter 5 5) Set the DIP switch SW382 [1] on the switch PCB When the foregoing fault has occurred, it can be as follows: remedied by changing the adjustment value in the negative direction. SW382 SW382 SW381 SW381 SW383 SW384 SW385 SW383 SW384 SW385 ENTER...

-

Page 140: Paddle Height Adjustment

Chapter 5 8) This adjustment is completed by pressing the push switch SW385 [1] again. SW382 SW381 SW383 SW384 SW385 F-5-109 4) Remove the screw [2], and detach the switch ENTER cover [1]. F-5-107 5.3.2.16 Paddle height adjustment 0016-6224 This adjustment is performed either when poor tray stacking occurs with thin papers shown in the figure below or when the EEPROM (IC107) on the finisher controller PCB is replaced. - Page 141 Chapter 5 6) The preparations for the paddle height adjustment are completed by pressing the push switch SW385 [1]. SW382 SW381 F-5-114 SW383 SW384 SW385 7) The adjustment amount is determined by pressing either one of the push switches: SW383 [1] or ENTER SW384 [2].

-

Page 142: Adjustment At Poor Tray Stackability (When The Upper Curl Occurs)

Chapter 5 5.3.2.17 Adjustment at poor tray stackability (when the upper curl occurs) 0016-6227 This adjustment is performed either when poor tray stackability occurs (when the upper curl occurs) shown in the figure below or when the EEPROM (IC107) on the finisher controller PCB is replaced. F-5-116 F-5-118... -

Page 143: Adjustment At Poor Tray Stackability (When The Lower Curl Occurs)

Chapter 5 6) The preparations for this adjustment are completed by pressing the push switch SW385 [1]. SW382 SW382 SW381 SW381 SW383 SW384 SW385 SW383 SW384 SW385 ENTER ENTER F-5-122 5.3.2.18 Adjustment at poor tray F-5-120 stackability (when the lower curl occurs) 7) When the push switch SW384 [1] is pressed once, "+1"... - Page 144 Chapter 5 3) Open the front door, and insert the door switch 5) Set the DIP switch SW382 [1] on the switch PCB actuator into the door switch [1]. as follows: SW382 SW381 F-5-124 SW383 SW384 SW385 4) Remove the screw [2], and detach the switch cover [1].

-

Page 145: Adjustment At Poor Tray Stackability (Run Over When Using Thin Paper)

Chapter 5 7) When the push switch SW384 [1] is pressed twice, "+2" appears on the LED [2]. SW382 F-5-130 SW381By executing this adjustment, the finisher reduces the feeding speed. As a result, the degree of curl of thin paper is reduced;... - Page 146 Chapter 5 4) Remove the screw [2], and detach the switch cover [1]. SW382 SW381 SW383 SW384 SW385 ENTER F-5-134 F-5-132 7) When the push switch SW384 [1] is pressed once, "+1" appears on the LED [2]. 5) Set the DIP switch SW382 [1] on the switch PCB as follows: SW382 SW382...

-

Page 147: Tray Stacking Limit Cancellation Adjustment

Chapter 5 8) This adjustment is completed when the push T-5-6 switch SW385 [1] is pressed again. Loading capacity Paper type Under normal When the stacking conditions limit is cancelled SW382 Plain paper (extra long 1,000 sheets 1,500 sheets size) Coated SW381 paper (half... - Page 148 Chapter 5 4) Remove the screw [2], and detach the switch cover [1]. SW382 SW381 SW383 SW384 SW385 ENTER F-5-141 7) When the push switch SW384 [1] is pressed once, F-5-139 "+1" appears on the LED [2]. 5) Set the DIP switch SW382 [1] on the switch PCB as follows: SW382 SW382...

-

Page 149: Saddle Staple Alignment Adjustment

Chapter 5 8) This adjustment is completed when the push switch SW385 [1] is pressed again. SW382 SW381 SW383 SW384 SW385 ENTER F-5-143 F-5-144 5.3.2.21 Saddle staple alignment adjustment 3) Detach the saddle inner cover (lower) [1]. - 4 screws [2] 0016-4897 - 1 knob [3] T-5-7... - Page 150 Chapter 5 4) Turn on the power of the finisher. 5) Turn on the power switch on the host machine to set the host machine to the standby mode. 6) Open the front door, and insert the door switch actuator into the door switch [1]. F-5-148 F-5-146 9) Place the sheets (A3 or LDR) [1] along the feeding...

- Page 151 Chapter 5 10) Set the DIP SW382 [1] on the switch PCB as shown in the figure below. SW382 SW381 SW382 SW383 SW384 SW385 SW381 ENTER SW383 SW384 SW385 F-5-152 ENTER 13) The sheets are folded and delivered by pressing the push switch SW383 [1] several times.

-

Page 152: Saddle Disengage Roller Position Adjustment

Chapter 5 14) Based on the output results, measure the degree 17) Return the finisher to the operable status by of misalignment [A] or [B] between the rear following steps 1) to 8) and step 15) but in reverse. staple position [1] and the front staple position 5.3.2.22 Saddle disengage roller position [2]. - Page 153 Chapter 5 Details of the adjustment method are as described 5) Set dipswitch DIP SW382 [1] on the switch PCB below. as illustrated below. 1) Turn the finisher power ON. 2) Turn on the host machine power switch and put the copier in standby.

- Page 154 Chapter 5 7) Press switch SW383 [1] or SW384 [2] to fix the degree of adjustment. Press SW383 once and the LED [3]will display "- 1" and the gap between the disengage roller and the paper will increase. (The disengage roller moves in the A direction.) Alternatively, press SW384 once and the LED [3] will display "+1"...

-

Page 155: The Amount Of Sending Of A Saddle Disengage Roller Adjustment

Chapter 5 8) Press switch SW385 [1] to complete the Details of the adjustment method are as described adjustment. below. 1) Turn the finisher power ON. 2) Turn on the copier main unit power switch and put the copier in standby. SW382 3) Open the front door and insert the door switch actuator into the door switch [1]. - Page 156 Chapter 5 5) Set dipswitch DIP SW382 [1] on the switch PCB as illustrated below. SW382 SW381 SW382 SW383 SW384 SW385 SW381 ENTER SW383 SW384 SW385 ENTER F-5-167 6) Press switch SW385 [1] to set up for the adjustment. SW382 F-5-169 SW381 8) Press switch SW385 [1] to complete the...

-

Page 157: Saddle Staple Position Adjustment

Chapter 5 5.3.2.24 Saddle staple position adjustment 0016-6929 This adjustment is to be carried out when there is a noticeable misalignment of the folding position with the stapling position.This operation adjusts the length of the paper feed time just before the folding operation is carried out. (Adjusts Mxxxx rotation time.) The adjustment prevents lack of feed caused by slippage of the disengage roller, so that the defect... - Page 158 Chapter 5 6) Press switch SW385 [1] to set up for the adjustment. M101 SW382 SW381 SW383 SW384 SW385 ENTER F-5-175 7) Press switch SW383 [1] or SW384 [2] to fix the degree of adjustment. Press SW383 once and the LED [3]will display "- 1"...

-

Page 159: Other

Chapter 5 5.3.3 Other 5.3.3.1 Service Mode (by DIP switch)0015-2245 The machine is equipped with a set of service mode items used to adjust it or to run checks on operation. The items may be executed from the machine or from its host machine. - From the Inserter See Maintenance>VR, LED, and Check Pins>DIP Switch. - Page 160 Chapter 5 T-5-8 DIP setting Item Description driving the drive switchover Press ENTER to start. A press on + will start tray A, SW382 motor while a press on - will start tray B. Press ENTER to end. driving tray pickup motor Press ENTER to start.

- Page 161 Chapter 5 DIP setting Item Description checking the sensors 2 Press ENTER to start. A press on +/- switches over SW382 sensors. Press ENTER to end. 1. feed sensor 2. not used 3. feed sensor 2 4. tray A lower limit sensor 5.

-

Page 162: Troubleshooting

Chapter 5 5.4 Troubleshooting 5.4.1 Malfunction 5.4.1.1 Malfunction/Faulty Detection 5.4.1.1.1 The output is sent to tray B even when tray A is selected. 0015-2247 [Case Study] Description Enabling the following in user mode will select tray B as the destination of output (large-capacity stacking mode): initial setup/registration>common spec setup>large-capacity stacking mode. - Page 163 Chapter 5 13) Execute the following adjustment. Each press enables to execute initializing EEPROM from SW385 to SW383 in order. - Sensor light intensity adjustment - Swing guide speed adjustment - Aligning plate width adjustment - Stapling position adjustment (rear 1-point binding) - Stapling position adjustment (front 1-point binding)

-

Page 164: Outline Of Electrical Components

Chapter 5 5.5 Outline of Electrical Components 5.5.1 Sensors (Finisher Unit) 0015-2249 PS32 PS34 PS33 PS35 PS24 PS26 PS25 PS31 PS29 PS30 PS28 PS27 PS18 PS42 PS21 PS22 PS12 PS23 PS16 PS17 PS13 PS20 PS15 PS11 PS14 PS19 F-5-183 5-58... - Page 165 Chapter 5 T-5-9 Notation Name Description Parts No. Error detects the state (open/closed) of the front FK2-0149 front cover open sensor 1422 cover upper cover open/closed detects the state (open/closed) of the FK2-0149 1422 sensor upper cover WG8-5736 inlet sensor detects paper at the inlet 1002/1103 WG8-5736...

- Page 166 Chapter 5 Notation Name Description Parts No. Error PS28 stapling position sensor 1 detects stapling position FK2-0149 PS29 stapling position sensor 2 detects stapling position FK2-0149 PS30 stapling position sensor 3 detects stapling position FK2-0149 PS31 stapling position sensor 4 detects stapling position FK2-0149 PS32...

- Page 167 Chapter 5 Shift relay PCB Transport motor driver PCB Notation Finisher controller PCB PS19 J253/J252 J104 PS20 J253/J252 J104 PS21 J253/J252 J104 PS22 J253/J252 J104 PS23 J253/J252 J104 PS24 J116 PS25 J263/J251 J104 PS26 J263/J251 J104 PS27 J114 PS28 J114 PS29 J114 PS30...

-

Page 168: Microswitches (Finisher Unit)

Chapter 5 5.5.2 Microswitches (Finisher Unit) 0015-2250 MSW2 MSW4 MSW6 MSW5 MSW3 MSW7 MSW1 F-5-184 5-62... - Page 169 Chapter 5 T-5-11 Finisher Notation Name Description Parts No. Error controller PCB MSW1 front door switch detects the state (open/closed) of the WC4-5231 1422 J101 front door MSW2 tray approach switch detects the approach of the tray WC4-5159 E540 J101 MSW3 tray safety switch detects the tray (front) for safety...

-

Page 170: Solenoids (Finisher Unit)

Chapter 5 5.5.3 Solenoids (Finisher Unit) 0015-2251 F-5-185 5-64... - Page 171 Chapter 5 T-5-12 Notati Name Parts No. Error FK2-1740 buffer switchover solenoid FK2-1740 upper path solenoid FK2-1740 saddle path switchover solenoid assist roller 1 shift solenoid FK2-1740 assist roller 2 shift solenoid FK2-1740 assist roller 3 shift solenoid FK2-1740 handling tray solenoid FK2-1782 T-5-13 Notati...

-

Page 172: Motors (Finisher Unit)

Chapter 5 5.5.4 Motors (Finisher Unit) 0015-2253 F-5-186 5-66... - Page 173 Chapter 5 T-5-14 Notation Name Parts No. Error inlet transport motor FK2-1704 shift transport motor FK2-1705 pre-buffer transport motor FK2-1705 buffer motor FK2-1704 delivery motor FK2-1704 horizontal registration detection unit shift motor FK2-1709 E566 horizontal shift motor FK2-1710 E567 transport roller shift motor FK2-1711 E568 front alignment motor...

- Page 174 Chapter 5 T-5-15 Transport motor Handling tray Stapler driver PCB tray A motor Finisher controller driver PCB driver PCB driver PCB/tray B motor driver PCB Notation J273/J271 J118 J278/J271 J118 J276/J271 J118 J277/J271 J118 J275/J271 J118 J276/J271 J118 J277/J271 J118 J279/J271 J118 J257/J252...

-

Page 175: Fans (Finisher Unit)

Chapter 5 5.5.5 Fans (Finisher Unit) 0015-2254 F-5-187 T-5-16 Notation Name Parts No. Error Finisher controller PCB E551 J103 power supply fan FK2-0636 E551 J116 transport fan 1 FK2-0636 E551 J116 transport fan 2 FK2-0636 5-69... -

Page 176: Pcbs (Finisher Unit)

Chapter 5 5.5.6 PCBs (Finisher Unit) 0015-2255 F-5-188 T-5-17 Code Name Parts No. Role Finisher controller PCB FM2-5695 Control the finisher Intermediate processing tray driver PCB FM2-5697 Control the load on the intermediate processing tray Feed motor driver PCB FM2-5698 Control the motor for the feed system Staple driver PCB FM2-5699... -

Page 177: Variable Resistors (Vr), Light-Emitting Diodes (Led), And Check Pins By Pcb

Chapter 5 5.6 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB 5.6.1 Overview 0015-2261 Of the LEDs and check pins used in the machine, those needed during servicing in the field are discussed. Do not touch the check pins not found in the list herein. They are exclusively for factory use, and require special tools and a high degree of accuracy. -

Page 178: Upgrading

Chapter 5 5.7 Upgrading 5.7.1 Upgrading 0015-2262 Perform upgrade of this machine by connecting a copy machine. Refer to the service manual of imagePRESS C7000 Series for a detailed procedure. 5.8 Service Tools 5.8.1 Solvents and Oils 0015-2263 T-5-19 Name Description Composition Remarks... -

Page 179: Chapter 6 Error Code

Chapter 6 ERROR CODE... - Page 180 Contents Contents 6.1 Jam Codes ......................6-1 6.1.1 Jam Codes ........................6-1 6.2 Error Codes......................6-2 6.2.1 Error Codes........................6-2...

-

Page 181: Jam Codes

Chapter 6 6.1 Jam Codes 6.1.1 Jam Codes T-6-1 Code Jam type Sensor Jam condition 1002 Inlet sensor delay jam PS3 In a case that the inlet sensor (PS3) does not detect a paper after the specified time (distance) has been passed from the delivery signal reception from the connected equipment. -

Page 182: Error Codes

Chapter 6 6.2 Error Codes 6.2.1 Error Codes T-6-2 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized. - Page 183 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 184 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 185 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 186 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 187 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 188 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 189 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 190 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 191 Chapter 6 Code Detail Occurrence Description Treatment/ detection timing code classification - Occurrence classification 02: Finisher (including inserter, puncher, trimmer) 11: POD deck 12: Secondary POD deck 51: Stacker 52: Secondary stacker - When turning ON the power, be sure to turn ON the power in the following order: pickup/delivery accessories -> Main Body: Otherwise the pickup/delivery accessories are not recognized.

- Page 192 APPENDIX...

- Page 193 1 General Circuit Diagram List Of Signals(finisher) T-1-1 Notation Signal name Notation Signal name Notation Signal name ASSIST-HP-SEN assist motor home position detection signal BTRY-P-SEN tray B paper sensor detection signal FRONT-BIN-M-IHA* front door open detection signal ASSIST-M-8FG* assist motor rotation detection signal BTRY-SHIMEN-SEN* tray B paper surface sensor detection signal FRONT-SW-OPEN...

- Page 194 Notation Signal name Notation Signal name Notation Signal name RLT-M-IHA* transport belt shift motor current switch signal STP-SLDM-IB stapler shift motor current switch signal ROLLER-HP transport roller home position detection signal STRY-P-SEN handling tray paper detection signal SDL-SL-ON saddle path switch solenoid signal STRY-SL-ON handling tray solenoid drive signal SHIFT-FEED-M-CW...

- Page 195 General Circuit Diagram General Circuit Diagram(Finisher1) CB1 Leakage breaker Stapler Transport motor driver Power supply driver PCB Main switch Power supply fan Fuse box PCB Finisher controller PCB Transceiver PCB MSW1 Front door switch Accessories switch PCB MSW4 MSW4 Tray safety Tray safety switch (rear) switch (front)

- Page 196 General Circuit Diagram(Finisher2) Finisher connector PCB UN24 UN14 UN16 Lower delivery Inlet sensor UN13 Buffer path 2 Upper cover Lower path transport transport Front door Tray A paper sensor Buffer path 1 Shift roller unit sensor open sensor sensor surface sensor fan 1 fan 2 open sensor...

- Page 197 General Circuit Diagram(Finisher3) Inlet transport motor Delivery motor Finisher controller PCB Transport motor driver PCB UN28 Shift relay Upper Transport delivery roller home Transport sensor position roller shift sensor Assist 3 shift motor UN26 solenoid Horizontal sensor Shift unit trail Shift edge sensor Horizontal...

- Page 198 General Circuit Diagram(Finisher4) Intermediary tray driver PCB PS14 PS21 PS22 Stack delivery Paddle lift Swing guide PS16 PS11 PS13 auxiliary tray home position Paper edge Assist home closed sensor Front alignment home position PS20 sensor area detection position sensor home position Paper edge sensor Paddle motor...

- Page 199 General Circuit Diagram(Finisher5) Intermediary tray driver PCB To INSERTER Finisher controller PCB To TRIMMER To Professional Puncher Assist motor Swing guide Handling tray motor solenoid Paddle lift Stack delivery Paddle rotation Stack delivery motor motor motor auxiliary motor (5/7) F26-7101-A505 F-1-5...

- Page 200 General Circuit Diagram(Finisher6) Finisher controller PCB Intermediary tray driver PCB PS42 Stapler waste case full sensor Stapler driver PCB PS30 PS28 Stapler Stapler position position Stapler unit sensor 3 sensor 1 PS31 PS29 PS27 UN17 UN18 stapler Stapler Stapler Stapler motor Tray B paper tray B paper home position...

- Page 201 General Circuit Diagram(Finisher7) Finisher controller PCB Tray B motor Tray A motor driver PCB driver PCB PS35 PS33 PS32 PS34 Tray B Tray B MSW2 Tray A paper tray A lift lift motor lift motor Tray approach Auxiliary tray sensor motor rotation rotation switch...

- Page 203 Saddle Finisher-AB2 SERVICE MANUAL MAY 2007 REV. 0 COPYRIGHT ©2007 CANON INC. CANON Saddle Finisher-AB2 REV. 0 PRINTED IN U.S.A.

- Page 204 This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

- Page 205 Introduction Symbols Used This documentation uses the following symbols to indicate special information: Symbol Description Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to avoid combustion (fire). Indicates an item prohibiting disassembly to avoid electric shocks or problems.

- Page 206 Introduction The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between elec- trical and mechanical systems with reference to the timing of operation. In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow indicates the direction of the electric signal.

- Page 207 Contents Contents Chapter 1 Specifications 1.1 Product Specifications..................1-1 1.1.1 Specifications (finisher) ..................... 1-1 1.1.2 Specifications (saddle finisher) ................1-4 1.2 Names of Parts....................1-5 1.2.1 External View......................1-5 1.2.2 Cross Section ......................1-6 Chapter 2 Installation 2.1 Making Pre-Checks................... 2-1 2.1.1 Checking the Contents....................

- Page 208 Contents 3.3.4 Tray Paper Surface Detection................. 3-8 3.4 Feeding Unit ....................... 3-9 3.4.1 Overview........................3-9 3.4.2 Basic Sequence of Operations ................3-12 3.4.3 Horizontal Registration Detection ................. 3-13 3.4.4 Horizontal Registration Correction/Alignment Operation ........3-15 3.4.5 Buffer Operation ...................... 3-18 3.4.6 Switching Over the Paper Path................

- Page 209 Contents 4.2.9 Inside Cover (Upper) ....................4-7 4.2.10 Inside Cover (Lower) ....................4-7 4.3 Drive System...................... 4-8 4.3.1 Staple Unit ........................4-8 4.3.2 Saddle Staple Unit .....................4-8 4.3.3 Front Alignment Motor ....................4-9 4.3.4 Rear Alignment Motor .....................4-10 4.3.5 Tray Shift Motor ......................4-12 4.3.6 Shift Motor .........................4-13 4.3.7 Positioning Plate Unit ....................4-17 4.3.8 Belt Controller Unit ....................4-17 4.4 Document Feeding System ................

- Page 210 Contents 5.2.1.2 Periodically Replaced Parts in the Saddle Finisher............5-2 5.2.2 Durables ........................5-2 5.2.2.1 Durables in the Finisher ...................... 5-2 5.2.2.2 Durables in the Saddle Stitcher ..................5-3 5.2.3 Periodical Servicing ....................5-3 5.2.3.1 Scheduled Servicing for the Finisher ................5-3 5.2.3.2 Scheduled Servicing for the Saddle Stitcher ..............

- Page 211 Contents 5.4 Troubleshooting....................5-66 5.4.1 Malfunction ........................5-66 5.4.1.1 Malfunction/Faulty Detection .................... 5-66 5.5 Outline of Electrical Components ..............5-68 5.5.1 Sensors (Finisher Unit) ................... 5-68 5.5.2 Microswitches (Finisher Unit) ................. 5-72 5.5.3 Solenoids (Finisher Unit)..................5-74 5.5.4 Motors (Finisher Unit)....................5-76 5.5.5 Fans (Finisher Unit) ....................

- Page 212 Chapter 1 SPECIFICATIONS...

- Page 213 Contents Contents 1.1 Product Specifications ..................1-1 1.1.1 Specifications (finisher)....................1-1 1.1.2 Specifications (saddle finisher)..................1-4 1.2 Names of Parts ...................... 1-5 1.2.1 External View ........................1-5 1.2.2 Cross Section .........................1-6...

-

Page 214: Chapter 1 Specifications

Chapter 1 1.1 Product Specifications 1.1.1 Specifications (finisher) 0015-2057 T-1-1 Item Description Remarks Stacking mechanism tray A/B by tray lift Stacking orientation tray A face-down/face-up tray B face-down Stack size tray A A3,A4,A4R,A5R,B4,B5,B5R,Jpn postcard in feed direction, 182 to R,279.4mmx432.8mm(11x17),LGL,LTR,EXE,LTRR,S 487.7 mm;... - Page 215 Chapter 1 Item Description Remarks Stapling method stapling by rotating cam Stapled stack if small-size, 100 sheets as converted with reference to paper of 80g/m2 if large-size, 50 sheets 1: The number of sheets refers to the result of conversion based on paper of 80g/m2 2: A sheet of paper may be grouped into the following: -large-size;...

- Page 216 Chapter 1 Item Description Remarks Dimensions W:800xD:786xH:1180mm Weight 126 kg (approx.) Power supply 100V,200-240V Maximum power consumption 360 W or less Staple Position 1-Point Stapling (front) 5 2.0 5 2.0 A3, B4, A4, B5, / 11"x17", LTR A4R / LGL, LTRR 1-Point Stapling (rear) 5 2.0 5 2.0...

-

Page 217: Specifications (Saddle Finisher)

Chapter 1 1.1.2 Specifications (saddle finisher) 0015-2059 T-1-3 Item Specifications Remarks Stapling method middle stapling, double-folding Paper size A3/A4R/B4/279.4mmx432.8mm/11×17/LGL/LTRR Stack 2 to 20 sheets including 1 cover Types of Paper Plain paper ((64g/m2 to 90g/m2), Heavy paper (91 g/m2 to 105 g/m2), Recycled paper, Colored paper. -

Page 218: Names Of Parts

Chapter 1 1.2 Names of Parts 1.2.1 External View 0015-2061 F-1-1 [1]Tray B [5]Saddle delivery belt [2]Tray A [6]Upper cover [3]Top delivery outlet [7]Inlet transport unit [4]Bottom delivery outlet [8]Front cover... -

Page 219: Cross Section

Chapter 1 1.2.2 Cross Section 0015-2063 [10] [12] [11] [13] [14] [15] [16] [17] [18] [19] [20] [28] [21] [22] [26] [27] [25] [24] [23] F-1-2 [1]Transport belt [11]Buffer roller 3 [20]Stapler [2]Stack delivery roller [12]Transport roller [21]Stitcher [3]Swing guide [13]Buffer roller 1 [22]Paper retaining plate [4]Paddle... -

Page 220: Chapter 2 Installation

Chapter 2 INSTALLATION... - Page 221 Contents Contents 2.1 Making Pre-Checks................... 2-1 2.1.1 Checking the Contents....................2-1 2.2 Installation Procedure..................2-3 2.2.1 Points to Note When Turning ON/OFF the power of Host Machine ....2-3 2.2.2 Before Installing Finisher ..................2-3 2.2.3 Connecting with Machine..................2-4 2.2.4 Connecting with High-Capacity Stacker ..............

-

Page 222: Making Pre-Checks

Chapter 2 2.1 Making Pre-Checks 2.1.1 Checking the Contents 0016-0898 [10] M_ _ ________ ___ _________ ___________ __ _____ ____________. M_ _ ________ ___ _________ ___________ __ _____ ____________. P_ _ ______ ___ __________ _____ ____________ ___ _____________. P_ _ ______ ___ __________ _____ ____________ ___ _____________. J_ ____ ____________ ___ ________ _____ ___ _______ _____________ _________. - Page 223 Chapter 2 [1]*1 Finisher Latch plate (for front) Latch plate (for rear) Positioning Pin ARCNET cable coaxial connector Shunt Cable Wire Saddle Screws (RS tight; M4X10) 10pc [10] Screw (Bind; M4X8) [11]*2 Guide map label [12]*3 Guide map label [13] Staple label [14]*3 LED Lamp Label (products for China, Korea...

-

Page 224: Installation Procedure

Chapter 2 2.2 Installation Procedure 2.2.2 Before Installing Finisher 0016-0901 1) Open the front cover of the finisher. 2.2.1 Points to Note When Turning 2) Remove 1 screw [2] from the front latch retainer ON/OFF the power of Host [1]. Machine 0016-5236 Power-On Order for Turning On the... -

Page 225: Connecting With Machine

Chapter 2 4) Remove 1 screw [1] on the rear latch retainer and pull the hinge [2] forward and downward. F-2-5 2) Fit the positioning pin [1]. F-2-4 - 2 screws (RS tight; M4X10) [2] 2.2.3 Connecting with Machine 0016-0903 Check the power on the host machine is surely turned off and the power supply cable is unplugged. -

Page 226

Chapter 2 3) While lifting up the front latch plate [1], fit the positioning pin on the machine side [2] to the finisher's positioning hole [3]. Connect the finisher with the machine.

F-2-9 F-2-7 5) Shut the front cover of the finisher. 6) Lift up the rear latch plate [1] to fit the pin and fix ... -

Page 227: Connecting With High-Capacity Stacker

Chapter 2 7) Attach the rear small cover. 1) Attach the front [1] and rear [2] latch plates to the 8) Remove 1 screw [1] on the rear lower cover of the left side of the high-capacity stacker. finisher. - 4 screws (RS tight; M4X10) Confirm the mark engraved on each latch plate when attaching. -

Page 228

Chapter 2 2) Fit the positioning pin [1] of the high-capacity

stacker to the position [A]. - 2 screws [2] F-2-16 4) Fix the front latch plate (front) [1]. - 1 screw [2] (Use the screw removed in step 2 of "Before Installing Finisher") F-2-14 3) While lifting up the front latch support [1], fit the... -

Page 229: After Installation

Chapter 2 5) Close the front cover of the finisher. 6) Lift up the rear latch plate [1] to fit the pin and fix - 1 screw [2] (Use the screw removed in step 4 of "Before Installing Finisher") F-2-20 10) See "After Installation"... - Page 230 Chapter 2 2) Connect the ARCNET cable [1] to the terminal [2] at sub station, and then turn the finger grip [3] in the direction of the arrow to connect. Be sure to turn off the host machine and unplug the power supply cable when connecting the ARCNET cable.

- Page 231 Chapter 2 6) Connect the power supply plug of the finisher. (Perform only for EUR) After setting the connection sequence, the host machine should be turned off and on to enable the setting. Power-On Order for Turning On the F-2-26 Power When Pickup/Delivery Accessories 7) For Finisher /Saddle Finisher , connect the power are Connected...

-

Page 232: Making Adjustments

Chapter 2 2.3 Making Adjustments 2) If the difference exceeds 2mm, adjust the height. 2.3.1 Height Adjustment 0016-1444 Adjust the height with 4 casters [1] as shown Depending on the floor condition of an installation site, you should adjust the height of the finisher. If in the figure. - Page 233 Chapter 2 3) For Finisher AB1, detach the caster front cover. - 1 screw [2] F-2-32 6) Measure the height [A] from the floor to the bottom of the machine to check the figure is in the F-2-30 range of 84.6+ -0.5mm. 4) For Saddle Finisher, detach the saddle inner cover (lower) [1].

- Page 234 Chapter 2 9) Tighten the fixing nut [1] in the direction of [B]. When loosening the fixing nut on the front caster of the saddle finisher, insert the wrench [3] into the opening just below the saddle bottom plate [2]. F-2-36 10) Repeat the steps above to adjust the height of other 3 casters.

-

Page 235: Attaching The Labels Etc

Chapter 2 2.4 Attaching the Labels etc. 2.4.1 Affixing Labels 0016-1445 1) Open the front cover of the finisher. 2) Affix the Guide map label [1] to the inside of the front cover. (Figure shows the saddle finisher). F-2-39 5) Open the upper cover to pull the shift guide [1] to M_ _ ________ ___ _________ ___________ __ _____ ____________. - Page 236 Chapter 2 6) Affix the jam removal label [2] in the local language on the position of [A] on the shift guide. F-2-41 7) Attach the parts removed in the previous steps in the following order. - The shift guide - upper cover 8) Close the front cover of the finisher.